Problem...tranny is stuck to the engine.

#1

Problem...tranny is stuck to the engine.

Alright...I've been trying to get the engine out, and I've already removed all the bolts from the pressure plate and the flywheel spins freely now. The problem is that when we tried to pull the engine away...the thing is just STUCK. From the bottom, it's very tight, barely any gap, but the top has about a half-inch to an inch gap in it.

I have an aftermarket ACT clutch, so I'm not sure if the throwout bearing is the same as the stock version. I did a search, and all the threads mention the throwout bearing, but if you couldn't get it, then just remove the bolts and separate the plate from the flywheel...which I did. It just won't budge.

My transimission was perfectly fine before this, I don't have any broken parts, etc...the tranny and engine JUST WON'T SEPARATE.

Does anyone have any advice on what might be holding it together? If the bolts are off, then the throwout bearing shouldn't matter right, because the flywheel is separated from everything? Should I lower the front end of the car maybe a bit? Let gravity help it out? I just don't get it...If I hoist the engine up higher, it takes the transmission with it...which is really confusing. What's holding it together still?

I have an aftermarket ACT clutch, so I'm not sure if the throwout bearing is the same as the stock version. I did a search, and all the threads mention the throwout bearing, but if you couldn't get it, then just remove the bolts and separate the plate from the flywheel...which I did. It just won't budge.

My transimission was perfectly fine before this, I don't have any broken parts, etc...the tranny and engine JUST WON'T SEPARATE.

Does anyone have any advice on what might be holding it together? If the bolts are off, then the throwout bearing shouldn't matter right, because the flywheel is separated from everything? Should I lower the front end of the car maybe a bit? Let gravity help it out? I just don't get it...If I hoist the engine up higher, it takes the transmission with it...which is really confusing. What's holding it together still?

#2

#3

if the tranny and engine are acutally seperated it just seems like you cant get the engine out you might try un bolting your engine mounts, thoses were stuck on my car and it wasent allowing room for the engine to come out, you might try that....also if you cant get the coller off on the clutch you can just unbolt the pressure plate.

#5

open the tranny instpection plate, you will be able to see the release ring, you need to pry it forward and once it popps all the way for ward the tranny will be released from the engine, search on it

#6

I remember there being some short dowel pins that held my tranny in place even after I removed all bolts and the release collar/ring. It took a little wiggling and pulling to get it free. Ideally, they would have a couple of tapped holes so you could gently push it off like you can with a brake rotor.

Dave

Dave

#7

my vote is for the dowels being corroded OR the engine mounts being in the way. They stick down just far enough to cause you headaches. If you have the PP seperated from the engine as you say, the release collar for the TO bearing should not be holding you back.

Try removeing the mounts and attempt again, or try a pry-bar lightly if the dowels are holding it in. Hawaii is hell on corrosion. I had a couple dowels do the same thing to me when working on cars their. more FC's then FD's,....since the FD's had all had the engines out in the near past,..or multiple times damn FD's and their ability to blow up.

damn FD's and their ability to blow up.

Also make sure you are not " binding" the input shaft in the end of the engine. If the engine gets cocked to much it will bind against the input shaft and cause similar sissues. PLUS damage the input shaft...IE: bend it

Try removeing the mounts and attempt again, or try a pry-bar lightly if the dowels are holding it in. Hawaii is hell on corrosion. I had a couple dowels do the same thing to me when working on cars their. more FC's then FD's,....since the FD's had all had the engines out in the near past,..or multiple times

damn FD's and their ability to blow up.

damn FD's and their ability to blow up.

Also make sure you are not " binding" the input shaft in the end of the engine. If the engine gets cocked to much it will bind against the input shaft and cause similar sissues. PLUS damage the input shaft...IE: bend it

Last edited by BigIslandSevens; 05-08-05 at 09:04 AM.

Trending Topics

#8

Welps, we removed the motor mounts before we tried to remove the engine, so that's a no-go, and the dowel pins on the pressure plate were separated as well (I thought it was just the bolts, but the pressure plate looked like it was cocked sideways until I removed them...then the flywheel spun free).

I think the engine might be cocked too much...that would explain why there's a gap at the top and not the bottom...damn...hope the input shaft isn't BENT. I'm going to lower the front of the car tomorrow at an angle, and hopefully gravity will help me out. I've done everything everyone has mentioned, so it's just gotta be that I guess...

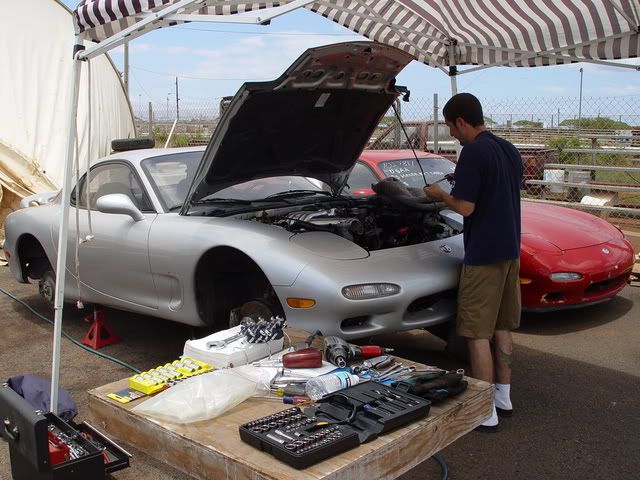

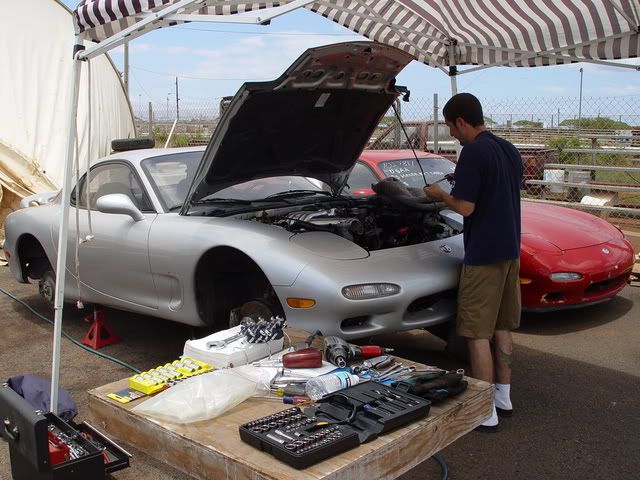

I'll let you guys know...in the meantime, here's some pics!

We took off the hood just because it was starting to annoy us. I should have borrowed turbojeff's crutch.

Separating the cat from the downpipe

I'll cut you, biatch!

A little trick to get the A/C compressor out...

Draining the oil! Draining the oil!

Little did I know...there's clips holding these suckers in.

Tom Bryant from HIRS takes a look...

Don't wanna lose these little suckers...

I think the engine might be cocked too much...that would explain why there's a gap at the top and not the bottom...damn...hope the input shaft isn't BENT. I'm going to lower the front of the car tomorrow at an angle, and hopefully gravity will help me out. I've done everything everyone has mentioned, so it's just gotta be that I guess...

I'll let you guys know...in the meantime, here's some pics!

We took off the hood just because it was starting to annoy us. I should have borrowed turbojeff's crutch.

Separating the cat from the downpipe

I'll cut you, biatch!

A little trick to get the A/C compressor out...

Draining the oil! Draining the oil!

Little did I know...there's clips holding these suckers in.

Tom Bryant from HIRS takes a look...

Don't wanna lose these little suckers...

Last edited by ArchangelX; 05-08-05 at 04:08 PM.

#9

Air tools are your friend. We need a lift.

All the comforts of home...sorta. In the beginning the front was higher than the rear, but then we adjusted the jacks to be level.

What a buncha freakin' plastic.

Ratchet Wrenches kick azz...

My friend Fred shows us his kung-fu grip!

All the comforts of home...sorta. In the beginning the front was higher than the rear, but then we adjusted the jacks to be level.

What a buncha freakin' plastic.

Ratchet Wrenches kick azz...

My friend Fred shows us his kung-fu grip!

#10

I had this problem when I was taking my tranny out adn it ended up being exactly what Damian said. There is a collar that holds the throw-out bearing on the presure plate. You need to do just as Damian said. I would be willing to bet on that being the problem.

#11

Originally Posted by damian

open the tranny instpection plate, you will be able to see the release ring, you need to pry it forward and once it popps all the way for ward the tranny will be released from the engine, search on it

#13

Pull the tranny with the engine= problem solved!

Anyway if the pressure plate bolts are off the engine should come off the trans. Motor mounts are off now? You might have to lift the engine and support the tranny separately to get it off.

Anyway if the pressure plate bolts are off the engine should come off the trans. Motor mounts are off now? You might have to lift the engine and support the tranny separately to get it off.

#15

Yah no kidding Jeff, I really should just pull the whole damn thing together...I think I might do that on Monday. I was just trying to save a bit of work, but it doesn't look like that's going to happen.

I tried giving you a yell, but you weren't home...thanks for the heads up though.

Thanks Seef...also thanks for the parts, we needed 'em.

I tried giving you a yell, but you weren't home...thanks for the heads up though.

Thanks Seef...also thanks for the parts, we needed 'em.

Last edited by ArchangelX; 05-09-05 at 01:06 AM.

#16

Originally Posted by Dan Stevenson

I think you need to buy some new jackstands or do you not like your friend much?

:-)

I'm fat. Leave me alone.

We put in some bigger jackstands after that anyways..heheh. Kinda stretched those to the limit.

#17

Push the engine/trans back together, then do the thing Damian suggested above. (I popped his off a couple weeks ago  ) I'm 90% sure that's what it is. Steve Kan showed D and I what to do at a tuning deal in April.

) I'm 90% sure that's what it is. Steve Kan showed D and I what to do at a tuning deal in April.

The guy I know who helped me a few months back get mine apart said FD's have pull-type clutches which need to be released before the engine/trans will come apart.

) I'm 90% sure that's what it is. Steve Kan showed D and I what to do at a tuning deal in April.

) I'm 90% sure that's what it is. Steve Kan showed D and I what to do at a tuning deal in April.The guy I know who helped me a few months back get mine apart said FD's have pull-type clutches which need to be released before the engine/trans will come apart.

#18

yeah guys, do what I said :-) (heheheh)

seriously, if you dont release this little ring, the two wont come apart without destroying something.... we got the instight on it from steve kan when he was here tuning, we had my car on GooRoo's lift and he showed us the 'easy' way to release the two. A simple screwdriver and he through the inspection plate he pushed the release ring forward and the two will come apart.

seriously, if you dont release this little ring, the two wont come apart without destroying something.... we got the instight on it from steve kan when he was here tuning, we had my car on GooRoo's lift and he showed us the 'easy' way to release the two. A simple screwdriver and he through the inspection plate he pushed the release ring forward and the two will come apart.

#19

Hello-

My vote is that you need to support the transmission better. You said that you have an inch gap at the top and no gap at the bottom... that's a HUGE angular mismatch. Hopefully the input shaft is still okay. You need to support the transmission and pull it out with an EVEN gap at top, bottom, left, and right. Otherwise, the input shaft will just bind. After you pull the transmission out evenly all around about 3/8" or so, it will be free of the dowel pins that mate it to the engine and, provided you keep a mostly even gap all around, should come out smoothly.

You said you already have the pressure plate bolts off and the flywheel spins freely (i.e. independently of the pressure plate). If this is the case, then the dowel pins, the throwout bearing, the ring around the throwout bearing, etc. are not your problem... having the flywheel and pressure plate spin independently means that none of these will affect you.

The other (very remote) possibility I can think of is that the pilot bearing has seized onto your input shaft somehow. Try the angular realignment before thinking about this, though :-).

Take care,

Shad

My vote is that you need to support the transmission better. You said that you have an inch gap at the top and no gap at the bottom... that's a HUGE angular mismatch. Hopefully the input shaft is still okay. You need to support the transmission and pull it out with an EVEN gap at top, bottom, left, and right. Otherwise, the input shaft will just bind. After you pull the transmission out evenly all around about 3/8" or so, it will be free of the dowel pins that mate it to the engine and, provided you keep a mostly even gap all around, should come out smoothly.

You said you already have the pressure plate bolts off and the flywheel spins freely (i.e. independently of the pressure plate). If this is the case, then the dowel pins, the throwout bearing, the ring around the throwout bearing, etc. are not your problem... having the flywheel and pressure plate spin independently means that none of these will affect you.

The other (very remote) possibility I can think of is that the pilot bearing has seized onto your input shaft somehow. Try the angular realignment before thinking about this, though :-).

Take care,

Shad

Last edited by Shad Laws; 05-09-05 at 04:27 AM.

#20

Hmmm... yeah, I'm not sure anyone mentioned that yet. When you pull the two apart you do need to have the transmission supported, otherwise it will fall and possibly clip the subframe or end up on the ground. You might already have known that.

Originally Posted by Shad Laws

Hello-

My vote is that you need to support the transmission better. You said that you have an inch gap at the top and no gap at the bottom... that's a HUGE angular mismatch. Hopefully the input shaft is still okay. You need to support the transmission and pull it out with an EVEN gap at top, bottom, left, and right. Otherwise, the input shaft will just bind. After you pull the transmission out evenly all around about 3/8" or so, it will be free of the dowel pins that mate it to the engine and, provided you keep a mostly even gap all around, should come out smoothly.

You said you already have the pressure plate bolts off and the flywheel spins freely (i.e. independently of the pressure plate). If this is the case, then the dowel pins, the throwout bearing, the ring around the throwout bearing, etc. are not your problem... having the flywheel and pressure plate spin independently means that none of these will affect you.

The other (very remote) possibility I can think of is that the pilot bearing has seized onto your input shaft somehow. Try the angular realignment before thinking about this, though :-).

Take care,

Shad

My vote is that you need to support the transmission better. You said that you have an inch gap at the top and no gap at the bottom... that's a HUGE angular mismatch. Hopefully the input shaft is still okay. You need to support the transmission and pull it out with an EVEN gap at top, bottom, left, and right. Otherwise, the input shaft will just bind. After you pull the transmission out evenly all around about 3/8" or so, it will be free of the dowel pins that mate it to the engine and, provided you keep a mostly even gap all around, should come out smoothly.

You said you already have the pressure plate bolts off and the flywheel spins freely (i.e. independently of the pressure plate). If this is the case, then the dowel pins, the throwout bearing, the ring around the throwout bearing, etc. are not your problem... having the flywheel and pressure plate spin independently means that none of these will affect you.

The other (very remote) possibility I can think of is that the pilot bearing has seized onto your input shaft somehow. Try the angular realignment before thinking about this, though :-).

Take care,

Shad

#21

Originally Posted by GooRoo

Hmmm... yeah, I'm not sure anyone mentioned that yet. When you pull the two apart you do need to have the transmission supported, .

Originally Posted by turbojeff

You might have to lift the engine and support the tranny separately to get it off.

.

.

#22

The transmission is already supported by a jack...but I agree that it's probably that angular mismatch that you're talking about. I'm going to bolt it all back together today, and just pull it all out at once.

Shad...thanks for reading my post so thoroughly, I'm glad you understood what I was trying to say...it's gotta be the uneven thing. We'll see, I guess.

Thanks for the help guys, I'll let you know what I get done today...

Shad...thanks for reading my post so thoroughly, I'm glad you understood what I was trying to say...it's gotta be the uneven thing. We'll see, I guess.

Thanks for the help guys, I'll let you know what I get done today...

#24

Originally Posted by ArchangelX

The transmission is already supported by a jack...but I agree that it's probably that angular mismatch that you're talking about. I'm going to bolt it all back together today, and just pull it all out at once.

Shad...thanks for reading my post so thoroughly, I'm glad you understood what I was trying to say...it's gotta be the uneven thing. We'll see, I guess.

Thanks for the help guys, I'll let you know what I get done today...

Shad...thanks for reading my post so thoroughly, I'm glad you understood what I was trying to say...it's gotta be the uneven thing. We'll see, I guess.

Thanks for the help guys, I'll let you know what I get done today...