Oil injector sprayed oil out vent hose...

#1

Thread Starter

Fast + Reliable = $$$$$

iTrader: (18)

Joined: Nov 2003

Posts: 1,223

Likes: 3

From: SoCal

Oil injector sprayed oil out vent hose...

Wondering how common this is? Mine are fresh ones with only 5K miles and vented to atmosphere. Was at the track today and I noticed some oil sprayed around under my UIM, looked around and saw some oil in the rear oil injector vent hose.

Also, I noticed a small puff of white smoke out the back when I fired her up in between a session, didn't think too much of it at the moment but it makes sense that the oil injector probably leaked in the chamber when the car sat.

Any one had this problem? Know how much pressure or vacuum it should hold with a Mityvac? I'm thinking the check valve maybe just got stuck for a minute or it's toast...

Also, I noticed a small puff of white smoke out the back when I fired her up in between a session, didn't think too much of it at the moment but it makes sense that the oil injector probably leaked in the chamber when the car sat.

Any one had this problem? Know how much pressure or vacuum it should hold with a Mityvac? I'm thinking the check valve maybe just got stuck for a minute or it's toast...

#2

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

They're one way check valves and yours have failed. They need to be replaced. You should be able to blow through them, but not suck through them.

Same thing happened to both of mine and I had no idea. Luckily my vacuum hoses from them routed to the compressor inlet, so the oil still made it's way into the motor indirectly. Mine were brand new with my brand new motor, less than 10k miles on them when this happened. I now have them vented with breather filters.

It's fairly common for us to replace them on engine jobs at this point, as more and more are stuck or clogged. Recently a mint 1995 FD with 32k original miles came in to IRP and they were both bad.

Same thing happened to both of mine and I had no idea. Luckily my vacuum hoses from them routed to the compressor inlet, so the oil still made it's way into the motor indirectly. Mine were brand new with my brand new motor, less than 10k miles on them when this happened. I now have them vented with breather filters.

It's fairly common for us to replace them on engine jobs at this point, as more and more are stuck or clogged. Recently a mint 1995 FD with 32k original miles came in to IRP and they were both bad.

Last edited by GoodfellaFD3S; 07-31-11 at 09:10 AM.

#3

Thread Starter

Fast + Reliable = $$$$$

iTrader: (18)

Joined: Nov 2003

Posts: 1,223

Likes: 3

From: SoCal

Hey Rich! Dude these are less than 5K miles... pisses me off that I need to get down to the block for these things and that it's *probably* going to happen again in the future. Funny thing is I'm only running 14psi max at the track.

Breather is a good idea, I think I'll just route the vent into my Jazz catch can... but I guess I'd need to check the line for oil once in a while (clear blue silicone hose) to make sure they're not leaking.

Breather is a good idea, I think I'll just route the vent into my Jazz catch can... but I guess I'd need to check the line for oil once in a while (clear blue silicone hose) to make sure they're not leaking.

#4

It should be routine to replace the check valves at engine rebuild and don't forget to put the rubber space fillers underneath. If oil has been comming through the vents then the injectors have not been oiling the apex seals; the oil is being blown out.

As a note in a stock configuration whereas the vent lines are connected to the primary compressor inlet and oil is seen at the inlet - the check valves are the principal suspect.

As a note in a stock configuration whereas the vent lines are connected to the primary compressor inlet and oil is seen at the inlet - the check valves are the principal suspect.

#5

I've had low mileage, newer style oil injectors fail under boost (the ones with the smaller oil injector holes) blowing off the vent lines and spraying oil all over the place under the UIM.

Since then, I have gone back to using my 120,000 mi.+ / 15 yr old ones (ID'd by the slightly larger oil injector holes) and have had no problems whatsoever, even with high boost. Lol.

Since then, I have gone back to using my 120,000 mi.+ / 15 yr old ones (ID'd by the slightly larger oil injector holes) and have had no problems whatsoever, even with high boost. Lol.

#6

Thread Starter

Fast + Reliable = $$$$$

iTrader: (18)

Joined: Nov 2003

Posts: 1,223

Likes: 3

From: SoCal

I've had low mileage, newer style oil injectors fail under boost (the ones with the smaller oil injector holes) blowing off the vent lines and spraying oil all over the place under the UIM.

Since then, I have gone back to using my 120,000 mi.+ / 15 yr old ones (ID'd by the slightly larger oil injector holes) and have had no problems whatsoever, even with high boost. Lol.

Since then, I have gone back to using my 120,000 mi.+ / 15 yr old ones (ID'd by the slightly larger oil injector holes) and have had no problems whatsoever, even with high boost. Lol.

Trending Topics

#8

Yes. They were apparently revised for the '99 spec motors, IIRC. There is also a white paper that was posted on the board somewhere that explains these changes. I believe they introduced the rubber grommets that go beneath the oil injectors at the same time.

#9

Here is the narrative on the change from https://www.rx7club.com/showthread.p...t=declassified:

"The rotary's reliability under the severest conditions was well proven in Mazda's competition activities in the late 80's and early 90's, including an outright win in the Le Mans 24-hour race for sports racing cars in 1991. A road car is subjected to a different kind of stress, said a Mazda designer responsible for the engine's innards, especially when the 13B-REW's output is increased to 209 kW (280 bhp). Possible problem areas are higher combustion temperature and pressure. The former could be dealt with by the cooling system's heat dissipating capacity. The later was thought to exert extraordinary pressure on the engine's gas sealing.

Apex seal lubrication has become a critical issue. In a race engine, oil supply to the rotor housing by means of injection was precisely monitored and controlled, whereas in the production unit, a larger amount is supplied, just to be on the safe side. Some of the lubricant is fed into the trochoid chamber through a metering nozzle. The previous nozzle's oil passage was 2.0 mm (0.08 in.) in diameter. Negative pressure created in the rotor chamber would cause all the oil within the nozzle to be sucked out. When the engine accelerated rapidly, oil supply could not keep up with the speed. To prevent oil starvation, the previous system supplied a larger amount of oil to be on the safe side. In the new metering nozzle, the passage diameter has been reduced to 0.08 mm (0.003 in.), halving its volume of 0.0005 L (0.03 cu. in.). A new rubber seal is also inserted to fill a gap within the nozzle body where oil used to be sidetracked. Now, there is still some oil left within the nozzle after each suction, so that the lubrication system responds to the apex seal's requirement."

The only thing I would do is to make sure there the rubber fillers are between the check valves and nozzles, the check valves are in good shape if not new and the oil lines are good. Unless you are running very high chamber pressures the oil system will support the engine just fine. If you are concerned step up the Mikuni pump; it will deliver about the same oil at low engine loads and more than the denso at high loads. Remember, it's not about engine RPM it's about load. There is no evidence the nozzle orifice diameter is affecting the 13b engine life.

"The rotary's reliability under the severest conditions was well proven in Mazda's competition activities in the late 80's and early 90's, including an outright win in the Le Mans 24-hour race for sports racing cars in 1991. A road car is subjected to a different kind of stress, said a Mazda designer responsible for the engine's innards, especially when the 13B-REW's output is increased to 209 kW (280 bhp). Possible problem areas are higher combustion temperature and pressure. The former could be dealt with by the cooling system's heat dissipating capacity. The later was thought to exert extraordinary pressure on the engine's gas sealing.

Apex seal lubrication has become a critical issue. In a race engine, oil supply to the rotor housing by means of injection was precisely monitored and controlled, whereas in the production unit, a larger amount is supplied, just to be on the safe side. Some of the lubricant is fed into the trochoid chamber through a metering nozzle. The previous nozzle's oil passage was 2.0 mm (0.08 in.) in diameter. Negative pressure created in the rotor chamber would cause all the oil within the nozzle to be sucked out. When the engine accelerated rapidly, oil supply could not keep up with the speed. To prevent oil starvation, the previous system supplied a larger amount of oil to be on the safe side. In the new metering nozzle, the passage diameter has been reduced to 0.08 mm (0.003 in.), halving its volume of 0.0005 L (0.03 cu. in.). A new rubber seal is also inserted to fill a gap within the nozzle body where oil used to be sidetracked. Now, there is still some oil left within the nozzle after each suction, so that the lubrication system responds to the apex seal's requirement."

The only thing I would do is to make sure there the rubber fillers are between the check valves and nozzles, the check valves are in good shape if not new and the oil lines are good. Unless you are running very high chamber pressures the oil system will support the engine just fine. If you are concerned step up the Mikuni pump; it will deliver about the same oil at low engine loads and more than the denso at high loads. Remember, it's not about engine RPM it's about load. There is no evidence the nozzle orifice diameter is affecting the 13b engine life.

#10

Thread Starter

Fast + Reliable = $$$$$

iTrader: (18)

Joined: Nov 2003

Posts: 1,223

Likes: 3

From: SoCal

The only thing I would do is to make sure there the rubber fillers are between the check valves and nozzles, the check valves are in good shape if not new and the oil lines are good. Unless you are running very high chamber pressures the oil system will support the engine just fine. If you are concerned step up the Mikuni pump; it will deliver about the same oil at low engine loads and more than the denso at high loads. Remember, it's not about engine RPM it's about load. There is no evidence the nozzle orifice diameter is affecting the 13b engine life.

As for the Mikuni, honestly I can't see myself spending over $200 for it if I'm also premixing...maybe when they get cheaper one day...

#11

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

I've spoken to Ray about it, and Mazda only sells the newer nozzles. Would be nice to have a choice....... my replacements are currently going strong, knock on wood

#12

Thread Starter

Fast + Reliable = $$$$$

iTrader: (18)

Joined: Nov 2003

Posts: 1,223

Likes: 3

From: SoCal

Funny thing I found my original ones and one of them was also bad!

#15

Joined: Jan 2008

Posts: 4,834

Likes: 318

From: Indiana

Our kit comes with port plugs to eliminate the oil injectors http://www.banzai-racing.com/product...tallation3.jpg

#16

[QUOTE=PandazRx-7;10754338]Wow what a difference, think I'll stick to the bigger old injectors...probably designed to work with the old OMP anyway...

These are not the orifice but only the check valves. The metering orifice are below the check valves and rubber cavity filler plugs and are pressed into the rotor housings. If you look down into the hole you will see a brass orifice. The only way I have found to get them out is to thread with a 6-32 tap and pull out with a screw. It is important during engine rebuild that they are well cleaned and unobstructed. You can also clean them with some brake cleaner and cutting torch cleaning wires. Just make sure if the engine is a runner to have the apex seal positioned so the wire will not scratch or damage the rotor or seal.

I would say however that the check valve with the smaller hole is the newer so as to reduce the total area the oil sits in

Here is a pretty crappy picture of the orifice:

These are not the orifice but only the check valves. The metering orifice are below the check valves and rubber cavity filler plugs and are pressed into the rotor housings. If you look down into the hole you will see a brass orifice. The only way I have found to get them out is to thread with a 6-32 tap and pull out with a screw. It is important during engine rebuild that they are well cleaned and unobstructed. You can also clean them with some brake cleaner and cutting torch cleaning wires. Just make sure if the engine is a runner to have the apex seal positioned so the wire will not scratch or damage the rotor or seal.

I would say however that the check valve with the smaller hole is the newer so as to reduce the total area the oil sits in

Here is a pretty crappy picture of the orifice:

#18

Thread Starter

Fast + Reliable = $$$$$

iTrader: (18)

Joined: Nov 2003

Posts: 1,223

Likes: 3

From: SoCal

Ok so Mazda changed both bottom orifice and the check valves opening... My housings already had the brass orifice...so no way to change that. But I think I'll use the old style check valve for reliability reasons... So far I've had 2 out of 4 newer style check valves go bad. Turns out I also had newer style ones prior to my rebuild... The ones pictured above with the bigger openings are from a friends shop and work perfect after years if abuse.

After thinking about these valves, really makes me wonder how in boost the oil injection system is able to flow... Can the OMP overcome the chambers boost pressure?

Also, having the hose connected to pre-turbo intake "vacuum" I think would help the check valve to close in higher rpm boost no? Chamber pressure push the valve closed and intake vacuum pull it closed... Maybe Mazda knew what was up connecting to intake. And when the motor is in vacuum the valve stays open because the intake vacuum is less than chamber vacuum.

After thinking about these valves, really makes me wonder how in boost the oil injection system is able to flow... Can the OMP overcome the chambers boost pressure?

Also, having the hose connected to pre-turbo intake "vacuum" I think would help the check valve to close in higher rpm boost no? Chamber pressure push the valve closed and intake vacuum pull it closed... Maybe Mazda knew what was up connecting to intake. And when the motor is in vacuum the valve stays open because the intake vacuum is less than chamber vacuum.

#19

Ok so Mazda changed both bottom orifice and the check valves opening... My housings already had the brass orifice...so no way to change that. But I think I'll use the old style check valve for reliability reasons... So far I've had 2 out of 4 newer style check valves go bad. Turns out I also had newer style ones prior to my rebuild... The ones pictured above with the bigger openings are from a friends shop and work perfect after years if abuse.

After thinking about these valves, really makes me wonder how in boost the oil injection system is able to flow... Can the OMP overcome the chambers boost pressure?

Also, having the hose connected to pre-turbo intake "vacuum" I think would help the check valve to close in higher rpm boost no? Chamber pressure push the valve closed and intake vacuum pull it closed... Maybe Mazda knew what was up connecting to intake. And when the motor is in vacuum the valve stays open because the intake vacuum is less than chamber vacuum.

After thinking about these valves, really makes me wonder how in boost the oil injection system is able to flow... Can the OMP overcome the chambers boost pressure?

Also, having the hose connected to pre-turbo intake "vacuum" I think would help the check valve to close in higher rpm boost no? Chamber pressure push the valve closed and intake vacuum pull it closed... Maybe Mazda knew what was up connecting to intake. And when the motor is in vacuum the valve stays open because the intake vacuum is less than chamber vacuum.

The OMP is a positive displacement pump and capable of rather high pressures; far above any realistic intake event pressures. If the orifice is plugged the OMP may even damage the check valve - need to make sure the oil has a path into the rotor housing. Is the same location failing?

#20

it is a metering pump,, with a variable inlet oriface , at a speed at a proportion to engine revs

and there is minimal pressure there after passing through the tiny feed passage in the timing cover

broken plastic feed pipes only dribble and do not jet oil and that is fair evidence of the pressure in the tiny pipes

AFAIK the factory nipple for the vacuum squid routes through the phelonic spacer through to front of the TB

it is not -just -filtered air

it is PURGE air , always over and above engine vacuum/boost

this means air can only ever flow in one direction towards the injection nipple , no matter what the -running- engine condition

the oil feeding from the banjo into the injector enters at right angles,

-venturi feed- which in uses pressure drop in the air-steam to draw in the oil

the check valves primarily act to block the oil injector when there in no pressure difference from engine side to TB side

- engine turned off --

this prevents the oil injector from dribbling down after shutdown and making a smoky start

now,, all those with back feeding systems might want to think about what happens

when you take free atmospheric pressure air instead of purge air from the front of the TB blades and run boost

-it flows backwards -

food for thought???

and there is minimal pressure there after passing through the tiny feed passage in the timing cover

broken plastic feed pipes only dribble and do not jet oil and that is fair evidence of the pressure in the tiny pipes

AFAIK the factory nipple for the vacuum squid routes through the phelonic spacer through to front of the TB

it is not -just -filtered air

it is PURGE air , always over and above engine vacuum/boost

this means air can only ever flow in one direction towards the injection nipple , no matter what the -running- engine condition

the oil feeding from the banjo into the injector enters at right angles,

-venturi feed- which in uses pressure drop in the air-steam to draw in the oil

the check valves primarily act to block the oil injector when there in no pressure difference from engine side to TB side

- engine turned off --

this prevents the oil injector from dribbling down after shutdown and making a smoky start

now,, all those with back feeding systems might want to think about what happens

when you take free atmospheric pressure air instead of purge air from the front of the TB blades and run boost

-it flows backwards -

food for thought???

#21

it is a metering pump,, with a variable inlet oriface , at a speed at a proportion to engine revs

and there is minimal pressure there after passing through the tiny feed passage in the timing cover

broken plastic feed pipes only dribble and do not jet oil and that is fair evidence of the pressure in the tiny pipes

Not true - the pressure is controlled by the springs above the plungers in the OMP. The plungers are very small diameter and the springs have a rate of over a pound. If you run the numbers the pump can put out close to 100 PSI. You are confusing pressure with flow rate

AFAIK the factory nipple for the vacuum squid routes through the phelonic spacer through to front of the TB

it is not -just -filtered air

it is PURGE air , always over and above engine vacuum/boost

this means air can only ever flow in one direction towards the injection nipple , no matter what the -running- engine condition

Not true again; the air tubes from the check valves in a factory configuration are routed to the inlet elbow of the primary turbocharger compressor

the oil feeding from the banjo into the injector enters at right angles,

-venturi feed- which in uses pressure drop in the air-steam to draw in the oil

the check valves primarily act to block the oil injector when there in no pressure difference from engine side to TB side

- engine turned off --

this prevents the oil injector from dribbling down after shutdown and making a smoky start

The air is to provide two things: one - to prevent the engine in a vacuum condition (90%) of driving from pulling the oil from the oil injection system and starving the engine of oil in boost situations when really needed. Two - There are evidence also that the air helps emulsify the oil to better lubricate larger surface areas in the chamber

now,, all those with back feeding systems might want to think about what happens

when you take free atmospheric pressure air instead of purge air from the front of the TB blades and run boost

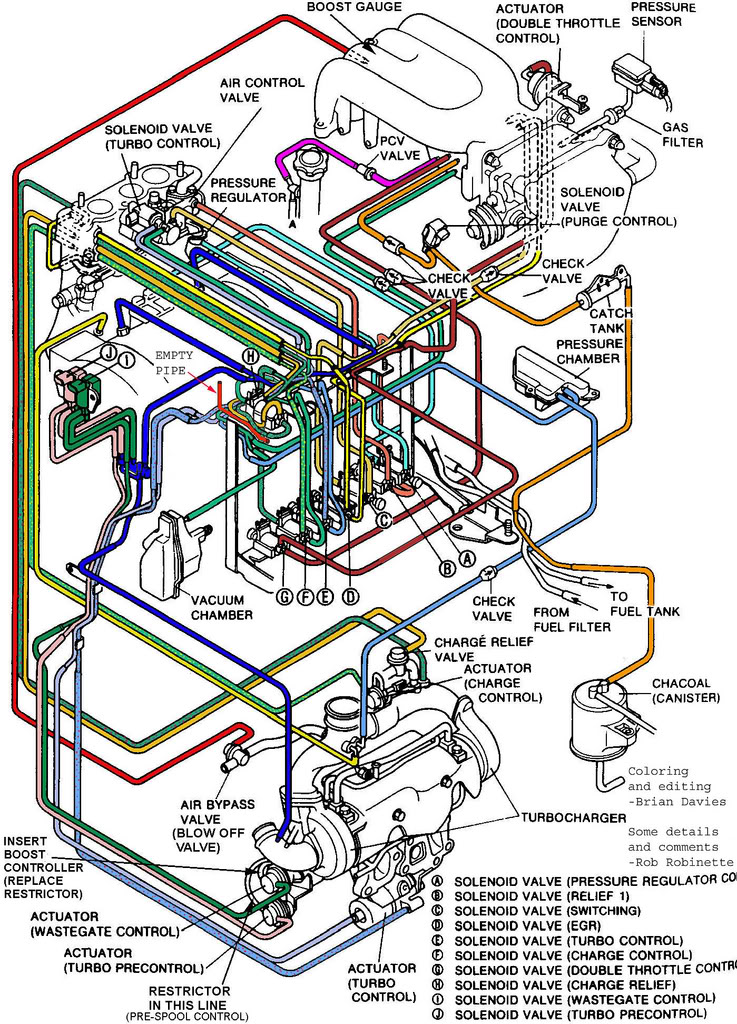

-it flows backwards - Please refer to the hose routing schematics.....

and there is minimal pressure there after passing through the tiny feed passage in the timing cover

broken plastic feed pipes only dribble and do not jet oil and that is fair evidence of the pressure in the tiny pipes

Not true - the pressure is controlled by the springs above the plungers in the OMP. The plungers are very small diameter and the springs have a rate of over a pound. If you run the numbers the pump can put out close to 100 PSI. You are confusing pressure with flow rate

AFAIK the factory nipple for the vacuum squid routes through the phelonic spacer through to front of the TB

it is not -just -filtered air

it is PURGE air , always over and above engine vacuum/boost

this means air can only ever flow in one direction towards the injection nipple , no matter what the -running- engine condition

Not true again; the air tubes from the check valves in a factory configuration are routed to the inlet elbow of the primary turbocharger compressor

the oil feeding from the banjo into the injector enters at right angles,

-venturi feed- which in uses pressure drop in the air-steam to draw in the oil

the check valves primarily act to block the oil injector when there in no pressure difference from engine side to TB side

- engine turned off --

this prevents the oil injector from dribbling down after shutdown and making a smoky start

The air is to provide two things: one - to prevent the engine in a vacuum condition (90%) of driving from pulling the oil from the oil injection system and starving the engine of oil in boost situations when really needed. Two - There are evidence also that the air helps emulsify the oil to better lubricate larger surface areas in the chamber

now,, all those with back feeding systems might want to think about what happens

when you take free atmospheric pressure air instead of purge air from the front of the TB blades and run boost

-it flows backwards - Please refer to the hose routing schematics.....

#23

it is a metering pump,, with a variable inlet oriface , at a speed at a proportion to engine revs

and there is minimal pressure there after passing through the tiny feed passage in the timing cover

broken plastic feed pipes only dribble and do not jet oil and that is fair evidence of the pressure in the tiny pipes

Not true - the pressure is controlled by the springs above the plungers in the OMP. The plungers are very small diameter and the springs have a rate of over a pound. If you run the numbers the pump can put out close to 100 PSI. You are confusing pressure with flow rate

AFAIK the factory nipple for the vacuum squid routes through the phelonic spacer through to front of the TB

it is not -just -filtered air

it is PURGE air , always over and above engine vacuum/boost

this means air can only ever flow in one direction towards the injection nipple , no matter what the -running- engine condition

Not true again; the air tubes from the check valves in a factory configuration are routed to the inlet elbow of the primary turbocharger compressor

the oil feeding from the banjo into the injector enters at right angles,

-venturi feed- which in uses pressure drop in the air-steam to draw in the oil

the check valves primarily act to block the oil injector when there in no pressure difference from engine side to TB side

- engine turned off --

this prevents the oil injector from dribbling down after shutdown and making a smoky start

The air is to provide two things: one - to prevent the engine in a vacuum condition (90%) of driving from pulling the oil from the oil injection system and starving the engine of oil in boost situations when really needed. Two - There are evidence also that the air helps emulsify the oil to better lubricate larger surface areas in the chamber

now,, all those with back feeding systems might want to think about what happens

when you take free atmospheric pressure air instead of purge air from the front of the TB blades and run boost

-it flows backwards - Please refer to the hose routing schematics.....

and there is minimal pressure there after passing through the tiny feed passage in the timing cover

broken plastic feed pipes only dribble and do not jet oil and that is fair evidence of the pressure in the tiny pipes

Not true - the pressure is controlled by the springs above the plungers in the OMP. The plungers are very small diameter and the springs have a rate of over a pound. If you run the numbers the pump can put out close to 100 PSI. You are confusing pressure with flow rate

AFAIK the factory nipple for the vacuum squid routes through the phelonic spacer through to front of the TB

it is not -just -filtered air

it is PURGE air , always over and above engine vacuum/boost

this means air can only ever flow in one direction towards the injection nipple , no matter what the -running- engine condition

Not true again; the air tubes from the check valves in a factory configuration are routed to the inlet elbow of the primary turbocharger compressor

the oil feeding from the banjo into the injector enters at right angles,

-venturi feed- which in uses pressure drop in the air-steam to draw in the oil

the check valves primarily act to block the oil injector when there in no pressure difference from engine side to TB side

- engine turned off --

this prevents the oil injector from dribbling down after shutdown and making a smoky start

The air is to provide two things: one - to prevent the engine in a vacuum condition (90%) of driving from pulling the oil from the oil injection system and starving the engine of oil in boost situations when really needed. Two - There are evidence also that the air helps emulsify the oil to better lubricate larger surface areas in the chamber

now,, all those with back feeding systems might want to think about what happens

when you take free atmospheric pressure air instead of purge air from the front of the TB blades and run boost

-it flows backwards - Please refer to the hose routing schematics.....

,, the schematic-

i can also go outside and blow down the nipple on a selection of TBs and UIM's

-they all feed from the purge air position-

,, for a good reason

now,,, that isnt going to help much when you run more than 7 psi of boost

UNLESS you have a s4/5 type purge air system ( with venturi entry for the oil )

it looks to me that the FD system is very badly thought out

,, as despite the EOMP holding the inlet opening wider for engine load when you go into boost the pressure differential will amount to less oil flow as boost increases

Not true - the pressure is controlled by the springs above the plungers in the OMP. The plungers are very small diameter and the springs have a rate of over a pound. If you run the numbers the pump can put out close to 100 PSI. You are confusing pressure with flow rate

where it claims -internal oil Pressure in EMOP's is between 7.3 and 21.7 PSI-

100 pounds of pressure through a small hole will still jet or spray

-even in tiny volumes,,,this is what the injector does at only 40 psi yes?

i see only dribbles ,, and not jets ,, not puddles ,, volume never came into it

and the later mazda litterature seems to back that up ,, no magic sum

#24

codes-

P1684-- OMP oil pressure low- 6 psi

P1685-- OMP oil pressure high - 26 psi

rx8 series 2 manual

now,,all omp run a 1/2 engine speed

( excepting the 2nd s2 rx8 pump which is engine speed )

they have variable inlet ,, and that inlet is timed for only a proportion of each revolution of the pump

the end of the oil injector is open ended

where then is the work that steps the pressure ratio 15 times in that tiny little "METERING" pump ?

it is not oversped,, the inlet is not open 100 % of the time ,, the head is open

and incidentally the s2 rx8 pump also does not compound off the other

now,, i worked for a long time in a mega million $$ refinery where the pumps are worth more than supercars and last only days if not done right

it was my job to specialize in operating many of them

and i understood them very well, both in theory and in practice

never have i seen such incredible feats from these refinery pumps as what this magic OMP is allegedly doing

also,, those nylon pipes on the s4/5,, they are NOT instrument tube

i highly doubt they will handle 100 psi

and if they did,, i expect a bit more of a jet to come out at that pressure

P1684-- OMP oil pressure low- 6 psi

P1685-- OMP oil pressure high - 26 psi

rx8 series 2 manual

now,,all omp run a 1/2 engine speed

( excepting the 2nd s2 rx8 pump which is engine speed )

they have variable inlet ,, and that inlet is timed for only a proportion of each revolution of the pump

the end of the oil injector is open ended

where then is the work that steps the pressure ratio 15 times in that tiny little "METERING" pump ?

it is not oversped,, the inlet is not open 100 % of the time ,, the head is open

and incidentally the s2 rx8 pump also does not compound off the other

now,, i worked for a long time in a mega million $$ refinery where the pumps are worth more than supercars and last only days if not done right

it was my job to specialize in operating many of them

and i understood them very well, both in theory and in practice

never have i seen such incredible feats from these refinery pumps as what this magic OMP is allegedly doing

also,, those nylon pipes on the s4/5,, they are NOT instrument tube

i highly doubt they will handle 100 psi

and if they did,, i expect a bit more of a jet to come out at that pressure

#25

There are several classes of fluid pumps; centrifugal, axial vane, diaphragm, gear-rotor, piston, etc.

Centrifugal and axial vane rely on fluid dynamics both behind and in front of the pump in order to move the fluid; these classes of pumps can be what is called “dead-headed” where as fluid flow can be shut-off down stream of the pump. The effect of stopping flow down stream of these pumps will realize a significant drop in output pressure due to cavitation and other effects.

A second class of pumps is positive displacement. These include gear-rotor, piston, and diaphragm. These pumps rely on a closed chamber being reduced in size and the fluid extruded through a discharge port. As most liquids are non-compressible very high pressures can be obtained with these type of pumps. Another feature of positive displacement pumps is the capability to precisely meter a fluid. In contrast to centrifugal pumps positive displacement pumps cannot be dead-headed as the pump will stall or something worse.

The Gen C and D RX7 metering oil pumps are variable positive displacement piston whereas the piston chamber volume is variable. Regardless as the piston moves into the chamber the oil is displaced to the plastic tubes and through the metering orifice. If one should block off the discharge ports the pressure would be very high and no doubt break the pump. The suction of the pump is provided by a pool of oil fed at virtually ambient pressure through the engine’s front cover.

The operating pressure for 1.8mm nylon 11 tubing (similar to the OMP discharge tubing) is over 400 psi. The below is from McMaster-Carr as an example. The weak link in the tube assembly is probably the mechanical connections at the ends. Regardless, the tube assemblies are sufficient for any probable pressure scenario.

Material Nylon 11

Shape Single Line

Outside Dia. 3 mm

Inside Dia. 1.8 mm

Wall Thickness .6 mm

Available Lengths 25, 50, and 100 feet

Reinforcement Unreinforced

Color Semi-Clear White

Maximum Pressure 410 psi @ 75º F

Operating Temperature Range -60° to +200° F

Performance Characteristics Vacuum Rated

Vacuum Rating 28" Hg at 72° F

Bend Radius 3/8" (.375")

Durometer 70D (Hard)

Tensile Strength 6,960 psi

The flow rates for the OMP are variable (see the below chart); regardless the flows will be a “dribble” from an open ended tube the size of the metering oil system. If you should block the tube the pressure will become very significant and most likely fail the tubing.

Centrifugal and axial vane rely on fluid dynamics both behind and in front of the pump in order to move the fluid; these classes of pumps can be what is called “dead-headed” where as fluid flow can be shut-off down stream of the pump. The effect of stopping flow down stream of these pumps will realize a significant drop in output pressure due to cavitation and other effects.

A second class of pumps is positive displacement. These include gear-rotor, piston, and diaphragm. These pumps rely on a closed chamber being reduced in size and the fluid extruded through a discharge port. As most liquids are non-compressible very high pressures can be obtained with these type of pumps. Another feature of positive displacement pumps is the capability to precisely meter a fluid. In contrast to centrifugal pumps positive displacement pumps cannot be dead-headed as the pump will stall or something worse.

The Gen C and D RX7 metering oil pumps are variable positive displacement piston whereas the piston chamber volume is variable. Regardless as the piston moves into the chamber the oil is displaced to the plastic tubes and through the metering orifice. If one should block off the discharge ports the pressure would be very high and no doubt break the pump. The suction of the pump is provided by a pool of oil fed at virtually ambient pressure through the engine’s front cover.

The operating pressure for 1.8mm nylon 11 tubing (similar to the OMP discharge tubing) is over 400 psi. The below is from McMaster-Carr as an example. The weak link in the tube assembly is probably the mechanical connections at the ends. Regardless, the tube assemblies are sufficient for any probable pressure scenario.

Material Nylon 11

Shape Single Line

Outside Dia. 3 mm

Inside Dia. 1.8 mm

Wall Thickness .6 mm

Available Lengths 25, 50, and 100 feet

Reinforcement Unreinforced

Color Semi-Clear White

Maximum Pressure 410 psi @ 75º F

Operating Temperature Range -60° to +200° F

Performance Characteristics Vacuum Rated

Vacuum Rating 28" Hg at 72° F

Bend Radius 3/8" (.375")

Durometer 70D (Hard)

Tensile Strength 6,960 psi

The flow rates for the OMP are variable (see the below chart); regardless the flows will be a “dribble” from an open ended tube the size of the metering oil system. If you should block the tube the pressure will become very significant and most likely fail the tubing.