Non Sequential Experts - Need Guidance - Have Pictures

#1

Ferrari Red Hotness

Thread Starter

Join Date: Nov 2005

Location: Las Vegas

Posts: 964

Likes: 0

Received 0 Likes

on

0 Posts

Non Sequential Experts - Need Guidance - Have Pictures

OK.....so I'm finally converting the car to non-sequential and have a few questions before I go cutting anything.

In the pictures attached below, I just wanted to verify what I'm going to do:

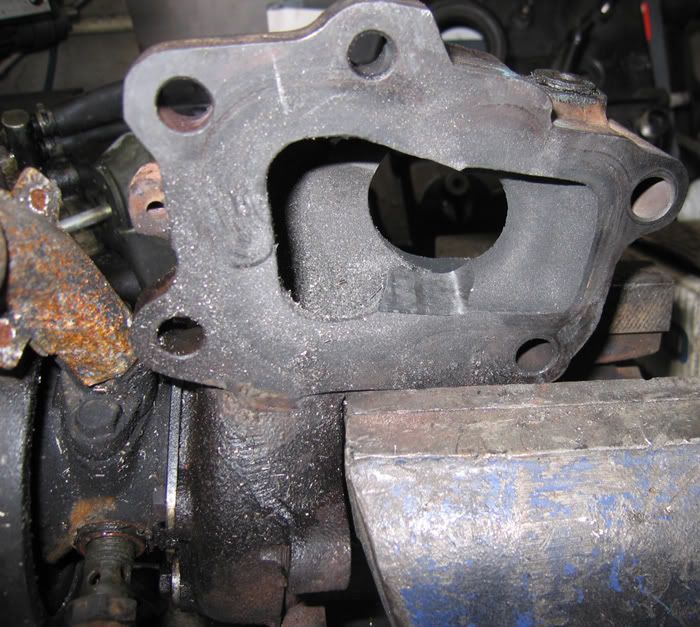

Pic 1: The manifold, I'm going to cut this flapper door completely off. Correct?

Pic 2: The manifold again, on this time I circled the section I will take out and tap once the flapper is off. Correct??

Pic 3: This is the pre-spool flapper i need to cut off or weld. Correct?

Pic 4: I am a little confused by this door..... it seems on most pictures there are only two bolts holding it down, and on some of the turbos I've seen this is not 100% secured down. Does this cover need to be 100% closed and secured?

That's it, thanks. I'm going to post pictures hopefully of my conversion step by step.

In the pictures attached below, I just wanted to verify what I'm going to do:

Pic 1: The manifold, I'm going to cut this flapper door completely off. Correct?

Pic 2: The manifold again, on this time I circled the section I will take out and tap once the flapper is off. Correct??

Pic 3: This is the pre-spool flapper i need to cut off or weld. Correct?

Pic 4: I am a little confused by this door..... it seems on most pictures there are only two bolts holding it down, and on some of the turbos I've seen this is not 100% secured down. Does this cover need to be 100% closed and secured?

That's it, thanks. I'm going to post pictures hopefully of my conversion step by step.

#3

here is what i did, for the door on the manifold i cut that completely off, then once it is cut off there will be a hole and that gets welded closed. then for the flap on the turbos i took the pre-controll acutator off then held the flap completely open and welded it in that position so it is always open. for the fourth picture, i did nothing with that. the two empty holes are where the two long bolts go when you mount the turbos to the manifold.

#4

Ferrari Red Hotness

Thread Starter

Join Date: Nov 2005

Location: Las Vegas

Posts: 964

Likes: 0

Received 0 Likes

on

0 Posts

Gotcha....thanks for the help. I haven't decided if I want to weld my pre-control door open or just cut it off. I've heard positive things about cutting it off, probably safer than welding it too. Hmmm

#5

Originally Posted by xblazinlv

OK.....so I'm finally converting the car to non-sequential and have a few questions before I go cutting anything.

In the pictures attached below, I just wanted to verify what I'm going to do:

Pic 1: The manifold, I'm going to cut this flapper door completely off. Correct?

Pic 2: The manifold again, on this time I circled the section I will take out and tap once the flapper is off. Correct??

Pic 3: This is the pre-spool flapper i need to cut off or weld. Correct?

Pic 4: I am a little confused by this door..... it seems on most pictures there are only two bolts holding it down, and on some of the turbos I've seen this is not 100% secured down. Does this cover need to be 100% closed and secured?

That's it, thanks. I'm going to post pictures hopefully of my conversion step by step.

In the pictures attached below, I just wanted to verify what I'm going to do:

Pic 1: The manifold, I'm going to cut this flapper door completely off. Correct?

Pic 2: The manifold again, on this time I circled the section I will take out and tap once the flapper is off. Correct??

Pic 3: This is the pre-spool flapper i need to cut off or weld. Correct?

Pic 4: I am a little confused by this door..... it seems on most pictures there are only two bolts holding it down, and on some of the turbos I've seen this is not 100% secured down. Does this cover need to be 100% closed and secured?

That's it, thanks. I'm going to post pictures hopefully of my conversion step by step.

Did you cut off the pre spooler flapper then, I'm doing mine as I type.

Or can anyone help, if it needs held open I'd rather machine it out which would be the same as holding it open.

#7

Ferrari Red Hotness

Thread Starter

Join Date: Nov 2005

Location: Las Vegas

Posts: 964

Likes: 0

Received 0 Likes

on

0 Posts

I just welded the pre-spool flapper control arm on the outside of the manifold so it would be open 90% of the way.

I guess if you cut it, it creates un-necessary turbulence.

I guess if you cut it, it creates un-necessary turbulence.

Trending Topics

#12

Cant really see it causing any more turbulence, might lose a bit of low down power and a bit of extra lag. But I have a half bridge port and will run these turbos till its all sorted and ready for a big single.

#14

Originally Posted by Speedworks

I read that thread and got info from it. Soem things were a little unclear thats why I posted on here.

#15

Rotary Freak

Yeah, it's not so hard to find theoretical info about this subject but the picture are nowhere to be found..

I'm still looking for the vac hose setup that goes with the FULL non seq setup like the one Jimlab put forward.

I'm still looking for the vac hose setup that goes with the FULL non seq setup like the one Jimlab put forward.

#16

Photos do help alot, another thing that confused me was people were on about wastegates fro the 1st and 2nd turbo's. When I ended up taken it apart there is only 1.

Photos are better in the long run.

Photos are better in the long run.

#17

Ferrari Red Hotness

Thread Starter

Join Date: Nov 2005

Location: Las Vegas

Posts: 964

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Speedworks

Yeah, it's not so hard to find theoretical info about this subject but the picture are nowhere to be found..

I'm still looking for the vac hose setup that goes with the FULL non seq setup like the one Jimlab put forward.

I'm still looking for the vac hose setup that goes with the FULL non seq setup like the one Jimlab put forward.

I have the diagram, give me a sec and I'll attach it

#19

Rotary Freak

^A+ many thanks. This is for the FULL non seq conversion yes?

Bucky, what do you mean tehre is only one waste gate? There are 3.

1. manifold flapper whcih you need to cut. Either remove and weld or just leave the flapper cilinder in there and spotwelf it on the outside.

2. wastegate on secundary turbo (the one behind the removable door). You can eiter spot weld it shut or open depending on your own theory about spool up times.

3. Primary turbo wastegate which needs to be machined and will be the only working wastegate remaining in the setup.

I'll be using a manual boost controler on this wastegate, because an electronic one is just a waste of money on this setup. A mechanical boost gauge will do just fine as it no longer has to reflect the quick transition boost drop.

Bucky, what do you mean tehre is only one waste gate? There are 3.

1. manifold flapper whcih you need to cut. Either remove and weld or just leave the flapper cilinder in there and spotwelf it on the outside.

2. wastegate on secundary turbo (the one behind the removable door). You can eiter spot weld it shut or open depending on your own theory about spool up times.

3. Primary turbo wastegate which needs to be machined and will be the only working wastegate remaining in the setup.

I'll be using a manual boost controler on this wastegate, because an electronic one is just a waste of money on this setup. A mechanical boost gauge will do just fine as it no longer has to reflect the quick transition boost drop.

#20

What's your point ?

Join Date: Feb 2001

Location: Gainesville, Fla.

Posts: 3,573

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Speedworks

^A+ many thanks. This is for the FULL non seq conversion yes?

Bucky, what do you mean tehre is only one waste gate? There are 3.

1. manifold flapper whcih you need to cut. Either remove and weld or just leave the flapper cilinder in there and spotwelf it on the outside.

2. wastegate on secundary turbo (the one behind the removable door). You can eiter spot weld it shut or open depending on your own theory about spool up times.

3. Primary turbo wastegate which needs to be machined and will be the only working wastegate remaining in the setup.

I'll be using a manual boost controler on this wastegate, because an electronic one is just a waste of money on this setup. A mechanical boost gauge will do just fine as it no longer has to reflect the quick transition boost drop.

Bucky, what do you mean tehre is only one waste gate? There are 3.

1. manifold flapper whcih you need to cut. Either remove and weld or just leave the flapper cilinder in there and spotwelf it on the outside.

2. wastegate on secundary turbo (the one behind the removable door). You can eiter spot weld it shut or open depending on your own theory about spool up times.

3. Primary turbo wastegate which needs to be machined and will be the only working wastegate remaining in the setup.

I'll be using a manual boost controler on this wastegate, because an electronic one is just a waste of money on this setup. A mechanical boost gauge will do just fine as it no longer has to reflect the quick transition boost drop.

#22

Originally Posted by Speedworks

^A+ many thanks. This is for the FULL non seq conversion yes?

Bucky, what do you mean tehre is only one waste gate? There are 3.

1. manifold flapper whcih you need to cut. Either remove and weld or just leave the flapper cilinder in there and spotwelf it on the outside.

2. wastegate on secundary turbo (the one behind the removable door). You can eiter spot weld it shut or open depending on your own theory about spool up times.

3. Primary turbo wastegate which needs to be machined and will be the only working wastegate remaining in the setup.

I'll be using a manual boost controler on this wastegate, because an electronic one is just a waste of money on this setup. A mechanical boost gauge will do just fine as it no longer has to reflect the quick transition boost drop.

Bucky, what do you mean tehre is only one waste gate? There are 3.

1. manifold flapper whcih you need to cut. Either remove and weld or just leave the flapper cilinder in there and spotwelf it on the outside.

2. wastegate on secundary turbo (the one behind the removable door). You can eiter spot weld it shut or open depending on your own theory about spool up times.

3. Primary turbo wastegate which needs to be machined and will be the only working wastegate remaining in the setup.

I'll be using a manual boost controler on this wastegate, because an electronic one is just a waste of money on this setup. A mechanical boost gauge will do just fine as it no longer has to reflect the quick transition boost drop.

Thats what I mean, before taking the turbos apart and having a look myself, I thought there was 3 gates. But 2 of them arn't really gates. They look like gates but do different things.

I have just done this conversion till I run the rebuilt motor in and convert to a T78. Plus I was bored at the time

#24

I bought the car with the engine blown, so i have never driven the car. Waiting for a couple of things to be delivered via post and it will be back together.

I drove a friend rx with seq turbos and it seems good, converted to poor mans non seq and he says its miles faster but there is a lot more lag bottom end. His engine is standard with bolt-ons but standard DP.

I drove a friend rx with seq turbos and it seems good, converted to poor mans non seq and he says its miles faster but there is a lot more lag bottom end. His engine is standard with bolt-ons but standard DP.

#25

Rotary Freak

Acc the people who did the full conversion and with filters,DP and catback/cat replacement it should hit near full boost at 3200 rpm or in that range. That's fine with me, just watch your self how little time you spend driving the car under that rpm -> very litle.

Unless you want to drift at every corner in town I don't really see the necessity to have bosst at lower rpm. I think it should add to mileage as well because driving in 5th gear at 3000rpm should give you a speed between 60 and 70 mph, which is good for highway cruising.

Just wondering what ECU you will be using? I have PFC and I was reading a PFC tune file on this forum and got intriged by the injector staging.

I think a little modification should be in place with the non seq setup as boost will kick in at a slightly different rpm and will be constant till redline and not drop at 4500 rpm.

Unless you want to drift at every corner in town I don't really see the necessity to have bosst at lower rpm. I think it should add to mileage as well because driving in 5th gear at 3000rpm should give you a speed between 60 and 70 mph, which is good for highway cruising.

Just wondering what ECU you will be using? I have PFC and I was reading a PFC tune file on this forum and got intriged by the injector staging.

I think a little modification should be in place with the non seq setup as boost will kick in at a slightly different rpm and will be constant till redline and not drop at 4500 rpm.