How strong do you think these welds are?

#1

Thread Starter

CURVE OF CONSTANT WIDTH

iTrader: (4)

Joined: Mar 2004

Posts: 2,314

Likes: 1

From: Wesley Chapel, FL

How strong do you think these welds are?

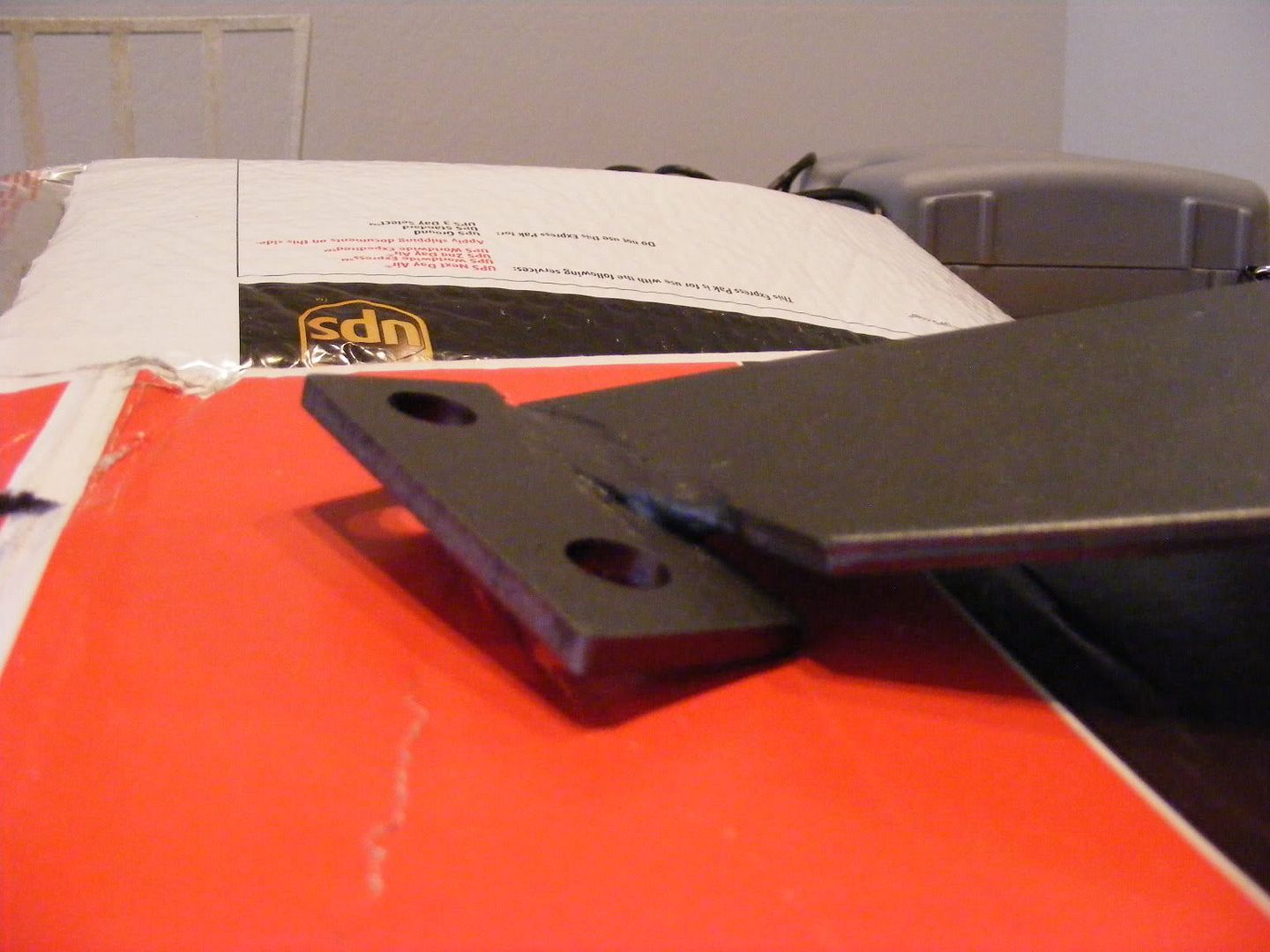

After waiting for a while. I finally got my Aspec transmission brace. But I'm not to sure on the quality of the welds. FYI I also got badddrx7 transmission brace and its a work of art. See this thread.

https://www.rx7club.com/good-members-184/badddrx7-guy-772091/#post8386442

https://www.rx7club.com/good-members-184/badddrx7-guy-772091/#post8386442

#5

I'm not an expert welder but I have done some welding to know they look quite a bit on the amateur side. I honestly wouldn't use them. Some parts of the beads look too thin, others look like there isn't enough penetration into the plates, and the small piece with two holes that is at an odd angle to the larger piece I think will fail somewhere along the line. It should be connected a lot better than that. I would get my money back and find someone that can make them as they should be.

#6

Thread Starter

CURVE OF CONSTANT WIDTH

iTrader: (4)

Joined: Mar 2004

Posts: 2,314

Likes: 1

From: Wesley Chapel, FL

I did get a baddrx7 transmission brace and will be using it instead. I think Aspec did this on purpose because I was being an impatient customer.

https://www.rx7club.com/showthread.php?t=770217

https://www.rx7club.com/showthread.php?t=770217

Trending Topics

#9

Ive seen better work from Sean and personally have seen him weld. I am certain this wasnt on purpose. I dont know if he did this but the welds do look like crap. I once lost my helmet and had to mig weld a dump tube with my eyes shut in a time of need and they still looked better. I am sure Sean will refund you and this call all go to rest.

#10

All I can say is wow! I am a certified welder of some 15 years now with my own shop and I guarantee all of my work. The welds in those pics are from a MIG weld gone bad. I have all three of the major welding procedures ( TIG, MIG and AC/DC reverse stick ) and primarily use DC reverse stick. All of those braces I made for you were mostly butt or lap welds using a 6010 root pass at 90 amps and then covered with 7018, all DC reverese.

I am sure that the folks you bought that one from will make it good.

Again thanks to those who called upon me to help them.

Later

I am sure that the folks you bought that one from will make it good.

Again thanks to those who called upon me to help them.

Later

#11

Thread Starter

CURVE OF CONSTANT WIDTH

iTrader: (4)

Joined: Mar 2004

Posts: 2,314

Likes: 1

From: Wesley Chapel, FL

All I can say is wow! I am a certified welder of some 15 years now with my own shop and I guarantee all of my work. The welds in those pics are from a MIG weld gone bad. I have all three of the major welding procedures ( TIG, MIG and AC/DC reverse stick ) and primarily use DC reverse stick. All of those braces I made for you were mostly butt or lap welds using a 6010 root pass at 90 amps and then covered with 7018, all DC reverese.

I am sure that the folks you bought that one from will make it good.

Again thanks to those who called upon me to help them.

Later

I am sure that the folks you bought that one from will make it good.

Again thanks to those who called upon me to help them.

Later

#12

Wow, you weld your braces with a stick? Last time I used a 6010 and 7018 rod was 3 years ago when I had to get certified...I like to TIG everything I do.

All I can say is wow! I am a certified welder of some 15 years now with my own shop and I guarantee all of my work. The welds in those pics are from a MIG weld gone bad. I have all three of the major welding procedures ( TIG, MIG and AC/DC reverse stick ) and primarily use DC reverse stick. All of those braces I made for you were mostly butt or lap welds using a 6010 root pass at 90 amps and then covered with 7018, all DC reverese.

I am sure that the folks you bought that one from will make it good.

Again thanks to those who called upon me to help them.

Later

I am sure that the folks you bought that one from will make it good.

Again thanks to those who called upon me to help them.

Later

#14

Goodfalla Engine Complete

iTrader: (28)

Joined: May 2005

Posts: 3,238

Likes: 34

From: Kennewick, Washington

Any company that would even ship that out is doing 1 of things:

TRYING to **** off a customer.

Or have no quality control.

There is spatter everywhere, nothing lines up properly, I don't see a single weld that I would consider satisfactory, or even good enough. looks terrible.

I'd tell them to shove that up their a** and to go get f***ed in the neck if they expect you to pay good money for that.

But I am only slightly picky.

TRYING to **** off a customer.

Or have no quality control.

There is spatter everywhere, nothing lines up properly, I don't see a single weld that I would consider satisfactory, or even good enough. looks terrible.

I'd tell them to shove that up their a** and to go get f***ed in the neck if they expect you to pay good money for that.

But I am only slightly picky.

#16

Argon, Argon/helium mix shield gases are sky high to refill. Only for aluminum. any thing else, good ole DC reverse does the job just fine.

Later

#25

A refund will be issued accordingly...sorry for the headache.