Help! installing greddy profec spec II JDM rx7

#1

Hi, All

After having some problems with boost spikes I've decided to get a greddy profec B spec II and I'm not sure how to install it/ set up properly... i found some info... but im getting more and more confused

1st i found this

https://www.rx7club.com/3rd-gen-archives-73/profec-b-spec-ii-install-review-192249/

but i found that there is different ways to install and as the post is pretty old... maybe there is better/easier ways to install properly

Please help me! i just want to keep my car running safe and with the stock boost pattern...

pictures/links any help will be highly appreciated

Many thanks in advance and Merry Christhmas to all!

After having some problems with boost spikes I've decided to get a greddy profec B spec II and I'm not sure how to install it/ set up properly... i found some info... but im getting more and more confused

1st i found this

https://www.rx7club.com/3rd-gen-archives-73/profec-b-spec-ii-install-review-192249/

but i found that there is different ways to install and as the post is pretty old... maybe there is better/easier ways to install properly

Please help me! i just want to keep my car running safe and with the stock boost pattern...

pictures/links any help will be highly appreciated

Many thanks in advance and Merry Christhmas to all!

Last edited by Arthas; 12-13-11 at 01:43 PM.

#2

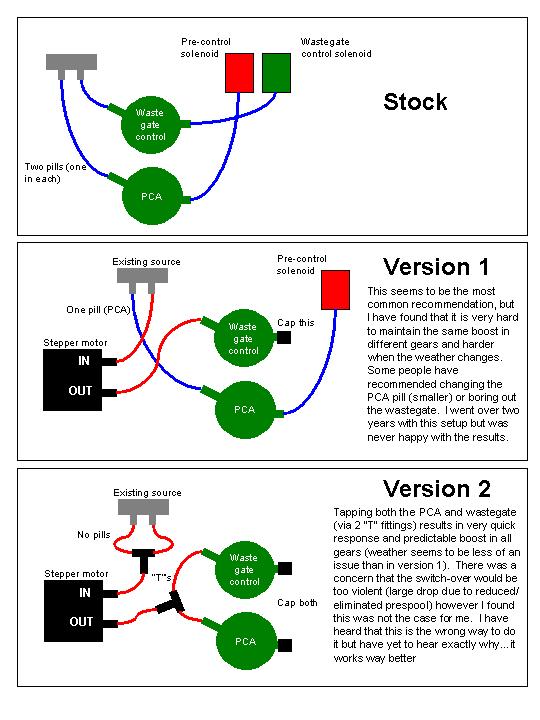

Version 2 is the way I install boost controllers on an FD. Just make sure all the lines are very secure and the caps are proper caps that can take the heat. I use vacuum caps from McMaster-Carr that are made of EPDM rubber, they can do the job.

Dale

Dale

#3

many thanks for your answer... do you have some real pictures? Im very lost on this... and i found some guides but all of them without some real pics...

I just dont have so clear what to tap, where to attach and i found this

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/greddy-profec-b-spec-2-intall-help-407914/

and im even more lost... he's using the boost gauge lane for the BC.... so what is that existing source

sorry for the dumb questions... but rotaries world is very complicated...

#6

Pull your airbox out so you can see down there and it will be clear. It seems confusing but really it's pretty damn simple.

The input to the boost controller can really be one hose. There are 2 nipples on the outlet of the front turbo, you can cap one then run the hose from the second nipple to the input on the boost controller. The output of the boost controller you run to a "T" then run two hoses from the T to each actuator. Cap the extra nipple on the actuator and done.

MAKE SURE to use a BRASS TEE, NEVER use a plastic T. Plastic will get brittle and break in the heat over time, boost goes crazy, motor goes boom. Use good silicone hose and clamp every hose end down, at minimum with a nylon zip tie pulled tight. The hoses need to be the right hoses and fit SNUGLY, not loose.

Dale

The input to the boost controller can really be one hose. There are 2 nipples on the outlet of the front turbo, you can cap one then run the hose from the second nipple to the input on the boost controller. The output of the boost controller you run to a "T" then run two hoses from the T to each actuator. Cap the extra nipple on the actuator and done.

MAKE SURE to use a BRASS TEE, NEVER use a plastic T. Plastic will get brittle and break in the heat over time, boost goes crazy, motor goes boom. Use good silicone hose and clamp every hose end down, at minimum with a nylon zip tie pulled tight. The hoses need to be the right hoses and fit SNUGLY, not loose.

Dale

Trending Topics

#9

The diagrams are for a stepper motor type EBC. Not many of those are available any more. In this case think of the "IN" port as the "NO" port on the solenoid, and the "OUT" port on the diagram as the "COM" port on the solenoid. The NC port can be left open. This applies only to internal wastegates/stock turbos.

#10

Pull your airbox out so you can see down there and it will be clear. It seems confusing but really it's pretty damn simple.

The input to the boost controller can really be one hose. There are 2 nipples on the outlet of the front turbo, you can cap one then run the hose from the second nipple to the input on the boost controller. The output of the boost controller you run to a "T" then run two hoses from the T to each actuator. Cap the extra nipple on the actuator and done.

MAKE SURE to use a BRASS TEE, NEVER use a plastic T. Plastic will get brittle and break in the heat over time, boost goes crazy, motor goes boom. Use good silicone hose and clamp every hose end down, at minimum with a nylon zip tie pulled tight. The hoses need to be the right hoses and fit SNUGLY, not loose.

Dale

The input to the boost controller can really be one hose. There are 2 nipples on the outlet of the front turbo, you can cap one then run the hose from the second nipple to the input on the boost controller. The output of the boost controller you run to a "T" then run two hoses from the T to each actuator. Cap the extra nipple on the actuator and done.

MAKE SURE to use a BRASS TEE, NEVER use a plastic T. Plastic will get brittle and break in the heat over time, boost goes crazy, motor goes boom. Use good silicone hose and clamp every hose end down, at minimum with a nylon zip tie pulled tight. The hoses need to be the right hoses and fit SNUGLY, not loose.

Dale

so after using "version 2" "precontrol solenoid" and "wastegate control solenoid" remains open? or capped too?

And what about the boost source for the controller itself can i attach a "T" to the boost gauge line?

thank you so much for the pictures

... between your pictures, diagram and dale explanation almost everything is clear... just i dont know what to do with the solenoids...

... between your pictures, diagram and dale explanation almost everything is clear... just i dont know what to do with the solenoids...The diagrams are for a stepper motor type EBC. Not many of those are available any more. In this case think of the "IN" port as the "NO" port on the solenoid, and the "OUT" port on the diagram as the "COM" port on the solenoid. The NC port can be left open. This applies only to internal wastegates/stock turbos.

here is a few pics... I just want to be sure and don't screw up anything...

the extra hole ..."NC" port can remain tapped with that plastic tap? or should i let it opened?

And for electrical, can i use any "ACC source"? for example lighter, car stereo? or there is any problem with that...

thank you so much to all... in a few answers... I've almost installed my Profec B!

#15

Well, finally I've installed everything, and I've tested the car with the boost controller off and it was boosting 7 psi (77) so i guess everything is correct...

so now my problem is tunning the unit... I've readed a lot of threads.... and there is many set ups but most of them... aiming for higher boost than 10-8-10 wich is my objective... and I'm a bit confused...

So, please any specialist can help me? I just want the 10-8-10 pattern... or atleast just give me a tip about how to set the "set" to get the 10 psi max boost...

and any explanation about the damn "set gain" setting... im so confused with this one due to I've read this

START BOOST (also known as SET GAIN because that is what is displayed on the unit when adjusting this setting) is the lowest boost that the Greddy unit will begin increasing the boost from under WOT. You want this to be as close to the SET value as possible, since you want to keep as close to your desired boost as possible. However, setting it too close to the SET value will cause the boost to spike. You should set this to a conservative setting when beginning to tune your Greddy unit. Then you can fine-tune it later to get it as close to the SET value as possible without causing the boost to spike. Fortunately, you can set this in psi or kPa, thankfully Greddy didn't decide to let this be adjustable in % like the SET value. START BOOST SHOULD BE SET TO YOUR DESIRED BOOST PRESSURE MINUS 4 PSI (about 28 kPa).

P.S. I've read all this http://www.sr20forum.com/turbo-guide...b-spec-ii.html

Many thanks in advance!

so now my problem is tunning the unit... I've readed a lot of threads.... and there is many set ups but most of them... aiming for higher boost than 10-8-10 wich is my objective... and I'm a bit confused...

So, please any specialist can help me? I just want the 10-8-10 pattern... or atleast just give me a tip about how to set the "set" to get the 10 psi max boost...

and any explanation about the damn "set gain" setting... im so confused with this one due to I've read this

START BOOST (also known as SET GAIN because that is what is displayed on the unit when adjusting this setting) is the lowest boost that the Greddy unit will begin increasing the boost from under WOT. You want this to be as close to the SET value as possible, since you want to keep as close to your desired boost as possible. However, setting it too close to the SET value will cause the boost to spike. You should set this to a conservative setting when beginning to tune your Greddy unit. Then you can fine-tune it later to get it as close to the SET value as possible without causing the boost to spike. Fortunately, you can set this in psi or kPa, thankfully Greddy didn't decide to let this be adjustable in % like the SET value. START BOOST SHOULD BE SET TO YOUR DESIRED BOOST PRESSURE MINUS 4 PSI (about 28 kPa).

P.S. I've read all this http://www.sr20forum.com/turbo-guide...b-spec-ii.html

Many thanks in advance!

Last edited by Arthas; 02-16-12 at 05:55 PM.

#16

^ That writeup is very old and full of half-truths. Whoever originally wrote it did not fully understand how this boost controller actually works, but I could see the advice in the writeup still working ok despite misleading explanations.

Start with SET, SET GAIN, and GAIN all near zero. Alternate between raising SET and SET GAIN until your boost gets near 10psi. You could add in a little GAIN if boost is falling off up top. You'll just have to fiddle with it. Usually if SET GAIN or GAIN are too high you will get surging or spiking. Use the LIMITER feature as a form of overboost protection.

I have thoroughly discussed this and most other boost controllers here https://www.rx7club.com/3rd-generation-specific-1993-2002-16/electronic-boost-controller-comparison-chart-952767/

Start with SET, SET GAIN, and GAIN all near zero. Alternate between raising SET and SET GAIN until your boost gets near 10psi. You could add in a little GAIN if boost is falling off up top. You'll just have to fiddle with it. Usually if SET GAIN or GAIN are too high you will get surging or spiking. Use the LIMITER feature as a form of overboost protection.

I have thoroughly discussed this and most other boost controllers here https://www.rx7club.com/3rd-generation-specific-1993-2002-16/electronic-boost-controller-comparison-chart-952767/

#17

Hi there! many thanks for your repply... after some runs... actually im with:

set: 42

gain: 6

set gain: 60

warning: 110

Limiter: 16%

I've reached max 100 (10 psi) but not consistently... around 5000/6000 boost starts to fall... and bounces something like a fuel cut (boost cut maybe but i didn't hit the limiter neither got any warning from unit)... should i add more gain? or reduce gain and play more with set gain???

my boost pattern actually is something like... 10-6.6-xxx (due to 5.5k/6k rpm boost is bouncing)

I'm hatting this thing... almost at low rpms everything is fine... but now problem is at high rpms...

all my tests in 3rd gear

any help?

my mods, greddy airinx, catback,

thanks in advance...

set: 42

gain: 6

set gain: 60

warning: 110

Limiter: 16%

I've reached max 100 (10 psi) but not consistently... around 5000/6000 boost starts to fall... and bounces something like a fuel cut (boost cut maybe but i didn't hit the limiter neither got any warning from unit)... should i add more gain? or reduce gain and play more with set gain???

my boost pattern actually is something like... 10-6.6-xxx (due to 5.5k/6k rpm boost is bouncing)

I'm hatting this thing... almost at low rpms everything is fine... but now problem is at high rpms...

all my tests in 3rd gear

any help?

my mods, greddy airinx, catback,

thanks in advance...

#18

Hi there! many thanks for your repply... after some runs... actually im with:

set: 42

gain: 6

set gain: 60

warning: 110

Limiter: 16%

I've reached max 100 (10 psi) but not consistently... around 5000/6000 boost starts to fall...

my boost pattern actually is something like... 10-6.6-xxx (due to 5.5k/6k rpm boost is bouncing)

. but now problem is at high rpms...

set: 42

gain: 6

set gain: 60

warning: 110

Limiter: 16%

I've reached max 100 (10 psi) but not consistently... around 5000/6000 boost starts to fall...

my boost pattern actually is something like... 10-6.6-xxx (due to 5.5k/6k rpm boost is bouncing)

. but now problem is at high rpms...

If everything is good good then it's your settings. As I said earlier I don't like your settings. Your set and set gain are too high while your gain is to low. Do you have the greddy instructions? It explains in detail how to set it and what it all means.

Start on page 16:

http://www.greddy.com/upload/file/PRofec_Bspec2.pdf

Basically;

SET: this value sets how high your boost level is going to be.

GAIN: Is your boost consistency. It can cause spikes if set too high; and if too low it can cause your boost to DROP at the higher RPMS (sound familiar?).

SET GAIN: This controls how the turbo spool time. The prime setting is somewhere close to the SET value but if adjusted TOO close you will spike; if adjusted TOO far from the SET value then you will be laggy.

Take notice that the SET value doesn't set the boost level in stone. The boost level will also vary when you adjust the GAIN and SET GAIN settings.

The best way to adjust the profect B is to start from scratch. So set everything back to 0 and only mess with the SET and GAIN settings. Increment the SET value and adjust the GAIN accordingly. Meaning up the set value and watch the boost level. If your boost level drops off: RAISE the GAIN value. Always keep an eye on your boost level as when you raise your gain it will also raise the boost level. If that happens then you lower the SET. If you are spiking then your GAIN is too high so lower it. Do this until you get the desired boost level.

Once you have your desired boost level (10 psi in your case) with no spikes or dropp off at high RPMS then you can work on your SET GAIN (boost response). This one is easy, just start incrementing the SET gain until you spike and when you do just back off. You may have to go back and slighty adjust the SET and GAIN settings if it raises your boost level.

Last you can set your warning level and limiter- The limiter lowers the boost if you go over your warning level. This is a safety feature and it should not be used to control boost other than when you over boost by accident, cold night, ect.

Remember always keep an eye on that boost and go up in small increments. It took me many WOT runs at 1:00 am to dial in my set up. But in the end I had a rock solid boost response.

Edit-

IIRC: Back when I had tock twins my Set was 22, Gain was 16, and my Set Gain was 24... Now that is just off memory so don't go by those numbers but my point is that it was no where near what your current settings are.

Good luck and let us know if you dial it in.

M-

Last edited by Montego; 02-20-12 at 06:10 PM.

#19

Hi there!

thx montego for your help! i was a bit busy and out of time to set it until today

1st I've tested the car with the controller off 3rd gear wot 7 psi but at high rpms it drops a bit profec shows something like 67/68 but car runs smothly... is the second time i do this test.... 1st time was just after installing everything and got 77 (profec showed) psi at wot

So I've tried again to set up... playing with "Set" and "Gain" to reach 10 psi was not so hard... and i almost got 10 psi consistently...

but here comes the nightmare... "set gain"... damn it.. i've started moving set gain... and boost started again to fall on top... solid 10 psi at 3k rpm 4k rpm... 4.5k rpm drops to 84 (greddy screen) 5k rpm boost starts to bounce... is something like a fuel cut on pistons cars... rpms can go higher but bouncing.... I've tried reducing gain, reducing set... increasing set gain... reducing set gain... and nothing the same stupid thing always... everything fine until 5k/5.5k rpm and then... ****...

On 1 of tests I've lowered gain thinking that maybe there is my problem... so everything fine until 7k rpm... but ****... from 5K rpm (+/-) boost was shitty 67 or maybe less

Settings at this point were (I'm stating ranges where i was playing)

set: 32 / 29

gain:35/26

set gain: 24

warning: 110

Limiter: 10%

so after getting so pissed off... i decided to start again.... and i ended up this night (due to i don't want cops catching me at 150 Km/h on 100 km/h highway) with

set: 29

gain:23

set gain: 0

warning: 110

Limiter: 10%

this settings are giving me almost solid 84/86 psi.. so, reaching 100 psi is not so hard... but from there play with the stupid "set gain" is the nightmare...

So I've to admit it... I'm so fu****ing lost with this stupid controller

Ps1: all tests in 3rd gear

Ps2: pics of solenoid installed... maybe is bad place... too hot.. (manual says that temperature can affect his operation) but I don't know if it really affects too much or nothing at all, you're the specialist

Ps3: please give me a hand with this!

thx montego for your help! i was a bit busy and out of time to set it until today

1st I've tested the car with the controller off 3rd gear wot 7 psi but at high rpms it drops a bit profec shows something like 67/68 but car runs smothly... is the second time i do this test.... 1st time was just after installing everything and got 77 (profec showed) psi at wot

So I've tried again to set up... playing with "Set" and "Gain" to reach 10 psi was not so hard... and i almost got 10 psi consistently...

but here comes the nightmare... "set gain"... damn it.. i've started moving set gain... and boost started again to fall on top... solid 10 psi at 3k rpm 4k rpm... 4.5k rpm drops to 84 (greddy screen) 5k rpm boost starts to bounce... is something like a fuel cut on pistons cars... rpms can go higher but bouncing.... I've tried reducing gain, reducing set... increasing set gain... reducing set gain... and nothing the same stupid thing always... everything fine until 5k/5.5k rpm and then... ****...

On 1 of tests I've lowered gain thinking that maybe there is my problem... so everything fine until 7k rpm... but ****... from 5K rpm (+/-) boost was shitty 67 or maybe less

Settings at this point were (I'm stating ranges where i was playing)

set: 32 / 29

gain:35/26

set gain: 24

warning: 110

Limiter: 10%

so after getting so pissed off... i decided to start again.... and i ended up this night (due to i don't want cops catching me at 150 Km/h on 100 km/h highway) with

set: 29

gain:23

set gain: 0

warning: 110

Limiter: 10%

this settings are giving me almost solid 84/86 psi.. so, reaching 100 psi is not so hard... but from there play with the stupid "set gain" is the nightmare...

So I've to admit it... I'm so fu****ing lost with this stupid controller

Ps1: all tests in 3rd gear

Ps2: pics of solenoid installed... maybe is bad place... too hot.. (manual says that temperature can affect his operation) but I don't know if it really affects too much or nothing at all, you're the specialist

Ps3: please give me a hand with this!

#20

That is what I'm contemplating. If you use an MBC on the PCA you can get instant boost response and let the Profec handle the wastegate. I made 220 + to the wheels on ONE turbo at 2800 rpm with the BNR's. That is more power than the stockers made at full boost at their peak at high RPM. Controlling the spool is paramount with twins.

#21

Arthas, is your Profec set in kPA or PSI for the units? It makes a difference.

"SET" and "GAIN" are in % units. SET GAIN is in pressure--it is the pressure at which the wastegate is allowed to open.

If you are more comfortable using English/non-metric units, set it to that. So "60" would actually be 6psi, as opposed to 60kpa which is actually 8.7psi . The reason why I say this is because a high "SET GAIN" or a high "GAIN" can result in surging or spiking, but for different reasons. I'll spare you the technical explanation for the most part.

Another method you could try is to put GAIN and SET GAIN back to 0. Start with SET at a low value. Alternate between raising SET and SET GAIN until you get very close to your target boost. Then adjust GAIN last.

With units in PSI, you could do a pattern something like this:

SET 20, SET GAIN 0, GAIN 0

SET 20, SET GAIN 30 (3psi), GAIN 0

SET 40, SET GAIN 30 (3psi), GAIN 0

SET 40, SET GAIN 50 (5psi), GAIN 0

SET 55, SET GAIN 60 (6psi), GAIN 0

target peak boost level has almost been achieved but boost seems to fall off at high rpm, so:

SET 55, SET GAIN 60 (6psi), GAIN 20

SET 60, SET GAIN 60 (6psi), GAIN 35

It depends how many pulls you want to do, but that is one way of going about it. You'll have to see how the engine actually responds when you pick what numbers to try. These 3 settings are found on many other electronic boost controllers but they will be named differently. I made a whole thread to explain that. So there's nothing especially weird about the Profec B Spec II except for maybe poor documentation and confusing setting names.

"SET" and "GAIN" are in % units. SET GAIN is in pressure--it is the pressure at which the wastegate is allowed to open.

If you are more comfortable using English/non-metric units, set it to that. So "60" would actually be 6psi, as opposed to 60kpa which is actually 8.7psi . The reason why I say this is because a high "SET GAIN" or a high "GAIN" can result in surging or spiking, but for different reasons. I'll spare you the technical explanation for the most part.

Another method you could try is to put GAIN and SET GAIN back to 0. Start with SET at a low value. Alternate between raising SET and SET GAIN until you get very close to your target boost. Then adjust GAIN last.

With units in PSI, you could do a pattern something like this:

SET 20, SET GAIN 0, GAIN 0

SET 20, SET GAIN 30 (3psi), GAIN 0

SET 40, SET GAIN 30 (3psi), GAIN 0

SET 40, SET GAIN 50 (5psi), GAIN 0

SET 55, SET GAIN 60 (6psi), GAIN 0

target peak boost level has almost been achieved but boost seems to fall off at high rpm, so:

SET 55, SET GAIN 60 (6psi), GAIN 20

SET 60, SET GAIN 60 (6psi), GAIN 35

It depends how many pulls you want to do, but that is one way of going about it. You'll have to see how the engine actually responds when you pick what numbers to try. These 3 settings are found on many other electronic boost controllers but they will be named differently. I made a whole thread to explain that. So there's nothing especially weird about the Profec B Spec II except for maybe poor documentation and confusing setting names.

#22

So I'm opened to hear any advise to set this thing which is making me crazy and I totally agree with you about stupid names and poor documentation...

So, I'm gonna try those settings on sunday night..

#23

When you adjust it, keep a log of every set of settings you tried. Also write down your peak boost number and any notes you need. For example:

Pull #5 SET 40 - SET GAIN 50 (5psi) - GAIN 30 -- peak boost 9psi -- boost falling quickly at high rpm

ideally you would have some kind of datalogging tool (Power FC etc) but that's not always possible. You have to keep track of what is happening after you make each change.

Pull #5 SET 40 - SET GAIN 50 (5psi) - GAIN 30 -- peak boost 9psi -- boost falling quickly at high rpm

ideally you would have some kind of datalogging tool (Power FC etc) but that's not always possible. You have to keep track of what is happening after you make each change.

#24