has anybody rebuilt a differential?

#1

has anybody rebuilt a differential?

Last night I decided to change the fluid in the diff. The chassis has 109,000 miles on it and I dont really don't know if it has ever been changed. Well the oil was alittle grey and notice a large chunk of a gear stuck to the magnet.

So now I need to rebuild the diff. So after a few hours of ripping the car apart to get the back plate off to see what the damage is. So I found out one of the worm gears tooth had broke off in side the LSD.

So now can I bebuild just the LSD? Also when putting it back in will I have to have the backlash checked? Since im not changing any of the shims. Or should I just leave it alone?

So now I need to rebuild the diff. So after a few hours of ripping the car apart to get the back plate off to see what the damage is. So I found out one of the worm gears tooth had broke off in side the LSD.

So now can I bebuild just the LSD? Also when putting it back in will I have to have the backlash checked? Since im not changing any of the shims. Or should I just leave it alone?

#2

when you rebuild, you need to check the ring gear closely, if its chipped u need a new ring gear.

u mite as well upgrade to a 4.3 final gear. get all new bearings and seals. make sure u have a dial gauge to check the backlash.

i would just upgrade to a better lsd and a better ring gear.

its not hard if you have all the specs

u mite as well upgrade to a 4.3 final gear. get all new bearings and seals. make sure u have a dial gauge to check the backlash.

i would just upgrade to a better lsd and a better ring gear.

its not hard if you have all the specs

#3

The Torsen LSD is not rebuildable.

The good news is that the S4 TII clutch style LSD bolts right into the FD housing, and is rebuildable. The S4 TII diffs can be found for as little as $50. Another option is to install a Kaaz, which is also a clutch style LSD with larger clutches then the TII, but is around $800.

The good news is that the S4 TII clutch style LSD bolts right into the FD housing, and is rebuildable. The S4 TII diffs can be found for as little as $50. Another option is to install a Kaaz, which is also a clutch style LSD with larger clutches then the TII, but is around $800.

#4

I'm rebuilding an S4TII diff right now. Pretty easy stuff.

As far as finding them for $50...I've looked off and on for the last year and a half and rarely see them for under $200 in the classifieds. If you have a local junkyard with a donor car, you could probably find them for that much.

As far as finding them for $50...I've looked off and on for the last year and a half and rarely see them for under $200 in the classifieds. If you have a local junkyard with a donor car, you could probably find them for that much.

#6

^blueTII that is a nice sig you got there. Ok so with the S4 diff is it as loud as the kazz. I have a lot of friends with the kazz diffs in their 240sx and I cant stand the kloking noise when they turn.

#7

Thanks, it is the engine and turbo that is in my car.

Anyway, the TII diff is not loud at all, they make virtually no noise if they are rebuilt and the clearances are set properly. I run the Kaaz in my car and there is no clunking, just a whine when engine braking (decel)

Anyway, the TII diff is not loud at all, they make virtually no noise if they are rebuilt and the clearances are set properly. I run the Kaaz in my car and there is no clunking, just a whine when engine braking (decel)

Trending Topics

#9

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

Not sure why you'd be better off with the kaaz. If you do purchase one, make sure they reverse about half of the clutch discs or you will be clunking like a **** around turns.

I found a brand new s4 TII diff for $400, had it cryo-treated for another $40, and had a professional tranny/diff shop install it along with some 4.3 gears. I also bought new oil seals, bearings, and a crush sleeve from ray at malloy. The diff makes zero noise (it is an oem part after all) and I am very pleased with the low gear acceleration increases from the 4.3 gears

I found a brand new s4 TII diff for $400, had it cryo-treated for another $40, and had a professional tranny/diff shop install it along with some 4.3 gears. I also bought new oil seals, bearings, and a crush sleeve from ray at malloy. The diff makes zero noise (it is an oem part after all) and I am very pleased with the low gear acceleration increases from the 4.3 gears

#11

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

Originally Posted by bryant

goodfellafd3s what did this gear change do to the top end? will it still do 200?

#12

fwiw, i've heard tons of people complaining about the noisiness of the KAAZ diff. Both on this board and others. Grassroots Motorsports even complained about it on their project Miata.

#13

As for the original question, you will need to pay very careful attention to setting the ring/pinion contact. The clearances and location are absolutely critical.

It shouldn't be too expensive to find a good axle rebuilder and take them the parts you want them to use and have them rebuild it on the bench.

Dave

It shouldn't be too expensive to find a good axle rebuilder and take them the parts you want them to use and have them rebuild it on the bench.

Dave

#14

Hey Andy, rebuilding a diff is super easy. Just keep track of your shims. Did you ever drive any of our cars with the diffs in? Clutch type feels super nice, you just dont want a 2-way, full locked on the decel causes alot of the harshness. When you put the ring gear back in use some assembly lube across a tooth of the ring gear to check the point where it meshes with the pinion gear, it should be right in the middle.

#15

^ Matt, I drove miguels car around the block and and been around a few others guys 240's with the 1.5 or 2 ways and they were just to loud.

Well I would like to rebuild the stock one but BlueTII says it not rebuildable. So I guess I will be in the market for a S4 diff.

Well I would like to rebuild the stock one but BlueTII says it not rebuildable. So I guess I will be in the market for a S4 diff.

#17

Originally Posted by eo2am

Well I would like to rebuild the stock one but BlueTII says it not rebuildable.

If the ring/pinion is what chipped, then a new set of gears and bearings will have you rolling again in no time. But only if the torsen 'chunk' is undamaged.

Dave

#18

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

Originally Posted by DriftDreamzSS

Make sure you get a 4.3 while ur in there

http://www.rx7.com/store/rx7/fddrivetrain_rearend.html

scroll all the way to the bottom.

According to that chart, 173 mph at 7500 rpms, still more than enough top end.

#19

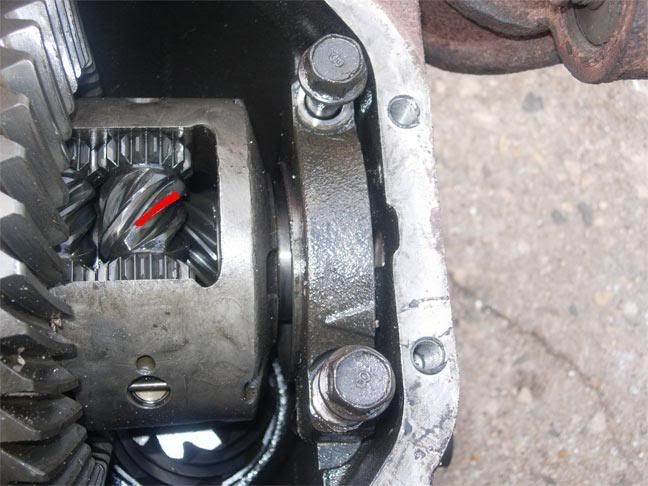

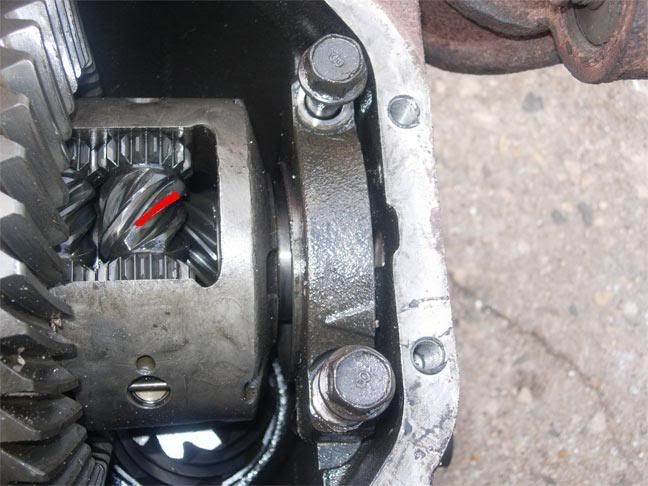

ok this is what broke just a 1/2 inch of the worm gear.

Oh and thank you CripsR6 for the pic I stole it from your thread. Im going to have to keep a eye on your thread it looks like I will be boing the same conversion.

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/differential-teardown-tii-lsd-install-writeup-535290/

Oh and thank you CripsR6 for the pic I stole it from your thread. Im going to have to keep a eye on your thread it looks like I will be boing the same conversion.

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/differential-teardown-tii-lsd-install-writeup-535290/

#21

Back lash and carrier bearing pre-load will will have to be adjusted because you are changing the side to side clearance as the tII diff is probably not the same exact length as the stock torsion....PINION DEPTH is not going to be needing adjustment if you keep the same ring and pinion....the way you make sure your pinion depth is correct is by painting some lead paint or white lithium grease on the ring teeth, then rotate the gears while applying pressure(load) with a prybar to duplicate the load applied while driving, then check the wear pattern on the teeth...if its too high or too low, then you will have to remove the pinion and place the appropriate shim to increase or reduce pinion depth on the ring gear....then after that is done, you have to measure break away torque(i believe its 15newton meters) with a needle torque wrench and use a NEW crush collar when tightening down the pinion nut...then you do your carrier bearing preload to make sure your whole diff assembly isnt moving around inside the diff case, once that is setup, then you can measure your ring+pinion gear backlash..its 3-4 thousanths of an inch backlash and shim that appropriately and you have to keep your carrier bearing preload the same, so whatever backlash you remove from one side, you have to add that amount equally to the other side with the shims....notes, MAKE SURE YOU KEEP YOUR CARRIER BEARING CAPS MARKED WHICH SIDE AND UP AND DOWN THEY CAME OUT OF THE CASE, THEY ARE MACHINED TO THAT CASE TO FIT PROPERLY.

basically its time consuming if you have to do all the measurements correctly,or you will have a whining noise, vibrations and will burn up your ring and pinion gears or burn up the bearings inside.

^^^also posted my quick write up in crisp6 thread,but ^^^^

Here is some useful information(i hope) if you are going to do it yourself, just have all the specs and proper tools (torque wrench, needle torque wrench for break away torque, dial indicator for carrier bearing preload and your ring gear backlash, micrometer or vernier caliper(mircrometer is more accurate though) for shim measuring, and tool for holding the driveshaft hub flange from turning while you torque down the pinion nut),plus all your other basic hand tools for removing the diff and assembly out of the car.

basically its time consuming if you have to do all the measurements correctly,or you will have a whining noise, vibrations and will burn up your ring and pinion gears or burn up the bearings inside.

^^^also posted my quick write up in crisp6 thread,but ^^^^

Here is some useful information(i hope) if you are going to do it yourself, just have all the specs and proper tools (torque wrench, needle torque wrench for break away torque, dial indicator for carrier bearing preload and your ring gear backlash, micrometer or vernier caliper(mircrometer is more accurate though) for shim measuring, and tool for holding the driveshaft hub flange from turning while you torque down the pinion nut),plus all your other basic hand tools for removing the diff and assembly out of the car.

#23

Yeah andy, thats the lsd itself. Inspect the ring and pinion closely for damage if you plan to re-use them, wouldnt want to to the tear down twice. Im gonna be ordering an ats deftforce soon and ill have the torsen guts laying around. Im sure you will want your car back up and running before I get around to doing that tho.