Fuel Pump Resistor

#1

Fuel Pump Resistor

I am at work and don't have my FSM to referance so bear with me. First the little box next to the ingitor, that is the fuel pump resistor right? Next, if i am running a Supra pump with an aftermarket FPR do i need that? I recently had an engine fire and it took out that connector and I haven't been able to locate one. I also run a Power FC if that helps.

#6

Is that kind of like an OEM Kenne Bell Boost-a-Pump?

By driving the pump with less voltage it can last longer by the simple fact that the less you push a component the longer you can expect it to last. Electrical drain is also reduced. Some fuel pumps can be loud when driven at full voltage and typical consumers don't want to hear a fuel pump whine on their stock car. Finally, and perhaps most importantly, a multi-speed fuel pump reduces evaporative emissions. Evaporative emissions are fuel vapors (HC) that collect in the tank and charcoal canister. As fuel heats up it is more likely to vaporize. On a return fuel system the fuel travels from the tank through the engine bay (where it heats up) and back to the tank. The more fuel vapors produced, the more must be captured in the charcoal canister and metered back into the engine through the evaporative purge solenoid.

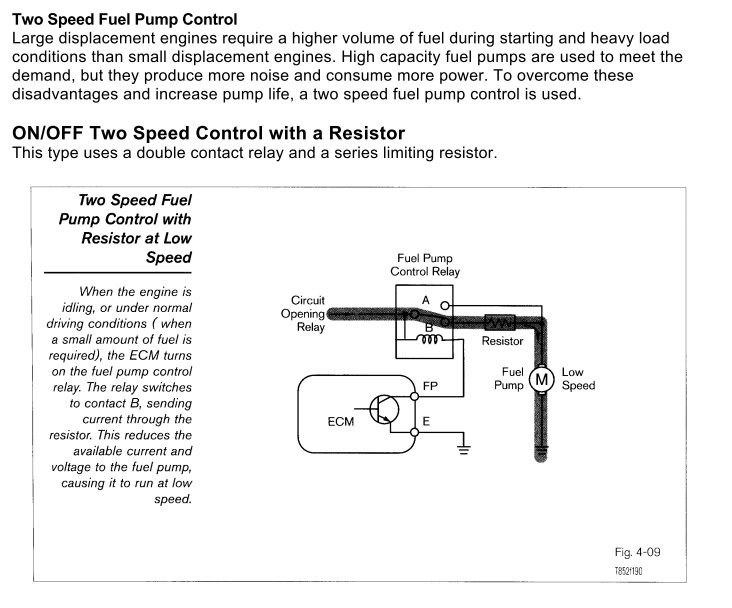

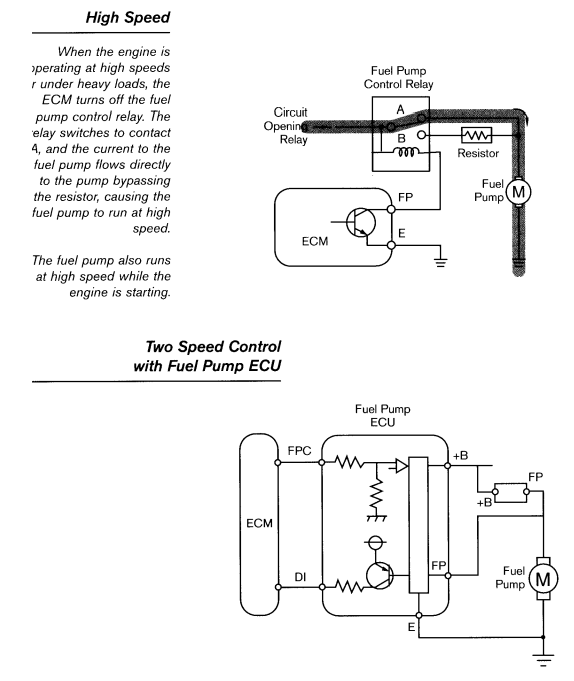

Multi-speed pumps are common on return fuel systems. The oldest style is the two speed, resistor type that is found on Rx-7's, 3000GT's, and other cars of that era. Newer cars (Subarus for example) may use a three speed duty type with an external fuel pump control module that receives commands from the ECU. Many newer cars like the Rx-8 may instead have a returnless fuel system. The pump is duty controlled and the fuel pressure regulator may be in the tank itself. By eliminating the fuel return line tank temperatures will be lower, resulting in less HC emissions. Less HC evaporative emissions means the government gets off the manufacturer's back and the engineers don't have to rely on as many expensive and unreliable emissions controls like precats.

The systems work fine on stock cars with stock fuel requirements. Now with all that being said, on these modified older cars I often recommend that people remove the resistor because maximizing pump flow at WOT trumps all the other issues. Removing the resistor allows you to run heavier gauge wire and it eliminates a possible failure point for the fuel system.

The following users liked this post:

tomatoto (03-29-20)

#7

It looks like that fuel pump resistor is not needed when doing fuel pump rewire upgrade.

I'm planning on using Bosch 044 pump and it's somewhat loud. I wonder if it would be possible to use two speed control in high current rewired line?

I'm planning on using Bosch 044 pump and it's somewhat loud. I wonder if it would be possible to use two speed control in high current rewired line?

Trending Topics

#8

Thread

Thread Starter

Forum

Replies

Last Post

trickster

2nd Generation Specific (1986-1992)

25

07-01-23 04:40 PM

ChrisRX8PR

Single Turbo RX-7's

21

10-18-15 04:01 PM

befarrer

Microtech

3

08-22-15 05:52 PM