Exhaust manifold studs...

#1

Exhaust manifold studs...

It's been a while since I've posted, I previously was changing out the exhaust gaskets on the block to mani and mani to turbo. Some studs broke, and I had to get them machined out.

My question is what studs should I buy? OEM? if so from where, dealership? is there a better quality stud? These things were brittle...

My question is what studs should I buy? OEM? if so from where, dealership? is there a better quality stud? These things were brittle...

#2

I have done some research on this and found there are really no better studs than stock. The OEM studs are iconel and will handle much higher temps than virtually anything else you can source. They are a dealer item; my suggestion is to call Ray at Malloy Mazda.

I have tried high grade, non-stock fasteners in the past and found that they will stretch at high temperature resulting in loss of the [expensive] gaskets and a redo. Been there done that. Hopefully this experience is helpful to you.

Also, be sure to use copper based anti-sieze on the studs and nuts and observe proper torque; in doing so, I have been able to reuse the OEM studs and nuts many times over the years.

I have tried high grade, non-stock fasteners in the past and found that they will stretch at high temperature resulting in loss of the [expensive] gaskets and a redo. Been there done that. Hopefully this experience is helpful to you.

Also, be sure to use copper based anti-sieze on the studs and nuts and observe proper torque; in doing so, I have been able to reuse the OEM studs and nuts many times over the years.

#3

If you ask around other turbocharged car enthusiasts with a different car you'll find many of them upgrading their manifold hardware to inconel because their steel or stainless studs are stretching at very high temps.

Now consider that RX-7s have very high EGTs compared to most other turbocharged cars. In my mind that makes the stock studs a no-brainer.

Now consider that RX-7s have very high EGTs compared to most other turbocharged cars. In my mind that makes the stock studs a no-brainer.

#5

i ordered new studs, and the small small stud decided to snap when i put the nut on, the nut seized onto the stud :/ i'll look into ordering them from the dealership one of you posted up. i didnt know if arp or another company made more efficient studs

#6

ditto for the OEM studs, most aftermarket studs will grab your threads and snap due to the excessive heat that they have to tolerate. sometimes the OEM studs do the same but believe it or not, they still are the most reliable.

#7

I just used heat treated studs from my local "do it best" iirc they were 1.27 a piece i haven't had a problem with them so far and i have switched my turboes multiple times.

I did however try stainless steel nuts/bolts on my exhaust flanges and i had to cut the off because they became stuck.

I did however try stainless steel nuts/bolts on my exhaust flanges and i had to cut the off because they became stuck.

Trending Topics

#9

#10

I did some research in the past on this topic. You can get the M10 and M8 studs as well as copper nuts from atpturbo. They should hold up to the heat.

http://www.atpturbo.com/mm5/merchant...egory_Code=FST

You can get the two bolts that are needed from Mcmaster.com

http://www.mcmaster.com/#cap-screws/=8v0h4l

The five 10mm studs are 1.5mm pitch and near enough 40mm long.

The single 8mm stud is 38mm long.

The two bolts through the wastegate housing are 64mm long, 10 x 1.5.

http://www.atpturbo.com/mm5/merchant...egory_Code=FST

You can get the two bolts that are needed from Mcmaster.com

http://www.mcmaster.com/#cap-screws/=8v0h4l

The five 10mm studs are 1.5mm pitch and near enough 40mm long.

The single 8mm stud is 38mm long.

The two bolts through the wastegate housing are 64mm long, 10 x 1.5.

#11

#12

....You can get the two bolts that are needed from Mcmaster.com

http://www.mcmaster.com/#cap-screws/=8v0h4l

The five 10mm studs are 1.5mm pitch and near enough 40mm long.

The single 8mm stud is 38mm long.

The two bolts through the wastegate housing are 64mm long, 10 x 1.5.

http://www.mcmaster.com/#cap-screws/=8v0h4l

The five 10mm studs are 1.5mm pitch and near enough 40mm long.

The single 8mm stud is 38mm long.

The two bolts through the wastegate housing are 64mm long, 10 x 1.5.

I highly recommend that you absolutely DO NOT substitute anything for the OEM Iconel bolts in the turbo housing. I tried the best bolts I could source aftermarket and they were not good enough. After a short period of use, they lost their hardness (due to the heat) and stretched about 1/4" after being re-torqued. As a result, I lost the $60 gasket and had to remove the manifold to extract one broken bolt. I'll try and find the pics for you non-believers. Given their cost from Ray, and the value of my time, it's just not worth messing with these fasteners; there is little, if nothing, to be gained. If you insist on buying from from some other supplier or turbo place, find out what the material is. If it's not Iconel, then don't waste your time for the FD application.

*BTW, all bolts are "heat treated" to some level. Heat treating and/or drawing temper affects the harness and strength of the bolt; it has little to do with the maximum working temperature, which is primarily determined by the material used to make the bolt.*

#13

#14

A useful old thread....

I installed a new RX7.com downpipe and new BNR turbos. The downpipe came with shorter than stock studs, which helped install quite a bit. After one track day, they were also very loose. I'm guessing they weren't inconel.

Searching for a better solution for shorter-than-stock studs, and after reading this thread, I found these inconel aftermarket studs at full-race.com, and they have some interesting features:

- M10x1.5 on the manifold side, but M10x1.25 thread on the turbo side, so it is more likely the nut will come off and not the stud.

- An anti-vibration compression washer

- Silver-coated inconel nuts that they say does not require anti-sieze (which in my experience burns off anyway).

I sent an inquiry in about the length (which the website doesn't give).

Anyone have any experience with these, or the company?

Also, has anyone used Resbond 907TS threadlocker advertised as good to 2100F ?

I installed a new RX7.com downpipe and new BNR turbos. The downpipe came with shorter than stock studs, which helped install quite a bit. After one track day, they were also very loose. I'm guessing they weren't inconel.

Searching for a better solution for shorter-than-stock studs, and after reading this thread, I found these inconel aftermarket studs at full-race.com, and they have some interesting features:

- M10x1.5 on the manifold side, but M10x1.25 thread on the turbo side, so it is more likely the nut will come off and not the stud.

- An anti-vibration compression washer

- Silver-coated inconel nuts that they say does not require anti-sieze (which in my experience burns off anyway).

I sent an inquiry in about the length (which the website doesn't give).

Anyone have any experience with these, or the company?

Also, has anyone used Resbond 907TS threadlocker advertised as good to 2100F ?

#15

Check this if you need the studs for the brick too:

https://www.rx7club.com/3rd-generati.../#post10669635

https://www.rx7club.com/3rd-generati.../#post10669635

I've gotten a few PMs from people due to my build thread asking for stud sizes and where I got them. Just wanted to update the thread with a follow up that includes everything in one post.

Here is everything you'll need to re-stud the stock turbo stuff:

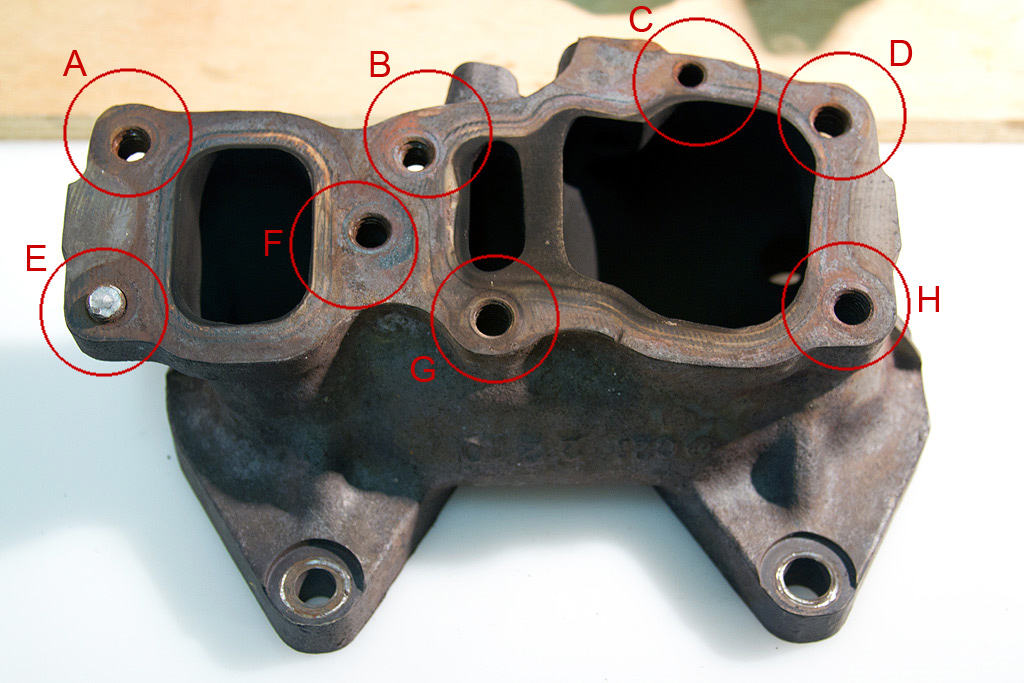

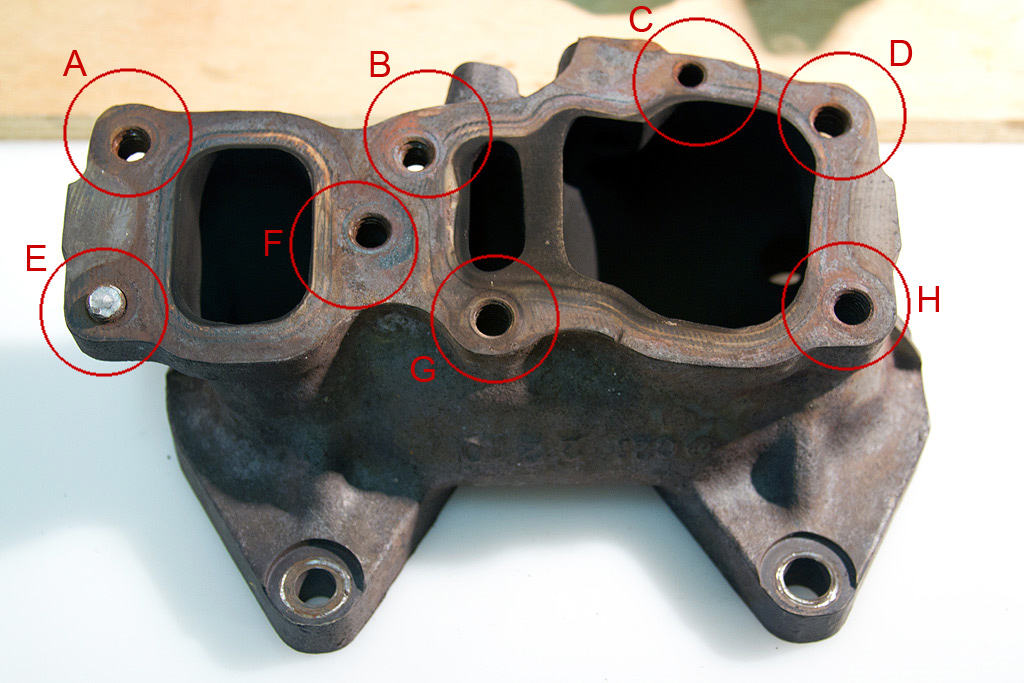

For the brick. See the photo in the 1st post for letter codes:

For the 4 studs that bolt the brick to the engine block:

For the downpipe:

You can use 4 of the M10x1.5 that are 37mm long (same as A,D,E,F,H on the brick). Part number 98867A350

You'll also want washers. I used these (sold by the bag):

For the copper lock nuts I used:

My brick all re-studed (I actually had to use one different stud because my brick had been heli-coiled, but you get the idea...):

Here is everything you'll need to re-stud the stock turbo stuff:

For the brick. See the photo in the 1st post for letter codes:

- A,D,E,F,H | 98867A350 | Metric Black Class 8.8 Steel Spacing Stud M10 Size, 37mm Overall Length, 1.5mm Pitch | Quantity 5 | $0.81 Each

- B,G | 98867A360 | Metric Black Class 8.8 Steel Spacing Stud M10 Size, 72mm Overall Length, 1.5mm Pitch | Quantity 2 | $1.28 Each

- C | 98867A315 | Metric Black Class 8.8 Steel Spacing Stud M8 Size, 35mm Overall Length, 1.25mm Pitch | Quantity 1 | $0.48 Each

For the 4 studs that bolt the brick to the engine block:

- 98867A355 | Metric Black Class 8.8 Steel Spacing Stud M10 Size, 62mm Overall Length, 1.5mm Pitch | Quantity 4 | $1.18 Each

For the downpipe:

You can use 4 of the M10x1.5 that are 37mm long (same as A,D,E,F,H on the brick). Part number 98867A350

You'll also want washers. I used these (sold by the bag):

- 91166A280 | Din 125 Zinc-plated Class 4 Steel Flat Washer, M10 Screw Size, 20mm Od, 1.8mm-2.2mm Thick | $3.98 per pack of 100

For the copper lock nuts I used:

- PM33629 | M10-1.5 Exhaust Lock Nut Copper Plated Steel 14mm Hex | $12.30 per pack of 25

- PM33627 | M8-1.25 Exhaust Lock Nut Copper Plated Steel 12mm Hex | $15.82 per pack of 25

My brick all re-studed (I actually had to use one different stud because my brick had been heli-coiled, but you get the idea...):

The following users liked this post:

tomatoto (09-30-18)

#16

A useful old thread....

I installed a new RX7.com downpipe and new BNR turbos. The downpipe came with shorter than stock studs, which helped install quite a bit. After one track day, they were also very loose. I'm guessing they weren't inconel.

Searching for a better solution for shorter-than-stock studs, and after reading this thread, I found these inconel aftermarket studs at full-race.com, and they have some interesting features:

- M10x1.5 on the manifold side, but M10x1.25 thread on the turbo side, so it is more likely the nut will come off and not the stud.

- An anti-vibration compression washer

- Silver-coated inconel nuts that they say does not require anti-sieze (which in my experience burns off anyway).

I sent an inquiry in about the length (which the website doesn't give).

Anyone have any experience with these, or the company?

Also, has anyone used Resbond 907TS threadlocker advertised as good to 2100F ?

I installed a new RX7.com downpipe and new BNR turbos. The downpipe came with shorter than stock studs, which helped install quite a bit. After one track day, they were also very loose. I'm guessing they weren't inconel.

Searching for a better solution for shorter-than-stock studs, and after reading this thread, I found these inconel aftermarket studs at full-race.com, and they have some interesting features:

- M10x1.5 on the manifold side, but M10x1.25 thread on the turbo side, so it is more likely the nut will come off and not the stud.

- An anti-vibration compression washer

- Silver-coated inconel nuts that they say does not require anti-sieze (which in my experience burns off anyway).

I sent an inquiry in about the length (which the website doesn't give).

Anyone have any experience with these, or the company?

Also, has anyone used Resbond 907TS threadlocker advertised as good to 2100F ?

And Theorie, thanks for all the detailed information. I did look at McMaster, but didn't see inconel versions available. Since I regularly track the car, and have already had studs loosen, I figured I better pay extra.

#17

Install update:

The shorter-than-stock inconel studs and silver coated bolts arrived. Even have some silver tarnish on the bolts.

I installed the studs in the manifold per the FSM (30 Nm torque). I didn't use the washers, as with my Bonez downpipe that would have meant not engaging all the bolt threads. Bolts also tightened per FSM (55 Nm if I recall correctly).

On the lower right hole, the flange on the silver-coated bolts is too large. So I used a flanged copper nut there (avail on Amazon). I have previously used the commonly recommended copper lock nuts with the split top, but those invariably locked on to the stud in my experience.

Additional research on the web also pointed me to nickel-based anti-seize as the highest temp commonly available (2400 deg F vs 1800 for copper based anti-seize). About 8 bucks on Amazon for a 4 oz tube. I'll use that on the copper nut when it arrives.

The shorter-than-stock inconel studs and silver coated bolts arrived. Even have some silver tarnish on the bolts.

I installed the studs in the manifold per the FSM (30 Nm torque). I didn't use the washers, as with my Bonez downpipe that would have meant not engaging all the bolt threads. Bolts also tightened per FSM (55 Nm if I recall correctly).

On the lower right hole, the flange on the silver-coated bolts is too large. So I used a flanged copper nut there (avail on Amazon). I have previously used the commonly recommended copper lock nuts with the split top, but those invariably locked on to the stud in my experience.

Additional research on the web also pointed me to nickel-based anti-seize as the highest temp commonly available (2400 deg F vs 1800 for copper based anti-seize). About 8 bucks on Amazon for a 4 oz tube. I'll use that on the copper nut when it arrives.

#18

Be careful with anti-seize and torque specs. A FSM torque spec is for an "as received fastener"... meaning no lubrication.

When lubricating the threads, the torque must be reduced by a factor or too much tension/preload will be placed on the studs. Pre-load is supposed to be 75% of tensile strength, but can easily by exceeded if lubricated and torqued too much.

I almost learned this the hard way and ended up torquing my mani nuts by feel rather than spec. The wrench wouldn't click and would have stretched my new studs to oblivion.

Those look like NORDLOCK washers in the above pic. They are ingenious and may be good for this app. We kept losing axle screws on the race car until we installed those bad boys. Way better than serrated lock or prevailing torque stock style.

When lubricating the threads, the torque must be reduced by a factor or too much tension/preload will be placed on the studs. Pre-load is supposed to be 75% of tensile strength, but can easily by exceeded if lubricated and torqued too much.

I almost learned this the hard way and ended up torquing my mani nuts by feel rather than spec. The wrench wouldn't click and would have stretched my new studs to oblivion.

Those look like NORDLOCK washers in the above pic. They are ingenious and may be good for this app. We kept losing axle screws on the race car until we installed those bad boys. Way better than serrated lock or prevailing torque stock style.

Last edited by alexdimen; 03-10-17 at 03:49 PM.

#19

Be careful with anti-seize and torque specs. A FSM torque spec is for an "as received fastener"... meaning no lubrication.

When lubricating the threads, the torque must be reduced by a factor or too much tension/preload will be placed on the studs. Pre-load is supposed to be 75% of tensile strength, but can easily by exceeded if lubricated and torqued too much.

I almost learned this the hard way and ended up torquing my mani nuts by feel rather than spec. The wrench wouldn't click and would have stretched my new studs to oblivion.

When lubricating the threads, the torque must be reduced by a factor or too much tension/preload will be placed on the studs. Pre-load is supposed to be 75% of tensile strength, but can easily by exceeded if lubricated and torqued too much.

I almost learned this the hard way and ended up torquing my mani nuts by feel rather than spec. The wrench wouldn't click and would have stretched my new studs to oblivion.

#20

i don't have any issue with the inconels stretching with anti seize. i would rather use it than not, because these nuts tend to lock in place otherwise.

anti seize and torque wrench just fine for me in this particular case.

anti seize and torque wrench just fine for me in this particular case.

#21

The factory torque spec likely takes the resistance from the prevailing torque nut into account, or the extra lube may not even effect torque spec on a prevailing torque nut because it's an interference fit.

That said, the manual usually has torque specs that don't account for additional lubricant except for cases where they tell you to lubricate such as the tension bolts for the engine assembly.

So, I was just warning OP to be careful if it seems like that nut wants to keep turning on there when it should be reaching correct stud tension! That was my experience.

#22

well, reason i say it's unlikely is because i dont use factory torque specs on some of the old and more abused parts. with those the stock torque is probably a little too lenient so i would tighten them as tight as i could with a 3/8" ratchet, those bolts are very difficult to break even with anti seize on them, really they don't stretch at all, once they do they snap immediately.

when the exhaust manifold studs seize and you have to break the stud to remove the turbo you get an idea of just how strong the damn little things are.

when the exhaust manifold studs seize and you have to break the stud to remove the turbo you get an idea of just how strong the damn little things are.

#23

One thing is for sure, iconel (as will most nickel based materials, e.g., stainless) will tend to gall if you don't use anti-sieze or keep it well lubricated while removing the fastener.