DaleClark's guide to idle troubleshooting (high, low, bouncing)

#1

RX-7 Bad Ass

Thread Starter

iTrader: (55)

Hey everyone -

This is a topic that comes up frequently and I feel like I've typed the same troubleshooting info in over and over again. Time to consolidate all this.

WHAT IDLE SHOULD BE LIKE

First, on a bone stock US car, you should have a 3000 RPM cold startup. This is the Accelerated Warmup System (AWS) - it will bring the idle to 3000 RPM for 5-10 seconds on a cold start in the morning. You can blip the throttle or start the car in gear to kick it off.

Once you get past that, the idle will be about 1500 RPM. This is due to the thermowax on the throttle body - it props the throttle open slightly when cold to give the higher RPM's. As the car warms up, a rod extends, which kicks the cam down that holds the idle higher. So, as the car warms up the idle will come down, eventually settling around 800 RPM.

On a hot start, you may have the engine rev up to 1000 RPM or so for a bit then settle down to 800 RPM. Idle may bump up slightly when you turn on AC, turn on electrical load (headlights, defrost), or turn the wheel (power steering). It should stay around 800 in general.

It is common to have the idle not rock solid - you may have small "pops" and tiny misses. This is normal. It can be caused by any number of things but in general it's due to an aging car, it's doubtful you can get the idle perfect and glass smooth.

IDLE TOO HIGH

OK, this is the easy thing that people can't wrap their head around. Idle speed is set by air entering the engine, period. If you have just the right amount of air, you get a correct idle. Too much air and it's too high.

At idle, the throttle plates should be closed and the Idle Speed Control (ISC) on the back of the upper intake manifold will control idle. It has a piston that moves in and out to increase or decrease idle.

The ISC can only compensate for a few hundred RPM of change - it adjusts when you turn on the AC, for example. If the air getting into the engine is too much it can't compensate.

Any air that gets in the engine between the throttle body and the engine itself will bump up idle. Anything before the throttle body - intercooler pipes, turbo Y-pipe, throttle body elbow - have NO impact on idle. Unless they somehow plumb in to the upper/lower intake manfolds and it's a leak after the throttle body.

It doesn't take much of a leak to bump idle up. Also, vacuum leak does not just mean vacuum hose - gaskets between the manifolds can leak, injector grommets can leak, etc. Again, anywhere air can get in.

If the throttle body itself isn't fully closing that will also cause a problem. This can be from the throttle cable being too tight, the throttle stop not adjusted right and cracking the throttle open, or the thermowax being stuck and keeping the throttle body propped open.

IDLE TOO LOW

This is similar to the Idle Too High but the opposite - not enough air is getting in. In this case it could be the ISC is stuck and can't move. Or, the ISC adjustment screw is screwed too far in - this is a screw just below the entrance to the throttle body that regulates the amount of air the ISC gets to work with.

ChrisFix just did a great video on cleaning ISC's -

Sticking ISC's are a common problem and it's an easy fix. If you have the original paper gasket for the ISC consider buying the newer metal gasket. Make sure the old gasket is totally removed and no little bits are still there before putting the metal one on. It goes on dry, no RTV or anything, just stick it on and bolt the ISC down.

IDLE IS BOUNCING

Again most likely ISC. Could also be Throttle Position Sensor (TPS) but the FD's TPS does pretty well, it's nowhere near as crap of a design as the FC's TPS. Unless you really mess with it it's typically OK or at least good enough to have a solid idle.

If you have a PowerFC you have to do the idle learn procedure, this is in the PFC FAQ I wrote ages ago, google it. Once the PFC learns idle it should be smooth.

CAR WON'T IDLE COMING TO STOP/DIES

Usually the dash pot - this is a greenish "mushroom" on the front of the throttle body. It has a white peg that comes out if it, that slows the throttle body as it closes. If the throttle snaps shut the ISC doesn't have enough time to react and the car can stall. Sometimes the dashpot just needs to be removed and cleaned, but if the white peg flops in and out with no resistance it needs to be replaced. They are available new from Mazda.

FINDING VACUUM LEAKS

High idle due to a vacuum leak seems to be the #1 thing I see people asking about. Again, you have to think - how is air getting in here? Don't think "vacuum" and immediately think "vacuum hose" - people will post up that they looked and alt the vacuum hoses look good and are hooked up. Good, but there's still air getting in - could be a gasket or a fuel injector grommet.

I recommend using STARTING FLUID with the engine running to find the vacuum leak. Yes you can use brake clean or other chemicals, but they don't evaporate quickly and sometimes can stain what you are spraying. I want something that will come out as a mist, get easily sucked into the engine, and won't hang around to puddle and be a fire risk or hang around so long that it's hard to find the exact leak.

That said, get your can and slowly spray around the area from the throttle body to the engine. When it hits the leak, the engine will rev up and smooth out. Use short bursts of spray to find the leak. You don't want to just hose it everywhere, go slow and try different areas and angles. You may also be able to hear the leak and may be able to plug it with your finger as part of the diagnosis.

There are also ways to make/use smoke machines to find leaks. This gets slightly more advanced and I'm not going into detail on this thread. But, it is a good way to find leaks as well.

ROUGH IDLE

First off make sure your engine is good. A blown engine (broken apex seal) will have a rough idle. I've seen people spend tons of time and money trying to fix an idle that was all due to a blown engine. If the engine is good, continue forward.

Old/worn spark plugs and ignition coils can be a cause of a rough idle as well as bad/dirty fuel injectors. Also make sure the plug wires are on properly, if they are mixed up the car will do VERY weird stuff when running/driving/idling.

If your car has an airpump and a stock ECU, the air pump needs to be there for the car to idle right. The ECU compensates for that air pump air, and without it it compensates wrong and gives a rough idle. Look for a blown fuse and shorted wiring to the air pump.

There's a lot more fine details to it but that hits the highlights. The FD has a pretty primitive idle system all things considered. The throttle body still has a lot of roots in carburetors and is a fairly complex mechanical device. New cars have drive-by-wire that incorporates everything into one unit - TPS, ISC, throttle body, thermowax, dashpot, you name it. Regardless, it can be hard to get the car to idle right but it can be done.

Dale

This is a topic that comes up frequently and I feel like I've typed the same troubleshooting info in over and over again. Time to consolidate all this.

WHAT IDLE SHOULD BE LIKE

First, on a bone stock US car, you should have a 3000 RPM cold startup. This is the Accelerated Warmup System (AWS) - it will bring the idle to 3000 RPM for 5-10 seconds on a cold start in the morning. You can blip the throttle or start the car in gear to kick it off.

Once you get past that, the idle will be about 1500 RPM. This is due to the thermowax on the throttle body - it props the throttle open slightly when cold to give the higher RPM's. As the car warms up, a rod extends, which kicks the cam down that holds the idle higher. So, as the car warms up the idle will come down, eventually settling around 800 RPM.

On a hot start, you may have the engine rev up to 1000 RPM or so for a bit then settle down to 800 RPM. Idle may bump up slightly when you turn on AC, turn on electrical load (headlights, defrost), or turn the wheel (power steering). It should stay around 800 in general.

It is common to have the idle not rock solid - you may have small "pops" and tiny misses. This is normal. It can be caused by any number of things but in general it's due to an aging car, it's doubtful you can get the idle perfect and glass smooth.

IDLE TOO HIGH

OK, this is the easy thing that people can't wrap their head around. Idle speed is set by air entering the engine, period. If you have just the right amount of air, you get a correct idle. Too much air and it's too high.

At idle, the throttle plates should be closed and the Idle Speed Control (ISC) on the back of the upper intake manifold will control idle. It has a piston that moves in and out to increase or decrease idle.

The ISC can only compensate for a few hundred RPM of change - it adjusts when you turn on the AC, for example. If the air getting into the engine is too much it can't compensate.

Any air that gets in the engine between the throttle body and the engine itself will bump up idle. Anything before the throttle body - intercooler pipes, turbo Y-pipe, throttle body elbow - have NO impact on idle. Unless they somehow plumb in to the upper/lower intake manfolds and it's a leak after the throttle body.

It doesn't take much of a leak to bump idle up. Also, vacuum leak does not just mean vacuum hose - gaskets between the manifolds can leak, injector grommets can leak, etc. Again, anywhere air can get in.

If the throttle body itself isn't fully closing that will also cause a problem. This can be from the throttle cable being too tight, the throttle stop not adjusted right and cracking the throttle open, or the thermowax being stuck and keeping the throttle body propped open.

IDLE TOO LOW

This is similar to the Idle Too High but the opposite - not enough air is getting in. In this case it could be the ISC is stuck and can't move. Or, the ISC adjustment screw is screwed too far in - this is a screw just below the entrance to the throttle body that regulates the amount of air the ISC gets to work with.

ChrisFix just did a great video on cleaning ISC's -

Sticking ISC's are a common problem and it's an easy fix. If you have the original paper gasket for the ISC consider buying the newer metal gasket. Make sure the old gasket is totally removed and no little bits are still there before putting the metal one on. It goes on dry, no RTV or anything, just stick it on and bolt the ISC down.

IDLE IS BOUNCING

Again most likely ISC. Could also be Throttle Position Sensor (TPS) but the FD's TPS does pretty well, it's nowhere near as crap of a design as the FC's TPS. Unless you really mess with it it's typically OK or at least good enough to have a solid idle.

If you have a PowerFC you have to do the idle learn procedure, this is in the PFC FAQ I wrote ages ago, google it. Once the PFC learns idle it should be smooth.

CAR WON'T IDLE COMING TO STOP/DIES

Usually the dash pot - this is a greenish "mushroom" on the front of the throttle body. It has a white peg that comes out if it, that slows the throttle body as it closes. If the throttle snaps shut the ISC doesn't have enough time to react and the car can stall. Sometimes the dashpot just needs to be removed and cleaned, but if the white peg flops in and out with no resistance it needs to be replaced. They are available new from Mazda.

FINDING VACUUM LEAKS

High idle due to a vacuum leak seems to be the #1 thing I see people asking about. Again, you have to think - how is air getting in here? Don't think "vacuum" and immediately think "vacuum hose" - people will post up that they looked and alt the vacuum hoses look good and are hooked up. Good, but there's still air getting in - could be a gasket or a fuel injector grommet.

I recommend using STARTING FLUID with the engine running to find the vacuum leak. Yes you can use brake clean or other chemicals, but they don't evaporate quickly and sometimes can stain what you are spraying. I want something that will come out as a mist, get easily sucked into the engine, and won't hang around to puddle and be a fire risk or hang around so long that it's hard to find the exact leak.

That said, get your can and slowly spray around the area from the throttle body to the engine. When it hits the leak, the engine will rev up and smooth out. Use short bursts of spray to find the leak. You don't want to just hose it everywhere, go slow and try different areas and angles. You may also be able to hear the leak and may be able to plug it with your finger as part of the diagnosis.

There are also ways to make/use smoke machines to find leaks. This gets slightly more advanced and I'm not going into detail on this thread. But, it is a good way to find leaks as well.

ROUGH IDLE

First off make sure your engine is good. A blown engine (broken apex seal) will have a rough idle. I've seen people spend tons of time and money trying to fix an idle that was all due to a blown engine. If the engine is good, continue forward.

Old/worn spark plugs and ignition coils can be a cause of a rough idle as well as bad/dirty fuel injectors. Also make sure the plug wires are on properly, if they are mixed up the car will do VERY weird stuff when running/driving/idling.

If your car has an airpump and a stock ECU, the air pump needs to be there for the car to idle right. The ECU compensates for that air pump air, and without it it compensates wrong and gives a rough idle. Look for a blown fuse and shorted wiring to the air pump.

There's a lot more fine details to it but that hits the highlights. The FD has a pretty primitive idle system all things considered. The throttle body still has a lot of roots in carburetors and is a fairly complex mechanical device. New cars have drive-by-wire that incorporates everything into one unit - TPS, ISC, throttle body, thermowax, dashpot, you name it. Regardless, it can be hard to get the car to idle right but it can be done.

Dale

Last edited by DaleClark; 09-04-20 at 11:36 AM.

The following 8 users liked this post by DaleClark:

Alchemyst6 (09-04-20),

F1blueRx7 (09-04-20),

HoldenKingsley (02-21-24),

moconnor (09-04-20),

pietrino (02-26-24),

and 3 others liked this post.

#2

RX-7 Bad Ass

Thread Starter

iTrader: (55)

Another thing that needs mentioning - many FD's have been modified where some of the stuff that controls idle is gone or is controlled differently. This can be REALLY confusing for a new owner who bought the car already modified. It's possible to have the ISC totally removed/blocked off and the idle set with the set screws on the throttle body - this generally works but doesn't compensate for load.

A lot of the same principles apply, however - high idle = vacuum leak.

Dale

A lot of the same principles apply, however - high idle = vacuum leak.

Dale

#4

RX-7 Bad Ass

Thread Starter

iTrader: (55)

I've never understood the desire to remove the ISC. Even with the "RACECAR BRO" mentality, why remove a small, light thing that's not in the way and does its job very well?

I can understand removing the air pump - bulky, in the way, etc. - but the ISC?

Dale

I can understand removing the air pump - bulky, in the way, etc. - but the ISC?

Dale

#5

Rotary Enthusiast

Are you going to add afr (idle tuning on this)? Like after fuel pump rewire?

#6

RX-7 Bad Ass

Thread Starter

iTrader: (55)

Not sure what you are asking....

Dale

Dale

#7

Rotary Enthusiast

Trending Topics

#8

Full Member

Hey everyone -

IDLE TOO LOW

This is similar to the Idle Too High but the opposite - not enough air is getting in. In this case it could be the ISC is stuck and can't move. Or, the ISC adjustment screw is screwed too far in - this is a screw just below the entrance to the throttle body that regulates the amount of air the ISC gets to work with.

Dale

IDLE TOO LOW

This is similar to the Idle Too High but the opposite - not enough air is getting in. In this case it could be the ISC is stuck and can't move. Or, the ISC adjustment screw is screwed too far in - this is a screw just below the entrance to the throttle body that regulates the amount of air the ISC gets to work with.

Dale

Have to correct you on this point though, as that screw just below the throttlebody entrance doesn't adjust the air the ISC has to work with, its just a simple air bleed across the primary port throttle plate. Even with the ISC unplugged and doing nothing, backing this screw out should increase the idle, and winding it in should decrease the idle. I'll cross post some stuff from my build thread here so people can find it when they're hunting their idle problems, I've hopefully given a good description of all the adjustment screws on the throttlebody, and my strategy for setting it up from scratch:

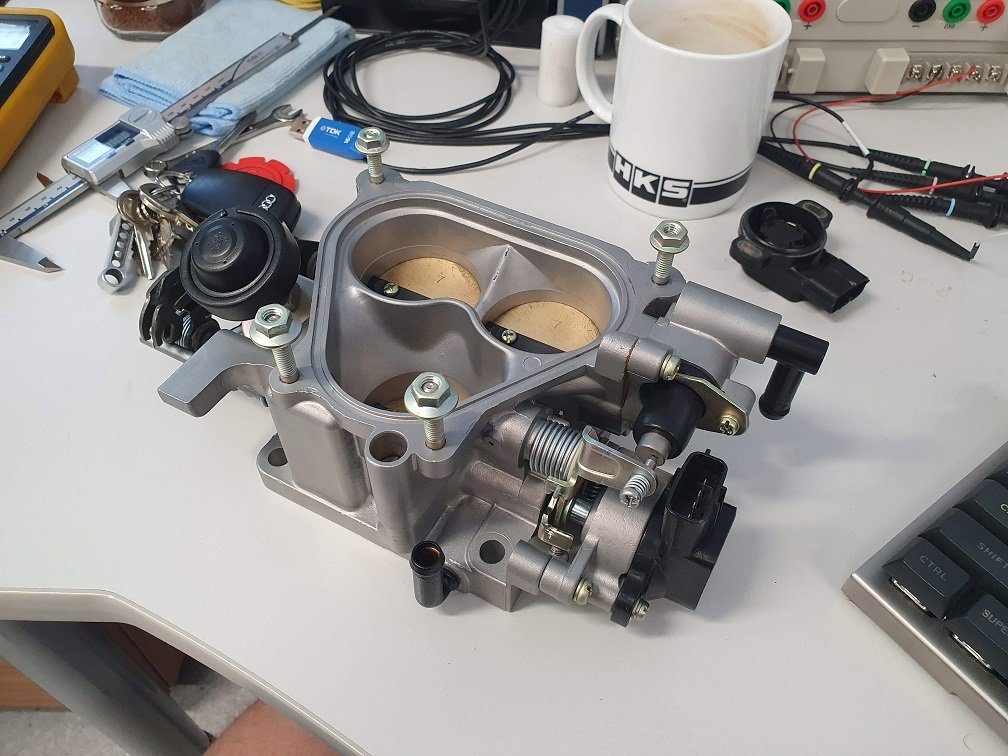

Whoa, the throttle bodies on these things are a..... thing. I got the above jigsaw all back together. Turns out I'd lost one of the plastic spring bushes, and the flange on the other was cracking off, so I grabbed an off cut of acetal from work and turned up a couple of new ones. That let me get the thing reassembled. I took a heap of photos of how everything came apart, so getting it back together wasn't too much of an issue. Kinda fiddly in spots, but follow your nose and it goes back together reasonably easily. The throttle shaft seals still seemed pliable and plump, so I didn't replace them... Time will tell if that comes around to bite me in the ***. Ideally I'd like to go with some sort of e-throttle setup in the future.

There wasn't actually a complete throttle body with the car when I got it, so I purchased this one secondhand, and it was pretty filthy:

But, it was complete, and moved smoothly :-). After stripping, blasting everything (lots of careful masking involved), kind of a pain in the ***....

Much better.

But holy crap, there are a lot of adjustments on these things! There are threads all over the internets of people having problems setting these up, so I thought I'd better develop a plan to follow. Not saying the plan is a 100% way to go, but I need something to follow so I can go through a process and collect data, and iterate from there. Going to write this plan out here so I can refer back to it later when I've forgotten all this again.

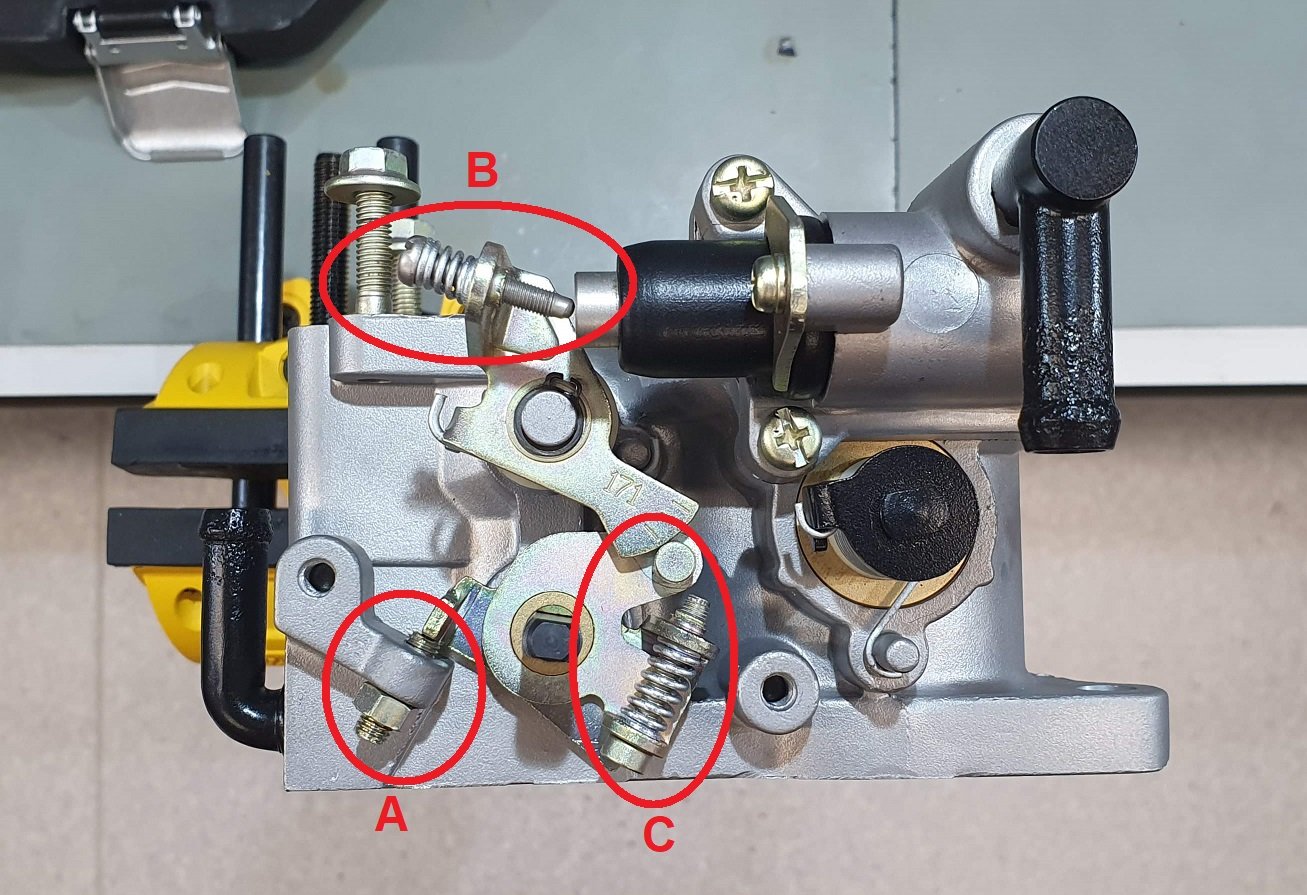

The first screw I've set is screw A. This is the stop that the single butterfly stops against. This single butterfly feeds the primary intake ports. As it's in the name, these port are the primary ones, so they're used all the time, along with the primary injectors always delivering fuel. My initial setting for this is that the primary butterfly stops against this when it is fully closed. After aligning the throttle blade, and thread locking the screws in place, I let the throttle close as far as it can against the housing. I then advanced this screw till it was just in contact, then about 1/10th of a turn more. This should mean the throttle blade is never eating the throttle body housing, but closes as much as possible.

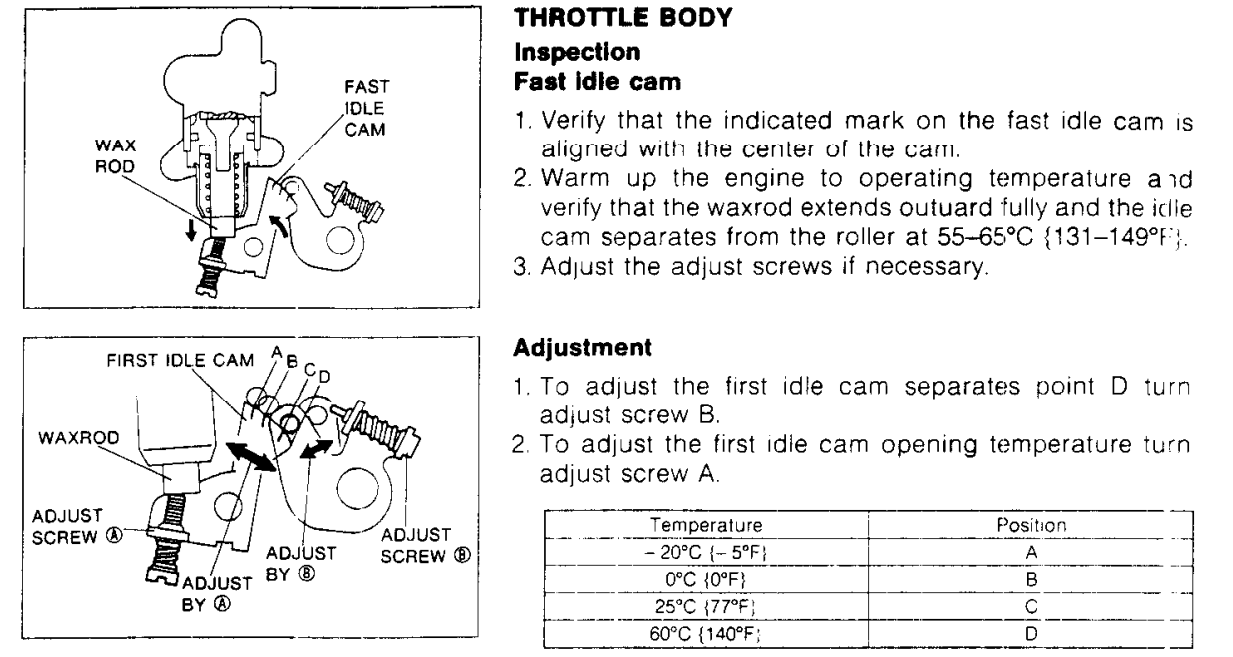

Screws B and C adjust the cold start warmup system. You can see the two black pipes in this picture. Coolant flows through these, which warms up and extends the wax pellet push-rod screw B is pushing against. Unfortunately they're a little corroded on the outside, but there is still heaps of metal there. Will always run anticorrosive coolant in this, so should progress any further. This wax pellet rod extends as the coolant gets hotter, and retracts as when things cool down. This screw is threaded into a cammed bracket, which has three marks on the cam (one of them is obscured by the red oval I've drawn, but its there). The FSM has specs for the relative positions of the roller on the bracket screw C threads into (we'll get to this one in a minute) and the cam at different temperatures. The upper most (in my picture) mark should be central on the roller at -20degC, the next one down at 0degC, the next one down at 25degC, and finally off the lower edge of the cam at 60 degC. It's pretty hot in my office today, so I've adjusted screw B such that the roller is lined up with the third mark.

Screw C adjusts how much effect this cam actually has on the throttle blade position. As you screw this in more and more, it opens the throttle blade more and more, as long as the roller is contacting the cam. I suspect the final setting for this will be such that the roller separates from the cam just as it is passing over the lower edge, with without a sudden jump in its movement. Currently, I've set it so the roller is only *just* touching the cam at this 25degC position, for reasons that will hopefully become clear :-).

Cold start systems are important, but they're only ever going to work properly if the base idle speed with the engine at normal operating temp is setup correctly. The throttle obviously has adjustments for this as well.

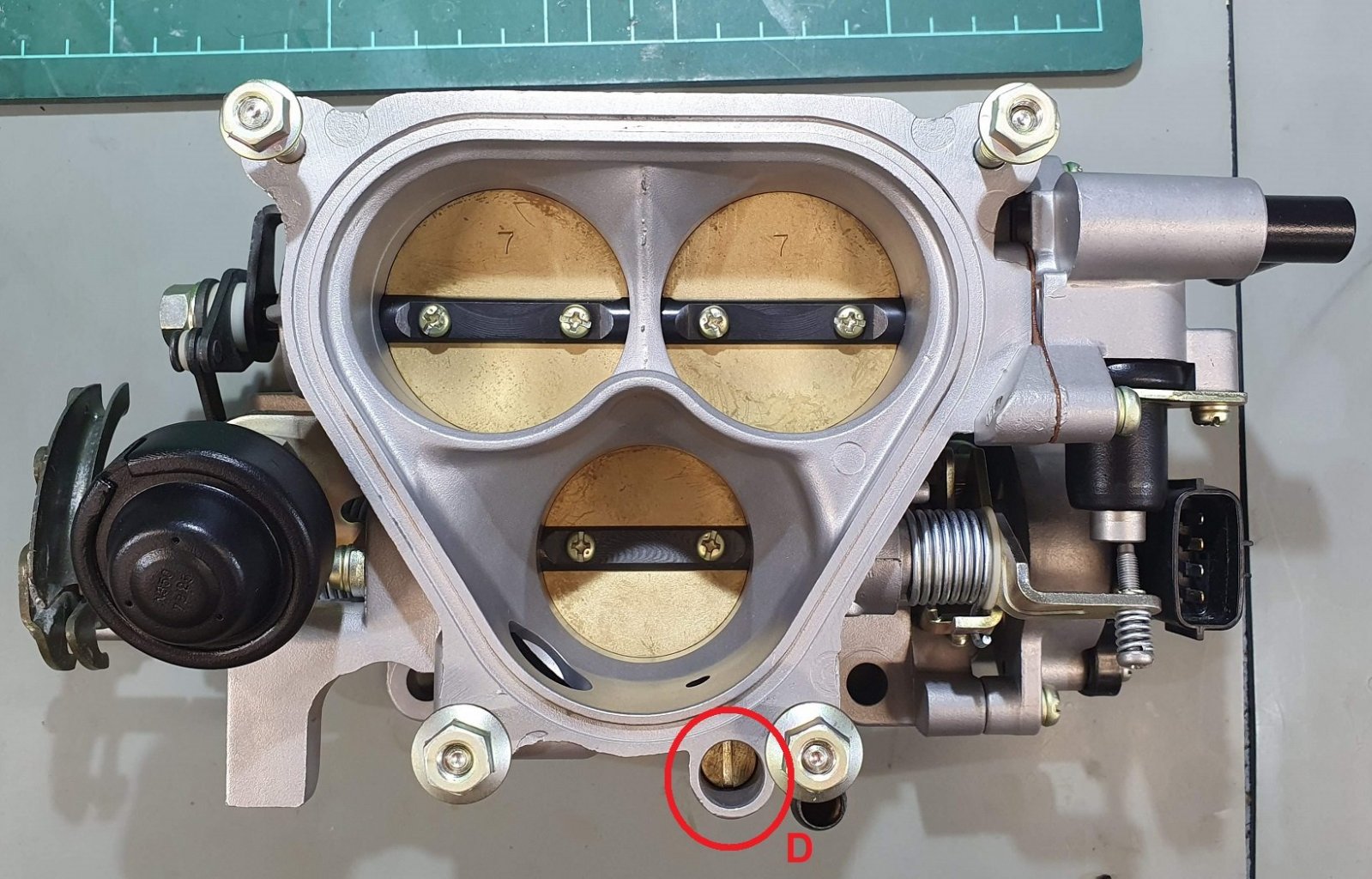

Screw D is called the Air Adjust Screw (AAS), and screw E is called the Throttle Adjust Screw (TAS). Screw D has a tapered end on it and fits into a matched tapered orifice. This orifice is connected across either side of the primary throttle blade, so as you back the screw out, it allows more and more air to bypass the throttle blade. Screw E is the stop for the the secondary throttle blades, and sets their closed position. In practice, these screws have the same effect on the idle, in that they will let more air into the engine. There is a slight difference though, as at idle the ECU wont be using the secondary injectors, so adjusting the idle with screw E will let more air into the engine via the secondary ports, but this wont have any fuel injected with it. This wont be an issue though, as at idle things are happening very slowly, and there is heaps of time for the charge to mix in the combustion chamber as it whizzes around to the other side of the motor to make brap brap noises. Reading the FSM, what I can parse out is that you use screw E to broadly set the normal operating temp idle speed, and then screw D to fine tune it.

I've set screw E in the same way I set screw A, such that the secondary throttle blades fully close to within a bee's dick of the throttle body housing. I've wound screw D all the way in, so there should be no air bypassing the primary throttle.

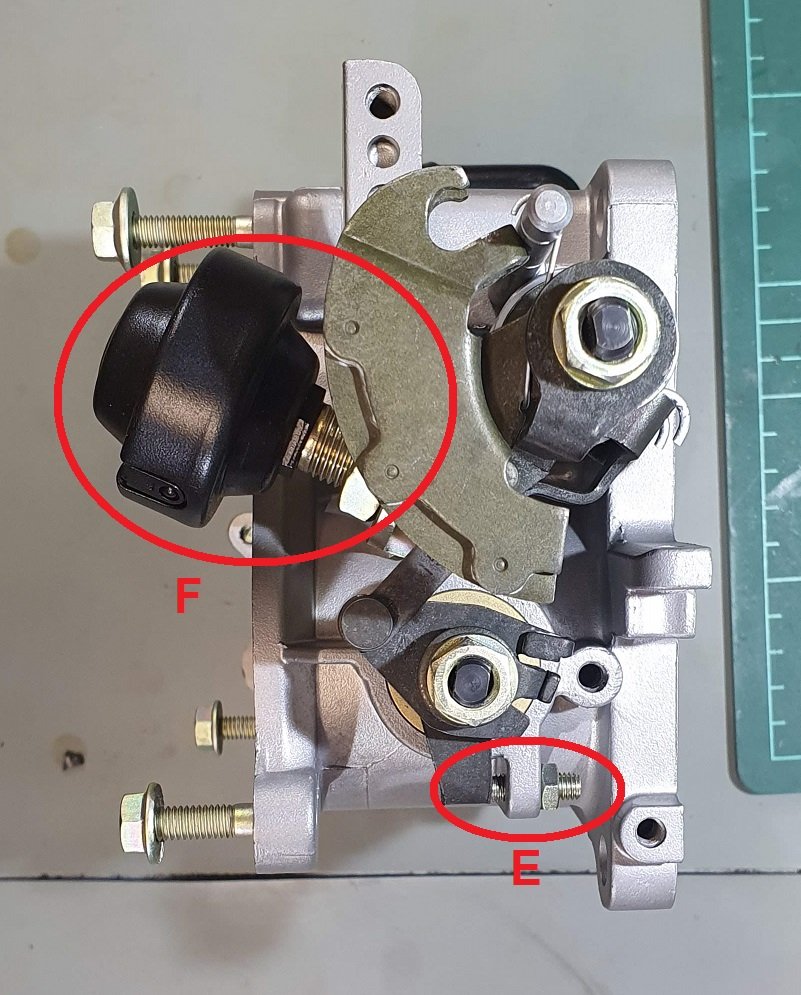

The last adjustment is the damper dashpot, F. This is a damper the throttle closes against. It's hard to push in, but extends with no effort. Lots of bump damping, no rebound damping. This needs to be set with the motor at normal operating temp, and such that the throttle breaks contact with the plunger at an engine speed of 2600 - 3000 rpm. Obviously this will need the engine running properly at N.O.T. To setup, so I've wound it out so it doesn't contact the throttle at all.

Reading through that, there might seem like some odd decisions, as I've essentially set the throttle up in such a way to ensure the thing isn't going to idle. It's going to have almost no air bypassing the throttle, will starve and die. This is for a reason however, and comes back to how I like to tune a setup. First thing is to get the engine firing and running, probably with some throttle manually applied. Then I can get it up to temperature, check for leaks, fires, all those things. With the engine up to temp I can use screws D and E to set the normal operating temp idle. It's really important this is done without the cold start system having any effect whatsoever, as if it is, when you go to set the cold start up, your normal idle setting will also be effected, and you'll end up chasing your tail.

Now, the FD also has an ECU control idle air solenoid which can allow varying amounts of air to bypass the throttle, but for all this initial mechanical setup, I'll keep this unplugged to eliminate it. AFAIK the ECU only uses it to idle up the motor when the A/C, power steering, or alternator are loading things up.

There is also the TPS to think about. The FD TPS is a little odd in that it has two analogue output channels, narrow range and full range. Talking to Ray (arghx), it sounds like this is a throwback to the FC3S days, and probably something to do with Mazda re-using existing code in the FD ECUs. Total speculation, but having been an engineer on a few evolving projects, this is totally something that would happen. The FSM has specs on setting this up. With the throttle closed, adjust it so the narrow-range signal is between 0.75V and 1.25V, and the full range signal is between 0.1V - 0.7V. I powered up the TPS from my bench supply and set it thusly.

Strats:

- Stock ECU initially, to get things running, proof the rest of the system, and ensure it doesn't burst into flames. It's a 'known quantity' as such.

- Make the thing run, will need the throttle manually opened to keep running.

- Get it up to normal operating temp

- Make sure everything is functioning like it should. No error codes from the ECU, so no limp modes or anything (exception to this is the idle control solenoid, but I can trick the ECU into thinking this is fine with a resistor in its place).

- Adjust the warm idle speed to just below target (~750RPM) with screw E

- Adjust the warm idle speed to the final target with screw D.

- Adjust dashpot F so the the throttle breaks away from the plunger at an engine speed of 2600RPM.

- Turn the thing off, go inside and have many whiskies.

- Recover from hangover. Remember: You're old now, this might take a couple of days.

- With the thing dead stone cold, try to start it with no throttle applied. Expectation is that it will not start.

- Advance screw C 1 turn, try again. Repeat this procedure till the engine starts with no manual throttle opening. Idle speed should be higher than warm idle target.

- Allow the engine to warm up, idle should reduce gradually as it does and the wax pellet rod extends.

- Iterate from here. The only screw that should need adjusting at this point is screw C.

Hopefully I can pull that off.

#10

Hey everyone -

This is a topic that comes up frequently and I feel like I've typed the same troubleshooting info in over and over again. Time to consolidate all this.

WHAT IDLE SHOULD BE LIKE

First, on a bone stock US car, you should have a 3000 RPM cold startup. This is the Accelerated Warmup System (AWS) - it will bring the idle to 3000 RPM for 5-10 seconds on a cold start in the morning. You can blip the throttle or start the car in gear to kick it off.

Once you get past that, the idle will be about 1500 RPM. This is due to the thermowax on the throttle body - it props the throttle open slightly when cold to give the higher RPM's. As the car warms up, a rod extends, which kicks the cam down that holds the idle higher. So, as the car warms up the idle will come down, eventually settling around 800 RPM.

On a hot start, you may have the engine rev up to 1000 RPM or so for a bit then settle down to 800 RPM. Idle may bump up slightly when you turn on AC, turn on electrical load (headlights, defrost), or turn the wheel (power steering). It should stay around 800 in general.

It is common to have the idle not rock solid - you may have small "pops" and tiny misses. This is normal. It can be caused by any number of things but in general it's due to an aging car, it's doubtful you can get the idle perfect and glass smooth.

IDLE TOO HIGH

OK, this is the easy thing that people can't wrap their head around. Idle speed is set by air entering the engine, period. If you have just the right amount of air, you get a correct idle. Too much air and it's too high.

At idle, the throttle plates should be closed and the Idle Speed Control (ISC) on the back of the upper intake manifold will control idle. It has a piston that moves in and out to increase or decrease idle.

The ISC can only compensate for a few hundred RPM of change - it adjusts when you turn on the AC, for example. If the air getting into the engine is too much it can't compensate.

Any air that gets in the engine between the throttle body and the engine itself will bump up idle. Anything before the throttle body - intercooler pipes, turbo Y-pipe, throttle body elbow - have NO impact on idle. Unless they somehow plumb in to the upper/lower intake manfolds and it's a leak after the throttle body.

It doesn't take much of a leak to bump idle up. Also, vacuum leak does not just mean vacuum hose - gaskets between the manifolds can leak, injector grommets can leak, etc. Again, anywhere air can get in.

If the throttle body itself isn't fully closing that will also cause a problem. This can be from the throttle cable being too tight, the throttle stop not adjusted right and cracking the throttle open, or the thermowax being stuck and keeping the throttle body propped open.

IDLE TOO LOW

This is similar to the Idle Too High but the opposite - not enough air is getting in. In this case it could be the ISC is stuck and can't move. Or, the ISC adjustment screw is screwed too far in - this is a screw just below the entrance to the throttle body that regulates the amount of air the ISC gets to work with.

ChrisFix just did a great video on cleaning ISC's -

https://www.youtube.com/watch?v=KhvqT3blzVs

Sticking ISC's are a common problem and it's an easy fix. If you have the original paper gasket for the ISC consider buying the newer metal gasket. Make sure the old gasket is totally removed and no little bits are still there before putting the metal one on. It goes on dry, no RTV or anything, just stick it on and bolt the ISC down.

IDLE IS BOUNCING

Again most likely ISC. Could also be Throttle Position Sensor (TPS) but the FD's TPS does pretty well, it's nowhere near as crap of a design as the FC's TPS. Unless you really mess with it it's typically OK or at least good enough to have a solid idle.

If you have a PowerFC you have to do the idle learn procedure, this is in the PFC FAQ I wrote ages ago, google it. Once the PFC learns idle it should be smooth.

CAR WON'T IDLE COMING TO STOP/DIES

Usually the dash pot - this is a greenish "mushroom" on the front of the throttle body. It has a white peg that comes out if it, that slows the throttle body as it closes. If the throttle snaps shut the ISC doesn't have enough time to react and the car can stall. Sometimes the dashpot just needs to be removed and cleaned, but if the white peg flops in and out with no resistance it needs to be replaced. They are available new from Mazda.

FINDING VACUUM LEAKS

High idle due to a vacuum leak seems to be the #1 thing I see people asking about. Again, you have to think - how is air getting in here? Don't think "vacuum" and immediately think "vacuum hose" - people will post up that they looked and alt the vacuum hoses look good and are hooked up. Good, but there's still air getting in - could be a gasket or a fuel injector grommet.

I recommend using STARTING FLUID with the engine running to find the vacuum leak. Yes you can use brake clean or other chemicals, but they don't evaporate quickly and sometimes can stain what you are spraying. I want something that will come out as a mist, get easily sucked into the engine, and won't hang around to puddle and be a fire risk or hang around so long that it's hard to find the exact leak.

That said, get your can and slowly spray around the area from the throttle body to the engine. When it hits the leak, the engine will rev up and smooth out. Use short bursts of spray to find the leak. You don't want to just hose it everywhere, go slow and try different areas and angles. You may also be able to hear the leak and may be able to plug it with your finger as part of the diagnosis.

There are also ways to make/use smoke machines to find leaks. This gets slightly more advanced and I'm not going into detail on this thread. But, it is a good way to find leaks as well.

ROUGH IDLE

First off make sure your engine is good. A blown engine (broken apex seal) will have a rough idle. I've seen people spend tons of time and money trying to fix an idle that was all due to a blown engine. If the engine is good, continue forward.

Old/worn spark plugs and ignition coils can be a cause of a rough idle as well as bad/dirty fuel injectors. Also make sure the plug wires are on properly, if they are mixed up the car will do VERY weird stuff when running/driving/idling.

If your car has an airpump and a stock ECU, the air pump needs to be there for the car to idle right. The ECU compensates for that air pump air, and without it it compensates wrong and gives a rough idle. Look for a blown fuse and shorted wiring to the air pump.

There's a lot more fine details to it but that hits the highlights. The FD has a pretty primitive idle system all things considered. The throttle body still has a lot of roots in carburetors and is a fairly complex mechanical device. New cars have drive-by-wire that incorporates everything into one unit - TPS, ISC, throttle body, thermowax, dashpot, you name it. Regardless, it can be hard to get the car to idle right but it can be done.

Dale

This is a topic that comes up frequently and I feel like I've typed the same troubleshooting info in over and over again. Time to consolidate all this.

WHAT IDLE SHOULD BE LIKE

First, on a bone stock US car, you should have a 3000 RPM cold startup. This is the Accelerated Warmup System (AWS) - it will bring the idle to 3000 RPM for 5-10 seconds on a cold start in the morning. You can blip the throttle or start the car in gear to kick it off.

Once you get past that, the idle will be about 1500 RPM. This is due to the thermowax on the throttle body - it props the throttle open slightly when cold to give the higher RPM's. As the car warms up, a rod extends, which kicks the cam down that holds the idle higher. So, as the car warms up the idle will come down, eventually settling around 800 RPM.

On a hot start, you may have the engine rev up to 1000 RPM or so for a bit then settle down to 800 RPM. Idle may bump up slightly when you turn on AC, turn on electrical load (headlights, defrost), or turn the wheel (power steering). It should stay around 800 in general.

It is common to have the idle not rock solid - you may have small "pops" and tiny misses. This is normal. It can be caused by any number of things but in general it's due to an aging car, it's doubtful you can get the idle perfect and glass smooth.

IDLE TOO HIGH

OK, this is the easy thing that people can't wrap their head around. Idle speed is set by air entering the engine, period. If you have just the right amount of air, you get a correct idle. Too much air and it's too high.

At idle, the throttle plates should be closed and the Idle Speed Control (ISC) on the back of the upper intake manifold will control idle. It has a piston that moves in and out to increase or decrease idle.

The ISC can only compensate for a few hundred RPM of change - it adjusts when you turn on the AC, for example. If the air getting into the engine is too much it can't compensate.

Any air that gets in the engine between the throttle body and the engine itself will bump up idle. Anything before the throttle body - intercooler pipes, turbo Y-pipe, throttle body elbow - have NO impact on idle. Unless they somehow plumb in to the upper/lower intake manfolds and it's a leak after the throttle body.

It doesn't take much of a leak to bump idle up. Also, vacuum leak does not just mean vacuum hose - gaskets between the manifolds can leak, injector grommets can leak, etc. Again, anywhere air can get in.

If the throttle body itself isn't fully closing that will also cause a problem. This can be from the throttle cable being too tight, the throttle stop not adjusted right and cracking the throttle open, or the thermowax being stuck and keeping the throttle body propped open.

IDLE TOO LOW

This is similar to the Idle Too High but the opposite - not enough air is getting in. In this case it could be the ISC is stuck and can't move. Or, the ISC adjustment screw is screwed too far in - this is a screw just below the entrance to the throttle body that regulates the amount of air the ISC gets to work with.

ChrisFix just did a great video on cleaning ISC's -

https://www.youtube.com/watch?v=KhvqT3blzVs

Sticking ISC's are a common problem and it's an easy fix. If you have the original paper gasket for the ISC consider buying the newer metal gasket. Make sure the old gasket is totally removed and no little bits are still there before putting the metal one on. It goes on dry, no RTV or anything, just stick it on and bolt the ISC down.

IDLE IS BOUNCING

Again most likely ISC. Could also be Throttle Position Sensor (TPS) but the FD's TPS does pretty well, it's nowhere near as crap of a design as the FC's TPS. Unless you really mess with it it's typically OK or at least good enough to have a solid idle.

If you have a PowerFC you have to do the idle learn procedure, this is in the PFC FAQ I wrote ages ago, google it. Once the PFC learns idle it should be smooth.

CAR WON'T IDLE COMING TO STOP/DIES

Usually the dash pot - this is a greenish "mushroom" on the front of the throttle body. It has a white peg that comes out if it, that slows the throttle body as it closes. If the throttle snaps shut the ISC doesn't have enough time to react and the car can stall. Sometimes the dashpot just needs to be removed and cleaned, but if the white peg flops in and out with no resistance it needs to be replaced. They are available new from Mazda.

FINDING VACUUM LEAKS

Spoiler

I recommend using STARTING FLUID with the engine running to find the vacuum leak. Yes you can use brake clean or other chemicals, but they don't evaporate quickly and sometimes can stain what you are spraying. I want something that will come out as a mist, get easily sucked into the engine, and won't hang around to puddle and be a fire risk or hang around so long that it's hard to find the exact leak.

That said, get your can and slowly spray around the area from the throttle body to the engine. When it hits the leak, the engine will rev up and smooth out. Use short bursts of spray to find the leak. You don't want to just hose it everywhere, go slow and try different areas and angles. You may also be able to hear the leak and may be able to plug it with your finger as part of the diagnosis.

There are also ways to make/use smoke machines to find leaks. This gets slightly more advanced and I'm not going into detail on this thread. But, it is a good way to find leaks as well.

ROUGH IDLE

First off make sure your engine is good. A blown engine (broken apex seal) will have a rough idle. I've seen people spend tons of time and money trying to fix an idle that was all due to a blown engine. If the engine is good, continue forward.

Old/worn spark plugs and ignition coils can be a cause of a rough idle as well as bad/dirty fuel injectors. Also make sure the plug wires are on properly, if they are mixed up the car will do VERY weird stuff when running/driving/idling.

If your car has an airpump and a stock ECU, the air pump needs to be there for the car to idle right. The ECU compensates for that air pump air, and without it it compensates wrong and gives a rough idle. Look for a blown fuse and shorted wiring to the air pump.

There's a lot more fine details to it but that hits the highlights. The FD has a pretty primitive idle system all things considered. The throttle body still has a lot of roots in carburetors and is a fairly complex mechanical device. New cars have drive-by-wire that incorporates everything into one unit - TPS, ISC, throttle body, thermowax, dashpot, you name it. Regardless, it can be hard to get the car to idle right but it can be done.

Dale

Thread

Thread Starter

Forum

Replies

Last Post

korea_senpai

3rd Generation Specific (1993-2002)

11

03-11-10 12:49 PM