The Big Fat FD3S Cooling Thread

#1

1. Introduction

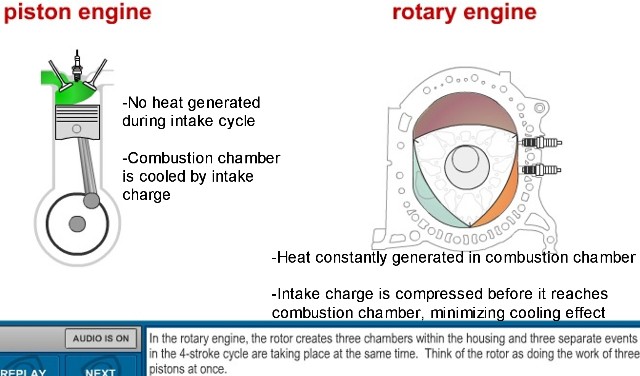

The 3rd Generation RX-7 was intended to be a “pure sports car.” Independent teams of engineers were assigned the task of reducing the weight of the car, and the performance and/or longevity of certain parts or subsystems was sometimes comprimised to reduce weight. In addition, the unique design of the rotary engine's combustion chamber generates more heat than conventional piston engines. For these and other reasons beyond the scope of this article, the RX-7 tends to run too hot, especially if the car is driven hard and/or modified for increased power. This can lead to overheating.

2. Measurements

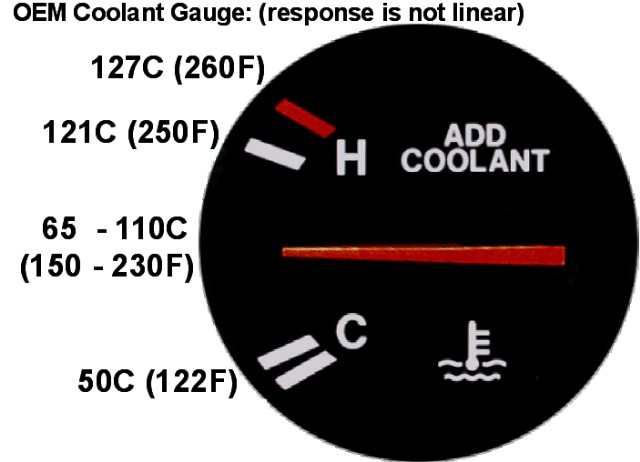

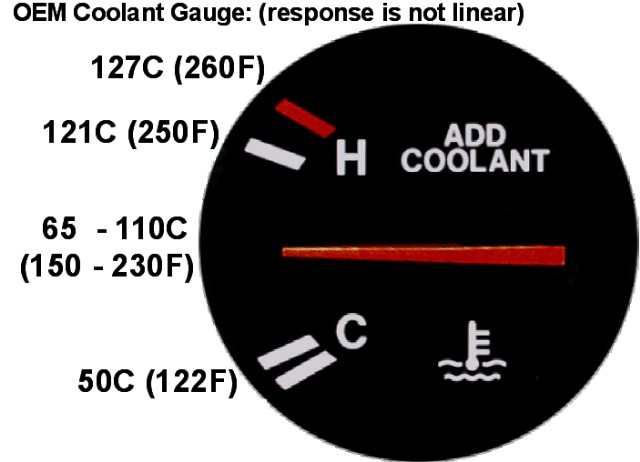

To further exacerbate this problem, the RX-7's coolant temperature gauge is center-weighted and inaccurate. It will indicate 'medium' temperature when the engine is still cold, and the needle does not move during normal operation. By the time the needle begins to rise, indicating the coolant is 'warm,' your motor has already reached dangerously high temperatures. It's recommended that every owner install an aftermarket coolant temp gauge, or perform the 'linearization' mod to the OEM temperature display. (see links section below)

3. Basics

The cooling system's purpose is to keep the engine parts (the iron and aluminum rotor housings, as well as the rubber/silicone/teflon coolant seals) from getting so hot that they warp or fail. If you don't already understand how cooling systems work, visit HowStuff Works.com for a good explanation.

http://auto.howstuffworks.com/cooling-system.htm

For the purpose of this article, we'll define overheating as the point when the cooling system is no longer removing enough heat from the engine. The signs of overheating are an uncontrollable increase in coolant temperature, usually accompanied by boiling coolant.

4. History

The original cooling system design called for a 1.3 bar (19 psi) pressure cap. This would allow the engine to run at high temperatures without boiling coolant, but it put additional stress on the hoses and rubber seals. At this pressure, the original rubber hoses would fail prematurely, and many owners experienced engine fires due to coolant hose failures. In addition, if the coolant was lost completely the engine would often overheat before the driver took action.

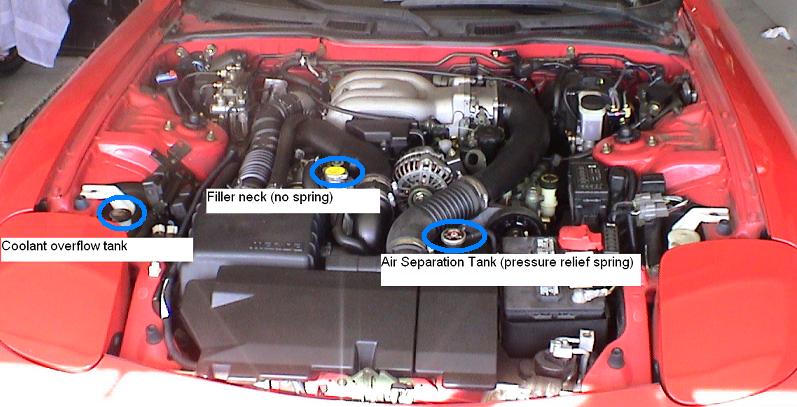

A recall in 1994 replaced the following: filler neck, filler neck cap, water pump bearing housing, water level sensor, upper radiator hose, thermostat gasket, all water hoses above the engine (throttle body lines, AST lines, possibly heater hoses). The AST cap was replaced with a lower-pressure 0.9 bar (13 psi) unit.

5. Maintenance

As with most things, preventative maintenance is the key. A healthy cooling system is adequate for an unmodified or lightly-modified RX-7. Here are some basic things that will ensure the health of the coolant system:

The coolant should be flushed yearly, and replaced with the proper water/coolant ratio. Mazda recommends a 70% water / 30% coolant mix for warm climates. Due to the superior heat-transfer properties of water, a few racers recommend running as high as 90% water/ 10% coolant in hot climates. Be sure to use the proper amount of antifreeze in cold climates.

When refilling the system, be sure to fill slowly to prevent air pockets from forming. Using a filler neck funnel is recommended (see links section); it's also very important to check the coolant level regularly for the next 2-5 trips after a coolant flush, adding coolant as necessary.

Ensure that the filler and AST caps are sealing properly, and venting at the correct pressure. If your pressure caps aren't working properly, the coolant will boil at a lower temperature, which will allow the engine to overheat more easily. New pressure caps are $12-25 from the dealer, which is much cheaper fixing an overheated engine. It wouldn't hurt to buy new caps every 3-5 years.

Replace old coolant hoses, every 5-10 years. If a coolant hose fails, the cooling system won't hold pressure, allowing the coolant to boil at a lower temperature, which will allow the engine to overheat. It's very common for hoses to develop small cracks or splits that are hard to see, so it's better to just replace old hoses than to wait for a catastrophic failure. Don't forget the coolant line that connects the AST to the overflow tank. If this line doesn't hold vacuum, coolant overflow won't be sucked back into system when the car cools down. The cooling system will slowly lose coolant (which decreases operating pressure and reduces the system boiling point, leading to overheating).

6. Modifications

If you modify your engine to make more power, it will generate more heat. The RX-7's cooling system is marginal compared to most other cars, so it's important that your cooling system is upgraded to handle the additonal heat generated by the motor. Don't forget that oil performs a large percentage of engine cooling in rotary engines, since there are no coolant passages for the rotors, rotor bearings or eccentric shaft. The only engine modification to the R1 and R2 models was an additional oil cooler, which suggests that the single stock oil cooler setup was inefficient for track use at stock power levels.

Upgrades, in order of cost: (it is assumed that 'free' mods cost time)

16psi cap (Stant 11233). Raises boiling point of coolant.

Drilled OEM thermostat. Reduces the amount of coolant bypassing the radiator, allowing more coolant to flow through the radiator.

Radiator ducting. Forces air to flow through the radiator, preventing 'spillage' at high speeds.

FC thermoswitch. Lowers the temperature at which the stock ECU activates the fans.

Fan mod. Similar to FC thermoswitch, but allows driver to control fan operation.

Removal of A/C and/or power steering. The removal of the air conditioning condenser will allow more airflow through the radiator.

Air Separator Tank (AST). OEM plastic tank is known to fail. Replace or eliminate.

Downpipe. The OEM precat generates a lot of heat in the engine bay, and its large size prevents hot air from escaping the enging bay. A downpipe will improve cooling system performance in addition to increasing HP.

Modified battery. installing a miniature battery, or relocating a normally-sized battery, will improve airflow through the radiator.

Radiator. OEM radiator uses plastic endtanks, which are known known to split, crack or fail.

Vented hood. Airflow to the radiator plays a huge role in cooling system efficiency. A vented hood will greatly improve airflow, allowing heated air to exit the cramped engine bay.

Upgraded oil coolers. Oil performs a large percentage of engine cooling in rotary engines; don't neglect it. The only engine modification to the R1 and R2 models was an additional oil cooler, which suggests that the single stock oil cooler setup was inefficient for track use at stock power levels.

Teflon-coated coolant seals. Modification performed during an engine rebuild; replaces OEM rubber seals with high-temp teflon-coated silicone o-rings.

Modified coolant passages. Modification performed to water jackets, carving grooves for increased heat transfer. A common trick among engine builders such as Racing Beat and Rotary Power; used for race engines. (Other builders might do this, such as Gotham, Pineapple, Rotary Aviation, etc..)

Electric water pump. Eliminates cavitation experienced by OEM mechanical water pump at certain RPM's; requires custom fabrication. (see links section)

The 3rd Generation RX-7 was intended to be a “pure sports car.” Independent teams of engineers were assigned the task of reducing the weight of the car, and the performance and/or longevity of certain parts or subsystems was sometimes comprimised to reduce weight. In addition, the unique design of the rotary engine's combustion chamber generates more heat than conventional piston engines. For these and other reasons beyond the scope of this article, the RX-7 tends to run too hot, especially if the car is driven hard and/or modified for increased power. This can lead to overheating.

2. Measurements

To further exacerbate this problem, the RX-7's coolant temperature gauge is center-weighted and inaccurate. It will indicate 'medium' temperature when the engine is still cold, and the needle does not move during normal operation. By the time the needle begins to rise, indicating the coolant is 'warm,' your motor has already reached dangerously high temperatures. It's recommended that every owner install an aftermarket coolant temp gauge, or perform the 'linearization' mod to the OEM temperature display. (see links section below)

3. Basics

The cooling system's purpose is to keep the engine parts (the iron and aluminum rotor housings, as well as the rubber/silicone/teflon coolant seals) from getting so hot that they warp or fail. If you don't already understand how cooling systems work, visit HowStuff Works.com for a good explanation.

http://auto.howstuffworks.com/cooling-system.htm

For the purpose of this article, we'll define overheating as the point when the cooling system is no longer removing enough heat from the engine. The signs of overheating are an uncontrollable increase in coolant temperature, usually accompanied by boiling coolant.

4. History

The original cooling system design called for a 1.3 bar (19 psi) pressure cap. This would allow the engine to run at high temperatures without boiling coolant, but it put additional stress on the hoses and rubber seals. At this pressure, the original rubber hoses would fail prematurely, and many owners experienced engine fires due to coolant hose failures. In addition, if the coolant was lost completely the engine would often overheat before the driver took action.

A recall in 1994 replaced the following: filler neck, filler neck cap, water pump bearing housing, water level sensor, upper radiator hose, thermostat gasket, all water hoses above the engine (throttle body lines, AST lines, possibly heater hoses). The AST cap was replaced with a lower-pressure 0.9 bar (13 psi) unit.

5. Maintenance

As with most things, preventative maintenance is the key. A healthy cooling system is adequate for an unmodified or lightly-modified RX-7. Here are some basic things that will ensure the health of the coolant system:

The coolant should be flushed yearly, and replaced with the proper water/coolant ratio. Mazda recommends a 70% water / 30% coolant mix for warm climates. Due to the superior heat-transfer properties of water, a few racers recommend running as high as 90% water/ 10% coolant in hot climates. Be sure to use the proper amount of antifreeze in cold climates.

When refilling the system, be sure to fill slowly to prevent air pockets from forming. Using a filler neck funnel is recommended (see links section); it's also very important to check the coolant level regularly for the next 2-5 trips after a coolant flush, adding coolant as necessary.

Ensure that the filler and AST caps are sealing properly, and venting at the correct pressure. If your pressure caps aren't working properly, the coolant will boil at a lower temperature, which will allow the engine to overheat more easily. New pressure caps are $12-25 from the dealer, which is much cheaper fixing an overheated engine. It wouldn't hurt to buy new caps every 3-5 years.

Replace old coolant hoses, every 5-10 years. If a coolant hose fails, the cooling system won't hold pressure, allowing the coolant to boil at a lower temperature, which will allow the engine to overheat. It's very common for hoses to develop small cracks or splits that are hard to see, so it's better to just replace old hoses than to wait for a catastrophic failure. Don't forget the coolant line that connects the AST to the overflow tank. If this line doesn't hold vacuum, coolant overflow won't be sucked back into system when the car cools down. The cooling system will slowly lose coolant (which decreases operating pressure and reduces the system boiling point, leading to overheating).

6. Modifications

If you modify your engine to make more power, it will generate more heat. The RX-7's cooling system is marginal compared to most other cars, so it's important that your cooling system is upgraded to handle the additonal heat generated by the motor. Don't forget that oil performs a large percentage of engine cooling in rotary engines, since there are no coolant passages for the rotors, rotor bearings or eccentric shaft. The only engine modification to the R1 and R2 models was an additional oil cooler, which suggests that the single stock oil cooler setup was inefficient for track use at stock power levels.

Upgrades, in order of cost: (it is assumed that 'free' mods cost time)

16psi cap (Stant 11233). Raises boiling point of coolant.

Drilled OEM thermostat. Reduces the amount of coolant bypassing the radiator, allowing more coolant to flow through the radiator.

Radiator ducting. Forces air to flow through the radiator, preventing 'spillage' at high speeds.

FC thermoswitch. Lowers the temperature at which the stock ECU activates the fans.

Fan mod. Similar to FC thermoswitch, but allows driver to control fan operation.

Removal of A/C and/or power steering. The removal of the air conditioning condenser will allow more airflow through the radiator.

Air Separator Tank (AST). OEM plastic tank is known to fail. Replace or eliminate.

Downpipe. The OEM precat generates a lot of heat in the engine bay, and its large size prevents hot air from escaping the enging bay. A downpipe will improve cooling system performance in addition to increasing HP.

Modified battery. installing a miniature battery, or relocating a normally-sized battery, will improve airflow through the radiator.

Radiator. OEM radiator uses plastic endtanks, which are known known to split, crack or fail.

Vented hood. Airflow to the radiator plays a huge role in cooling system efficiency. A vented hood will greatly improve airflow, allowing heated air to exit the cramped engine bay.

Upgraded oil coolers. Oil performs a large percentage of engine cooling in rotary engines; don't neglect it. The only engine modification to the R1 and R2 models was an additional oil cooler, which suggests that the single stock oil cooler setup was inefficient for track use at stock power levels.

Teflon-coated coolant seals. Modification performed during an engine rebuild; replaces OEM rubber seals with high-temp teflon-coated silicone o-rings.

Modified coolant passages. Modification performed to water jackets, carving grooves for increased heat transfer. A common trick among engine builders such as Racing Beat and Rotary Power; used for race engines. (Other builders might do this, such as Gotham, Pineapple, Rotary Aviation, etc..)

Electric water pump. Eliminates cavitation experienced by OEM mechanical water pump at certain RPM's; requires custom fabrication. (see links section)

Last edited by dgeesaman; 05-31-08 at 02:29 PM.

The following 3 users liked this post by scotty305:

#2

(Note: this post cannibalized by dgeesaman, content by scotty305)

7. Optimum Temps

65C (150F): too cold. According to service manual, EGR valve is non-operational below 150F, "to improve drivability when cold."

82C (180F): getting warm. Thermostat begins to open, circulating coolant through the radiator. Some coolant is still bypassing the radiator.

95C (203F): fully warm. Thermostat is fully open, not bypassing the radiator at all.

100C (212F): boiling point of pure water at atmospheric pressure.

105C (221F): getting hot. Stock ECU will activate fans to cool the car down. Fan speed will be low, or medium (if A/C is already on).

108C (226F): hot. Stock 93-95 coolant thermoswitch activates, changing fan speeds from low>> medium (or med>>high if A/C is already on) (switching to an FC thermoswitch will change this temp to 203F)

115C (240F): getting dangerous. OEM temp gauge begins to rise.

117C (243F): dangerous. boiling point of pure water with 13psi pressure cap.

121C (250F): too hot. OEM temp gauge will point to white line. Boiling point of pure water with 16psi pressure cap.

124C (256F): way too hot. Boiling point of pure water with 19psi pressure cap. Boiling point of 50/50 coolant mix with 13psi pressure cap.

127C (260F): way too hot. OEM temp gauge will point to red line.

A Mazda competition preparation manual, dated 1980, gives the following recommendations. Note that this is for a non-turbo 12A motor in a racing environment:

Warm the engine up at an idle speed of 2000-2500 RPM, until the oil temp reaches 160F (70C).

Recommended coolant temperature (outlet side): 160-195F (70-90C).

Max coolant temperature: 205F (95C).

Recommended oil temperature (oil pan): 195-230F (90-110C).

Max oil temperature: 250F (120C).

Pure water at atmospheric pressure boils at 212F (100C).

Pure water at 13psi (0.9bar) boils at 243F (117C). This is the standard pressure cap for many 3rd Gens after the cooling recall.

Pure water at 16psi (1.1bar) boils at 250F (121C).

Pure water at 19psi (1.3bar) boils at 256F (124C). This was the original pressure cap for the '93 RX-7s before the recall.

Pure water at 30psi (2.0bar) boils at 273F (133C). This is what Carlos Iglesias is using on his car. Many race cars use even higher pressures: I've heard that F1 teams run their coolant (pure water for efficiency) at 50 psi or higher (boiling point over 290F).

^^Remember, these numbers are for pure water; a 70/30 mix of water/ethylene glycol (standard yellow-green coolant) will raise the boiling point by about 8 F, and a 50/50 mix will raise the boiling point by about 13F.

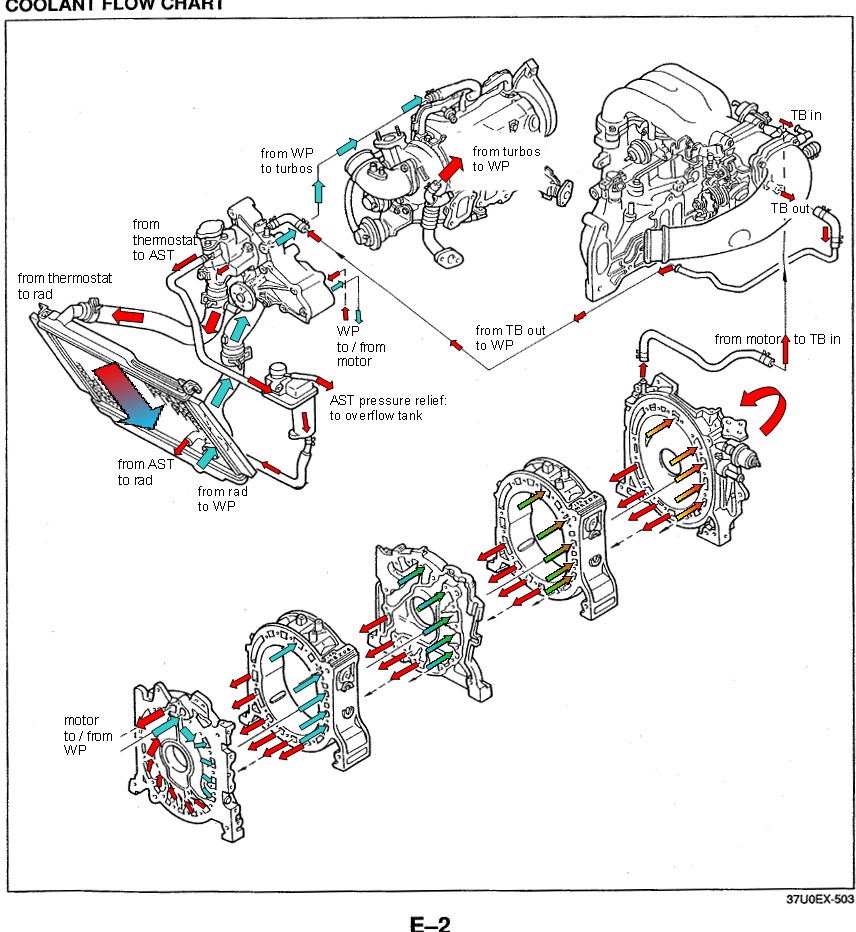

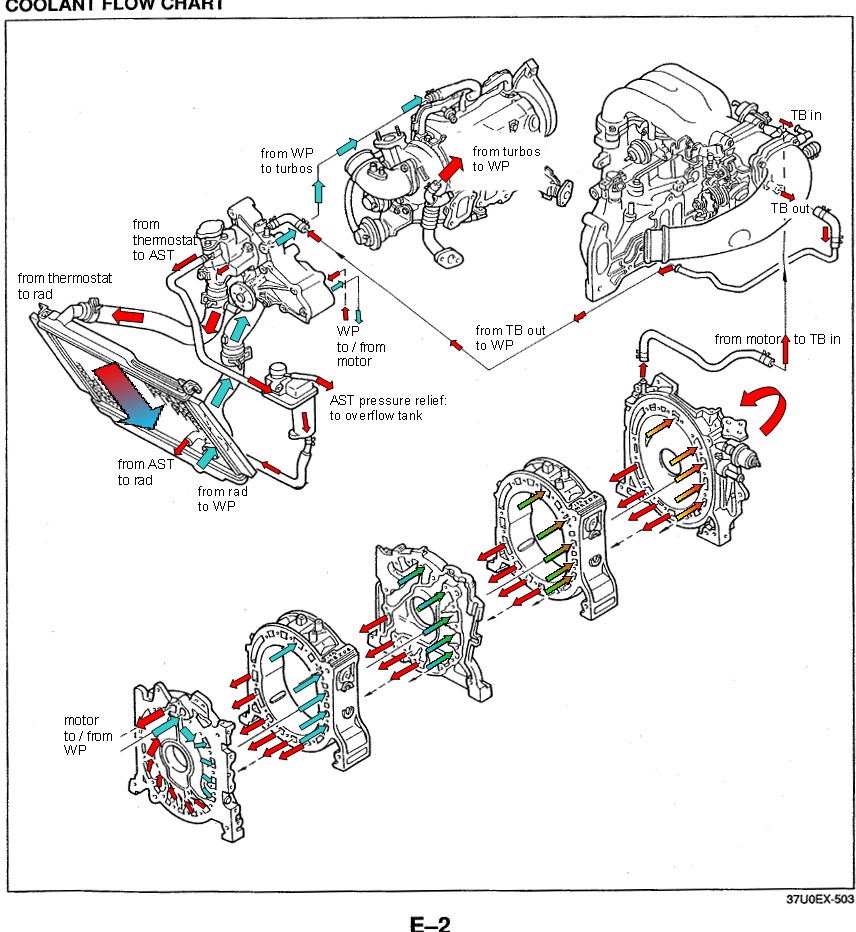

8. Coolant Flow

Water Pump exit port pushes coolant directly into driver's side of the engine block, comes back on exhaust side to wp inlet port.

If thermostat is closed, a bypass is open and coolant goes back through the water pump again without flowing through rad or AST.

As the OEM thermostat opens, it closes the bypass port. Hot flow exiting the waterpump flows through the open t-stat, out the filler neck to upper rad hose, through the radiator where it is cooled. The water pump sucks coolant from the lower radiator hose. Warning: rumor has it that 'parts-store' brand thermostats don't close this bypass.

Regardless of thermostat position, the throttle body coolant line comes from the back of the engine block, and is pulled back into the waterpump housing inlet.

Regardless of thermostat position, the heater core is fed by a large coolant line below the oil filter, and is pulled back into the waterpump housing inlet. It always has substantial flow, and always bypasses the radiator, decreasing cooling capacity. Turning the heater on, and running the cabin fans at full speed will dissipate some heat.

Turbo cooling starts at the return port for the wp, goes to turbos, returns at wp inlet pipe. Not much pressure drop, so not much flow, and flow reverses at shutdown, making t-stat housing gages jump, but this is very local volume of hot coolant thermally siphoning through turbos.

AST is functional when thermostat opens, and flow goes across top of filler neck and drops to 10mm exit port. Then comes in a 10mm port to ast mid body, and lower hose feeds this flow to lower rad tank, then to wp inlet. To limit the amount of coolant bypassing the radiator, a .086 pill is intregrated to the lower nipple of the stock AST.

Coolant expands as it heats up, and pushes air and coolant through AST pressure-releif cap to overflow tank. (description taken from KevinK2 , https://www.rx7club.com/3rd-generation-specific-1993-2002-16/any-real-tech-heads-coolant-flow-465083/)

9. Links

Maintenance:

Coolant Flush How-To's:

http://www.fd3s.net/cooling_system_flush.html

http://www.robrobinette.com/flush.htm

Coolant Burping Tool/ Radiator Cap Funnel

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/radiator-cap-funnel-eliminate-air-bubbles-342309/

Part Numbers for replacement Coolant Lines:

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/all-coolant-hose-part-numbers-331644/

Replacing Turbo Coolant Lines:

http://www.robrobinette.com/turbo_lines.htm

Modifications:

Stock Water Temp Gauge Linearization:

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/temp-guage-inaccuracy-252334/

AST Elimination

http://www.robrobinette.com/coolant_tank.htm

http://www.fd3s.net/coolant_tank_elimination.html

Fan Mod:

http://www.fd3s.net/fan_mod.html

http://rx7.voodoobox.net/howto/fanswitch/fanswitch.html

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/2-trigger-cooling-fans-462760/ << electrical schematic of relay circuit, with description

Electric Water Pump:

www.meziere.com << Meziere sells electric pumps and adapters for the 13B

https://www.rx7club.com/build-threads-292/spic-racer-gt40r-414533/ <<example here

10. Misc / Unfinished Business

It would be nice to get some before/after temperature data for various mods, using the following test:

-Let the car sit at idle, measuring time from 180F >> 210F (stock ECU will activate the fans at 210F when the parking lights are on).

-Fans will turn on, then measure time from 210>> fans turnoff (180F).

Thanks for reading,

-scott-

7. Optimum Temps

65C (150F): too cold. According to service manual, EGR valve is non-operational below 150F, "to improve drivability when cold."

82C (180F): getting warm. Thermostat begins to open, circulating coolant through the radiator. Some coolant is still bypassing the radiator.

95C (203F): fully warm. Thermostat is fully open, not bypassing the radiator at all.

100C (212F): boiling point of pure water at atmospheric pressure.

105C (221F): getting hot. Stock ECU will activate fans to cool the car down. Fan speed will be low, or medium (if A/C is already on).

108C (226F): hot. Stock 93-95 coolant thermoswitch activates, changing fan speeds from low>> medium (or med>>high if A/C is already on) (switching to an FC thermoswitch will change this temp to 203F)

115C (240F): getting dangerous. OEM temp gauge begins to rise.

117C (243F): dangerous. boiling point of pure water with 13psi pressure cap.

121C (250F): too hot. OEM temp gauge will point to white line. Boiling point of pure water with 16psi pressure cap.

124C (256F): way too hot. Boiling point of pure water with 19psi pressure cap. Boiling point of 50/50 coolant mix with 13psi pressure cap.

127C (260F): way too hot. OEM temp gauge will point to red line.

A Mazda competition preparation manual, dated 1980, gives the following recommendations. Note that this is for a non-turbo 12A motor in a racing environment:

Warm the engine up at an idle speed of 2000-2500 RPM, until the oil temp reaches 160F (70C).

Recommended coolant temperature (outlet side): 160-195F (70-90C).

Max coolant temperature: 205F (95C).

Recommended oil temperature (oil pan): 195-230F (90-110C).

Max oil temperature: 250F (120C).

Pure water at atmospheric pressure boils at 212F (100C).

Pure water at 13psi (0.9bar) boils at 243F (117C). This is the standard pressure cap for many 3rd Gens after the cooling recall.

Pure water at 16psi (1.1bar) boils at 250F (121C).

Pure water at 19psi (1.3bar) boils at 256F (124C). This was the original pressure cap for the '93 RX-7s before the recall.

Pure water at 30psi (2.0bar) boils at 273F (133C). This is what Carlos Iglesias is using on his car. Many race cars use even higher pressures: I've heard that F1 teams run their coolant (pure water for efficiency) at 50 psi or higher (boiling point over 290F).

^^Remember, these numbers are for pure water; a 70/30 mix of water/ethylene glycol (standard yellow-green coolant) will raise the boiling point by about 8 F, and a 50/50 mix will raise the boiling point by about 13F.

8. Coolant Flow

Water Pump exit port pushes coolant directly into driver's side of the engine block, comes back on exhaust side to wp inlet port.

If thermostat is closed, a bypass is open and coolant goes back through the water pump again without flowing through rad or AST.

As the OEM thermostat opens, it closes the bypass port. Hot flow exiting the waterpump flows through the open t-stat, out the filler neck to upper rad hose, through the radiator where it is cooled. The water pump sucks coolant from the lower radiator hose. Warning: rumor has it that 'parts-store' brand thermostats don't close this bypass.

Regardless of thermostat position, the throttle body coolant line comes from the back of the engine block, and is pulled back into the waterpump housing inlet.

Regardless of thermostat position, the heater core is fed by a large coolant line below the oil filter, and is pulled back into the waterpump housing inlet. It always has substantial flow, and always bypasses the radiator, decreasing cooling capacity. Turning the heater on, and running the cabin fans at full speed will dissipate some heat.

Turbo cooling starts at the return port for the wp, goes to turbos, returns at wp inlet pipe. Not much pressure drop, so not much flow, and flow reverses at shutdown, making t-stat housing gages jump, but this is very local volume of hot coolant thermally siphoning through turbos.

AST is functional when thermostat opens, and flow goes across top of filler neck and drops to 10mm exit port. Then comes in a 10mm port to ast mid body, and lower hose feeds this flow to lower rad tank, then to wp inlet. To limit the amount of coolant bypassing the radiator, a .086 pill is intregrated to the lower nipple of the stock AST.

Coolant expands as it heats up, and pushes air and coolant through AST pressure-releif cap to overflow tank. (description taken from KevinK2 , https://www.rx7club.com/3rd-generation-specific-1993-2002-16/any-real-tech-heads-coolant-flow-465083/)

9. Links

Maintenance:

Coolant Flush How-To's:

http://www.fd3s.net/cooling_system_flush.html

http://www.robrobinette.com/flush.htm

Coolant Burping Tool/ Radiator Cap Funnel

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/radiator-cap-funnel-eliminate-air-bubbles-342309/

Part Numbers for replacement Coolant Lines:

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/all-coolant-hose-part-numbers-331644/

Replacing Turbo Coolant Lines:

http://www.robrobinette.com/turbo_lines.htm

Modifications:

Stock Water Temp Gauge Linearization:

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/temp-guage-inaccuracy-252334/

AST Elimination

http://www.robrobinette.com/coolant_tank.htm

http://www.fd3s.net/coolant_tank_elimination.html

Fan Mod:

http://www.fd3s.net/fan_mod.html

http://rx7.voodoobox.net/howto/fanswitch/fanswitch.html

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/2-trigger-cooling-fans-462760/ << electrical schematic of relay circuit, with description

Electric Water Pump:

www.meziere.com << Meziere sells electric pumps and adapters for the 13B

https://www.rx7club.com/build-threads-292/spic-racer-gt40r-414533/ <<example here

10. Misc / Unfinished Business

It would be nice to get some before/after temperature data for various mods, using the following test:

-Let the car sit at idle, measuring time from 180F >> 210F (stock ECU will activate the fans at 210F when the parking lights are on).

-Fans will turn on, then measure time from 210>> fans turnoff (180F).

Thanks for reading,

-scott-

Last edited by dgeesaman; 05-31-08 at 02:30 PM.

The following 2 users liked this post by neit_jnf:

Johnnyblaze (02-11-20),

pietrino (04-21-20)

The following users liked this post:

chadtucker15 (07-21-21)

The following users liked this post:

chadtucker15 (07-21-21)

Trending Topics

#14

Awesome, awesome job. Captures everything I've been preaching to folks for years, but it's all gathered in one tidy spot. Thanks for the effort in putting this together.

#15

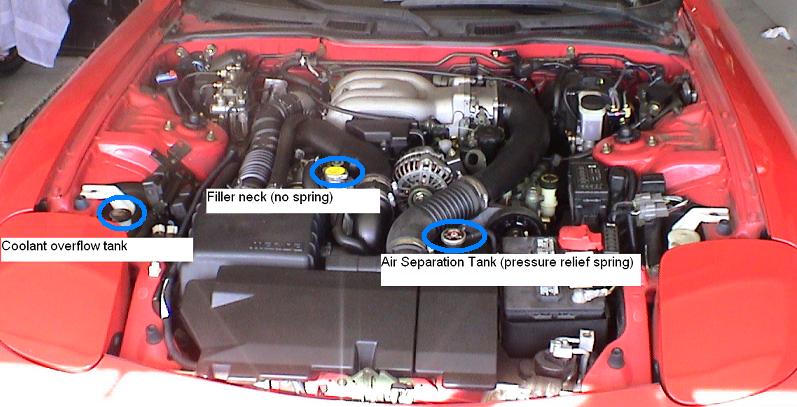

WHOA....so...in that pic of the engine bay...you see the rad cap oin the filler neck and the rad cap on the ast? Mine are switched around! I wonder if the pressure ratings are different between the caps...

Trev

Trev

#16

the_glass_man , I agree that I should have mentioned Evans and Water Wetter. I haven't got any experience with either of them (because I don't think my mostly stock motor is generating enough heat to justify adding them), but I'll look into it. Evans seems to be a great safeguard for cars that see a lot of racing duty.

supraturbo1987 , the cap on the filler neck should not have a pressure-relief spring. The cap on the AST should have a 0.9-1.1 bar (13-16 psi) pressure-relief spring on it. If the caps are reversed, coolant will spill out into the engine bay rather than going into the overflow tank.

supraturbo1987 , the cap on the filler neck should not have a pressure-relief spring. The cap on the AST should have a 0.9-1.1 bar (13-16 psi) pressure-relief spring on it. If the caps are reversed, coolant will spill out into the engine bay rather than going into the overflow tank.

#19

Originally Posted by supraturbo1987

Both caps say 0.9 on them...but both look exactly like the ones in the pic...so I need a cap that doesn't have any spring to it on the filler neck?

Trev

Trev

#22

I had a question regarding oil temps. I see a lot of data regarding water temps, what is safe/what isn't safe. But, I have had a really hard time finding what sort of oil temps I should see. In 110 degree ambient temps my PFC coolant temp will go as high as 105 C with the A/C on or 95 C or so with the A/C off (A/C condensor must be a significant source of heat at those temperatures). My oil temp will hover around 115 C or a little higher. If you run at a slightly higher rpm (NOT boosting!) the oil temp can climb as high as 120C.

This is all in stop and go traffic. If you get out on the open road and get some real flow through the radiator, the temps come down...maybe 95-99 C coolant with the A/C on. 110 C or so oil temp.

My question would be...What is a safe oil temp? When do things start to get dangerous? Can we just go off of dangerous coolant temps? Will the coolant system fail because of overheat before the oiling system?

I just get a little scared of my oil temps sometimes, but my coolant temps have never been TOO alarming.

FWIW...when the ambient drops to 95ish, my coolant temps hover around 89C with the A/C on and my oil temps around 105C... The extra 15 degrees ambient temperature is HUGE!

This is all in stop and go traffic. If you get out on the open road and get some real flow through the radiator, the temps come down...maybe 95-99 C coolant with the A/C on. 110 C or so oil temp.

My question would be...What is a safe oil temp? When do things start to get dangerous? Can we just go off of dangerous coolant temps? Will the coolant system fail because of overheat before the oiling system?

I just get a little scared of my oil temps sometimes, but my coolant temps have never been TOO alarming.

FWIW...when the ambient drops to 95ish, my coolant temps hover around 89C with the A/C on and my oil temps around 105C... The extra 15 degrees ambient temperature is HUGE!

#23

cozmo, there aren't a lot of people who monitor oil temps closely. To be honest, I haven't installed an oil temp gauge yet. Hopefully some veterans with track time can chime in here.

I found an old (1980's) RX-7 Competition handbook, it's got a few recommendations for oil temps. They're listed in section 7 (optimum temps):

...Remember, these values are for a 12A non-turbo, used in a race environment.

Recommended oil temperature (oil pan): 195-230F (90-110C).

Max oil temperature: 250F (120C).

My personal opinion is that anyone who sees high ambient temps or track duty should look at simple oil cooling upgrades (for instance: temperature-controlled fan for oil cooler, second OEM oil cooler from an R1) before performing major cooling upgrades (eg: V-mount radiator setup, aftermarket front bumper, vented hood).

-s-

I found an old (1980's) RX-7 Competition handbook, it's got a few recommendations for oil temps. They're listed in section 7 (optimum temps):

...Remember, these values are for a 12A non-turbo, used in a race environment.

Recommended oil temperature (oil pan): 195-230F (90-110C).

Max oil temperature: 250F (120C).

My personal opinion is that anyone who sees high ambient temps or track duty should look at simple oil cooling upgrades (for instance: temperature-controlled fan for oil cooler, second OEM oil cooler from an R1) before performing major cooling upgrades (eg: V-mount radiator setup, aftermarket front bumper, vented hood).

-s-