asp medium installed - pics

#1

asp medium installed - pics

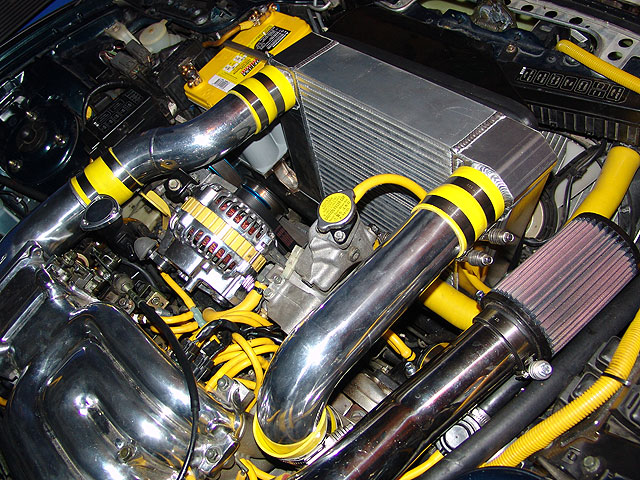

here is my asp medium installed:

another angle:

notes:

install went fine for me, no battery or airfilter issues since i have a smaller battery now and i have open filters dont even come close to the ic.

the only issue left to determine is if the ic pipes will rub on the strut brace... i put the brace on after the pics, and the fit is VERY tight, the pipe ALMOST tough the brace but dont, i have custom motor mounts so my motor dosnt move much, but under hard load it may torque enough to hit, ..... i may have to grind the brace a bit, but time will tell. this is with the pipes fitted the best i could get them concidering rubbing , et.

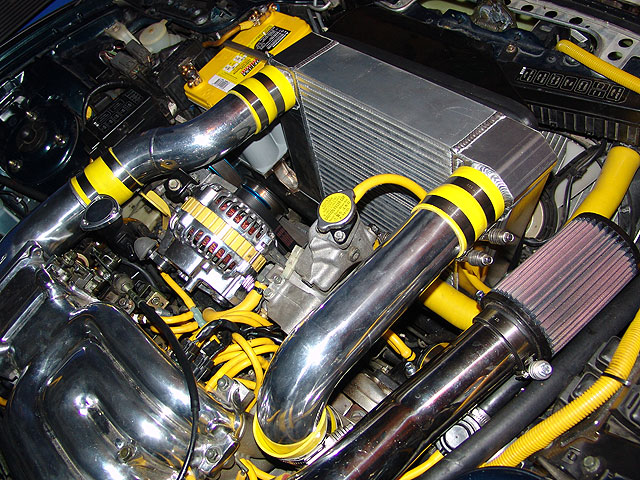

another angle:

notes:

install went fine for me, no battery or airfilter issues since i have a smaller battery now and i have open filters dont even come close to the ic.

the only issue left to determine is if the ic pipes will rub on the strut brace... i put the brace on after the pics, and the fit is VERY tight, the pipe ALMOST tough the brace but dont, i have custom motor mounts so my motor dosnt move much, but under hard load it may torque enough to hit, ..... i may have to grind the brace a bit, but time will tell. this is with the pipes fitted the best i could get them concidering rubbing , et.

#3

Originally posted by iceman4357

looks cool....like yellow?

looks cool....like yellow?

#7

Originally posted by cloud9

looks good I would be interested as too how well that thing cools on the track

looks good I would be interested as too how well that thing cools on the track

Trending Topics

#8

Originally posted by Kevin T. Wyum

If you have any issues with the strut bar we can shorten the pipe before you grind your strut bar.

Kevin T. Wyum

If you have any issues with the strut bar we can shorten the pipe before you grind your strut bar.

Kevin T. Wyum

#14

I personally love the yellow accents. I plan on doing some of the same when I complete my rebuild. I too have a Montego Blue car, and the yellow brake calipers look awesome, so I want to continue the yellow accents.

That alternator is just kick ***! How hard was that to do?

Nice job!

That alternator is just kick ***! How hard was that to do?

Nice job!

#16

Originally posted by bajaman

I personally love the yellow accents. I plan on doing some of the same when I complete my rebuild. I too have a Montego Blue car, and the yellow brake calipers look awesome, so I want to continue the yellow accents.

That alternator is just kick ***! How hard was that to do?

Nice job!

I personally love the yellow accents. I plan on doing some of the same when I complete my rebuild. I too have a Montego Blue car, and the yellow brake calipers look awesome, so I want to continue the yellow accents.

That alternator is just kick ***! How hard was that to do?

Nice job!

https://www.rx7club.com/showthread.p...ght=alternator

#20

Damian, the car looks great! Which Optima battery is that? It looks like the same size as the T51 battery upgrade, but I would really prefer that one since it's an Optima. Thanx in advance.

Zach

Zach

#21

Here is something I posted way back and I found it just for you By the way Kevin, can I get a new cross over pipe from you? I have an older segmented one from M2 that sucks and I don't have an air pump. Thanks

By the way Kevin, can I get a new cross over pipe from you? I have an older segmented one from M2 that sucks and I don't have an air pump. Thanks

Here is one I did a while back for somebody else.

Allright dang it. someone better sticky this,as it is a problem for all the M2 installs I have seen, even the ones installed at M2. Do this. The problem is that the crossover pipe:1 now goes to a slightly lower spot under the hood as before it went to the middle and highest point. 2 the pipe is not bent sharply enough. As the stock one has a 90 deg. sharp bend in it. The pipe now sits higher due to the coupler getting in the way of putting the pipe down low enough to get the position that the stock one is in. You need to carefully cut the coupler at a bias so the front (under the bend) is shorter than the rear. Do it slowly and cut a little off then more as needed so you don't cut too much and have no coupler. Basically if you look at the coupler head on it is flat across the top. You want to cut it so it slants down from one side. Only cut the side that couples to the crossover pipe. You then put the coupler onto the crossover pipe and see how much there is when it stops sliding up. If it looks like about the right amount so that the turbo outlet will contact the M2 crossover when you put it together (about 1and1/2 inch or so +/-) you're in good shape. Now hold the coupler on the M2 pipe so the bottom is flat and put the clamp on so it is just above the rib on the pipe. This may take a few tries as the coupler wants to slide off the pipe and get crooked. When you get it on there now put the pipe onto the turbo outlet. the pipe should now set lower and clear the brace.

Make sure that the fan wires are not under the intercooler duct too as this will cause it to set up a bit and short your wires to boot.

One more thing to check is a bolt on the frame brace that holds a clamp for a coolant line must be removed to get the intertcooler to set right.

The intercooler also can be moved in position slightly front to back and it will slightly change the height of the pipe. Just loosen the clamps and move it a bit. it will also help with the duct not lining up if you push the intercooler against it.

This now should cure one problem but the rubbing on the hood will still happen untill you take a mallet and some wood and LIGHTLY bang the pipe a bit flatter where it is rubbing on the hood. this is with the stock rad. and fans so some may not have the secondary problem.Also I have some rubber under the intercooler that sets it up just a bit which may be causing this.

By the way Kevin, can I get a new cross over pipe from you? I have an older segmented one from M2 that sucks and I don't have an air pump. Thanks

By the way Kevin, can I get a new cross over pipe from you? I have an older segmented one from M2 that sucks and I don't have an air pump. ThanksHere is one I did a while back for somebody else.

Allright dang it. someone better sticky this,as it is a problem for all the M2 installs I have seen, even the ones installed at M2. Do this. The problem is that the crossover pipe:1 now goes to a slightly lower spot under the hood as before it went to the middle and highest point. 2 the pipe is not bent sharply enough. As the stock one has a 90 deg. sharp bend in it. The pipe now sits higher due to the coupler getting in the way of putting the pipe down low enough to get the position that the stock one is in. You need to carefully cut the coupler at a bias so the front (under the bend) is shorter than the rear. Do it slowly and cut a little off then more as needed so you don't cut too much and have no coupler. Basically if you look at the coupler head on it is flat across the top. You want to cut it so it slants down from one side. Only cut the side that couples to the crossover pipe. You then put the coupler onto the crossover pipe and see how much there is when it stops sliding up. If it looks like about the right amount so that the turbo outlet will contact the M2 crossover when you put it together (about 1and1/2 inch or so +/-) you're in good shape. Now hold the coupler on the M2 pipe so the bottom is flat and put the clamp on so it is just above the rib on the pipe. This may take a few tries as the coupler wants to slide off the pipe and get crooked. When you get it on there now put the pipe onto the turbo outlet. the pipe should now set lower and clear the brace.

Make sure that the fan wires are not under the intercooler duct too as this will cause it to set up a bit and short your wires to boot.

One more thing to check is a bolt on the frame brace that holds a clamp for a coolant line must be removed to get the intertcooler to set right.

The intercooler also can be moved in position slightly front to back and it will slightly change the height of the pipe. Just loosen the clamps and move it a bit. it will also help with the duct not lining up if you push the intercooler against it.

This now should cure one problem but the rubbing on the hood will still happen untill you take a mallet and some wood and LIGHTLY bang the pipe a bit flatter where it is rubbing on the hood. this is with the stock rad. and fans so some may not have the secondary problem.Also I have some rubber under the intercooler that sets it up just a bit which may be causing this.

#22

"By the way Kevin, can I get a new cross over pipe from you?"

The new cast ones or the straight ones?

"Allright dang it. someone better sticky this,as it is a problem for all the M2 installs I have seen, even the ones installed at M2. Do this. The problem is that the crossover pipe:1 now goes to a slightly lower spot under the hood as before it went to the middle and highest point. 2 the pipe is not bent sharply enough. As the stock one has a 90 deg. sharp bend in it."

I can't speak the M2 ones as I haven't seen one in person or used one but my normal turbo side tubes are actually not 90 degree bends, they're 105 degree bends.

"The pipe now sits higher due to the coupler getting in the way of putting the pipe down low enough to get the position that the stock one is in. You need to carefully cut the coupler at a bias so the front (under the bend) is shorter than the rear. Do it slowly and cut a little off then more as needed so you don't cut too much and have no coupler. Basically if you look at the coupler head on it is flat across the top. You want to cut it so it slants down from one side. Only cut the side that couples to the crossover pipe. You then put the coupler onto the crossover pipe and see how much there is when it stops sliding up. If it looks like about the right amount so that the turbo outlet will contact the M2 crossover when you put it together (about 1and1/2 inch or so +/-) you're in good shape. Now hold the coupler on the M2 pipe so the bottom is flat and put the clamp on so it is just above the rib on the pipe. This may take a few tries as the coupler wants to slide off the pipe and get crooked. When you get it on there now put the pipe onto the turbo outlet. the pipe should now set lower and clear the brace."

The coupler shouldn't cause an issue, at least with the black ones I use, I suppose those rigid glossy ones could create the problem you describe though and I believe M2 was using those. So M2 was using a 90 degree bend out of the turbo outlet?

"Make sure that the fan wires are not under the intercooler duct too as this will cause it to set up a bit and short your wires to boot.

One more thing to check is a bolt on the frame brace that holds a clamp for a coolant line must be removed to get the intertcooler to set right.

The intercooler also can be moved in position slightly front to back and it will slightly change the height of the pipe. Just loosen the clamps and move it a bit. it will also help with the duct not lining up if you push the intercooler against it.

This now should cure one problem but the rubbing on the hood will still happen untill you take a mallet and some wood and LIGHTLY bang the pipe a bit flatter where it is rubbing on the hood. this is with the stock rad. and fans so some may not have the secondary problem.Also I have some rubber under the intercooler that sets it up just a bit which may be causing this."

A lot of good tips in there that people likely miss, although I don't like the banging on the tubes. The details a lot of people miss that you've pointed out including your rubber piece under the IC would cause rubbing. Eliminate those problems and there shouldn't be an issue. Good post.

Kevin T. Wyum

The new cast ones or the straight ones?

"Allright dang it. someone better sticky this,as it is a problem for all the M2 installs I have seen, even the ones installed at M2. Do this. The problem is that the crossover pipe:1 now goes to a slightly lower spot under the hood as before it went to the middle and highest point. 2 the pipe is not bent sharply enough. As the stock one has a 90 deg. sharp bend in it."

I can't speak the M2 ones as I haven't seen one in person or used one but my normal turbo side tubes are actually not 90 degree bends, they're 105 degree bends.

"The pipe now sits higher due to the coupler getting in the way of putting the pipe down low enough to get the position that the stock one is in. You need to carefully cut the coupler at a bias so the front (under the bend) is shorter than the rear. Do it slowly and cut a little off then more as needed so you don't cut too much and have no coupler. Basically if you look at the coupler head on it is flat across the top. You want to cut it so it slants down from one side. Only cut the side that couples to the crossover pipe. You then put the coupler onto the crossover pipe and see how much there is when it stops sliding up. If it looks like about the right amount so that the turbo outlet will contact the M2 crossover when you put it together (about 1and1/2 inch or so +/-) you're in good shape. Now hold the coupler on the M2 pipe so the bottom is flat and put the clamp on so it is just above the rib on the pipe. This may take a few tries as the coupler wants to slide off the pipe and get crooked. When you get it on there now put the pipe onto the turbo outlet. the pipe should now set lower and clear the brace."

The coupler shouldn't cause an issue, at least with the black ones I use, I suppose those rigid glossy ones could create the problem you describe though and I believe M2 was using those. So M2 was using a 90 degree bend out of the turbo outlet?

"Make sure that the fan wires are not under the intercooler duct too as this will cause it to set up a bit and short your wires to boot.

One more thing to check is a bolt on the frame brace that holds a clamp for a coolant line must be removed to get the intertcooler to set right.

The intercooler also can be moved in position slightly front to back and it will slightly change the height of the pipe. Just loosen the clamps and move it a bit. it will also help with the duct not lining up if you push the intercooler against it.

This now should cure one problem but the rubbing on the hood will still happen untill you take a mallet and some wood and LIGHTLY bang the pipe a bit flatter where it is rubbing on the hood. this is with the stock rad. and fans so some may not have the secondary problem.Also I have some rubber under the intercooler that sets it up just a bit which may be causing this."

A lot of good tips in there that people likely miss, although I don't like the banging on the tubes. The details a lot of people miss that you've pointed out including your rubber piece under the IC would cause rubbing. Eliminate those problems and there shouldn't be an issue. Good post.

Kevin T. Wyum

#23

Originally posted by BoostedRex

Damian, the car looks great! Which Optima battery is that? It looks like the same size as the T51 battery upgrade, but I would really prefer that one since it's an Optima. Thanx in advance.

Zach

Damian, the car looks great! Which Optima battery is that? It looks like the same size as the T51 battery upgrade, but I would really prefer that one since it's an Optima. Thanx in advance.

Zach

its the 51R, r for reversed terminals i think.

here is my thread on it and the tray:

https://www.rx7club.com/showthread.p...hlight=battery

#24

Hey there Kevin. I don't know the differance between the two "new" pipes, do you have them posted somewhere?

Mine is pretty beat and I need a new one. Mine is also a M2 unit designed to go around the air pump I think???

The cut I made in the coupler is where the bend is comming out of the turbo. You can see in the pics above the 2nd one where the bend creates an deformation of the yellow coupler. This is what causes (on mine at least) the pipe to sit up high and causes a contition where in the new pipe does not sit paralell to the turbo outlet. I have no idea if this has been cured but I'm interested to find out!!

Mine is pretty beat and I need a new one. Mine is also a M2 unit designed to go around the air pump I think???

The cut I made in the coupler is where the bend is comming out of the turbo. You can see in the pics above the 2nd one where the bend creates an deformation of the yellow coupler. This is what causes (on mine at least) the pipe to sit up high and causes a contition where in the new pipe does not sit paralell to the turbo outlet. I have no idea if this has been cured but I'm interested to find out!!