Are all ceramic coatings equal?

#1

Are all ceramic coatings equal?

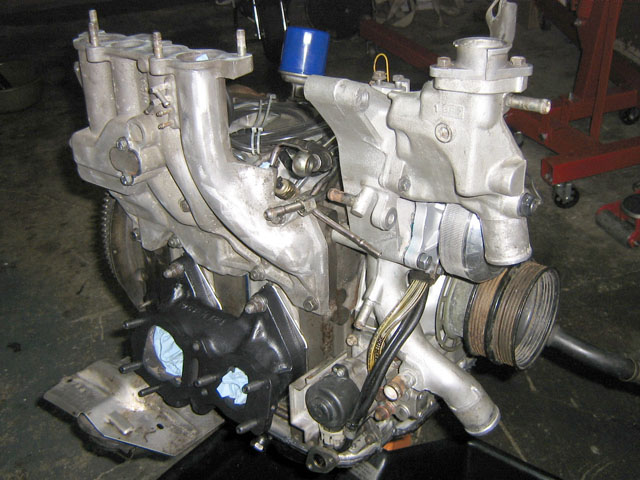

I understand that there is black, chrome like and grey, but are all black ceramic coatins the same quality and heat range? Is there any difference between the way it is applied, or the base material itself? Just a thought as I am getting my UIM and LIM done soon.

#3

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

I'll see if I can get my coater to post something up.....

The coatings that he uses are meant specifically for the heat of the rotary engine. Especially when it comes to exhaust components, all ceramic coatings aren't created equal. My jet-hotted dp flaked to nothing after about a year.

The coatings that he uses are meant specifically for the heat of the rotary engine. Especially when it comes to exhaust components, all ceramic coatings aren't created equal. My jet-hotted dp flaked to nothing after about a year.

#4

I've had 2 downpipes Jet-Hot coated with their 2000 degree coating, and it's VERY durable. Ran one for years, daily driven, looked like new when I took it off.

Hell, you can't remove the Jet-Hot with a wire wheel! I TRIED!

Now, this is the 2000 degree stuff. Their lesser stuff will doubtless have problems. And, I wouldn't trust it on real hot stuff, like manifolds and turbine housings - 3600 or go home there.

Dale

Hell, you can't remove the Jet-Hot with a wire wheel! I TRIED!

Now, this is the 2000 degree stuff. Their lesser stuff will doubtless have problems. And, I wouldn't trust it on real hot stuff, like manifolds and turbine housings - 3600 or go home there.

Dale

#7

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

Dale, thanks for the input. It's possible that I had a lower temp jet hot on my dp.

Northern7, it's a satin black. if you search under my username and 'ceramic coating' in the fs section you'll find pics.

Northern7, it's a satin black. if you search under my username and 'ceramic coating' in the fs section you'll find pics.

Trending Topics

#11

Just thought I'd put this out there....I was an engineer at Piper Aircraft for several years and was involved in fixing a problem with the turbine exhaust manifolds on the PT6 in the Malibu Meridian aircraft (500hp). Initially they where steel that was polished, but after about 6 months, they would start to rust and customer complaints would roll in. For those not familiar, if you have ever flown a commercial turbo-prop aircraft they are the exhaust tips that stick out of the engine cowl just aft of the prop. Anyway, we had them ceramic coated gray/silver and never had any problems, or customer complaints, after that. I'll have to reveiw my docs for the specs and the vendor as it has been several years since I was involved. I'm not sure the color plays a role in the operating temp of the coating.

#13

#15

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

something that size is around 125. it's warranted for life against unprovoked cracking, peeling etc. when you send old rusty parts, you really get your money's worth b/c there's no extra prep charge. I have some pics from a customer's T78 setup (treceb) and i wish like hell i'd taken 'before' pics, his parts looked like they'd spent time with the Titanic  after I got them back he didnt believe they were his parts, they looked better than new

after I got them back he didnt believe they were his parts, they looked better than new

after I got them back he didnt believe they were his parts, they looked better than new

after I got them back he didnt believe they were his parts, they looked better than new

#19

#20

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

Thanks for the props guys  . turnaround on ceramic'ed parts varies based on the workload of the shop doing it, but it's usually from 1-2 weeks for prep, coating, baking, and tumbling.

. turnaround on ceramic'ed parts varies based on the workload of the shop doing it, but it's usually from 1-2 weeks for prep, coating, baking, and tumbling.

Anyone interested can PM me for any quotes.

Riz, polished parts do look better in the short term, but in the long run the ceramic'ed parts will retain their shine. The polish is nice and smooth, whereas the ceramic is a coating over the grainy stock finish. I've had my guy give a quick sanding to some parts (usually uim's) to smooth them a bit, then coat over that.

. turnaround on ceramic'ed parts varies based on the workload of the shop doing it, but it's usually from 1-2 weeks for prep, coating, baking, and tumbling.

. turnaround on ceramic'ed parts varies based on the workload of the shop doing it, but it's usually from 1-2 weeks for prep, coating, baking, and tumbling.Anyone interested can PM me for any quotes.

Riz, polished parts do look better in the short term, but in the long run the ceramic'ed parts will retain their shine. The polish is nice and smooth, whereas the ceramic is a coating over the grainy stock finish. I've had my guy give a quick sanding to some parts (usually uim's) to smooth them a bit, then coat over that.

#21

Thanks for the props guys  . turnaround on ceramic'ed parts varies based on the workload of the shop doing it, but it's usually from 1-2 weeks for prep, coating, baking, and tumbling.

. turnaround on ceramic'ed parts varies based on the workload of the shop doing it, but it's usually from 1-2 weeks for prep, coating, baking, and tumbling.

Anyone interested can PM me for any quotes.

Riz, polished parts do look better in the short term, but in the long run the ceramic'ed parts will retain their shine. The polish is nice and smooth, whereas the ceramic is a coating over the grainy stock finish. I've had my guy give a quick sanding to some parts (usually uim's) to smooth them a bit, then coat over that.

. turnaround on ceramic'ed parts varies based on the workload of the shop doing it, but it's usually from 1-2 weeks for prep, coating, baking, and tumbling.

. turnaround on ceramic'ed parts varies based on the workload of the shop doing it, but it's usually from 1-2 weeks for prep, coating, baking, and tumbling.Anyone interested can PM me for any quotes.

Riz, polished parts do look better in the short term, but in the long run the ceramic'ed parts will retain their shine. The polish is nice and smooth, whereas the ceramic is a coating over the grainy stock finish. I've had my guy give a quick sanding to some parts (usually uim's) to smooth them a bit, then coat over that.

You have any pictures of a sanded down, then CC'd part? I always wondered why it looked grainy like that. Didn't realize that was the stock finish.

Rich, I've been debating whether to polish or CC my LIM. I'll be running stock turbos on my set-up for the time being so I wanted to know whether heat retention would still be as big an issue to warrant CC'ing (Chrome Finish) over polishing? Also, what about the black finish? I have parts that were powdercoated black and was wondering if you have any black finish that would match that?

If you'd like, I could PM you the questions or you could PM me the answers, but I'm sure this info could help someone else debating between polish and CC out.

TIA!

#22

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

Hey Riz,

i'd absolutely recommend coating the LIM in either the 1200 degree chrome or 3600 degree satin black due to it's close proximity to the turbo(s). The UIM is really a toss up......i'm not a big fan of polishing b/c of the upkeep required, plus it has only aesthetic benefits.

As to whether it'll match the black powdercoating, it's tough to say. it prolly won't be an exact match, but will be close.

i'd absolutely recommend coating the LIM in either the 1200 degree chrome or 3600 degree satin black due to it's close proximity to the turbo(s). The UIM is really a toss up......i'm not a big fan of polishing b/c of the upkeep required, plus it has only aesthetic benefits.

As to whether it'll match the black powdercoating, it's tough to say. it prolly won't be an exact match, but will be close.

Thread

Thread Starter

Forum

Replies

Last Post

eplusz

General Rotary Tech Support

15

10-07-15 05:04 PM