AEM IGN-1A Mercury Marine ignition coil info/install

#176

The AEM instructions for the 30-2853 coils says to connect pin C to ground on the same cylinder head that the spark from that coil goes to.

Is it necessary/advisable to run individual grounds from each coil? Or can they be ganged together then split to connect at each rotor housing?

Is it necessary/advisable to run individual grounds from each coil? Or can they be ganged together then split to connect at each rotor housing?

#177

As was mentioned, all the negative wires can be combined and grounded to one point on the rotor housing(s) The C terminal ground reference is for OEM application to sense a fault/misfire. Our systems are simple and just require 3 key elements, trigger/power/ground!

#179

Joined: Jan 2011

Posts: 2,196

Likes: 235

From: California

We created an instructional video for our adapter harness customers, but would like to share it with the community  Our video demonstrates how to effectively de-pin the OEM igniter connector using common items and can easily be done at home. The re-pinning procedure in the is specific to our harness, but the wire colors can be used as a reference. Enjoy!

Our video demonstrates how to effectively de-pin the OEM igniter connector using common items and can easily be done at home. The re-pinning procedure in the is specific to our harness, but the wire colors can be used as a reference. Enjoy!

Note: We take no responsibility for any damage our harm caused from using this video, use it at your own risk!

-Dan

Our video demonstrates how to effectively de-pin the OEM igniter connector using common items and can easily be done at home. The re-pinning procedure in the is specific to our harness, but the wire colors can be used as a reference. Enjoy!

Our video demonstrates how to effectively de-pin the OEM igniter connector using common items and can easily be done at home. The re-pinning procedure in the is specific to our harness, but the wire colors can be used as a reference. Enjoy! Note: We take no responsibility for any damage our harm caused from using this video, use it at your own risk!

-Dan

#180

Joined: Jan 2011

Posts: 2,196

Likes: 235

From: California

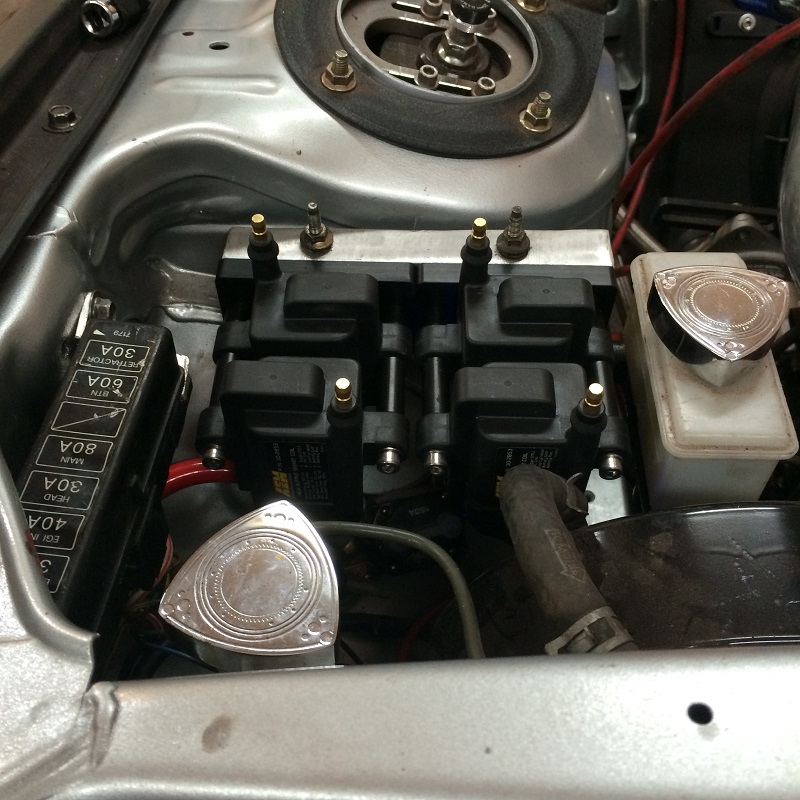

Hey everyone, here's a piece we've been working on for those of you looking for an universal coil mounting solution. There are a few options out there currently (including making your own setup, or our current cruise control location mount -> FD3S AEM Coil Upgrade - SakeBomb Garage ). This is however not an optimal solution for those with a RHD car (ABS unit is in the way), those wishing to keep cruise control, or those with other motor swaps requiring extra coils. Mounting coils to the AC bracket is an option if you are willing to delete AC or PS and make your own mounting provisions.

For those looking for something more straight forward we have designed a simple and effective no-compromise solution. These mounts also facilitate custom installations or mounting these coils on other chassis. Our universal coil mounts in 6061 Aluminum are in production now. We're just waiting at this point for CNC production run to finish.

Each mount holds two coils. They are modular and can connected back-to-back, side-to-side, both (in one large block), or mounted individually. Threaded provisions on the sides and back of the coil mount brackets allow for attachment to a secondary bracket for a non-flat location, or to be attached directly to a flat section of your chassis. We are also finishing up an FD specific sheet metal mount that sits low-down on the frame rail for 13b-20b applications.

IMG_8533_zpsf3ef96f8.jpg?t=1372708962

(back to back) http://i723.photobucket.com/albums/w...ps72d184a1.jpg

For those looking for something more straight forward we have designed a simple and effective no-compromise solution. These mounts also facilitate custom installations or mounting these coils on other chassis. Our universal coil mounts in 6061 Aluminum are in production now. We're just waiting at this point for CNC production run to finish.

Each mount holds two coils. They are modular and can connected back-to-back, side-to-side, both (in one large block), or mounted individually. Threaded provisions on the sides and back of the coil mount brackets allow for attachment to a secondary bracket for a non-flat location, or to be attached directly to a flat section of your chassis. We are also finishing up an FD specific sheet metal mount that sits low-down on the frame rail for 13b-20b applications.

IMG_8533_zpsf3ef96f8.jpg?t=1372708962

(back to back) http://i723.photobucket.com/albums/w...ps72d184a1.jpg

Last edited by SakeBomb Garage; 07-03-13 at 02:44 PM.

#186

so is anyone doing 30min - 1hr track sessions with these coils? let's hear some feedback!

street or dynos don't really stress the coils but high rpm for prolonged periods is another story.

I got a set since everybody praises them (hype train) but I did some more reading and found out we're getting the leading coils to about 90% duty cycle (60% in direct fire) at 8000 rpm and the trailings to 60% at the most recommended dwell settings.

I worry about burning leading coils during a track session in high rpm boost and maybe losing the engine! Comments?

street or dynos don't really stress the coils but high rpm for prolonged periods is another story.

I got a set since everybody praises them (hype train) but I did some more reading and found out we're getting the leading coils to about 90% duty cycle (60% in direct fire) at 8000 rpm and the trailings to 60% at the most recommended dwell settings.

I worry about burning leading coils during a track session in high rpm boost and maybe losing the engine! Comments?

#187

so is anyone doing 30min - 1hr track sessions with these coils? let's hear some feedback!

street or dynos don't really stress the coils but high rpm for prolonged periods is another story.

I got a set since everybody praises them (hype train) but I did some more reading and found out we're getting the leading coils to about 90% duty cycle (60% in direct fire) at 8000 rpm and the trailings to 60% at the most recommended dwell settings.

I worry about burning leading coils during a track session in high rpm boost and maybe losing the engine! Comments?

street or dynos don't really stress the coils but high rpm for prolonged periods is another story.

I got a set since everybody praises them (hype train) but I did some more reading and found out we're getting the leading coils to about 90% duty cycle (60% in direct fire) at 8000 rpm and the trailings to 60% at the most recommended dwell settings.

I worry about burning leading coils during a track session in high rpm boost and maybe losing the engine! Comments?

What settings are you basing this 90% dwell figure on? I am assuming you are using the PFC since you are discussing waste spark. Did you look into the dwell settings that SBG provides? The way they have it setup they only dwell it up to 80% duty cycle on the leadings at 8000 RPM for PFC users. More gains could be had by running direct fire, but you would need another ECU for that.

#189

If you are concerned about it, reduce the dwell. You only need enough dwell time to be able to light off the mixture. If your car can run well at 3.0 ms there is no need to run a larger dwell setting just for the sake of running more dwell. Once again, with direct fire you can run longer dwell settings with lower duty cycle which is nice. For you with waste spark you have less of a window to operate in. The 80% duty cycle is not a hard number, you can dwell higher as long as you are not sitting there at that duty cycle. There is no set amount of time you are "allowed" to run over 80% so the general practice is to keep it to a minimum whenever possible.

Even though you are running through high RPM's a lot more on track than you are on street, you are still not sitting in those RPM areas for long extended times unless you have a track with a long high speed straight.

Even though you are running through high RPM's a lot more on track than you are on street, you are still not sitting in those RPM areas for long extended times unless you have a track with a long high speed straight.

#190

Could someone please please PLEASE god forbid make a bracket for the FC so i can buy it? i dont have access to a welder and i just need to hurry up and get these damn things mounted.

#194

Joined: Jan 2011

Posts: 2,196

Likes: 235

From: California

We've had a few FC customers use our universal bracket with the AEM / ign-1a coils with great results. To make for a straight forward install we also offer a plug and play flying lead harness (everything is ready to go, you just hook up 4 signal wires and a power signal to flip the relay on). And if you're feeling lazy, we can make custom length ultra-low resistance wires to your spec (we have a separate page for the custom wire sets).

We've also had a handful of 3 rotor, v6, and v8 customers as well... the FC has plenty of room for the mounts, and they allow you to place them in various orientations as space/design allows.

Universal mounts, flying lead, and coils: AEM/IGN-1A Universal Smart Coil Mounting System - SakeBomb Garage LLC

Custom Plug wires: Custom Length Spark Plug Wires for AEM Smart Coils or Custom Applications - SakeBomb Garage LLC

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

#195

has anyone installed this on a car running an AEM ecu as well?

i see all the coil dwell settings for PFC, but its nothing like that in the AEM.

anyone know the settings to use with these coils on an AEM ecu?

thanks!

i see all the coil dwell settings for PFC, but its nothing like that in the AEM.

anyone know the settings to use with these coils on an AEM ecu?

thanks!

#199

I use them in direct fire configuration on a GTX4294R turbo @ 30psi on E85.

C. Ludwig made the harness and altered my existing map to accommodate the changes for direct fire. I highly recommend you reach out to him for assistance.

#200

I've been using them with the AEM EMS v1 ECU for about 2 years now.

I use them in direct fire configuration on a GTX4294R turbo @ 30psi on E85.

C. Ludwig made the harness and altered my existing map to accommodate the changes for direct fire. I highly recommend you reach out to him for assistance.

I use them in direct fire configuration on a GTX4294R turbo @ 30psi on E85.

C. Ludwig made the harness and altered my existing map to accommodate the changes for direct fire. I highly recommend you reach out to him for assistance.

i bought the setup from Sakebomb, so i don't feel its right to reach out to ludwig to support something he didn't sell. Sakebomb didn't know how to set the aem up though.

about to just part this thing out!