2k rpm idle. STILL!

#1

aright so i've posted a few different threads about my fd's shitty condition and have replaced all the parts thaught to have been the problem: ecu, tps, iac valve. currently my car has a apexi ecu but maby it just needs to be tuned, i dont know all i know is that it runs smooth buth idles way to high.

#2

aright so i've posted a few different threads about my fd's shitty condition and have replaced all the parts thaught to have been the problem: ecu, tps, iac valve. currently my car has a apexi ecu but maby it just needs to be tuned, i dont know all i know is that it runs smooth buth idles way to high.

Im assuming you have already cut the 4 wires to prevent it from idleing high?

#3

One of my butterfly valves was stuck slightly open on the throttle body and caused a high idle. It took me forever and a day to figure that out.

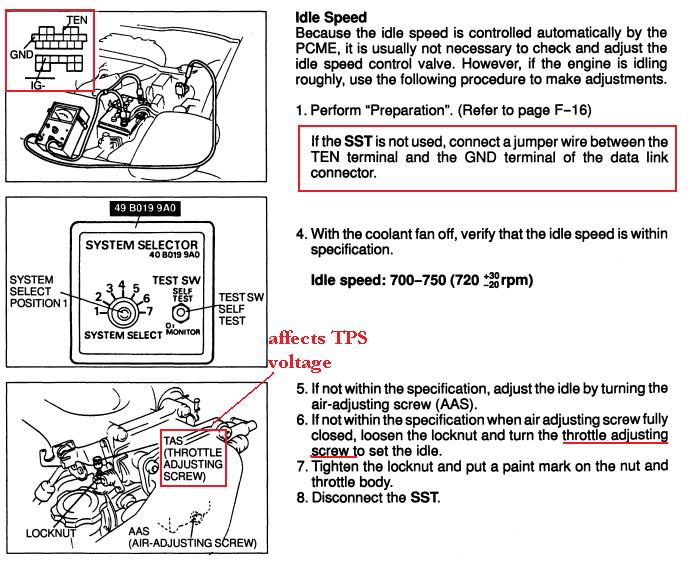

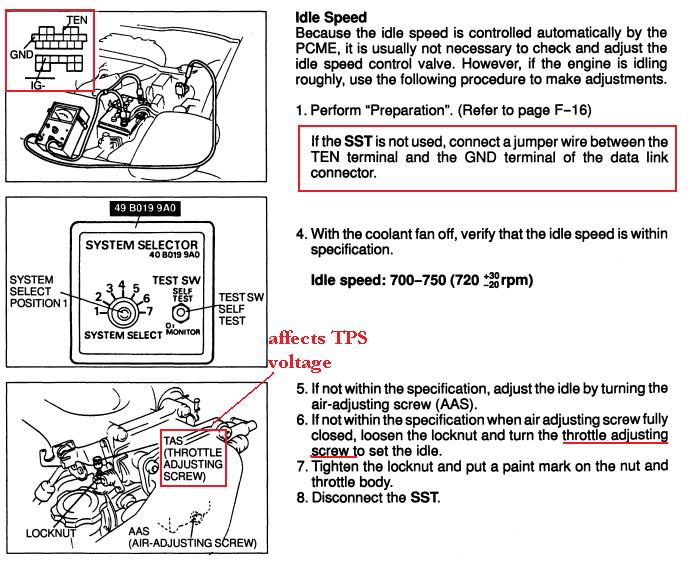

Or have you tried using the idle adjustment screws? One on the top or one on the throttle body?

Or have you tried using the idle adjustment screws? One on the top or one on the throttle body?

#5

1. Verify no vacuum leaks. Pressure testing your intake system works well, do some searches on that

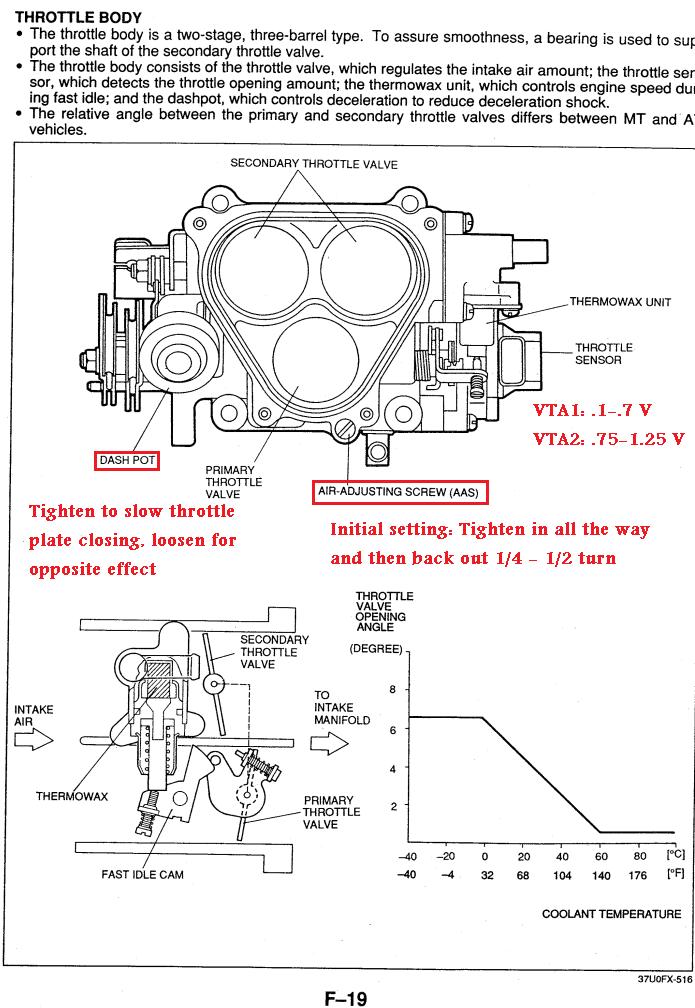

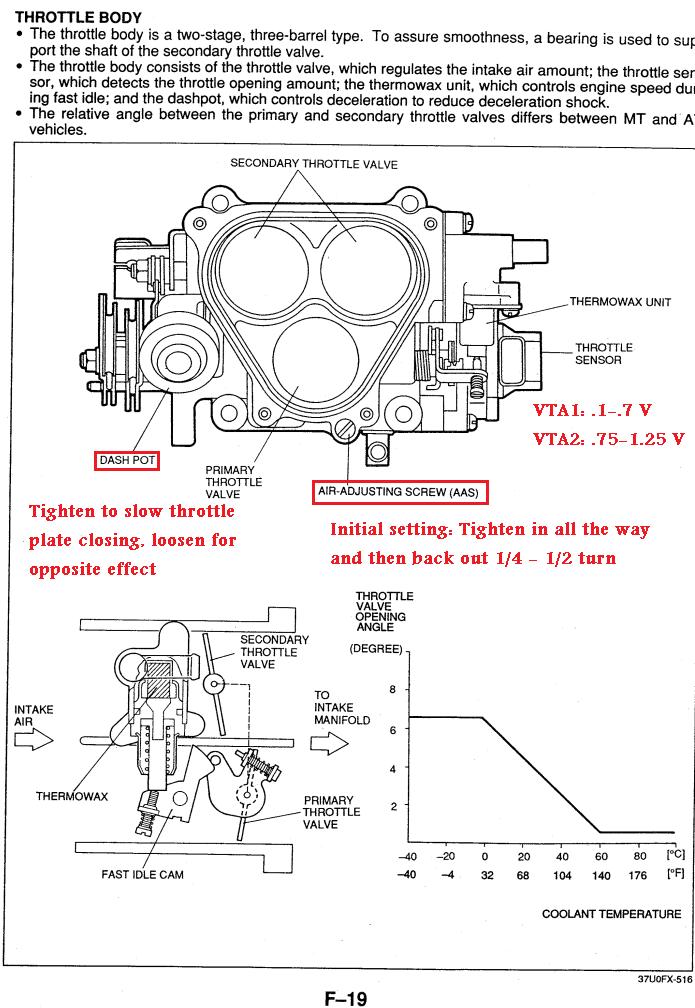

2. adjust air adjust screw under TB elbow and verify throttle plates aren't being held open for whatever reason (throttle cable etc). Set TPS.

2. disengage dashpot completely so that it does not make contact with the throttle plates on deceleration

3. perform PFC idle learn. search for this, I have covered it in one of my threads.

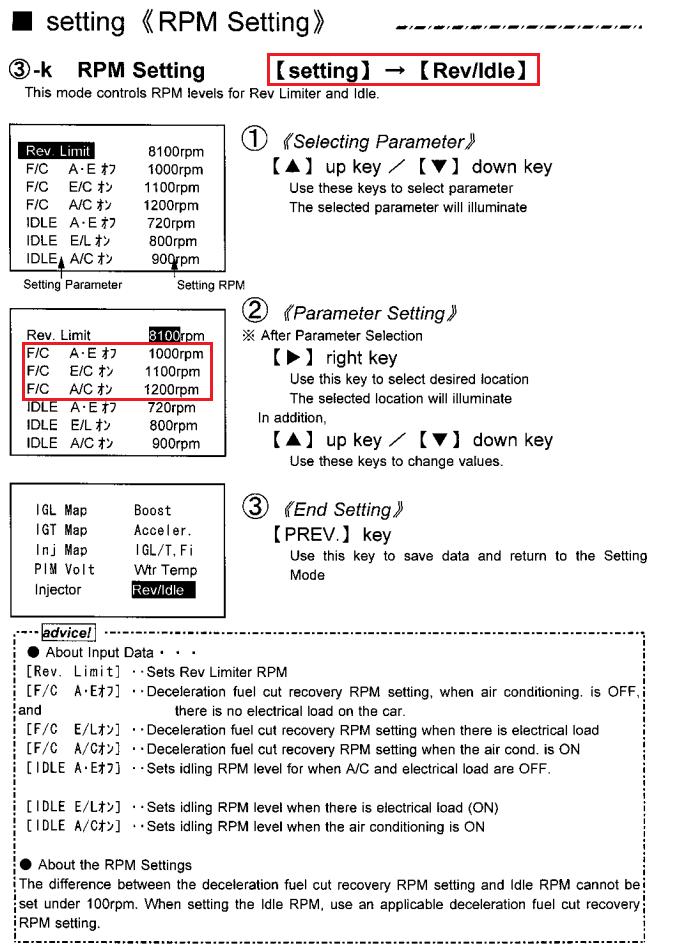

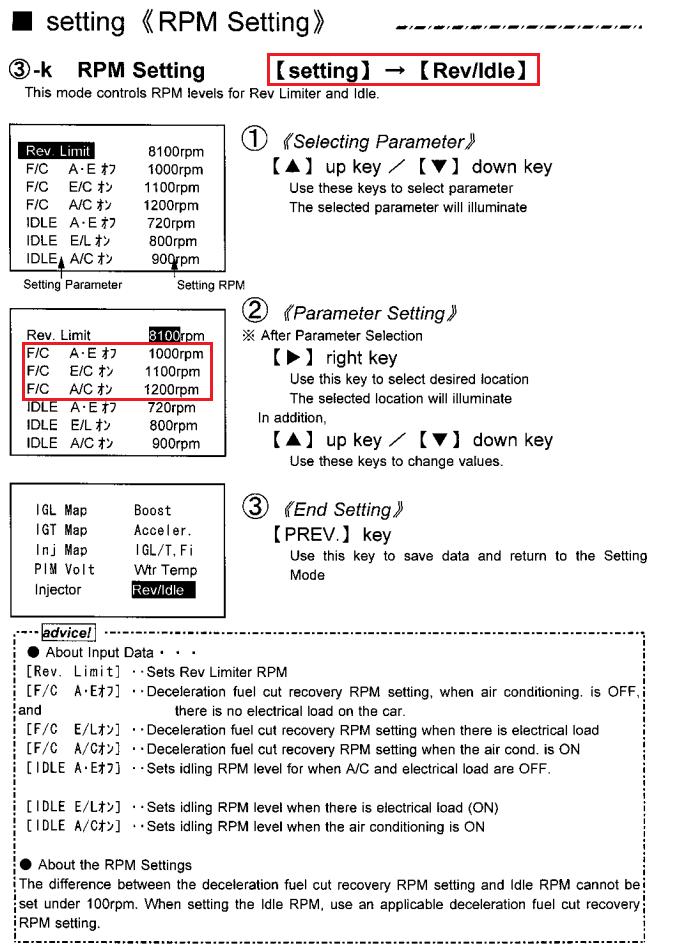

4. set all three fuel cut settings (under settings --> rev/idle) to 1280. If idle still sticks on decel, decrease all 3 setting progressively in 10 rpm increments, testing each time. If idle stumbles on decel, increase all 3 settings progressively in 10 rpm increments, testing each time

#6

i tried the one that you can see when you take off the tb elbow pipe

#7

1. Verify no vacuum leaks. Pressure testing your intake system works well, do some searches on that

2. adjust air adjust screw under TB elbow and verify throttle plates aren't being held open for whatever reason (throttle cable etc). Set TPS.

2. disengage dashpot completely so that it does not make contact with the throttle plates on deceleration

3. perform PFC idle learn. search for this, I have covered it in one of my threads.

4. set all three fuel cut settings (under settings --> rev/idle) to 1280. If idle still sticks on decel, decrease all 3 setting progressively in 10 rpm increments, testing each time. If idle stumbles on decel, increase all 3 settings progressively in 10 rpm increments, testing each time

Trending Topics

#13

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

Just because the throttle cable seems fine doesnt mean it is. Mine seemed fine too and installing a new one solved my persistent 1500 rpm sticking idle problem.

I'd recommend replacing it, through Ray it's like 50 bucks and it can be replaced in 10 minutes.

I'd recommend replacing it, through Ray it's like 50 bucks and it can be replaced in 10 minutes.

#14

Assuming a functional TPS was originally calibrated with the throttle plates not stuck open (factory TB adjustment with no throttle/cruise cable problems),

you will notice your TPS voltages are too high if something is wrong. You would go to etc.-->sensor check. VTA2 (narrow range sensor) should be at or under 1 volt with the engine warmed up and the fast idle disengaged. I mean technically it could be a little higher than that (spec is .75-1.25), but usually you will see narrow range TPS voltage at 2+ volts if something is making the throttle plates stick.

you will notice your TPS voltages are too high if something is wrong. You would go to etc.-->sensor check. VTA2 (narrow range sensor) should be at or under 1 volt with the engine warmed up and the fast idle disengaged. I mean technically it could be a little higher than that (spec is .75-1.25), but usually you will see narrow range TPS voltage at 2+ volts if something is making the throttle plates stick.

#15

alright i got it to idle between 1200 and 1550 with the pfc, i tried putting the stock ecu but it would die, is that just cuz of the 4 wires that i cut for the pfc?

but i did what arghx said and that got the idle to drop a few 100 rpms.

and with the stock ecu the check engine lights on, partially because of the 4 wires i think but i doubt thats the only reason.

nik

but i did what arghx said and that got the idle to drop a few 100 rpms.

and with the stock ecu the check engine lights on, partially because of the 4 wires i think but i doubt thats the only reason.

nik

#16

Disconnect the throttle cable and cruise control cables. Check TPS voltage (VTA1 and VTA2 under etc. --> sensor check) both before and after this. If it changes, you have a problem with either cable. There should be 1-2mm freeplay in each per FSM specs.

What you have to do now is keep decreasing the amount of idle air until the idle no longer sticks high but rather begins to idle pretty low or even stumble. Then you can add air back to get a stable idle at a good rpm. Make sure O2 feedback is off under etc. --> function select .

For now set all 3 fuel cut settings to 950 rpm and all three idle speeds to 850 (you will have to raise the F/C settings later to prevent stalling). Loosen the dashpot all the way. Then reset your air adjusting screw to 1/4 turn open. Then with the engine on you need to close the throttle adjust screw until the idle begins to drop. you don't need to jumper the diagnostic connector, that's only for stock ECU. For now, any time you make adjustments to idle speed or fuel cut settings, set all 3 fuel cut or all 3 idle speed values the same. You can make individual changes later down the line.

you don't need to jumper the diagnostic connector, that's only for stock ECU. For now, any time you make adjustments to idle speed or fuel cut settings, set all 3 fuel cut or all 3 idle speed values the same. You can make individual changes later down the line.

If you reduce all the sources of idle air, the idle speed should eventually drop if there are no vacuum leaks. It has to. After adjusting the throttle plate screw (TAS) you may need to check that your TPS is still in spec and possibly adjust it. Then you may need to perform the PFC idle learning procedure, making sure you put the same settings back in after you reset the PFC.

Tuning idle is a cyclical process sometimes involving multiple steps in parallel. You don't do one thing, then do another, then you're done. You go back and forth among multiple processes in both hardware and software. Check for mechanical issues, fiddle with the TB itself and in the PFC, re learn idle, adjust some stuff again in both the hardware and software, maybe even relearn idle again. But if you have a vacuum leak or a messed up throttle cable or some other kind of mechanical problem then that needs to be corrected first.

It can take many hours to get the car to idle like stock, but it's worth it.

What you have to do now is keep decreasing the amount of idle air until the idle no longer sticks high but rather begins to idle pretty low or even stumble. Then you can add air back to get a stable idle at a good rpm. Make sure O2 feedback is off under etc. --> function select .

For now set all 3 fuel cut settings to 950 rpm and all three idle speeds to 850 (you will have to raise the F/C settings later to prevent stalling). Loosen the dashpot all the way. Then reset your air adjusting screw to 1/4 turn open. Then with the engine on you need to close the throttle adjust screw until the idle begins to drop.

you don't need to jumper the diagnostic connector, that's only for stock ECU. For now, any time you make adjustments to idle speed or fuel cut settings, set all 3 fuel cut or all 3 idle speed values the same. You can make individual changes later down the line.

you don't need to jumper the diagnostic connector, that's only for stock ECU. For now, any time you make adjustments to idle speed or fuel cut settings, set all 3 fuel cut or all 3 idle speed values the same. You can make individual changes later down the line.If you reduce all the sources of idle air, the idle speed should eventually drop if there are no vacuum leaks. It has to. After adjusting the throttle plate screw (TAS) you may need to check that your TPS is still in spec and possibly adjust it. Then you may need to perform the PFC idle learning procedure, making sure you put the same settings back in after you reset the PFC.

Tuning idle is a cyclical process sometimes involving multiple steps in parallel. You don't do one thing, then do another, then you're done. You go back and forth among multiple processes in both hardware and software. Check for mechanical issues, fiddle with the TB itself and in the PFC, re learn idle, adjust some stuff again in both the hardware and software, maybe even relearn idle again. But if you have a vacuum leak or a messed up throttle cable or some other kind of mechanical problem then that needs to be corrected first.

It can take many hours to get the car to idle like stock, but it's worth it.

#18

On a Power FC, idle speed is a function of:

-vacuum leaks (must eliminate all)

-primary throttle plate opening angle (throttle adjust screw, fast idle system, anything random that may be holding the throttle plates open)

-air bypassing throttle plates (air adjust screw)

-ISC valve duty cycle (fuel cut and idle speed settings in the PFC, idle learn procedure, TPS voltage to a certain extent, other engine conditions)

-ignition timing (idle IG control for closed loop idle ignition control if ISC is retained. IGL and IGT map in the idle cells if ISC is removed and idle speeds set to 0 in Datalogit)

-stability of vacuum signal, which is a function of porting and ignition timing more than anything else.

-idle mixture if it is too lean, which can result in some surging or stumbling. "too lean" depends on porting, but richer than 13:1 is a good guideline AFR to start with in order to keep idle stable

-vacuum leaks (must eliminate all)

-primary throttle plate opening angle (throttle adjust screw, fast idle system, anything random that may be holding the throttle plates open)

-air bypassing throttle plates (air adjust screw)

-ISC valve duty cycle (fuel cut and idle speed settings in the PFC, idle learn procedure, TPS voltage to a certain extent, other engine conditions)

-ignition timing (idle IG control for closed loop idle ignition control if ISC is retained. IGL and IGT map in the idle cells if ISC is removed and idle speeds set to 0 in Datalogit)

-stability of vacuum signal, which is a function of porting and ignition timing more than anything else.

-idle mixture if it is too lean, which can result in some surging or stumbling. "too lean" depends on porting, but richer than 13:1 is a good guideline AFR to start with in order to keep idle stable

#20

I'm thinking about making a huge idle troubleshooting guide for those who have retained the ISC valve (Chuck Westbrook has covered ISC removal very well). I just have to figure out how I want to organize it, as I can't possibly cover every single cause/problem.

#23

Thread

Thread Starter

Forum

Replies

Last Post

LongDuck

1st Generation Specific (1979-1985)

12

10-07-15 09:12 PM

eplusz

General Rotary Tech Support

15

10-07-15 05:04 PM