My boost control setup - perfect 10-8-10 pattern

#51

C L E A N.

Have you given any consideration that they are close to the turbos and might be heat "influenced:?

I am going to mount mine further forward and am looking for a place where the temperature might be more constant. As goofy as it sounds right behind the radiator may be the best place..........

Keep up the good work!

Have you given any consideration that they are close to the turbos and might be heat "influenced:?

I am going to mount mine further forward and am looking for a place where the temperature might be more constant. As goofy as it sounds right behind the radiator may be the best place..........

Keep up the good work!

#52

good question Ron, i did think about the heat after touching those dam controlers after driving, veeery hot...but you play a trade off of closer = more heat but smaller lines, farther = less heat but longer lines... longer lines = less responsive

but we are talking only a small amount of added line to move them up front more, so its proabably not measurable.... and i dunno if the heat affects these controlers at all...so far i see constant response/level in normal runs (just after warm up) and heat soaked operation ... but I will look for a spot to mount them further up if it presents itself.

another thing to concider is that they are going to get hot no matter where you put them, the air going through them is very hot (primary turbo, super heated air) and the heat transfer of that aluminum is pretty good so they will get hot from the inside out outside, if not from the outside in

but we are talking only a small amount of added line to move them up front more, so its proabably not measurable.... and i dunno if the heat affects these controlers at all...so far i see constant response/level in normal runs (just after warm up) and heat soaked operation ... but I will look for a spot to mount them further up if it presents itself.

another thing to concider is that they are going to get hot no matter where you put them, the air going through them is very hot (primary turbo, super heated air) and the heat transfer of that aluminum is pretty good so they will get hot from the inside out outside, if not from the outside in

Last edited by damian; 04-25-03 at 12:08 AM.

#53

Yeah, I think the elasticity of the line will be a factor, although small. I'm going to use a Gates brand vacuum hose on mine. I have no clue if it is actually "better" than the silicone but it is certificated for use in airplanes. In my orbit that is usually better. It looks like you have Hose Techniques silicone, No?

Geez, talk about fine points - but hey - why not?

Vanishing green car - HAHAHAHAHAHHHHHHHHAAAAAA!

Geez, talk about fine points - but hey - why not?

Vanishing green car - HAHAHAHAHAHHHHHHHHAAAAAA!

Last edited by RonKMiller; 04-25-03 at 12:30 AM.

#54

>> It looks like you have Hose Techniques silicone, No?

nope, akimoto silicone hose kit, very thick walls - only $30 for a kit and 2 kits will do an entire hose job, even comes with some bigger stuff you can use on the brake vac and coolant lines

>>Vanishing green car - HAHAHAHAHHHHHHHHAAAAAA!

ahh, so you watched my vids huh LOL

nope, akimoto silicone hose kit, very thick walls - only $30 for a kit and 2 kits will do an entire hose job, even comes with some bigger stuff you can use on the brake vac and coolant lines

>>Vanishing green car - HAHAHAHAHHHHHHHHAAAAAA!

ahh, so you watched my vids huh LOL

#55

Originally posted by RonKMiller

Yeah, I think the elasticity of the line will be a factor, although small

Yeah, I think the elasticity of the line will be a factor, although small

And yes, we might be "building watches" here (my physics teacher et al) but how about a harpipe connection? Copper tubing? Dunno just brainstorming.

#56

>>than increased friction factors from using longer hose

cover8, i think you have it mixed up...the problem of longer hose IS expansion, not friction...the silicone hose (and rubber) is a bit stretchy and the more hose you have, the more reaction time is lost due to expansion of the hose....

I was talking about heat being an issue with the controller, if the internal parts are changed enough by the heat to cause a change in boost control behavior

cover8, i think you have it mixed up...the problem of longer hose IS expansion, not friction...the silicone hose (and rubber) is a bit stretchy and the more hose you have, the more reaction time is lost due to expansion of the hose....

I was talking about heat being an issue with the controller, if the internal parts are changed enough by the heat to cause a change in boost control behavior

#57

Originally posted by damian

>>than increased friction factors from using longer hose

cover8, i think you have it mixed up...the problem of longer hose IS expansion, not friction...the silicone hose (and rubber) is a bit stretchy and the more hose you have, the more reaction time is lost due to expansion of the hose....

yes, precisely as I wrote...with hardpipe you should not have any flex and therefore have better controllability...with less dampening of control.

I was talking about heat being an issue with the controller, if the internal parts are changed enough by the heat to cause a change in boost control behavior

>>than increased friction factors from using longer hose

cover8, i think you have it mixed up...the problem of longer hose IS expansion, not friction...the silicone hose (and rubber) is a bit stretchy and the more hose you have, the more reaction time is lost due to expansion of the hose....

yes, precisely as I wrote...with hardpipe you should not have any flex and therefore have better controllability...with less dampening of control.

I was talking about heat being an issue with the controller, if the internal parts are changed enough by the heat to cause a change in boost control behavior

#58

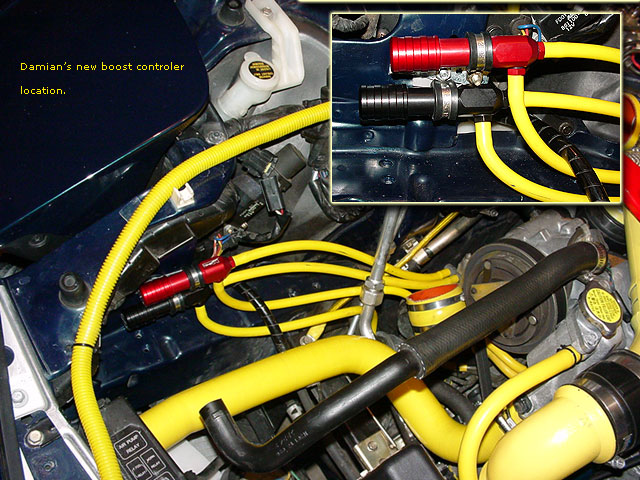

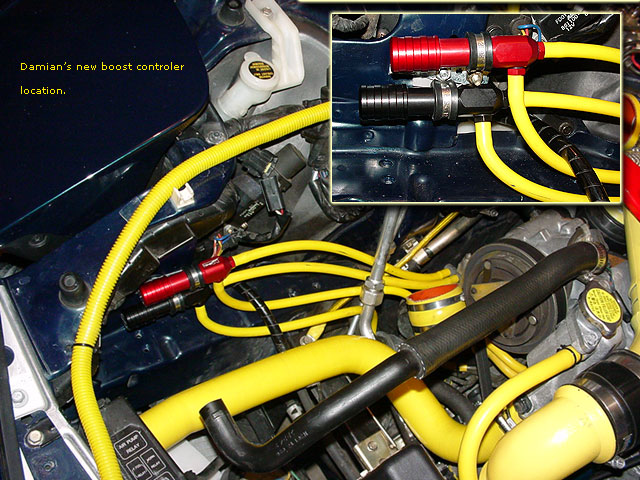

i decided to move the controllers based on the suggestion to get them further away from the turbo heat, so here is my new setup.

Also, i decided to try 'un-looping' them from the stock hose circut, in other words, earlier i just had them tubed like the stock system, but as if they were the solenoids. ..but now I'm trying them with the actuator vents capped off (i know what i just said probably made no sence lol)

pics:

here is the feeble bracket holder i made

new mounting location, up front away from the heat and easier to adjust.

back together

Also, i decided to try 'un-looping' them from the stock hose circut, in other words, earlier i just had them tubed like the stock system, but as if they were the solenoids. ..but now I'm trying them with the actuator vents capped off (i know what i just said probably made no sence lol)

pics:

here is the feeble bracket holder i made

new mounting location, up front away from the heat and easier to adjust.

back together

Last edited by damian; 05-26-03 at 01:24 AM.

#61

Yep, I think they are going to like living there better.

Now that you've had some time to live with the set-up is everything still humming along? I'm not going to be able to get to mine until September.

Now that you've had some time to live with the set-up is everything still humming along? I'm not going to be able to get to mine until September.

#62

What would you think about using the stock precontrol pill for prespool and the hallman device for wastegate...still capping off the header line as mentioned? (cheap *** me trying to avoid buying two Hallmans)

#63

Better yet, get two of the JoeP controllers for the price of one of those Hallmans, assuming the lighter spring he gave me works.

I'm getting ahead of myself. I contacted the guy who makes JoeP controllers, another of the available ball-and-spring controllers, and also available from boostcontrollers.com or wherever the Hallmans were, and he said he had a lighter spring he was messing with and he'd send it to me if I wanted to be a guinea pig. I haven't had time to install them yet, but I will of course let everyone know how it works. The Joe Ps aren't quite as pretty, but they look OK.

jds

I'm getting ahead of myself. I contacted the guy who makes JoeP controllers, another of the available ball-and-spring controllers, and also available from boostcontrollers.com or wherever the Hallmans were, and he said he had a lighter spring he was messing with and he'd send it to me if I wanted to be a guinea pig. I haven't had time to install them yet, but I will of course let everyone know how it works. The Joe Ps aren't quite as pretty, but they look OK.

jds

Originally posted by cover8

What would you think about using the stock precontrol pill for prespool and the hallman device for wastegate...still capping off the header line as mentioned? (cheap *** me trying to avoid buying two Hallmans)

What would you think about using the stock precontrol pill for prespool and the hallman device for wastegate...still capping off the header line as mentioned? (cheap *** me trying to avoid buying two Hallmans)

#64

Well, my initial attempt at doing this with the JoeP valves does not appear to be successful, however I'm not sure if its something I did or something about the controllers themselves. I'm pretty sure I hooked everything up the same as in Damian's setup at the start of the thread, but even at the lowest possible screw position without the thing falling out I am boosting over 10 psi...I didn't push it to see how high, as I still kind of like my apex seals. This is just the primary...I tried to nurse it up into twin mode and see what it would do, and it seemed like maybe it was holding at 10 or so, but I couldn't really tell...once you start being careful with the throttle its not a true test really. At any rate, I had certainly hoped to be able to have a low setting of something less than 10 psi. Damian or anyone else, do you know any particulars about the Hallman spring in your controllers? Mine are supposed to be lighter than the standard JoeP springs, but I wonder if they're still too stiff?

I did notice something a little odd...when I was messing with the hoses connected to the boost and precontrol duty solenoids I noticed two nipples with no hoses attached. One was in the row of three, the other two of which had hoses leading to the afore-mentioned solenoids while the other was off by itself. I have a picture but I haven't yet pulled it out of my camera.

jds

I did notice something a little odd...when I was messing with the hoses connected to the boost and precontrol duty solenoids I noticed two nipples with no hoses attached. One was in the row of three, the other two of which had hoses leading to the afore-mentioned solenoids while the other was off by itself. I have a picture but I haven't yet pulled it out of my camera.

jds

#66

Don't you hate people who answer their own questions? I found a better diagram than the one I was using, and it appears that for autos there is a hose connecting those two unused nipples. They were probably capped on my car at one time, but the caps have since disappeared. I'm guessing this is NOT responsible for my poor boost control :-(

jds

jds

Originally posted by bureau_c

I did notice something a little odd...when I was messing with the hoses connected to the boost and precontrol duty solenoids I noticed two nipples with no hoses attached. One was in the row of three, the other two of which had hoses leading to the afore-mentioned solenoids while the other was off by itself. I have a picture but I haven't yet pulled it out of my camera.

jds

I did notice something a little odd...when I was messing with the hoses connected to the boost and precontrol duty solenoids I noticed two nipples with no hoses attached. One was in the row of three, the other two of which had hoses leading to the afore-mentioned solenoids while the other was off by itself. I have a picture but I haven't yet pulled it out of my camera.

jds

#67

OK, I've done some more testing, and I'm reasonably certain that once I get into twin mode, my boost holds right around 10 psi. However it gets pretty wild on the primary. I'm not sure if its just a spike, or if its completely unregulated...I don't want to keep my foot in it long enough to find out. I also don't know about the transition point for the same reason. But, it does seem like the wastegate part in twin mode is working.

Now, I think I need a refresher in the workings of the stock boost control system. Does the wastegate duty solenoid use a different duty cycle (more closed, i.e. less pressure on the wastegate actuator) when only the primary is active, in order to compensate for the precontrol robbing some of that to spool the secondary? Or am I way off base?

jds

PS: Just to clarify...yes I know I've removed the duty solenoids from the equation, however if the stock system was acting that way, it gives me a clue as to why I may be having a problem. Maybe!

Now, I think I need a refresher in the workings of the stock boost control system. Does the wastegate duty solenoid use a different duty cycle (more closed, i.e. less pressure on the wastegate actuator) when only the primary is active, in order to compensate for the precontrol robbing some of that to spool the secondary? Or am I way off base?

jds

PS: Just to clarify...yes I know I've removed the duty solenoids from the equation, however if the stock system was acting that way, it gives me a clue as to why I may be having a problem. Maybe!

#69

hey bureau, i may have already missed this answer, but are you still using the stock pill for the pre-control line? ... that is what controll your primary boost NOT the wastegate controller you put in.... that only controll post-transition boost level (well, actually they do affect each other slightly, but we wont get into that for now...hehehe)

#70

by the way guys, just wanted to let you all know that i have an apexi PFC going in tomorrow and so i will be setting the boost control back to the stock setup for testing purposes sicne the PFC activly controls boost (unlike the stock computer that uses maps).... I'll post back on the results.

#71

Hey Damian,

I'm actually mimicing your original setup, with a pair of ball-and-spring valves. One replaced the wastegate pill and the other one the precontrol pill.

It looks like there must be something causing my precontrol stuff to not work...whether its the valve, the lines, or the actuator...I don't know. The lines all look good, and its seems unlikely that the valve itself is bad...maybe my actuator is broken? I'll have to check it out.

jds

I'm actually mimicing your original setup, with a pair of ball-and-spring valves. One replaced the wastegate pill and the other one the precontrol pill.

It looks like there must be something causing my precontrol stuff to not work...whether its the valve, the lines, or the actuator...I don't know. The lines all look good, and its seems unlikely that the valve itself is bad...maybe my actuator is broken? I'll have to check it out.

jds

Originally posted by damian

hey bureau, i may have already missed this answer, but are you still using the stock pill for the pre-control line? ... that is what controll your primary boost NOT the wastegate controller you put in.... that only controll post-transition boost level (well, actually they do affect each other slightly, but we wont get into that for now...hehehe)

hey bureau, i may have already missed this answer, but are you still using the stock pill for the pre-control line? ... that is what controll your primary boost NOT the wastegate controller you put in.... that only controll post-transition boost level (well, actually they do affect each other slightly, but we wont get into that for now...hehehe)

#75

Here's a pretty stupid question, but I'll ask it just in case my assumption is wrong. There is a little thing sticking out of the turbo with two nipples on it, one goes to the precontrol actuator and the other to the wastegate actuator. These are the two lines that originally had the pills. It doesn't matter which line goes where right? I mean...they're both seeing the same pressure at the same time? I ask because on my car they were reversed when compared to the pictures posted in this thread. It looks like the two nipples are connected to the same pressure source but I just wanted to make sure.

jds

jds