vacuum 6 ports

#1

vacuum 6 ports

This is just the first one here, I just got done with this so bear with me. Also, please express comments or questions.

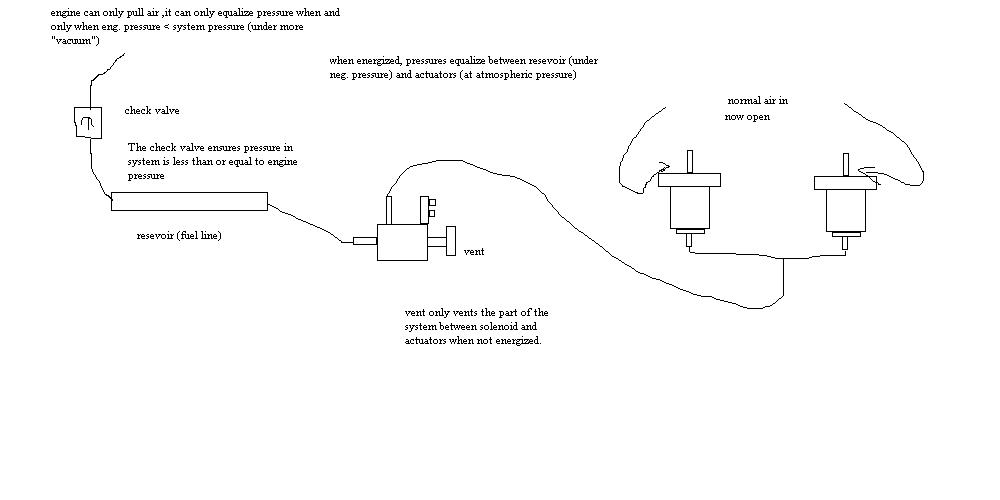

I decided to try and figure a way to work the 6 port system in an NA so it uses no extra parts. I figured the best way to do it would be to use something the engine makes naturally, vacuum. Looking at the actuators, I noticed the bottom had vent holes for the air displaced by the original operation.

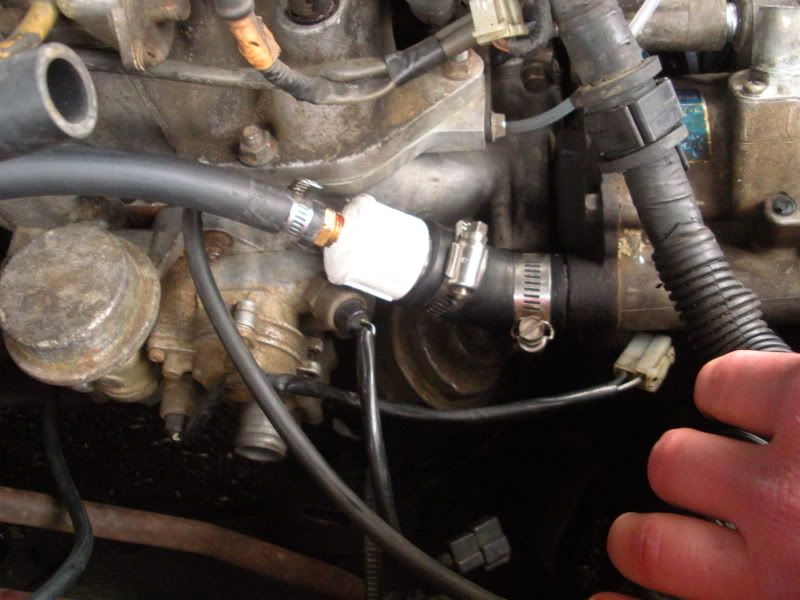

What I did was take washers and JB weld them to the bottom, after cutting the screws off, of course. These washers are 3/8" center hole, and big enough to cover the entire bottom. Then I took 1/8" NPT barb fittings and JB welded them in to the center hole. Next I hooked a short length of vac. kine to a check valve, with arrow towards engine.

Next, I hooked this line to a 5/16th" fuel line approx 12" long for the increased volume. From there the lines return to a smaller size hose to connect to a stock solenoid removed from the rats nest. This goes to the nipple inline with the length of the solenoid. Then run a line to the actuators through a "T" fitting and all you need to do is wiring.

To run the wire, simply use the clip to the solenoid, then run the wires however is best for you. I used a switch that switches the ground, only because the easiest power is from the AAS. I taped the solenoid to the wire harness near the cruise control. For vacuum I used one of the nipple near the cold start block off plate.

Pictures will come soon, please be patient.

I decided to try and figure a way to work the 6 port system in an NA so it uses no extra parts. I figured the best way to do it would be to use something the engine makes naturally, vacuum. Looking at the actuators, I noticed the bottom had vent holes for the air displaced by the original operation.

What I did was take washers and JB weld them to the bottom, after cutting the screws off, of course. These washers are 3/8" center hole, and big enough to cover the entire bottom. Then I took 1/8" NPT barb fittings and JB welded them in to the center hole. Next I hooked a short length of vac. kine to a check valve, with arrow towards engine.

Next, I hooked this line to a 5/16th" fuel line approx 12" long for the increased volume. From there the lines return to a smaller size hose to connect to a stock solenoid removed from the rats nest. This goes to the nipple inline with the length of the solenoid. Then run a line to the actuators through a "T" fitting and all you need to do is wiring.

To run the wire, simply use the clip to the solenoid, then run the wires however is best for you. I used a switch that switches the ground, only because the easiest power is from the AAS. I taped the solenoid to the wire harness near the cruise control. For vacuum I used one of the nipple near the cold start block off plate.

Pictures will come soon, please be patient.

#2

I should also note that it does work. Even while at full throttle, the check valve kept the vacuum in the system and allowed it to operate. I noticed however, it is slow and I will end up putting 2 solenoids in parallel to allow more flow to the actuators.

#3

ummm,.. you know a motor make no vacume when you floor it right?

*edit*check valve wont matter, if you floor the car below 4k your not going to get any ports opening because you never made any vacume to begin with.

*edit*check valve wont matter, if you floor the car below 4k your not going to get any ports opening because you never made any vacume to begin with.

Last edited by drago86; 03-09-06 at 11:47 PM.

#4

thats why I made use of the check valve, it allows the motor to pull air out, but once the - pressure is greater (more vacuum) on the system side, IE full throttle, the valve closes, not allowing equalization of pressures. Also, whenever you shift, you let the throttle close, this creates vacuum, so unless you are doing WOT shifts and still letting the revs drop below the activation point, it will have vacuum. When this is hooked to an rpm switch and set at say, 4300rpm, if you shift at redline, you will stay above the activation point, so the system never disengages.

Last edited by papiogxl; 03-09-06 at 11:51 PM.

#5

rig up a microswitch to an LED to see if it actually opens them while driving, it doesnt sound like it would work to me at all.

If you floor the car below the 6-port opening rpm there will be no vacume going to the checkvalve anyway because the solenoid upstream will be open, thus, oyu never get any vacume to drive the system.

*edit* that still means they arnt going to open until you make your first shift. it also means that they are never going to close once they open because of the check valve.

If you floor the car below the 6-port opening rpm there will be no vacume going to the checkvalve anyway because the solenoid upstream will be open, thus, oyu never get any vacume to drive the system.

*edit* that still means they arnt going to open until you make your first shift. it also means that they are never going to close once they open because of the check valve.

Last edited by drago86; 03-09-06 at 11:57 PM.

#6

Originally Posted by drago86

ummm,.. you know a motor make no vacume when you floor it right?

I've often wondered about rotating the valves 180 degrees and using vacuum instead of pressure to actuate the valves CLOSED. The hard part would be opening the acutators to reverse the spring. The easy part would be finding some way to DECREASE the actuator vacuum as engine rpm increases thus rotating the valves open.

Has anyone done this before? Is the cutting of the port designed for the valve to open in a certain direction? ~rich

Trending Topics

#9

hmmm ok that looks conceivable now that i see it. I still would like to see you hook up an indicator light to test the system under real world driving conditions.

And the pressure drop on an NA motor is a couple inches of water (far far less then 1 psi), not significant.

And the pressure drop on an NA motor is a couple inches of water (far far less then 1 psi), not significant.

#10

sorry ive been busy, but I tested it last night and it works correctly.

I did a WOT run in 2nd and switched it at 4500 then before letting off the gas turned it off and checked when I got home and it slid the grease over all the way so, under racing conditions it does work.

I did a WOT run in 2nd and switched it at 4500 then before letting off the gas turned it off and checked when I got home and it slid the grease over all the way so, under racing conditions it does work.

#11

has anybody thought to use electric actuators for the ports? im talking like the ones used for door locks and gas lids etc... the only concievable problem i can think of is that they are usualy made of plastic and the ports are right next to the exhaust manifold. If I can find ones made of metal wouldnt this work? an actuator extends when you give is 12v and retracts when you take it away.

#14

#15

I have not seen the OP's setup. If I were to do it, I would use a vacuum chamber + check valve instead of just a check valve. That's how the Rx-8 opens the secondary ports (secondary shutter valve) and that's also how several of the actuators on the FD work. The best solution for controlling it would be an Rtek 2.1 because of the built-in rpm activated switch.

#16

Holy old thread! I was 16 when I made this post. Haha

I had a pseudo-vacuum chamber on mine, using a larger diameter about 2 foot length of hose I had laying around. If my current engine were a 6port, I would still be using it. I think I still have the modded pots laying around in the garage.

I had a pseudo-vacuum chamber on mine, using a larger diameter about 2 foot length of hose I had laying around. If my current engine were a 6port, I would still be using it. I think I still have the modded pots laying around in the garage.

#17

Holy old thread! I was 16 when I made this post. Haha

I had a pseudo-vacuum chamber on mine, using a larger diameter about 2 foot length of hose I had laying around. If my current engine were a 6port, I would still be using it. I think I still have the modded pots laying around in the garage.

I had a pseudo-vacuum chamber on mine, using a larger diameter about 2 foot length of hose I had laying around. If my current engine were a 6port, I would still be using it. I think I still have the modded pots laying around in the garage.

#18

It's cake. JB weld, fender washers and a brass nipple appropriately sized for the vac line and hole in the washer. Next time I'm over at my garage, I'll dig for them.

Thread

Thread Starter

Forum

Replies

Last Post

Jeff20B

1st Generation Specific (1979-1985)

73

09-16-18 08:16 PM