S4 Engine Bay Paint Job (Pic Heavy)

#101

rocket,

after many bad experiences with shitty summit hose I discovered that you really have to get the good stuff. This means aeroquip or earls hose and fittings. I am sure there are other good brands out there, but these are the ones I am sticking with.

With this being said check out the price of earls proflex hose, this **** is expensive, and is hard to route in tight areas. The answer is the alum hardline. At the time I knew nothing about it, but I was talked into it, and for good reason, the stuff is as light as a feather, and no more bloody fingers.

The only real drawbacks of the hardline are the initial investment in the tooling, about 140bucks total for the flaring tool and the bender. This is another place you dont want to cheap out, get a top notch 37degree flaring tool.

I also axially sliced some fuel hose and put it around the hardline in a few spots, just to keep it from vibrating against the car, hopfully it wont vibrate at all with the good brackets I made, we will see.

As for those little brackets, I wanted to use factory threaed holes, just to make it easy. I used 6000 series alum for those, does not bend very well, if you do it get 3000 series, should bend alot better.

A few more pics...

[IMG]<a href="http://s169.photobucket.com/albums/u216/NateFrame69/Mazda/?action=view¤t=Mazda119-1.jpg" target="_blank"><img src="http://i169.photobucket.com/albums/u216/NateFrame69/Mazda/Mazda119-1.jpg" border="0" alt="Photobucket"></a>[/IMG]

[IMG]<a href="http://s169.photobucket.com/albums/u216/NateFrame69/Mazda/?action=view¤t=Mazda121-1.jpg" target="_blank"><img src="http://i169.photobucket.com/albums/u216/NateFrame69/Mazda/Mazda121-1.jpg" border="0" alt="Photobucket"></a>[/IMG]

[IMG]<a href="http://s169.photobucket.com/albums/u216/NateFrame69/Mazda/?action=view¤t=Mazda127-1.jpg" target="_blank"><img src="http://i169.photobucket.com/albums/u216/NateFrame69/Mazda/Mazda127-1.jpg" border="0" alt="Photobucket"></a>[/IMG]

cheers

after many bad experiences with shitty summit hose I discovered that you really have to get the good stuff. This means aeroquip or earls hose and fittings. I am sure there are other good brands out there, but these are the ones I am sticking with.

With this being said check out the price of earls proflex hose, this **** is expensive, and is hard to route in tight areas. The answer is the alum hardline. At the time I knew nothing about it, but I was talked into it, and for good reason, the stuff is as light as a feather, and no more bloody fingers.

The only real drawbacks of the hardline are the initial investment in the tooling, about 140bucks total for the flaring tool and the bender. This is another place you dont want to cheap out, get a top notch 37degree flaring tool.

I also axially sliced some fuel hose and put it around the hardline in a few spots, just to keep it from vibrating against the car, hopfully it wont vibrate at all with the good brackets I made, we will see.

As for those little brackets, I wanted to use factory threaed holes, just to make it easy. I used 6000 series alum for those, does not bend very well, if you do it get 3000 series, should bend alot better.

A few more pics...

[IMG]<a href="http://s169.photobucket.com/albums/u216/NateFrame69/Mazda/?action=view¤t=Mazda119-1.jpg" target="_blank"><img src="http://i169.photobucket.com/albums/u216/NateFrame69/Mazda/Mazda119-1.jpg" border="0" alt="Photobucket"></a>[/IMG]

[IMG]<a href="http://s169.photobucket.com/albums/u216/NateFrame69/Mazda/?action=view¤t=Mazda121-1.jpg" target="_blank"><img src="http://i169.photobucket.com/albums/u216/NateFrame69/Mazda/Mazda121-1.jpg" border="0" alt="Photobucket"></a>[/IMG]

[IMG]<a href="http://s169.photobucket.com/albums/u216/NateFrame69/Mazda/?action=view¤t=Mazda127-1.jpg" target="_blank"><img src="http://i169.photobucket.com/albums/u216/NateFrame69/Mazda/Mazda127-1.jpg" border="0" alt="Photobucket"></a>[/IMG]

cheers

#103

Long time since an update. Been so damn busy doing absolutly nothing.

My intake pipe interfered with my oil fill tube. I got this tube used from mazdatrix, thing was in really good shape.

So I made a few mods to it.

[IMG] [/IMG]

[/IMG]

The leftovers

[IMG] [/IMG]

[/IMG]

Back to the fuel system, here I ran the necessary wires thru a -8AN bulkhead fitting. Yea I know, it sucks....

I successivly used larger and larger heat shrink around all the wires until they fit tight into the inside diameter or the fitting. Then you can see what I did on the outside. I dont know how long its going to last with gasoline in there, but i'm sure i'll be able to get some drive time before I get a mil-spec bulkhead electical connector.

[IMG] [/IMG]

[/IMG]

Getting ready to finish off my oil cooler lines, with my homemade radiator brackets the OEM lines wont fit, so time to get some stainless steel ones.

[IMG] [/IMG]

[/IMG]

Here you can see the direction of the fittings...

[IMG] [/IMG]

[/IMG]

Can you see the latest addition to my engine bay?

[IMG] [/IMG]

[/IMG]

This little coil bracket took so damn long!!!!!!!!!!!!! It used all factory provided mounting point. No welding in nuts of anything like that.

[IMG] [/IMG]

[/IMG]

I hope like hell I wired them correctly. I followed the haltech manual and the best pinout diagram I could find for the ls2 coils.

[IMG] [/IMG]

[/IMG]

More to come soon, follow me on my adventure of trying to get a working fuel level gauge. Much more to come!

cheers

My intake pipe interfered with my oil fill tube. I got this tube used from mazdatrix, thing was in really good shape.

So I made a few mods to it.

[IMG]

[/IMG]

[/IMG]The leftovers

[IMG]

[/IMG]

[/IMG]Back to the fuel system, here I ran the necessary wires thru a -8AN bulkhead fitting. Yea I know, it sucks....

I successivly used larger and larger heat shrink around all the wires until they fit tight into the inside diameter or the fitting. Then you can see what I did on the outside. I dont know how long its going to last with gasoline in there, but i'm sure i'll be able to get some drive time before I get a mil-spec bulkhead electical connector.

[IMG]

[/IMG]

[/IMG]Getting ready to finish off my oil cooler lines, with my homemade radiator brackets the OEM lines wont fit, so time to get some stainless steel ones.

[IMG]

[/IMG]

[/IMG]Here you can see the direction of the fittings...

[IMG]

[/IMG]

[/IMG]Can you see the latest addition to my engine bay?

[IMG]

[/IMG]

[/IMG]This little coil bracket took so damn long!!!!!!!!!!!!! It used all factory provided mounting point. No welding in nuts of anything like that.

[IMG]

[/IMG]

[/IMG]I hope like hell I wired them correctly. I followed the haltech manual and the best pinout diagram I could find for the ls2 coils.

[IMG]

[/IMG]

[/IMG]More to come soon, follow me on my adventure of trying to get a working fuel level gauge. Much more to come!

cheers

#106

I haven't been to this thread in way too long! Looks suuuuuuuuppperr nice. You've done a ton of stuff that i always wanted to do but never had the space/time/skill to do. I absolutely love the fuel lines and wiring. Engine bay looks a million times better than it did before.

nice work!

nice work!

#108

If there was a way to reprodue the pieces quickly then maby. But its just way to much work to make something like this.

Just a couple more weeks and i'll be trying to start it up. Still have to wire up a few more gauges. And get seths old calibration on my ECU.

Just a couple more weeks and i'll be trying to start it up. Still have to wire up a few more gauges. And get seths old calibration on my ECU.

#109

???

Seth, care to chime in?

#111

Sweet job Nate! Once you get it running you should come to Kazoo for the Furin autocrosses (very fast tracks) or 131 motorsports park (1/4).

If you head to the dyno let me know.

Later

Lee

If you head to the dyno let me know.

Later

Lee

#113

looks as if I have finally found all of my graduated kettering rotorheads, lee and jordan. Max will probally soon be on that list, I wish I could say the same for my self.

Seth has been nice enough to let me barrow his haltech for a couple of weeks, I am hoping to finish all the non engine related ****(list is shrinking) and then tackle the E8. I still have to wire up the wideband and get it interfaced with the E8. Should be lots of fun.

Seths feeling as far as the "pickyness" of the internal compustion engine has been rubbing off on me. Its like if the clearences arn't just right and the tune is a litte off then the motor is going to be toast. I suspect that this is wrong, I would like to think that I could start the car on his calibration and have to problems.

then again with my luck....it would die.

Seth has been nice enough to let me barrow his haltech for a couple of weeks, I am hoping to finish all the non engine related ****(list is shrinking) and then tackle the E8. I still have to wire up the wideband and get it interfaced with the E8. Should be lots of fun.

Seths feeling as far as the "pickyness" of the internal compustion engine has been rubbing off on me. Its like if the clearences arn't just right and the tune is a litte off then the motor is going to be toast. I suspect that this is wrong, I would like to think that I could start the car on his calibration and have to problems.

then again with my luck....it would die.

#114

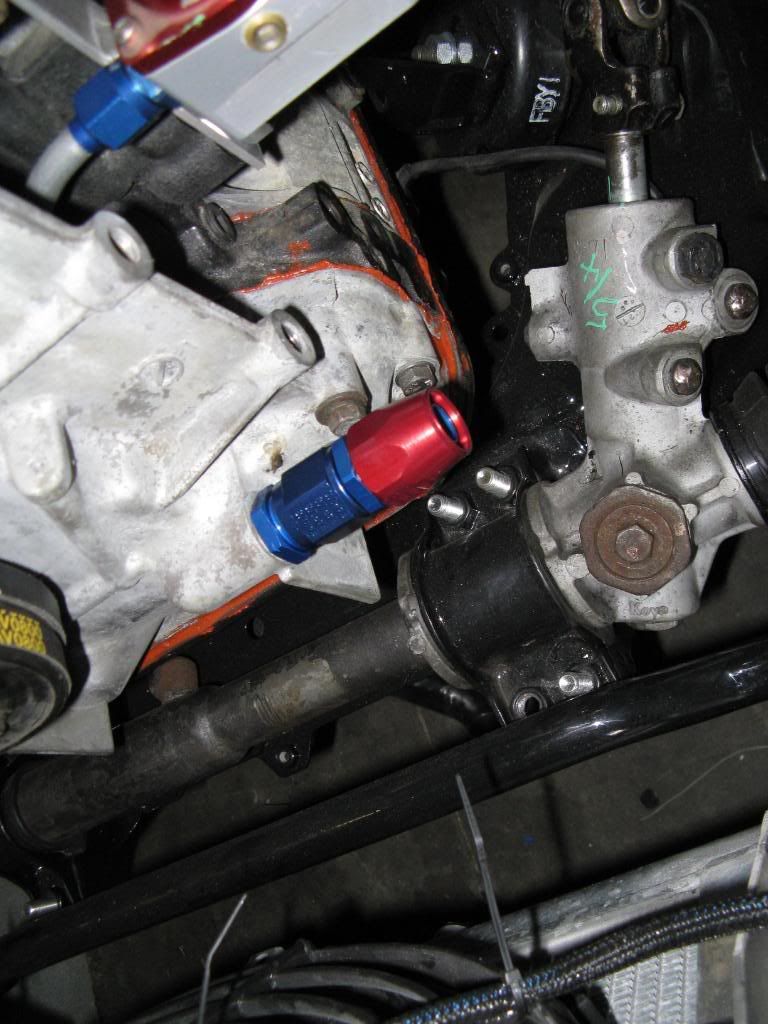

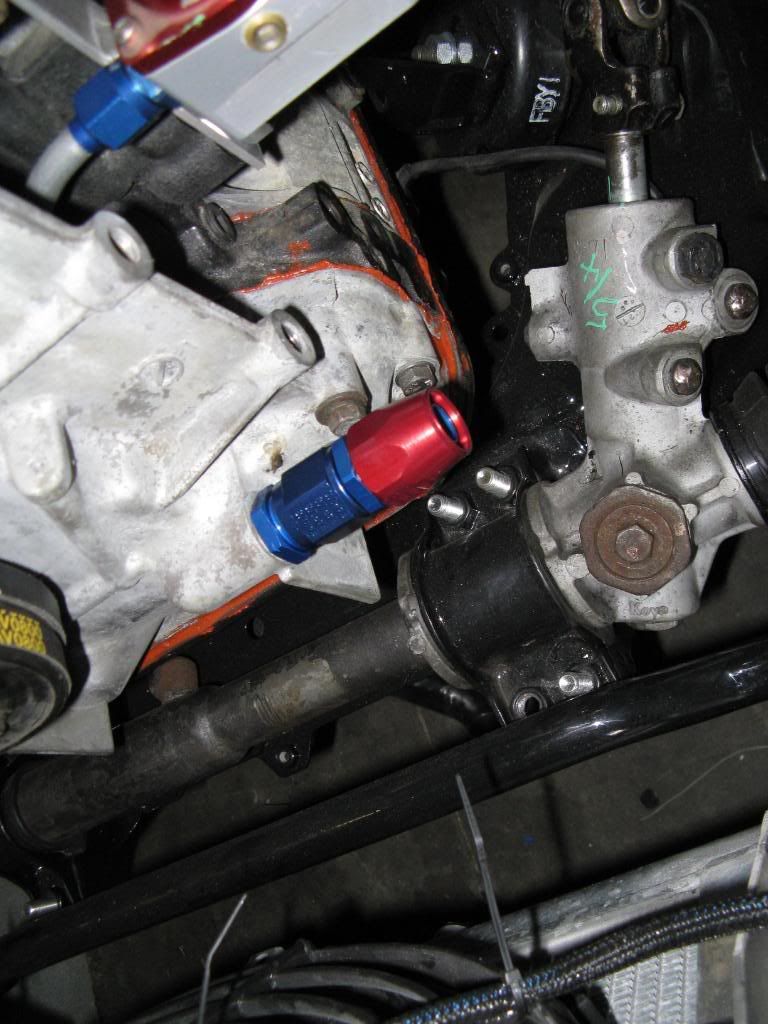

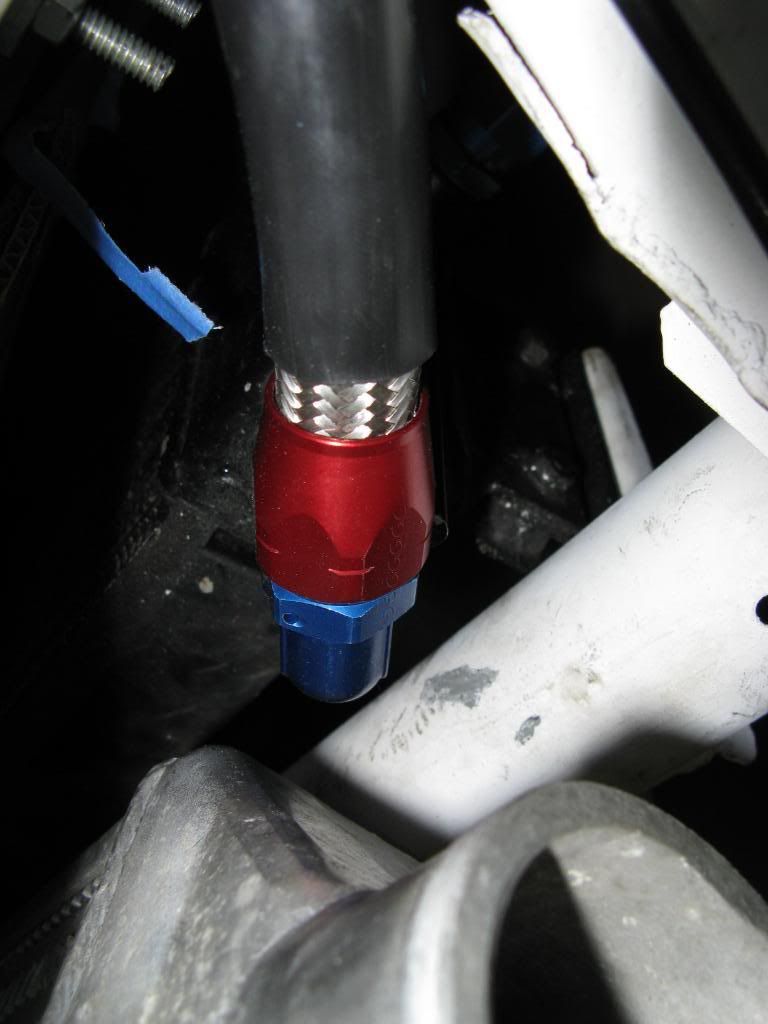

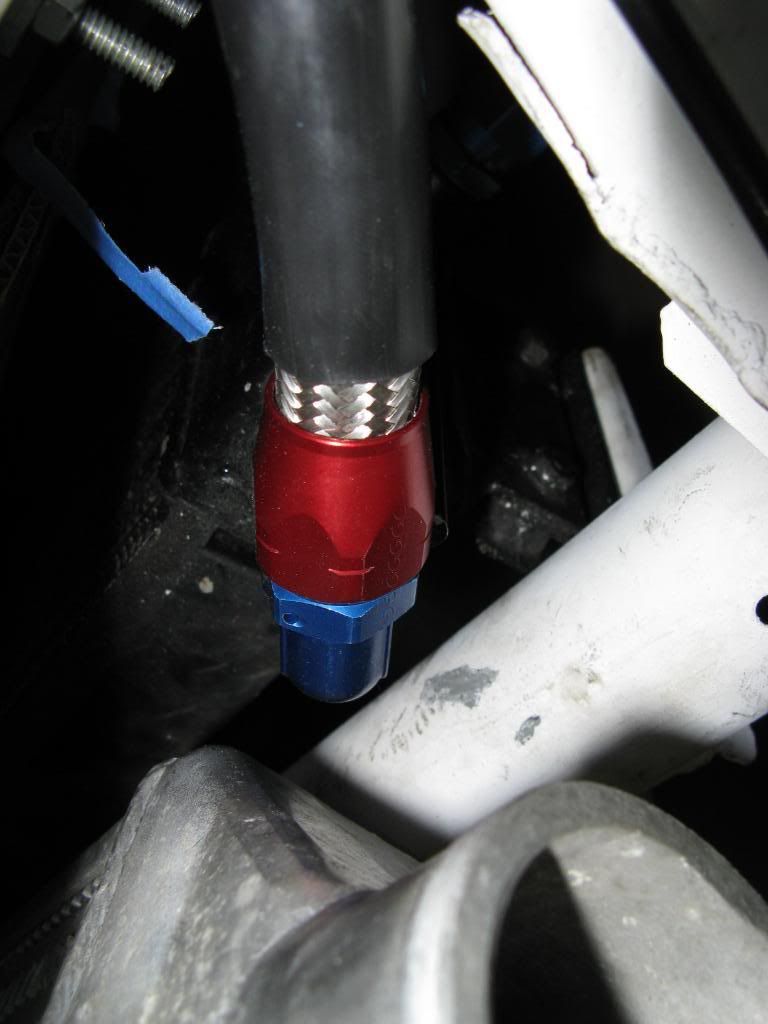

Just got another thing crossed off the list. Oil cooler lines are done. Also visible in close proximity are my spark plug wires. I dont ever want to do that again, just pay someone to do it. Bought a kit for a V8 and messed up two of them. So if anyone has a one rotor engine with two lsx coils let me know and i'll hook you up with some wires.

Here are the pictures of todays work.

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

Getting closer to being done.

Cheers

Here are the pictures of todays work.

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]Getting closer to being done.

Cheers

#116

Is the heat shrink on the oil cooler lines to stop the lines from rubbing off paint in the engine bay? Good idea!

Yeah, my tune might get it started and "drivable," but mine wasn't close to being finished. I wouldn't think about boosting on my tune. We have different porting (he has a full street port, I had a halfie), my turbo was more efficient (~70% vs ~80%), we had different exhaust manifolds (fully divided, stainless steel vs undevided, cast iron), scalloped rotors vs non scalloped and different exhaust porting. Also, I had an RE engine, and his is S4.

With all that being said, I would bet that mine would be safe as I hadn't even come close to finish tuning mine, and it was running rediculously rich, like 9.5:1 AFR. I may have also made more torque at any given load point due to more efficient turbo, which would mean more fuel yet.

However, I wouldn't even bother. Since he has his calibration off the old E6X, all he needs to do is copy the calibration to a spreadsheet (physically - and tedious) and then copy those values back to the E8 ecu (values like fuel injector pulse width vs load vs RPM, ignition advance vs. load vs RPM, and trailing ignition split vs load vs RPM). If he decides to run 250 RPM increments instead of 500, a linear interpolation is acceptable, although he can get nuts and use polynomial interpolation if he wants to do some real engineering (you could also explore Hermitian interpolation which matches data points in both value and first derivative).

If there are any stand alone experts or electrical engineers out there, chime in if you think it is a bad idea to copy injector pulsewidth, ignition advance, and trailing spark split from one ECU to the next. Would there be any issues with one computer not pulsing the injector exactly like the other? Is the tolerance from an E6X more loose than that of an E8? Just some thoughts...

Seth

With all that being said, I would bet that mine would be safe as I hadn't even come close to finish tuning mine, and it was running rediculously rich, like 9.5:1 AFR. I may have also made more torque at any given load point due to more efficient turbo, which would mean more fuel yet.

However, I wouldn't even bother. Since he has his calibration off the old E6X, all he needs to do is copy the calibration to a spreadsheet (physically - and tedious) and then copy those values back to the E8 ecu (values like fuel injector pulse width vs load vs RPM, ignition advance vs. load vs RPM, and trailing ignition split vs load vs RPM). If he decides to run 250 RPM increments instead of 500, a linear interpolation is acceptable, although he can get nuts and use polynomial interpolation if he wants to do some real engineering (you could also explore Hermitian interpolation which matches data points in both value and first derivative).

If there are any stand alone experts or electrical engineers out there, chime in if you think it is a bad idea to copy injector pulsewidth, ignition advance, and trailing spark split from one ECU to the next. Would there be any issues with one computer not pulsing the injector exactly like the other? Is the tolerance from an E6X more loose than that of an E8? Just some thoughts...

Seth

#117

Is the heat shrink on the oil cooler lines to stop the lines from rubbing off paint in the engine bay? Good idea!

Yeah, my tune might get it started and "drivable," but mine wasn't close to being finished. I wouldn't think about boosting on my tune. We have different porting (he has a full street port, I had a halfie), my turbo was more efficient (~70% vs ~80%), we had different exhaust manifolds (fully divided, stainless steel vs undevided, cast iron), scalloped rotors vs non scalloped and different exhaust porting. Also, I had an RE engine, and his is S4.

With all that being said, I would bet that mine would be safe as I hadn't even come close to finish tuning mine, and it was running rediculously rich, like 9.5:1 AFR. I may have also made more torque at any given load point due to more efficient turbo, which would mean more fuel yet.

However, I wouldn't even bother. Since he has his calibration off the old E6X, all he needs to do is copy the calibration to a spreadsheet (physically - and tedious) and then copy those values back to the E8 ecu (values like fuel injector pulse width vs load vs RPM, ignition advance vs. load vs RPM, and trailing ignition split vs load vs RPM). If he decides to run 250 RPM increments instead of 500, a linear interpolation is acceptable, although he can get nuts and use polynomial interpolation if he wants to do some real engineering (you could also explore Hermitian interpolation which matches data points in both value and first derivative).

If there are any stand alone experts or electrical engineers out there, chime in if you think it is a bad idea to copy injector pulsewidth, ignition advance, and trailing spark split from one ECU to the next. Would there be any issues with one computer not pulsing the injector exactly like the other? Is the tolerance from an E6X more loose than that of an E8? Just some thoughts...

Seth

Yeah, my tune might get it started and "drivable," but mine wasn't close to being finished. I wouldn't think about boosting on my tune. We have different porting (he has a full street port, I had a halfie), my turbo was more efficient (~70% vs ~80%), we had different exhaust manifolds (fully divided, stainless steel vs undevided, cast iron), scalloped rotors vs non scalloped and different exhaust porting. Also, I had an RE engine, and his is S4.

With all that being said, I would bet that mine would be safe as I hadn't even come close to finish tuning mine, and it was running rediculously rich, like 9.5:1 AFR. I may have also made more torque at any given load point due to more efficient turbo, which would mean more fuel yet.

However, I wouldn't even bother. Since he has his calibration off the old E6X, all he needs to do is copy the calibration to a spreadsheet (physically - and tedious) and then copy those values back to the E8 ecu (values like fuel injector pulse width vs load vs RPM, ignition advance vs. load vs RPM, and trailing ignition split vs load vs RPM). If he decides to run 250 RPM increments instead of 500, a linear interpolation is acceptable, although he can get nuts and use polynomial interpolation if he wants to do some real engineering (you could also explore Hermitian interpolation which matches data points in both value and first derivative).

If there are any stand alone experts or electrical engineers out there, chime in if you think it is a bad idea to copy injector pulsewidth, ignition advance, and trailing spark split from one ECU to the next. Would there be any issues with one computer not pulsing the injector exactly like the other? Is the tolerance from an E6X more loose than that of an E8? Just some thoughts...

Seth

#118

If there are any stand alone experts or electrical engineers out there, chime in if you think it is a bad idea to copy injector pulsewidth, ignition advance, and trailing spark split from one ECU to the next. Would there be any issues with one computer not pulsing the injector exactly like the other? Is the tolerance from an E6X more loose than that of an E8? Just some thoughts...

Seth

Seth

That said, both of them should do the same thing, look up values and output them. So I don't see why they shouldn't carry over well. There might be some holes created where different table values are returned.

Think of it as Schrodinger's Stand Alone, it is both better and worse at the same time!

#119

My dad says I should replace each column vector in the matrix with a continous equation. Nobody likes discrete math around here, continous is way better.

There were some rough edges in the engine bay, I dident want any cutting of my oil cooler hoses. I guess it protects the paint a little too. Next time that engine is out I really want to paint it right, the flat white was a horrible idea, why dident i wake up? That heat shrink is just big enough to slide over a -10 hose end. I thought it was pretty slick.

I thought the claim to fame of all this modern electrical **** was repeatability. One casio watch would be exactly the same as any other one? cant be loosing seconds in time, or could we?

Maby excel could do a nice interpolation for me, not going to do it by hand thats for sure.

If I could only copy this table into S-Plus, almost anything could be done very quickly.

Its sure going to be intresting, add it to my list of things to do.

after my final(friday @ 1800hrs) there is a ton of **** dad wants/demands i do.

wants a spare tire carrier made for his truck. that will suck. and 4 brackets for our new kitchen bar that are exactly the same. plus of minus .000000000000000001 inch.

hopfully the streets of flint will not be silent this spring term!!

updates to come this weekend! got a programmable fuel gauge!!!!! turns out that a mazda level sender is almost exactly the same as a honda civic( dont quote me), anyways this autometer gauge happans to have that setting programmed already. There are like 8 cals it comes with. i thought i was going to have to do my own. I owe a big thanks to all the honda ricers out there was a triple gauge a-pillar pod. Apparently volts and oil pressure were not enough, they also needed another aftermarket fuel gauge.

thankyou for the nice comments and encouragment.

the last 10% of the project takes 10 times longer than you thought and cost 10 times as much as you budgeted.

cheers

There were some rough edges in the engine bay, I dident want any cutting of my oil cooler hoses. I guess it protects the paint a little too. Next time that engine is out I really want to paint it right, the flat white was a horrible idea, why dident i wake up? That heat shrink is just big enough to slide over a -10 hose end. I thought it was pretty slick.

I thought the claim to fame of all this modern electrical **** was repeatability. One casio watch would be exactly the same as any other one? cant be loosing seconds in time, or could we?

Maby excel could do a nice interpolation for me, not going to do it by hand thats for sure.

If I could only copy this table into S-Plus, almost anything could be done very quickly.

Its sure going to be intresting, add it to my list of things to do.

after my final(friday @ 1800hrs) there is a ton of **** dad wants/demands i do.

wants a spare tire carrier made for his truck. that will suck. and 4 brackets for our new kitchen bar that are exactly the same. plus of minus .000000000000000001 inch.

hopfully the streets of flint will not be silent this spring term!!

updates to come this weekend! got a programmable fuel gauge!!!!! turns out that a mazda level sender is almost exactly the same as a honda civic( dont quote me), anyways this autometer gauge happans to have that setting programmed already. There are like 8 cals it comes with. i thought i was going to have to do my own. I owe a big thanks to all the honda ricers out there was a triple gauge a-pillar pod. Apparently volts and oil pressure were not enough, they also needed another aftermarket fuel gauge.

thankyou for the nice comments and encouragment.

the last 10% of the project takes 10 times longer than you thought and cost 10 times as much as you budgeted.

cheers

#120

#121

To my knowledge, Excel will only do a linear interpolation. You could program a simple code in visual basic to plugin to excel. At that point, you may decide to use a better program than excel, but for that sort of stuff, excel and VB is fine.

#122

#125

Updates???????

I gave up my summer to take a few math classes. So these has been almost zero progress.

Let me say this, the guy who commented about the paint choice was right. It has to be done over. Its simply unacceptable.

My wiring job was not up to snuff so its gotta go to.

As of now the cars interior floor is being stripped, next is the engine bay. I havent been taking any pictures, its all to depressing to think about.

Will get back on top of things in a few months. When its done it will be done right, it just takes lots of time.

cheers

I gave up my summer to take a few math classes. So these has been almost zero progress.

Let me say this, the guy who commented about the paint choice was right. It has to be done over. Its simply unacceptable.

My wiring job was not up to snuff so its gotta go to.

As of now the cars interior floor is being stripped, next is the engine bay. I havent been taking any pictures, its all to depressing to think about.

Will get back on top of things in a few months. When its done it will be done right, it just takes lots of time.

cheers

Thread

Thread Starter

Forum

Replies

Last Post

immanuel__7

2nd Generation Specific (1986-1992)

89

09-05-15 11:23 AM