Project GTUs: The S means Six port Sequential!

#1

Thread Starter

Super Raterhater

iTrader: (6)

Joined: Dec 2001

Posts: 10,630

Likes: 3

From: NY, MA, MI, OR, TX, and now LA or AZ!

Project GTUs: The S means Six port Sequential!

It's poject time! RETed will love this one. I left the boring history/backlog of what lead to this (and my return to the rx7 'scene') at the bottom for those interested.

Total Cost invested so far: $13 (for some porting bits)

Completed: Oil feed, coolant lines, both oil drain lines, intake ducts, fuel pump, vacuum routing

Left to do: Finish LIM, install ECU, match up exhaust, fabricate/build FMIC

Parts Needed: ECU, Intercooler

Installation

First things first, the twins will HIT the **** out of your stock intake, and if you space them outwards, you'll hit the frame. Unless you move them out, forward, and tilt them (so the downpipe fits) don't bother. N/A, TII alike, neither will work easily.

Having a spare FD LIM in hand, I went about comparing the two. The FD LIM has 3 bolt holes that line up with the S5 6port gasket (These being the holes along the outer edges).

As you can see, there's a lot that's different. The center housing lines up better than it shows in the picture, but from then on it gets a little crazy. Although those 3 bolts line up, their position on the motor compared to that of the S5 block is considerably higher, this is why in relation, the two 'studs' seem to be lower on the manifold. This is problem #1, as when you attempt to mount the FD LIM, the exhaust manifold won't fit any longer as those interfere. The first step was to cut those sections out. (There's casting in the manifold that gives you an idea of where the exhaust manifold goes, so I just cut along those casting lines. Problem #1 solved.

Now, this moved my entire intake DOWN about 1.5" from where it would be on a REW block (Again, REW ports are higher up on the side housings than the 13B 6port.) The heatshield hit the center intake runner, but upon removal I had plenty of space, and after mild modification to the heatshield with a hammer, that fit as well. So, with the trouble of actually fitting everything on resolved. Now comes the hard part. As you can obviously tell, the manifolds have severe differences. The bottom outside ports line up fairly well, and just some minor port work here will resolve this issue. But what you can't see is that the intake runner continues under the gasket a bit, this will need to be filled in and smoothed out to simulate the original port design. It won't take much, as they're pretty close. The top ports (where the 5th & 6th sleeves used to be is by far the worse area, this entire area will need material added, then the port cut into it and shaped. Thus, it's good to have a welder in the family! I'll have pictures of the finished/cleaned up manifold once we're all done welding it.

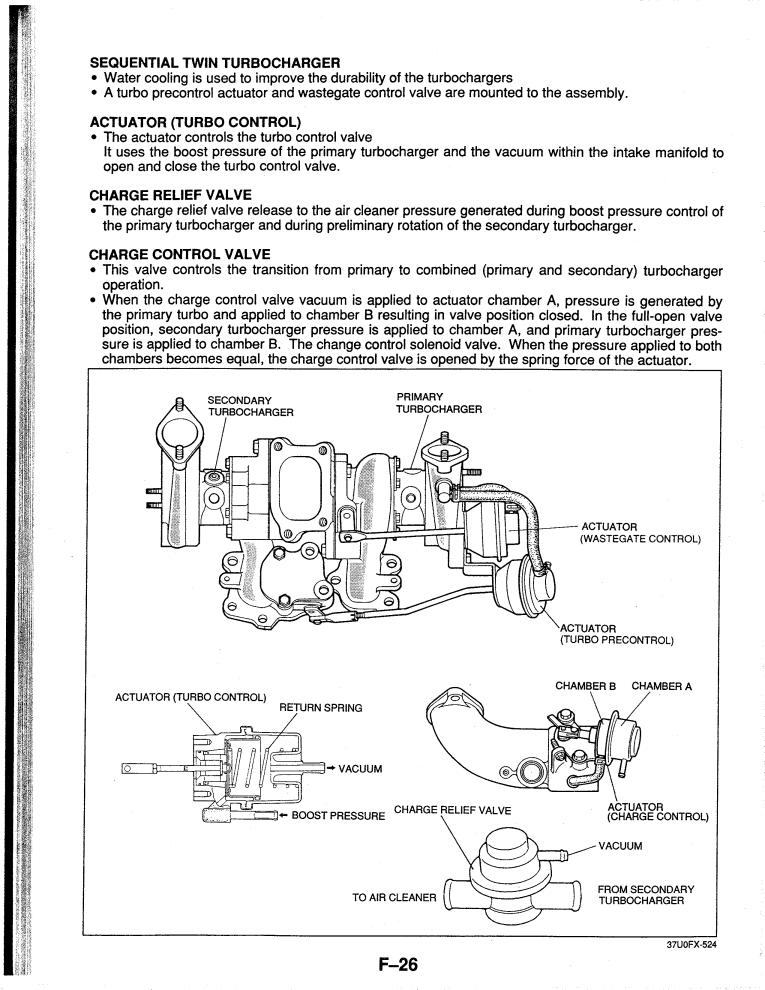

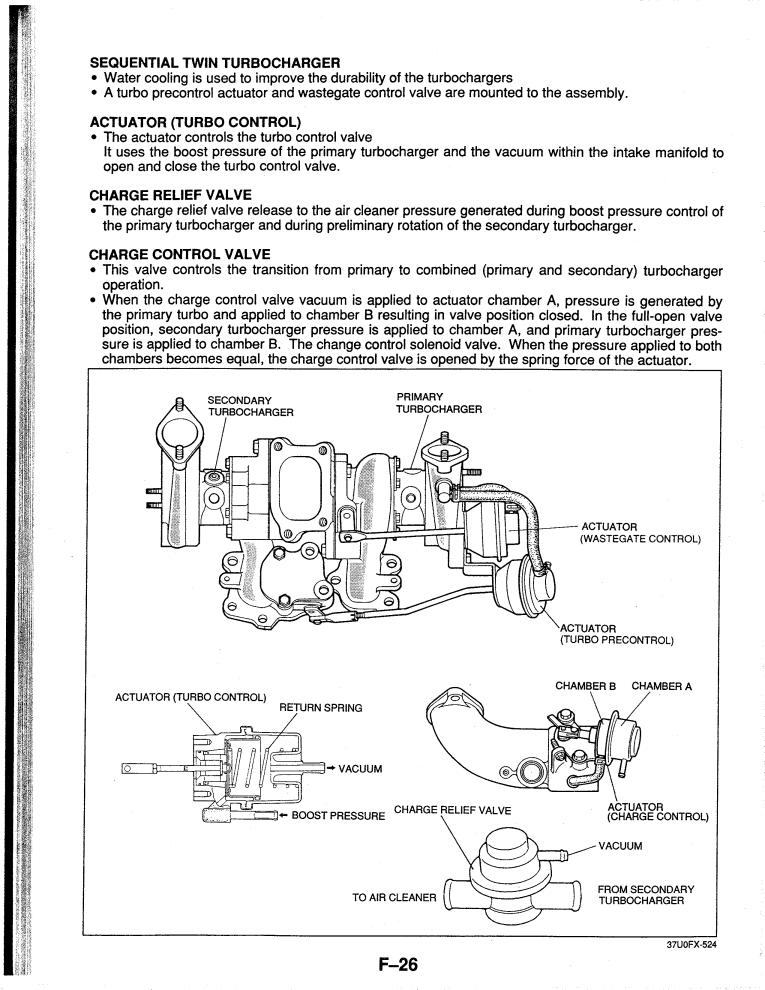

Now, as for keeping the sequential system. A lot of people seem to believe that it requires some overly complex mess (and often, the stock ECU or PowerFC) to keep functioning. This isn't exactly true. I've managed to quite successfully replicate almost stock performance/boost pattern and behavior using a single output triggering 3 solenoids. I'll be using either a Profec B or other similar EBC, turbo pre-spool will be controlled by a TurboXS mbc that I had laying around. The vacuum diagram for the sequential's as I'll be running it is below. I haven't decided on the final ECU for the car yet, it's a tossup between Microtech and Megasquirt. I like Microtech simply due to their easy to use nature, and I've used them a ton before, but I despise their customer relations/support. Megasquirt is a bit hard to find solid documentation/people who know it, so I'm a bit hesitant. I'll have more on that later when the LIM is finished.

History

So, as most of you may remember my GTUs has been my frankenstein project car for about as long as I've had it. It began life (with me) as a generic bone stock GTUs and stayed that way for a short period. After my success with the ghetto fabulous '87 Sport turbo, I decided to turbo the GTUs in a more 'proper' method. I had used a Weber IDA LIM, and a 50MM IDA TB with the stock turbo, then decided I was tired of lag and threw a number of different superchargers at it, then I couldn't get the numbers I wanted back to turbo it went with a GT42R. After it's last dyno session with the 42R the car was parked as I was in the process of moving and the majority of the performance parts were stolen, which was about the same time I left the forum and the rx7 scene. There it sat with no intakes/turbo/anything else for quite some time.

I had a full REW longblock, rebuilt low mileage twins, FD fuel pump, downpipe, pretty much everything I would need for the conversion, so what better way to upgrade the car than with what I've already got that costs nothing?

Total Cost invested so far: $13 (for some porting bits)

Completed: Oil feed, coolant lines, both oil drain lines, intake ducts, fuel pump, vacuum routing

Left to do: Finish LIM, install ECU, match up exhaust, fabricate/build FMIC

Parts Needed: ECU, Intercooler

Installation

First things first, the twins will HIT the **** out of your stock intake, and if you space them outwards, you'll hit the frame. Unless you move them out, forward, and tilt them (so the downpipe fits) don't bother. N/A, TII alike, neither will work easily.

Having a spare FD LIM in hand, I went about comparing the two. The FD LIM has 3 bolt holes that line up with the S5 6port gasket (These being the holes along the outer edges).

As you can see, there's a lot that's different. The center housing lines up better than it shows in the picture, but from then on it gets a little crazy. Although those 3 bolts line up, their position on the motor compared to that of the S5 block is considerably higher, this is why in relation, the two 'studs' seem to be lower on the manifold. This is problem #1, as when you attempt to mount the FD LIM, the exhaust manifold won't fit any longer as those interfere. The first step was to cut those sections out. (There's casting in the manifold that gives you an idea of where the exhaust manifold goes, so I just cut along those casting lines. Problem #1 solved.

Now, this moved my entire intake DOWN about 1.5" from where it would be on a REW block (Again, REW ports are higher up on the side housings than the 13B 6port.) The heatshield hit the center intake runner, but upon removal I had plenty of space, and after mild modification to the heatshield with a hammer, that fit as well. So, with the trouble of actually fitting everything on resolved. Now comes the hard part. As you can obviously tell, the manifolds have severe differences. The bottom outside ports line up fairly well, and just some minor port work here will resolve this issue. But what you can't see is that the intake runner continues under the gasket a bit, this will need to be filled in and smoothed out to simulate the original port design. It won't take much, as they're pretty close. The top ports (where the 5th & 6th sleeves used to be is by far the worse area, this entire area will need material added, then the port cut into it and shaped. Thus, it's good to have a welder in the family! I'll have pictures of the finished/cleaned up manifold once we're all done welding it.

Now, as for keeping the sequential system. A lot of people seem to believe that it requires some overly complex mess (and often, the stock ECU or PowerFC) to keep functioning. This isn't exactly true. I've managed to quite successfully replicate almost stock performance/boost pattern and behavior using a single output triggering 3 solenoids. I'll be using either a Profec B or other similar EBC, turbo pre-spool will be controlled by a TurboXS mbc that I had laying around. The vacuum diagram for the sequential's as I'll be running it is below. I haven't decided on the final ECU for the car yet, it's a tossup between Microtech and Megasquirt. I like Microtech simply due to their easy to use nature, and I've used them a ton before, but I despise their customer relations/support. Megasquirt is a bit hard to find solid documentation/people who know it, so I'm a bit hesitant. I'll have more on that later when the LIM is finished.

History

So, as most of you may remember my GTUs has been my frankenstein project car for about as long as I've had it. It began life (with me) as a generic bone stock GTUs and stayed that way for a short period. After my success with the ghetto fabulous '87 Sport turbo, I decided to turbo the GTUs in a more 'proper' method. I had used a Weber IDA LIM, and a 50MM IDA TB with the stock turbo, then decided I was tired of lag and threw a number of different superchargers at it, then I couldn't get the numbers I wanted back to turbo it went with a GT42R. After it's last dyno session with the 42R the car was parked as I was in the process of moving and the majority of the performance parts were stolen, which was about the same time I left the forum and the rx7 scene. There it sat with no intakes/turbo/anything else for quite some time.

I had a full REW longblock, rebuilt low mileage twins, FD fuel pump, downpipe, pretty much everything I would need for the conversion, so what better way to upgrade the car than with what I've already got that costs nothing?

#2

Thread Starter

Super Raterhater

iTrader: (6)

Joined: Dec 2001

Posts: 10,630

Likes: 3

From: NY, MA, MI, OR, TX, and now LA or AZ!

So, sadly there's been a lot less to report back on as I've had very little time to work on it, but I haven't given up! I finally got the intake manifold all finished up, and sadly I still have clearance issues. So, I've got a RB flange shaved down quite a bit and some longer exhaust studs to give me plenty of clearance and room for a heat shield. I finally began just test fitting everything in the car as well, once I get things better routed I'll get some pictures of how things are all fitting together.

Trending Topics

#8

Let me help you out with the vacuum routing. I have studied the sequential system very closely.

Full thread is here: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/why-engine-so-damn-complicated-part-1-sequential-turbos-demystified-841821/

Charge control and turbo control should be switched at the same time. That opens the compressor and turbine sides of the secondary turbo respectively. Turbo control requires a switched ground and Charge control requires switched +12V. Wastegate and precontrol are fine with an EBC or MBC, just cap off one of the nipples. The stock configuration vents away air, kind of like the stock s5 boost control solenoid except that the vent is after the actuator instead of before.

Turbo control has 2 solenoids: vacuum and boost. If you really wanted to simplify things, you could ditch the pressure solenoid and pressure chamber and only run the vacuum solenoid. It may marginally affect response. Charge relief and charge control have 3 nipples, and switch from a fresh air/boost source to a vacuum source. The two solenoids are inverted with regards to that: charge relief is fresh air by default and then switches to vacuum, charge control is vacuum by default and then switches to fresh air.

Charge relief is going to have to come on earlier than charge control and charge relief. It vents during prespool, and prespool takes a little while. Preferably you would have a hysteresis function to switch back into sequential mode on deceleration at a different RPM that you switched into it. Default hysteresis value is 3000rpm but I prefer 3500. Otherwise, to make it easier you can just set your target transition to 4000rpm (both during acceleration and switching back during deceleration) and be done with it.

Summary:

I guess if you want to keep it simple, you could do it this way:

-- Charge control: +12V switched ON about 4000 and OFF below 4000. Vacuum output switches to pressure output per the diagram.

-- Turbo control (vacuum only): GND switched ON about 4000 and OFF below 4000. Vacuum output is switched when solenoid is engaged. Eliminate pressure tank and check valve.

-- Charge relief: Window switch needed. GND switched ON maybe 2500 and OFF by 4000. Pressure output switches to vacuum output per the diagram.

Technically this could all be done with RPM switches if you don't have a standalone with the appropriate outputs. I would make a nice control-panel looking thing that would allow you to adjust the rpms for each one quickly.

-- Boost control: I would try running the EBC to both precontrol and wastegate first using a tee, and only run an MBC on precontrol if you have to. They seem to respond to similar boost control duty cycle levels based on my testing. Using one EBC is one less thing to hassle with. Make sure you port the wastegate significantly.

Full thread is here: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/why-engine-so-damn-complicated-part-1-sequential-turbos-demystified-841821/

Charge control and turbo control should be switched at the same time. That opens the compressor and turbine sides of the secondary turbo respectively. Turbo control requires a switched ground and Charge control requires switched +12V. Wastegate and precontrol are fine with an EBC or MBC, just cap off one of the nipples. The stock configuration vents away air, kind of like the stock s5 boost control solenoid except that the vent is after the actuator instead of before.

Turbo control has 2 solenoids: vacuum and boost. If you really wanted to simplify things, you could ditch the pressure solenoid and pressure chamber and only run the vacuum solenoid. It may marginally affect response. Charge relief and charge control have 3 nipples, and switch from a fresh air/boost source to a vacuum source. The two solenoids are inverted with regards to that: charge relief is fresh air by default and then switches to vacuum, charge control is vacuum by default and then switches to fresh air.

Charge relief is going to have to come on earlier than charge control and charge relief. It vents during prespool, and prespool takes a little while. Preferably you would have a hysteresis function to switch back into sequential mode on deceleration at a different RPM that you switched into it. Default hysteresis value is 3000rpm but I prefer 3500. Otherwise, to make it easier you can just set your target transition to 4000rpm (both during acceleration and switching back during deceleration) and be done with it.

Summary:

I guess if you want to keep it simple, you could do it this way:

-- Charge control: +12V switched ON about 4000 and OFF below 4000. Vacuum output switches to pressure output per the diagram.

-- Turbo control (vacuum only): GND switched ON about 4000 and OFF below 4000. Vacuum output is switched when solenoid is engaged. Eliminate pressure tank and check valve.

-- Charge relief: Window switch needed. GND switched ON maybe 2500 and OFF by 4000. Pressure output switches to vacuum output per the diagram.

Technically this could all be done with RPM switches if you don't have a standalone with the appropriate outputs. I would make a nice control-panel looking thing that would allow you to adjust the rpms for each one quickly.

-- Boost control: I would try running the EBC to both precontrol and wastegate first using a tee, and only run an MBC on precontrol if you have to. They seem to respond to similar boost control duty cycle levels based on my testing. Using one EBC is one less thing to hassle with. Make sure you port the wastegate significantly.

#9

Thread Starter

Super Raterhater

iTrader: (6)

Joined: Dec 2001

Posts: 10,630

Likes: 3

From: NY, MA, MI, OR, TX, and now LA or AZ!

I've already worked out my vacuum routing and solenoid control. I've tested all of it down to a single output and got very good results, I never was quite sure of the effect I was having on the secondary turbo spooling it in this method though, as in my scenario it tends to start to come on with more load applied than original. The only difference I noticed in running those on two seperate triggers was a slightly different transition boost (which I just adjusted out with the MBC anyway). I think ideally a second boost source from the secondary tract would be useful in controlling the charge, but given the current state it seems to work out alright.

To better explain how my setup works:

Charge Relief really has no need as far as I can come up with the be managed at any other time than transition. Under normal conditions the valve is under vacuum at all times, so when pre-spool begins it vents as per normal and allows the charger to spin up. At transition it switches the valve to boost, which closes it, causing the charge control to properly equalize and open under spring pressure (which is also given boost at this time and vacuum is removed allowing for this to occur). If the turbo is underspooled, it'll equalize before the charge control opens. The only thing i've been able to achieve by changing the closing of the charge relief is by increasing the transition boost (probably from slightly overspooling). On decel with this setup the boost is still equalized and the excessive pressure vents off through the primary BOV until the charge control closes under spring power, if you were to accel prior to the defined 'reset' it'd act similarly to a non-sequential in being that both turbos would spool together (turbo control still being on) and the charge control would open at an equalized pressure. The behavior was very similar to stock from what I've found.

To better explain how my setup works:

Charge Relief really has no need as far as I can come up with the be managed at any other time than transition. Under normal conditions the valve is under vacuum at all times, so when pre-spool begins it vents as per normal and allows the charger to spin up. At transition it switches the valve to boost, which closes it, causing the charge control to properly equalize and open under spring pressure (which is also given boost at this time and vacuum is removed allowing for this to occur). If the turbo is underspooled, it'll equalize before the charge control opens. The only thing i've been able to achieve by changing the closing of the charge relief is by increasing the transition boost (probably from slightly overspooling). On decel with this setup the boost is still equalized and the excessive pressure vents off through the primary BOV until the charge control closes under spring power, if you were to accel prior to the defined 'reset' it'd act similarly to a non-sequential in being that both turbos would spool together (turbo control still being on) and the charge control would open at an equalized pressure. The behavior was very similar to stock from what I've found.

#11

Thread Starter

Super Raterhater

iTrader: (6)

Joined: Dec 2001

Posts: 10,630

Likes: 3

From: NY, MA, MI, OR, TX, and now LA or AZ!

Four years later, and I'm back!

I finished the project back in '09 and the car ran reasonably well, although I was never quite satisfied with the LIM setup. I had near constant boost leaks at the LIM gasket, as I could never get the center iron to seal well. Furthermore, the runner design simply did not go well with the 6port block despite having been lowered, welded in, and ported. As a result, I parked the GTUs and pilfered parts for my FD, and it has remained in this state ever since.

Recently, after getting the FD to a state I'm fairly content with, I've decided to reapproach the GTUs and start from scratch.

So, here's the future outlook:

The car will remain twin-turbo, sequentially controlled. (Same diagram as above, controlled via a MS-II)

Instead of the FD LIM modified and port matched to the 6 port block, I've decided to switch to a S5 TII LIM port matched to the 6port. This involves a bit of creative work to space the twins in such a manner that they clear the LIM while leaving room for the downpipe.

Retaining the FD UIM (porting to fit, not wasting money on an adapter)

Configuring closed loop idle speed control, EGO, and boost

Generic, Y-pipe mounted water/alcohol injection system (this will be incorporated after the car is tuned, not tuned to the injection system)

Complete TII drivetrain swap. I exploded my 4.3 rear end, and ate some teeth off the 4.1 i replaced it with, so I've decided its time to go back to the TII driveline. (This will be the 3rd driveline swap this car has seen!)

So, while this is a fairly boring update after 4 years, it's a precursor to a renewed interest in getting my GTUs once more road worthy. I'll be updating this thread more frequently with my progress, as I move from theory-crafting and preparation into execution.

I finished the project back in '09 and the car ran reasonably well, although I was never quite satisfied with the LIM setup. I had near constant boost leaks at the LIM gasket, as I could never get the center iron to seal well. Furthermore, the runner design simply did not go well with the 6port block despite having been lowered, welded in, and ported. As a result, I parked the GTUs and pilfered parts for my FD, and it has remained in this state ever since.

Recently, after getting the FD to a state I'm fairly content with, I've decided to reapproach the GTUs and start from scratch.

So, here's the future outlook:

The car will remain twin-turbo, sequentially controlled. (Same diagram as above, controlled via a MS-II)

Instead of the FD LIM modified and port matched to the 6 port block, I've decided to switch to a S5 TII LIM port matched to the 6port. This involves a bit of creative work to space the twins in such a manner that they clear the LIM while leaving room for the downpipe.

Retaining the FD UIM (porting to fit, not wasting money on an adapter)

Configuring closed loop idle speed control, EGO, and boost

Generic, Y-pipe mounted water/alcohol injection system (this will be incorporated after the car is tuned, not tuned to the injection system)

Complete TII drivetrain swap. I exploded my 4.3 rear end, and ate some teeth off the 4.1 i replaced it with, so I've decided its time to go back to the TII driveline. (This will be the 3rd driveline swap this car has seen!)

So, while this is a fairly boring update after 4 years, it's a precursor to a renewed interest in getting my GTUs once more road worthy. I'll be updating this thread more frequently with my progress, as I move from theory-crafting and preparation into execution.

#13

Thread Starter

Super Raterhater

iTrader: (6)

Joined: Dec 2001

Posts: 10,630

Likes: 3

From: NY, MA, MI, OR, TX, and now LA or AZ!

That was the plan, but the location on the FD manifold wouldn't work. This was a major reason for deciding to go with the S5 TII LIM instead and ditch the FD manifold all together. It'll be a bit tighter quarters than I had hoped for, but it won't require me to change any of my exhaust components, and even my oil drain and feed will still fit, so it won't be too bad of a swap.

Thread

Thread Starter

Forum

Replies

Last Post

Good luck with it, looks like it'll be interesting when it's done.

Good luck with it, looks like it'll be interesting when it's done.