Premix sucks and OMP sucks

#1

Thread Starter

Rotary Enthusiast

iTrader: (8)

Joined: Jul 2007

Posts: 893

Likes: 1

From: London, CANADA

Premix sucks and OMP sucks

I have read enough threads to know that generally, people feel premixing 2-stroke in the gas tank is superior to the OMP due to better lubrication, cleaner burning, less carbon, etc.. I get it.

I don't premix now, and I don't want to start premixing. Am I a bad person? Am I punishing my rotary engine...no. I'm behaving like Mazda engineers want me to. I hate stopping for gas (which happens often enough). I don't want to drag on the process by digging up a little bottle of two stoke and guessing how much to pour in this time; considering how much I added last time; and worry about a half bottle rolling around under the seat, smelling and leaking.

The oil metering pump was designed to do a job. And it has been working for me so far, on a 25 year old engine with 182,000 km. But couldn't I improve on it by feeding the OMP with 2stroke instead of 4 stroke oil? And maybe I wouldn't have to check my dip stick and top up my oil pan so often. And maybe I could even put synthetic oil in my oil pan, knowing it wasn't going to get sucked into the combustion chamber. That way, I can burn cleaner 2stroke oil and lub other engine parts with superior synthetic oil. And no premixing per fill-up.

An OMP adaptor, as offered by Rotary Aviation, or something similar that sucks oil from a separate reservoir will provide the sought after benefits. Even in a pinch, if I canít get my hands on 2stroke oil, I can use 4stroke motor oil. (Try premixing with regular oil and see how your fuel injectors like you.) Letís say I just continue to use conventional dino oil in the oil pan as well as the OMP reservoir, I have nothing to lose, but still something to gain. Just by separating the engine oil pan from the OMP reservoir and running 10w40 in both means I am injecting the combustion chamber with cool clean oil, not hot re-filtered motor oil.

Convinced??

I don't premix now, and I don't want to start premixing. Am I a bad person? Am I punishing my rotary engine...no. I'm behaving like Mazda engineers want me to. I hate stopping for gas (which happens often enough). I don't want to drag on the process by digging up a little bottle of two stoke and guessing how much to pour in this time; considering how much I added last time; and worry about a half bottle rolling around under the seat, smelling and leaking.

The oil metering pump was designed to do a job. And it has been working for me so far, on a 25 year old engine with 182,000 km. But couldn't I improve on it by feeding the OMP with 2stroke instead of 4 stroke oil? And maybe I wouldn't have to check my dip stick and top up my oil pan so often. And maybe I could even put synthetic oil in my oil pan, knowing it wasn't going to get sucked into the combustion chamber. That way, I can burn cleaner 2stroke oil and lub other engine parts with superior synthetic oil. And no premixing per fill-up.

An OMP adaptor, as offered by Rotary Aviation, or something similar that sucks oil from a separate reservoir will provide the sought after benefits. Even in a pinch, if I canít get my hands on 2stroke oil, I can use 4stroke motor oil. (Try premixing with regular oil and see how your fuel injectors like you.) Letís say I just continue to use conventional dino oil in the oil pan as well as the OMP reservoir, I have nothing to lose, but still something to gain. Just by separating the engine oil pan from the OMP reservoir and running 10w40 in both means I am injecting the combustion chamber with cool clean oil, not hot re-filtered motor oil.

Convinced??

#2

since i have the link to the picture may as well..

see that wear line in the middle? that is your lubrication tract from the OMP which mazda designed. now take the renesis which moved the single injector to 2 in the housing at the edges of the seal where you see the chrome wearing at the edges. guess what? the seal started to wear more again in the center and warp due to friction. then mazda made the renesis with 3 oil injectors in the rotor housing to essentially do a similar job of premixing to maximize affected lubricated areas.

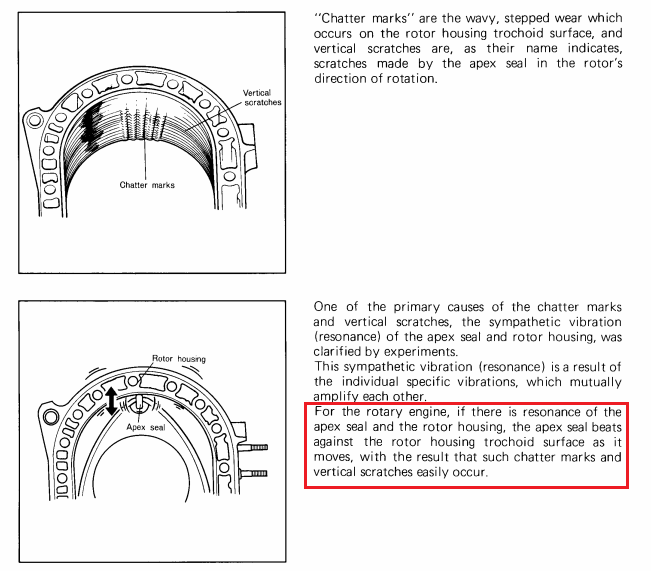

premixing is superior no matter how you feel about it. premixing has been known to improve engine life and reduce wear by up to 30% or MORE while reducing chatter of the seals which can also kill the housings(notice the chatter in the picture as well? this was not even an abused high RPM engine).

problem with 2 stroke oil through the OMP pump is the lubrication is still isolated to certain areas of the motor. premixing fuel gets to all points of friction inside the combustion chamber.

so feel free to do whatever you want.

but keep in mind, mazda made the oil metering system just to conform to the pure FACT that not everyone is willing to premix oil and fuel.

jesus, we just had this argument on the 8 club...

this all has been thoroughly proven by your friendly rotary specialty rebuilders.

on top of that, premixing in rotaries has been around for as long as these motors have existed and still remains today. perhaps some things get redesigned and better with age, premixing remains.

see that wear line in the middle? that is your lubrication tract from the OMP which mazda designed. now take the renesis which moved the single injector to 2 in the housing at the edges of the seal where you see the chrome wearing at the edges. guess what? the seal started to wear more again in the center and warp due to friction. then mazda made the renesis with 3 oil injectors in the rotor housing to essentially do a similar job of premixing to maximize affected lubricated areas.

premixing is superior no matter how you feel about it. premixing has been known to improve engine life and reduce wear by up to 30% or MORE while reducing chatter of the seals which can also kill the housings(notice the chatter in the picture as well? this was not even an abused high RPM engine).

problem with 2 stroke oil through the OMP pump is the lubrication is still isolated to certain areas of the motor. premixing fuel gets to all points of friction inside the combustion chamber.

so feel free to do whatever you want.

but keep in mind, mazda made the oil metering system just to conform to the pure FACT that not everyone is willing to premix oil and fuel.

jesus, we just had this argument on the 8 club...

this all has been thoroughly proven by your friendly rotary specialty rebuilders.

on top of that, premixing in rotaries has been around for as long as these motors have existed and still remains today. perhaps some things get redesigned and better with age, premixing remains.

Last edited by RotaryEvolution; 10-31-11 at 04:25 PM.

#3

^ I'm not sure if I agree with your assessment of the cause-and-effect relationships here. Did the OMP cause that pattern in the middle, or is the middle of the apex seal just prone to more friction and wear over 15-20 years and a gazillion heat cycles? Here are some things we know based on what Mazda has published.

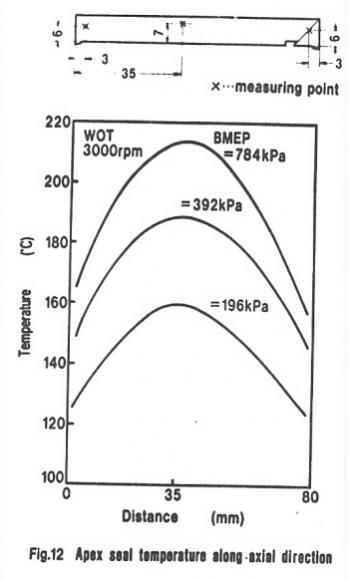

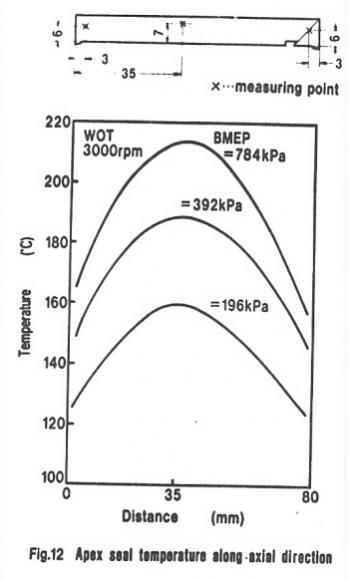

1) On a peripheral exhaust port rotary engine, the center of the apex seal is by far the hottest portion of the seal (obviously gets pretty hot on a Renesis too). The temperature at a given point on the apex seal is directly related to the friction along the sliding surface.

(Muroki, "Material Technology Applied to Rotary Engine at Mazda," 1986)

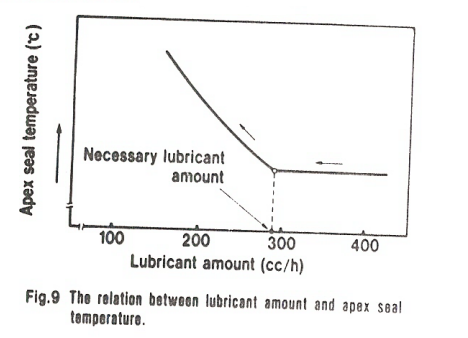

Soo... since the middle of the apex seal gets hottest, Mazda installed an oil injector there to cool it off with lubricating oil. They did a number of calculations to figure out what would be the least amount of oil they could deliver to meet their internal targets for wear. The apex seal temperature and friction are directly related to the amount of load (BMEP is a type of load measurement)

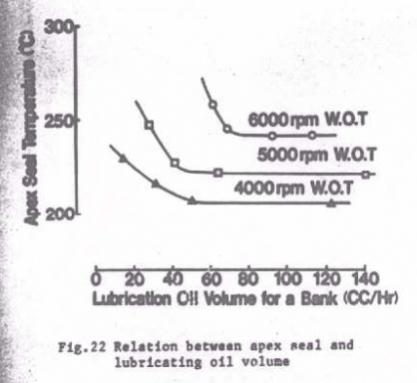

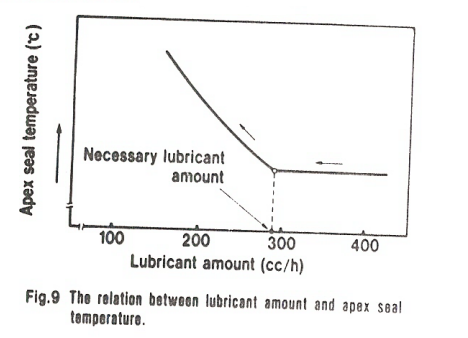

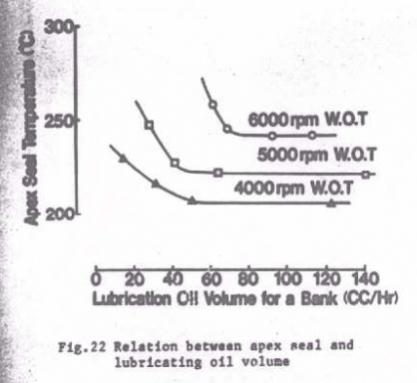

In the diagram above, the seal temperature begins to drop at high rpm because of mixture enrichment under heavy load. Here is another chart showing the relationship of rpm, lubricating oil, and apex seal temperature:

(Matsuda, "New Technology Employed for the Latest 13B-Rotary Engine," 1990)

Under a given condition you can reach a point where increasing the lubricating oil just wastes oil.

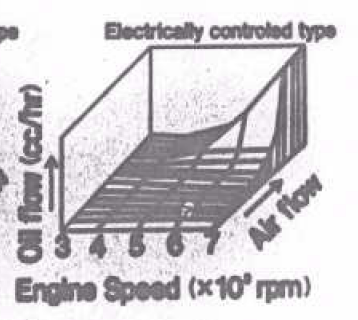

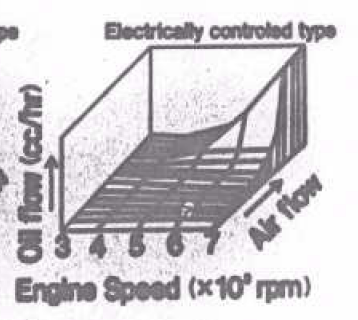

Mazda tried to figure out where that point is based on lab tests and certain calculations. They may not have always been right, but I also doubt they were intending for the housings to be used 150k (they probably should have though). The amount of lubricating oil used on the electric OMP's is directly related to the intake airflow:

It's not surprising to me that housings may have a color change in the area where the direct oil injectors were operating. It also does not surprise me that they have higher levels of wear in the area with the hottest temperatures and greatest friction--coincidentally, the same locations where the oil injectors were installed.

The thing that makes it hard to compare premixing and the OMP is that the premixing is done in a fixed ratio, and you have the ability to change that ratio based on how much you put in the gas tank. The OMP's delivery of lubrication depends on the mechanical characteristics of the pump and how Mazda configured it (or calibrated it in the ECU for later models).

On the FC the OMP also delivered oil into the intake manifold in a manner similar to premix. By similar I mean it was misted into the intake stroke, just like the primary injector sends droplets of fuel into the intake stroke. On the old carb'd engines the OMP also injected the oil through the intake system (there were no direct oil injectors). If you read the literature, they specifically installed oil injectors on the housings to concentrate the lubricating oil where the sliding surface needs it the most. They could have stuck with only misting it into the intake (like premix does) but that would have led to what they determined to be unacceptably high oil consumption on the higher output rotary engines.

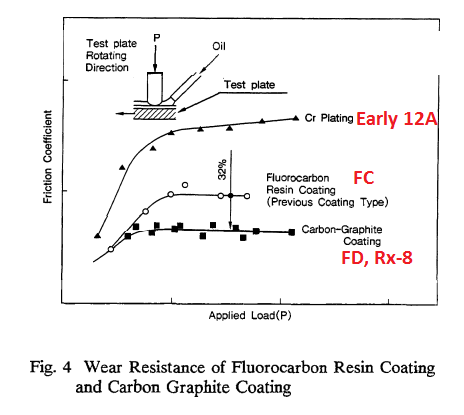

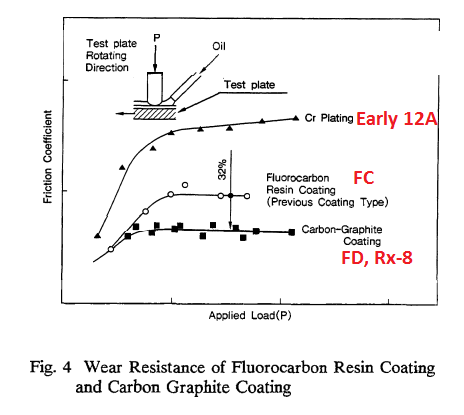

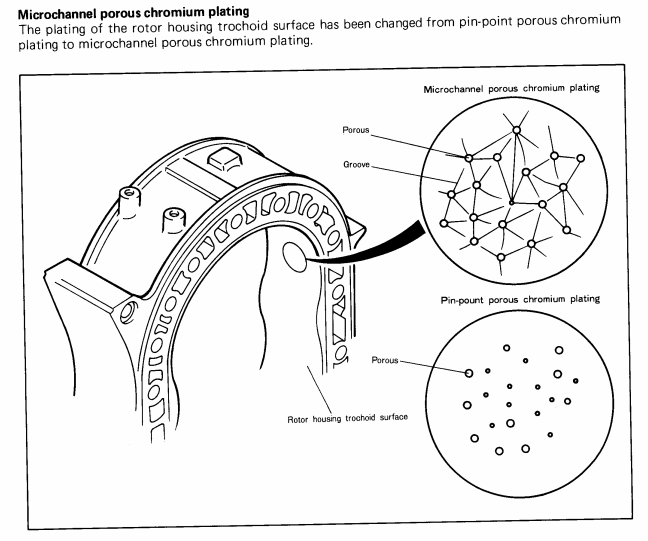

The other thing to consider is the way the car was driven, the type of oil that was used, and the surface treatment that was used when manufacturing the rotor housings. The FD and later rotor housings have a graphite treatment to reduce friction and improve retention of the oil film:

(Tashima, "Sequential Twin Turbocharged Rotary Engine of the Latest Rx-7, 1994)

When Mazda adopted the carbon-graphite treatment for the FD, they felt it unnecessary to mist oil into the intake stroke like they had been doing since the 10A engine. This was because of reduced friction on the new housings and their desire to lower oil consumption. They figured they could get away with it based on what their assumptions and simulations for how the engines would be driven. They kept the injector in the middle because the middle of the seal is what needs it the most.

On the Renesis, a LOT of heat is concentrated on the side of the apex seals near the irons due to the exhaust flow there. That's why Mazda put oil injectors there. They figured they could get away with leaving out an oil injector in the middle, because the exhaust was exiting out the side housing. They were wrong for the most part, hence all the warranty claims and the redesign which added an injector to the middle again.

The point I'm trying to make here is that premix allows you to easily increase the amount of lubricating oil. That's the main reason why it preserves the seals. Direct injection of oil onto the sliding surface is specifically there to lower apex seal temperatures in areas prone to high friction and heat. You can accomplish the same thing with a lot (comparatively speaking) of premix . The calibration for the OMP system was based on certain assumptions made by Mazda's engineers that we may not agree with.

1) On a peripheral exhaust port rotary engine, the center of the apex seal is by far the hottest portion of the seal (obviously gets pretty hot on a Renesis too). The temperature at a given point on the apex seal is directly related to the friction along the sliding surface.

(Muroki, "Material Technology Applied to Rotary Engine at Mazda," 1986)

Soo... since the middle of the apex seal gets hottest, Mazda installed an oil injector there to cool it off with lubricating oil. They did a number of calculations to figure out what would be the least amount of oil they could deliver to meet their internal targets for wear. The apex seal temperature and friction are directly related to the amount of load (BMEP is a type of load measurement)

In the diagram above, the seal temperature begins to drop at high rpm because of mixture enrichment under heavy load. Here is another chart showing the relationship of rpm, lubricating oil, and apex seal temperature:

(Matsuda, "New Technology Employed for the Latest 13B-Rotary Engine," 1990)

Under a given condition you can reach a point where increasing the lubricating oil just wastes oil.

Mazda tried to figure out where that point is based on lab tests and certain calculations. They may not have always been right, but I also doubt they were intending for the housings to be used 150k (they probably should have though). The amount of lubricating oil used on the electric OMP's is directly related to the intake airflow:

It's not surprising to me that housings may have a color change in the area where the direct oil injectors were operating. It also does not surprise me that they have higher levels of wear in the area with the hottest temperatures and greatest friction--coincidentally, the same locations where the oil injectors were installed.

The thing that makes it hard to compare premixing and the OMP is that the premixing is done in a fixed ratio, and you have the ability to change that ratio based on how much you put in the gas tank. The OMP's delivery of lubrication depends on the mechanical characteristics of the pump and how Mazda configured it (or calibrated it in the ECU for later models).

On the FC the OMP also delivered oil into the intake manifold in a manner similar to premix. By similar I mean it was misted into the intake stroke, just like the primary injector sends droplets of fuel into the intake stroke. On the old carb'd engines the OMP also injected the oil through the intake system (there were no direct oil injectors). If you read the literature, they specifically installed oil injectors on the housings to concentrate the lubricating oil where the sliding surface needs it the most. They could have stuck with only misting it into the intake (like premix does) but that would have led to what they determined to be unacceptably high oil consumption on the higher output rotary engines.

The other thing to consider is the way the car was driven, the type of oil that was used, and the surface treatment that was used when manufacturing the rotor housings. The FD and later rotor housings have a graphite treatment to reduce friction and improve retention of the oil film:

(Tashima, "Sequential Twin Turbocharged Rotary Engine of the Latest Rx-7, 1994)

When Mazda adopted the carbon-graphite treatment for the FD, they felt it unnecessary to mist oil into the intake stroke like they had been doing since the 10A engine. This was because of reduced friction on the new housings and their desire to lower oil consumption. They figured they could get away with it based on what their assumptions and simulations for how the engines would be driven. They kept the injector in the middle because the middle of the seal is what needs it the most.

On the Renesis, a LOT of heat is concentrated on the side of the apex seals near the irons due to the exhaust flow there. That's why Mazda put oil injectors there. They figured they could get away with leaving out an oil injector in the middle, because the exhaust was exiting out the side housing. They were wrong for the most part, hence all the warranty claims and the redesign which added an injector to the middle again.

The point I'm trying to make here is that premix allows you to easily increase the amount of lubricating oil. That's the main reason why it preserves the seals. Direct injection of oil onto the sliding surface is specifically there to lower apex seal temperatures in areas prone to high friction and heat. You can accomplish the same thing with a lot (comparatively speaking) of premix . The calibration for the OMP system was based on certain assumptions made by Mazda's engineers that we may not agree with.

The following users liked this post:

capn (12-14-21)

#4

i'm pretty sure it is 100% related to the OMP nozzle location and expansion/contraction rates, without a doubt.

it is far too common of a wear point, can be traced started at the nozzle location around to the exhaust port where it spreads wider and wider. why would the apex seal otherwise have a small wear channel directly in the center? perhaps from the hole itself, but at any rate i have noticed much less wear when premixing versus using conventional oils(OMP) with the nozzle port still in the same location.

it's quite obvious mazda didn't know everything so i ignore alot of their publishings. i'm a real world test junky, not a paper pushing analyst. each have their place to give starting points for testing purposes, otherwise i wouldn't have all these wonderful things to test, modify and adapt.

i am curious how my engine is doing also after several k miles of 0 combustion chamber lubrication whatsoever, perhaps soon i will tear it down and check up on it. but that is also with non OE seals, running the softer atkins seals.

most of the wear in the early engines was at the outer edges of the seal, namely the boot portion. im sure additional lubrication might not solely cure this but im quite sure it helps more than the OMP provides.

there is also the catalyst to keep in mind and plug fouling, too much 2 stroke fouls the plugs prematurely and clogs the cat. as well would the OMP system if they say doubled the amount of injected oil.

it is far too common of a wear point, can be traced started at the nozzle location around to the exhaust port where it spreads wider and wider. why would the apex seal otherwise have a small wear channel directly in the center? perhaps from the hole itself, but at any rate i have noticed much less wear when premixing versus using conventional oils(OMP) with the nozzle port still in the same location.

it's quite obvious mazda didn't know everything so i ignore alot of their publishings. i'm a real world test junky, not a paper pushing analyst. each have their place to give starting points for testing purposes, otherwise i wouldn't have all these wonderful things to test, modify and adapt.

i am curious how my engine is doing also after several k miles of 0 combustion chamber lubrication whatsoever, perhaps soon i will tear it down and check up on it. but that is also with non OE seals, running the softer atkins seals.

most of the wear in the early engines was at the outer edges of the seal, namely the boot portion. im sure additional lubrication might not solely cure this but im quite sure it helps more than the OMP provides.

there is also the catalyst to keep in mind and plug fouling, too much 2 stroke fouls the plugs prematurely and clogs the cat. as well would the OMP system if they say doubled the amount of injected oil.

Last edited by RotaryEvolution; 10-31-11 at 05:31 PM.

#5

It has a wear point directly in the center because the center of the apex seal is the part that gets the hottest. It has an OMP injector in the center for the same reason. The wear starts right near the OMP nozzle possibly due to chemical interactions and heat cycles related to the injector itself. But I also suspect that Mazda located the OMP nozzle there specifically because that's where the friction, high temperatures, and wear are most likely to start occurring as the rotor moves across the sliding surface.

#6

im leaning more towards the OMP hole itself gouging the seal. most if not all housings generally have more force applied to the housing during the intake stroke than the exhaust stroke. this is visibly evident by the polishing and sometimes excessive chattering effect you see on the topside of the housings. if chatter develops in this area it is usually 5 times worse than if it develops in the bottom chamber.

i'm sure you are also right that it is the hottest point on the seal due to the peripheral exhaust.

i'm sure you are also right that it is the hottest point on the seal due to the peripheral exhaust.

Last edited by RotaryEvolution; 10-31-11 at 05:36 PM.

#7

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,203

Likes: 2,826

From: https://www2.mazda.com/en/100th/

just a few points.

1. not that its common knowledge, but the NSU engines have an oil metering pump too. even in the 60's they didn't want to sell a new car where you have to premix.

2. mazda is trying to use the MINIMUM amount of oil to meet their needs. premix is usually done to meet a spec at high power (100:1 is listed for the P port 12A, 260hp@9000rpm), the rest of the time you're way over oiling. which is better than #3

3. with premix you get NO OIL at zero throttle.

4. why not look at what mazda did? you may not agree with the direction they took, but it does give you an idea of what to expect. its a time saver. for example we can look at the temp vs amount of oil graph that arghx posted, and we quickly know that 100cc/hr per rotor is way more than enough.

5. NONE of the oem metering systems mix the oil and gas directly, even the carbed cars have nozzles right in the venturi. the RB holley kits put the oil into the float bowls, it seems to be fine, i'm not sure why mazda didn't do it.

6. running with no metering oil for any length of time and you can expect all 5 housings, and both rotors to be junk. i've seen it, you're talking .250" wear on the side housings, apex seal grooves that are severely V'ed, and rotor housings and apex seals that are just shot.

for ME i have a P port 12A, and i've been premixing, but i have been thinking about putting the metering pump back on just because the engine gets too much oil at idle and low throttle, the premix doesn't even burn it just fills the mufflers, and fouls spark plugs. plus on the track i get no oiling at zero throttle, which is important

1. not that its common knowledge, but the NSU engines have an oil metering pump too. even in the 60's they didn't want to sell a new car where you have to premix.

2. mazda is trying to use the MINIMUM amount of oil to meet their needs. premix is usually done to meet a spec at high power (100:1 is listed for the P port 12A, 260hp@9000rpm), the rest of the time you're way over oiling. which is better than #3

3. with premix you get NO OIL at zero throttle.

4. why not look at what mazda did? you may not agree with the direction they took, but it does give you an idea of what to expect. its a time saver. for example we can look at the temp vs amount of oil graph that arghx posted, and we quickly know that 100cc/hr per rotor is way more than enough.

5. NONE of the oem metering systems mix the oil and gas directly, even the carbed cars have nozzles right in the venturi. the RB holley kits put the oil into the float bowls, it seems to be fine, i'm not sure why mazda didn't do it.

6. running with no metering oil for any length of time and you can expect all 5 housings, and both rotors to be junk. i've seen it, you're talking .250" wear on the side housings, apex seal grooves that are severely V'ed, and rotor housings and apex seals that are just shot.

for ME i have a P port 12A, and i've been premixing, but i have been thinking about putting the metering pump back on just because the engine gets too much oil at idle and low throttle, the premix doesn't even burn it just fills the mufflers, and fouls spark plugs. plus on the track i get no oiling at zero throttle, which is important

Trending Topics

#8

no lubrication on fuel cut doesn't seem to hurt the engine as much as the benefit of over lubricating it.

point is, most of these engines are already worn unless you have a very low mileage engine or have one built with new parts. longevity is very important when you're taking into account a motor with 125k+ miles that is starting to eat away at the internals more rapidly, where more lubrication is required if you want it to retain any sort of lengthy lifespan further than that. the OMP simply doesn't cut it at that point, partly because you can't vary the amount it injects much and because the lubrication is aimed at certain areas inside the motor which will get more lubrication than others. in my opinion ALL areas need equal lubrication when you start to reach that point where the wear begins to ramp up more rapidly due to age/revolutions.

point is, most of these engines are already worn unless you have a very low mileage engine or have one built with new parts. longevity is very important when you're taking into account a motor with 125k+ miles that is starting to eat away at the internals more rapidly, where more lubrication is required if you want it to retain any sort of lengthy lifespan further than that. the OMP simply doesn't cut it at that point, partly because you can't vary the amount it injects much and because the lubrication is aimed at certain areas inside the motor which will get more lubrication than others. in my opinion ALL areas need equal lubrication when you start to reach that point where the wear begins to ramp up more rapidly due to age/revolutions.

Last edited by RotaryEvolution; 10-31-11 at 05:56 PM.

#9

Oil dripper.

I love how everyone refers to them as injectors like they atomize or something.

They drip, thats it. Premix lubricates the whole combustion chamber. OMP drips oil on the center of rotor which is ****.

As far as the wear marks on the outside of the housings. I feel its from expansion and contraction at that point. When you heat up aluminum swells and pushes on cast iron, now think what the chromelike wear surface does at the crunch point. rinse and repeat.

I got a tip years a go to put a very tiny chamfer arround the edge of the housings from some old racers. Ive done it ever since. They claim that premix plus the chamfer greatly decreases plate and housing wear.

Karack dose have something tho. If it was the oil injector hole, where are the marks from the exhast port and the plug holes? Its the oil dripping and spinning off the rotor in a circle.

I love how everyone refers to them as injectors like they atomize or something.

They drip, thats it. Premix lubricates the whole combustion chamber. OMP drips oil on the center of rotor which is ****.

As far as the wear marks on the outside of the housings. I feel its from expansion and contraction at that point. When you heat up aluminum swells and pushes on cast iron, now think what the chromelike wear surface does at the crunch point. rinse and repeat.

I got a tip years a go to put a very tiny chamfer arround the edge of the housings from some old racers. Ive done it ever since. They claim that premix plus the chamfer greatly decreases plate and housing wear.

Karack dose have something tho. If it was the oil injector hole, where are the marks from the exhast port and the plug holes? Its the oil dripping and spinning off the rotor in a circle.

#10

im leaning more towards the OMP hole itself gouging the seal. most if not all housings generally have more force applied to the housing during the intake stroke than the exhaust stroke. this is visibly evident by the polishing and sometimes excessive chattering effect you see on the topside of the housings. if chatter develops in this area it is usually 5 times worse than if it develops in the bottom chamber.

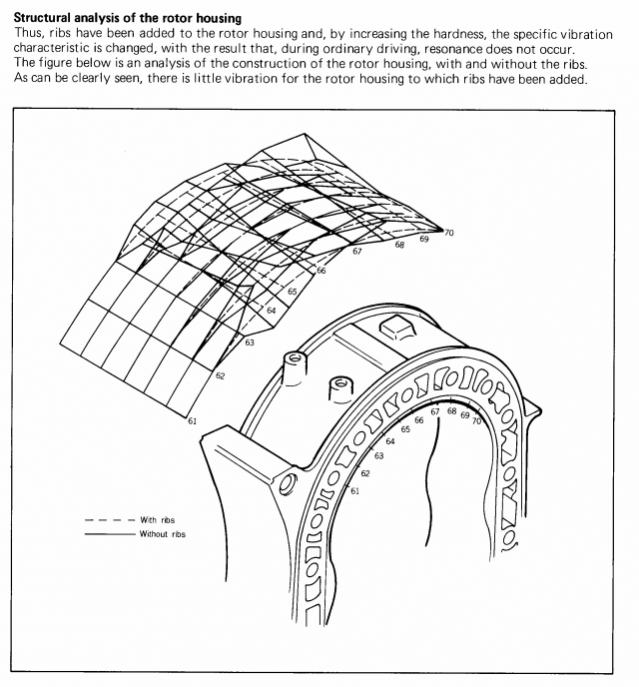

There is some discussion in the literature (GSL-SE training manual and another paper from the mid 80s) about the channels and pores on the chrome surface being there to specifically help reduce scratches and chatter marks. I can see those eventually breaking down over the life of the housing. They also talk about how Mazda changed the rib structure of the housings starting with series 3 in order to reduce certain vibrations leading to chatter marks near the top.

If the chatter marks and scratches are caused by vibration and resonance frequencies, I wonder what it takes to aggravate them.

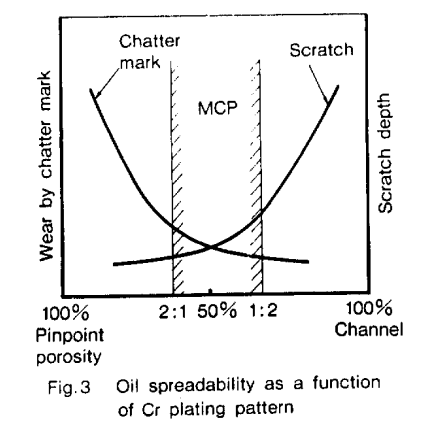

Could certain modifications such as exhaust, engine mounts, flywheels, etc change the vibration characteristics and contribute to the chatter marks? Or is it inevitable when engaging in any enough sporty driving? The channels and pores on the chrome surface are supposed to help spread the oil and retain the lubrication film:

These relationships were established when Mazda was developing the pores and channels right around the time of the series 3 engines. If there are no pores, the housing is prone to scratches. If there are no channels, the housing is prone to chatter marks--that's how I interpret it anyway.

So if the housing is old and the channels/pores break down due to normal wear, are chatter marks and scratches inevitable then? Especially at the top of the housing which is prone to the vibration-related effects?

Interesting questions indeed. It seems that premix addresses a lot of these problems because ultimately it provides so much lubrication that the apex seal can ride along the sliding surface more easily.

Last edited by arghx; 10-31-11 at 06:16 PM. Reason: premix

The following users liked this post:

capn (12-14-21)

#11

Spent a good chunk of my teen years whailing on dirt bikes and rebuilding 2stroke engines I had abused. I would contend that there is more than enough oil present when you let off the gas from 10k and downshift with zero throttle.

There is always some residual left over, specially if your doing 1oz to 1gallon. 60 deg cross hatch on your housings almost ensures that. I never liked mazdas "chrome" solution to what piston engines had figured out in the 1800's.

There is always some residual left over, specially if your doing 1oz to 1gallon. 60 deg cross hatch on your housings almost ensures that. I never liked mazdas "chrome" solution to what piston engines had figured out in the 1800's.

just a few points.

1. not that its common knowledge, but the NSU engines have an oil metering pump too. even in the 60's they didn't want to sell a new car where you have to premix.

2. mazda is trying to use the MINIMUM amount of oil to meet their needs. premix is usually done to meet a spec at high power (100:1 is listed for the P port 12A, 260hp@9000rpm), the rest of the time you're way over oiling. which is better than #3

3. with premix you get NO OIL at zero throttle.

4. why not look at what mazda did? you may not agree with the direction they took, but it does give you an idea of what to expect. its a time saver. for example we can look at the temp vs amount of oil graph that arghx posted, and we quickly know that 100cc/hr per rotor is way more than enough.

5. NONE of the oem metering systems mix the oil and gas directly, even the carbed cars have nozzles right in the venturi. the RB holley kits put the oil into the float bowls, it seems to be fine, i'm not sure why mazda didn't do it.

6. running with no metering oil for any length of time and you can expect all 5 housings, and both rotors to be junk. i've seen it, you're talking .250" wear on the side housings, apex seal grooves that are severely V'ed, and rotor housings and apex seals that are just shot.

for ME i have a P port 12A, and i've been premixing, but i have been thinking about putting the metering pump back on just because the engine gets too much oil at idle and low throttle, the premix doesn't even burn it just fills the mufflers, and fouls spark plugs. plus on the track i get no oiling at zero throttle, which is important

1. not that its common knowledge, but the NSU engines have an oil metering pump too. even in the 60's they didn't want to sell a new car where you have to premix.

2. mazda is trying to use the MINIMUM amount of oil to meet their needs. premix is usually done to meet a spec at high power (100:1 is listed for the P port 12A, 260hp@9000rpm), the rest of the time you're way over oiling. which is better than #3

3. with premix you get NO OIL at zero throttle.

4. why not look at what mazda did? you may not agree with the direction they took, but it does give you an idea of what to expect. its a time saver. for example we can look at the temp vs amount of oil graph that arghx posted, and we quickly know that 100cc/hr per rotor is way more than enough.

5. NONE of the oem metering systems mix the oil and gas directly, even the carbed cars have nozzles right in the venturi. the RB holley kits put the oil into the float bowls, it seems to be fine, i'm not sure why mazda didn't do it.

6. running with no metering oil for any length of time and you can expect all 5 housings, and both rotors to be junk. i've seen it, you're talking .250" wear on the side housings, apex seal grooves that are severely V'ed, and rotor housings and apex seals that are just shot.

for ME i have a P port 12A, and i've been premixing, but i have been thinking about putting the metering pump back on just because the engine gets too much oil at idle and low throttle, the premix doesn't even burn it just fills the mufflers, and fouls spark plugs. plus on the track i get no oiling at zero throttle, which is important

#12

#14

Thread Starter

Rotary Enthusiast

iTrader: (8)

Joined: Jul 2007

Posts: 893

Likes: 1

From: London, CANADA

Do they feel that having the OMP using 2stroke oil is better than regular oil?

Has any premixer ever run short at the pump and wished they could flip flop to regular motor oil on the spot?

I'm not saying premixing isn't the best solution. But what is the second best solution? Isn't an OMP running clean 2stroke worth considering? It has got to have some benefit over stealing hot dirty engine oil from the oil pan and dripping it into the combustion.

Yes, there is evident of damaged housings from using motor oil through the OMP. I'm suggesting a better solution that is easier than premixing.

#15

I'm not sure if carbon and ceramic seals do better because of some natural resonance/frequency aspect or if it's the fact that they retain lubrication better. It might be a little bit of both. There has to be some drawbacks to them for regular passenger cars or Mazda would have used them. They might cost too much, or they may not wear too well or seal well enough to meet emissions.

#16

my 2c

A-

mazda test things and dont presume

B-

the original nikki on 69-71 r100 and 71 rx2 used to mix the OMP oil into the fuel bowl and not directly into the inlet air stream

ie,, premixing that is engine load dependent

they soon learned to take a different path

,, possibly because at zero throttle there is very little lubrication at idle and during decel

premixing is not advantageous in these situations

C-

carbon and ceramic chatter less cause they have less mass to overcome the spring harmonics ,, period

they wear less because they have less mass and have some self lubricating properties

and importantly they are thermally less conductive than steel/iron and less prone to the middle bowing under heat loads and making uneven housing wear

the rate of lube is a function of the friction and load , the friction and load is a function directly related to the mass, and speed of the seal

D-

for the iron seals , mazda developed crowning of the apex seal to combat uneven housing wear and promote better warm sealing

putting oil in the center of the apex seal where it is hottest is also part of the same strategy of getting things flat under heat and load

premixing is not helping here

E-

edge wear-- caused purely by the wedge section of the apex seal end having all its mass concentrated on a very narrow point

the original 74/75 3mm apex seal had a wider tip on the wedge piece and didnt have this issue

some aftermarket apex seals take the same approach,, and wear less at the edge

premixing is not helping here

F-

adding a 2 stroke bowl to the OMP is relying heavily on the fact you keep it topped up

run it dry for a short period and you undo any good work it may have done

G-

two stroke oils are intended to mix readily with fuels and lubricate the crank on the two stroke engine prior to combustion

engine oil is not , it is intended to lubricate, cool and protect the metal surfaces from gall and sheer forces

running too rich with fuel in fact increases wear cause it has diluted to ability of the housing lube oil to protect against sheer

i know that because i run propane gas ( good luck adding premix to that )

and have found remarkably low rates of wear , even with the OMP turned down

i have no dilution, so my lube oil does a better job

F-

the stripe in the middle from the OMP drip is the UNWEAR mark, not a wear mark

they also correspond usually to a clear spot on the rotor itself

evidence that OMP oil does not contribute to carbon build up as much as excessive mixtures burning to acetylene byproducts due to incomplete combustion

-------------

the only issues i see with OMP are

A-

that if unserviced, they leak and the lines can fail

if you do preemptive maintenance

then it is not an issue as much as forgetting to to top up the OMP 2 stroke feed tank

or getting the maths wrong and running excessive oil mixtures full time,, which may also contribute to carbon buildup

( as well as being a PITA and costing the hip pocket )

B- dont lubricate the entire seal in some instances as well as it should

( looking squarely at the s1 rx8 engine with its unique heat issues )

C- are not designed to keep up with mass flows above a certain point, at which point supplementation of the OMP with premix is advised

D- not designed to work with aftermarket apex seals which inevitably require more lube to bandaid the poor material selections

evidence that mazda got things right is the fact that many FC NA engines run to 250 000 km unopened and stock

A-

mazda test things and dont presume

B-

the original nikki on 69-71 r100 and 71 rx2 used to mix the OMP oil into the fuel bowl and not directly into the inlet air stream

ie,, premixing that is engine load dependent

they soon learned to take a different path

,, possibly because at zero throttle there is very little lubrication at idle and during decel

premixing is not advantageous in these situations

C-

carbon and ceramic chatter less cause they have less mass to overcome the spring harmonics ,, period

they wear less because they have less mass and have some self lubricating properties

and importantly they are thermally less conductive than steel/iron and less prone to the middle bowing under heat loads and making uneven housing wear

the rate of lube is a function of the friction and load , the friction and load is a function directly related to the mass, and speed of the seal

D-

for the iron seals , mazda developed crowning of the apex seal to combat uneven housing wear and promote better warm sealing

putting oil in the center of the apex seal where it is hottest is also part of the same strategy of getting things flat under heat and load

premixing is not helping here

E-

edge wear-- caused purely by the wedge section of the apex seal end having all its mass concentrated on a very narrow point

the original 74/75 3mm apex seal had a wider tip on the wedge piece and didnt have this issue

some aftermarket apex seals take the same approach,, and wear less at the edge

premixing is not helping here

F-

adding a 2 stroke bowl to the OMP is relying heavily on the fact you keep it topped up

run it dry for a short period and you undo any good work it may have done

G-

two stroke oils are intended to mix readily with fuels and lubricate the crank on the two stroke engine prior to combustion

engine oil is not , it is intended to lubricate, cool and protect the metal surfaces from gall and sheer forces

running too rich with fuel in fact increases wear cause it has diluted to ability of the housing lube oil to protect against sheer

i know that because i run propane gas ( good luck adding premix to that )

and have found remarkably low rates of wear , even with the OMP turned down

i have no dilution, so my lube oil does a better job

F-

the stripe in the middle from the OMP drip is the UNWEAR mark, not a wear mark

they also correspond usually to a clear spot on the rotor itself

evidence that OMP oil does not contribute to carbon build up as much as excessive mixtures burning to acetylene byproducts due to incomplete combustion

-------------

the only issues i see with OMP are

A-

that if unserviced, they leak and the lines can fail

if you do preemptive maintenance

then it is not an issue as much as forgetting to to top up the OMP 2 stroke feed tank

or getting the maths wrong and running excessive oil mixtures full time,, which may also contribute to carbon buildup

( as well as being a PITA and costing the hip pocket )

B- dont lubricate the entire seal in some instances as well as it should

( looking squarely at the s1 rx8 engine with its unique heat issues )

C- are not designed to keep up with mass flows above a certain point, at which point supplementation of the OMP with premix is advised

D- not designed to work with aftermarket apex seals which inevitably require more lube to bandaid the poor material selections

evidence that mazda got things right is the fact that many FC NA engines run to 250 000 km unopened and stock

#17

disadvantage -

E- if you choose fully syn oil, will inject this into the housing where some types are known to burn to residues that may cause issues with gumming

( and i have already somewhere posted some choice pics of thus residue ruined housings and rotors )

racers and street cars have differing needs in regards to the issues at hand

and i can see why in a race engine at 100% more than intended factory power levels would prefer the premix and do away with the risk of a failed OMP, and have no issues with carbonisation due to frequent pull down

on the other hand i see entirely why mazda provided this system for street cars and its advantages in that lower power scenario

E- if you choose fully syn oil, will inject this into the housing where some types are known to burn to residues that may cause issues with gumming

( and i have already somewhere posted some choice pics of thus residue ruined housings and rotors )

racers and street cars have differing needs in regards to the issues at hand

and i can see why in a race engine at 100% more than intended factory power levels would prefer the premix and do away with the risk of a failed OMP, and have no issues with carbonisation due to frequent pull down

on the other hand i see entirely why mazda provided this system for street cars and its advantages in that lower power scenario

#18

Are you seeing these patterns on previously unopened engines or ones that have been rebuilt with used housings, or both? Is there a pattern to it? I'm a little skeptical about the OMP nozzle hole causing wear. The plug holes are a lot bigger. Seems like the biggest issues with putting holes in the housings are gas leakage.

after about 30k miles the pores in the housings have worn in spots to a smooth finish so the housing can't retain oil for lubrication.

Last edited by RotaryEvolution; 11-01-11 at 01:55 PM.

#19

I premix. It's easy, I put in a half bottle per fill up. So probably slightly more rich than 1oz / 1 gallon on any given fill up.

I don't DD my car but still how hard is it to add oil?

I like being able to run whatever oil I want in the oil pan and the reduced complexity under the hood.

I don't DD my car but still how hard is it to add oil?

I like being able to run whatever oil I want in the oil pan and the reduced complexity under the hood.

#20

ceramics weren't cost effective to use in mass produced vehicles which is why they were only used for racing applications. i have seen engines that were raced for almost 10 seasons with ceramics that had no chatter and almost no rotor housing wear in boosted applications.

for testing, i know mazda tests their products thoroughly BUT we are dealing with criteria rebuilding these engines that were out of their scope in order to keep the engines alive longer. for example the issue with the irons rotting and blowing the coolant seal valley, they figured out the issue after many years and corrected it again on the renesis but we still have to deal with the ramifications. the rotor housings also won't be available forever so we have to work out methods of refurbishing the housings OR getting the most miles from them which is where i feel premixing steps in.

the rotors can always be milled for larger seals to add in a second lifespan to them.

irons can be lapped/milled and re-nitrited also for a second lifespan, but the coolant seal wall breakage is still an issue for which i have been testing my inserts.

for testing, i know mazda tests their products thoroughly BUT we are dealing with criteria rebuilding these engines that were out of their scope in order to keep the engines alive longer. for example the issue with the irons rotting and blowing the coolant seal valley, they figured out the issue after many years and corrected it again on the renesis but we still have to deal with the ramifications. the rotor housings also won't be available forever so we have to work out methods of refurbishing the housings OR getting the most miles from them which is where i feel premixing steps in.

the rotors can always be milled for larger seals to add in a second lifespan to them.

irons can be lapped/milled and re-nitrited also for a second lifespan, but the coolant seal wall breakage is still an issue for which i have been testing my inserts.

Last edited by RotaryEvolution; 11-01-11 at 02:04 PM.

#21

There seems to be strong stand point for each way. I was thinking about using the Rotary avaiton adapter and running two cycle oil thru the OMP but ..... i am not sure now.

#22

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,203

Likes: 2,826

From: https://www2.mazda.com/en/100th/

ceramics weren't cost effective to use in mass produced vehicles which is why they were only used for racing applications. i have seen engines that were raced for almost 10 seasons with ceramics that had no chatter and almost no rotor housing wear in boosted applications.

#23

the pettit FD race motor that won the '98 GT2 series. not sure if it was rebuilt prior to selling the car to the new owner but it popped a seal back in '08 ish where it was sent to me to be gone through. blew due to a lean condition which i believe was sourced and repaired afterwards, he just wanted the engine gone through and the transmission inspected(wouldn't go into 5th, all appeared ok but it was still locked out after i reassembled it).

http://www.pettitracing.com/racing-heritage/

another reason ceramics are bad, they take out the whole portion of the engine when they fail. 2 irons, 1 rotor and 1 housing needed to be replaced.

http://www.pettitracing.com/racing-heritage/

another reason ceramics are bad, they take out the whole portion of the engine when they fail. 2 irons, 1 rotor and 1 housing needed to be replaced.

Last edited by RotaryEvolution; 11-01-11 at 05:11 PM.

#24

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,203

Likes: 2,826

From: https://www2.mazda.com/en/100th/

the pettit FD race motor that won the '98 GT2 series. not sure if it was rebuilt prior to selling the car to the new owner but it popped a seal back in '08 ish where it was sent to me to be gone through. blew due to a lean condition which i believe was sourced and repaired afterwards, he just wanted the engine gone through and the transmission inspected(wouldn't go into 5th, all appeared ok but it was still locked out after i reassembled it).

http://www.pettitracing.com/racing-heritage/

another reason ceramics are bad, they take out the whole portion of the engine when they fail. 2 irons, 1 rotor and 1 housing needed to be replaced.

http://www.pettitracing.com/racing-heritage/

another reason ceramics are bad, they take out the whole portion of the engine when they fail. 2 irons, 1 rotor and 1 housing needed to be replaced.