Power drop and noticeable hesitation issue at high (6300) rpm

#26

Thread Starter

Joined: Jul 2006

Posts: 383

Likes: 9

From: Haywards 5000

^^ good find.

I'm wondering if exhaust restriction of the stock system could be responsible for this. The only mods on the "stock" car are RB header, according to the site. Still, that dyno chart looks rather extreme to me. My other s5na has a stock motor, RB header, high-flow cat, and stock behind the cat. But it produces good torque up to redline at 8K.

I will follow up with Ludwig Motorsports to see if I can get any further info.

If you go to

http://www.digitaltuning.com/index.p...age=2&ecu=S5NA

and look at the stock dyno charts (click "show dyno charts"), you see a big drop in hp and torque right around 6300 rpm.

http://www.digitaltuning.com/index.p...age=2&ecu=S5NA

and look at the stock dyno charts (click "show dyno charts"), you see a big drop in hp and torque right around 6300 rpm.

I will follow up with Ludwig Motorsports to see if I can get any further info.

#27

Thread Starter

Joined: Jul 2006

Posts: 383

Likes: 9

From: Haywards 5000

Originally Posted by 088

I will follow up with Ludwig Motorsports to see if I can get any further info.

He also made this comment:

6300 should be the area where you find peak torque. At that point detonation is most likely and it's also there area where a weak ignition can begin to show itself as working chamber pressure is at its peak.

However, in my case, ignition problems have essentially been ruled out. There are no problems up to 6300 rpm, and various ignition components have already been replaced with known good units.

The power drop behavior is 100% reproducible, which is consistent with the drop in injector pulse width described earlier.

#28

Thread Starter

Joined: Jul 2006

Posts: 383

Likes: 9

From: Haywards 5000

Voltage at injectors checked.

Voltage drop test of grounds for engine: no greater than 0.1.

Checked oil metering pump connectors.

Swapped MAF with tII version (has a different spring rate).

Routed engine harness wires away from the alternator.

Next steps:

Investigate temp sensor signal.

Other input sensor signal tests?

There are ~4 grounds for the ECU. Possible grounding issue in that area?

Borrow modded s5 ECU that has data logging capability. See if we can get any additional useful data in the problem rpm range.

I'm wondering if the high amp alternator is causing some undesirable noise. Perhaps it's worth just swapping it out with a known good stock unit?

Voltage drop test of grounds for engine: no greater than 0.1.

Checked oil metering pump connectors.

Swapped MAF with tII version (has a different spring rate).

Routed engine harness wires away from the alternator.

Next steps:

Investigate temp sensor signal.

Other input sensor signal tests?

There are ~4 grounds for the ECU. Possible grounding issue in that area?

Borrow modded s5 ECU that has data logging capability. See if we can get any additional useful data in the problem rpm range.

I'm wondering if the high amp alternator is causing some undesirable noise. Perhaps it's worth just swapping it out with a known good stock unit?

#29

Thread Starter

Joined: Jul 2006

Posts: 383

Likes: 9

From: Haywards 5000

Final Diagnosis

The problem is, at last, solved! In Ben's words before he left for Vegas (sent April 22):

Originally Posted by Karack

took some figures and tried to single out the issue but it wasn't easily pinpointed by the ECU logging or the wideband. we knew there was a secondary injector issue and the staging wasn't working properly. i made and installed the new restrictor pill into the MAP sensor line and that helped smooth out the vacuum signal so there wasn't so many spikes in the signal to the ECU which helped drivability, timing and fuel maps but the problem still persisted.

i started focusing on the secondary injector circuit, wired up a new power wire to the batter to feed the secondaries fresh power but it still had the issue. last i looked at the ground circuit from the ECU which appeared ok but i had to do some unorthodox diagnostic techniques, i pulled the secondary wires out of the ECU terminals and swapped them with the primaries so the secondaries would be used for idling the car which allows me to test the secondary circuits without a dyno and at all times. the car started and ran on one rotor so i started pulling each of the connectors off to see which was getting fue and which wasn't, the front rotor wasn't functioning at all so i ran a new backup wire from the injector clip to the ECU which bypassed the whole engine wiring harness and started the car, it idled ok at that point so i knew i was at the root of the problem. i swapped the wires back in the plugs and took the car out for a drive and it smoothed out the power curve in the 6300+ RPM range. i had to lean it out a bit in fact because the upgraded fuel pump was pushing too much fuel through the secondaries in the upper range.

i started focusing on the secondary injector circuit, wired up a new power wire to the batter to feed the secondaries fresh power but it still had the issue. last i looked at the ground circuit from the ECU which appeared ok but i had to do some unorthodox diagnostic techniques, i pulled the secondary wires out of the ECU terminals and swapped them with the primaries so the secondaries would be used for idling the car which allows me to test the secondary circuits without a dyno and at all times. the car started and ran on one rotor so i started pulling each of the connectors off to see which was getting fue and which wasn't, the front rotor wasn't functioning at all so i ran a new backup wire from the injector clip to the ECU which bypassed the whole engine wiring harness and started the car, it idled ok at that point so i knew i was at the root of the problem. i swapped the wires back in the plugs and took the car out for a drive and it smoothed out the power curve in the 6300+ RPM range. i had to lean it out a bit in fact because the upgraded fuel pump was pushing too much fuel through the secondaries in the upper range.

#30

Thread Starter

Joined: Jul 2006

Posts: 383

Likes: 9

From: Haywards 5000

It came down to a single wire.....

.....

Originally Posted by 088

I should have remembered to ask you which wire you replaced in the harness.

Originally Posted by Karack

the faulty wire was the secondary rear injector ground signal wire from the ECU to the injector, it is the smaller of the 2 wires that leads into the plug, the larger black/yellow wires have constant power while the ignition is on from the main relay which also feeds power to the ignition. the wire ohm tested ok so i assume it is somehow grounding out somewhere slightly or is rubbed through into another wire and is getting mixed signals so the ground signal is bleeding off to another circuit.

#31

Thread Starter

Joined: Jul 2006

Posts: 383

Likes: 9

From: Haywards 5000

Final Words

It's incredible that the root cause turned out to be a component that was already replaced, early on in the diagnosis/repair process. There was literally zero improvement after the engine harness was replaced back in August 2007, two months after I bought the car. All further diagnostic work (nearly 3 years on & off) was done with the assumption that the harness was no longer a possible culprit.

Why not just ditch the car and get something else? There are quite a few track-prepared FCs that come up for sale.....

It came down to three things: stubbornness; out-of-sight / out-of-mind phenomenon -- the car remained in California while I spent most of my time in Redmond, WA, so it was not something that I thought about daily; and psychology -- it replaced another white n/a FC that I sold because I didn't want to deal with the bodywork after a van whacked it on driver side front (and miraculously didn't cause any mechanical damage). Covering up for an old regret, I suppose.

Some good things / info / lessons to come out of this:

Thanks to this problem, I became acquainted with all three Bay Area rotary shops fairly well, especially PR Motorsports in Hayward and Rotorsport in Santa Clara. As a bonus, I found out that Rotorsport is a Mazdaspeed Protegé expert. He has an MSP with 40 miles (possibly the only one in the world in essentially new condition) and has an MP3 with a V6, among other things. (Important info for me, as I am part of an ever-shrinking small club of MSP owners. That car has other interesting issues of its own .)

.)

Rotary Evolution (Ben Blankenhorn) is a damn good mechanic. His excellent reputation as a rotary engine builder is well-documented in other threads. It's too bad he left California. Fixed my car just before he left, under threats that it would follow him to Las Vegas.

A logical, diagnostic approach will save time and money in the end. Everyone involved started out with a logical troubleshooting process. Later on, this devolved into some combination of experience-based guesswork, assumptions, and maybe even hastiness on occasion.

Pay attention to your data, and check proper function after replacing parts. The injector pulse width measurements taken by Rick's Rotary were valuable clues. Adding the RTek 2.0 gave decent data-collection capabilities; well worth the $450 and would have saved time and money, had I decided to put it in earlier.

With this problem out of the way, the car enjoys a typical streetported powerband. And with the solenoid rack, 6PI, and VDI actuators eliminated, there is very little torque at low and mid-range RPM. Although the intended purpose of the car is road course track days at 5500 to 8000 rpm, I do intend to drive it on the street occasionally, and the absence of low-end torque bothers me a bit. I'm left to wonder if I should just put everything back the way it was (solenoids and the actuators), change gear ratios (Miata gears?), replace the rear end, etc. Or maybe operate the actuators with an ignition switch & small air pump instead of the stock vacuum arrangement. But those are topics for another thread (and probably covered extensively already).

So if YOU have an FC plagued with high-end power loss, you now have another thread to read. Long, tortuous, verbose, but with a happy ending.

Why not just ditch the car and get something else? There are quite a few track-prepared FCs that come up for sale.....

It came down to three things: stubbornness; out-of-sight / out-of-mind phenomenon -- the car remained in California while I spent most of my time in Redmond, WA, so it was not something that I thought about daily; and psychology -- it replaced another white n/a FC that I sold because I didn't want to deal with the bodywork after a van whacked it on driver side front (and miraculously didn't cause any mechanical damage). Covering up for an old regret, I suppose.

Some good things / info / lessons to come out of this:

Thanks to this problem, I became acquainted with all three Bay Area rotary shops fairly well, especially PR Motorsports in Hayward and Rotorsport in Santa Clara. As a bonus, I found out that Rotorsport is a Mazdaspeed Protegé expert. He has an MSP with 40 miles (possibly the only one in the world in essentially new condition) and has an MP3 with a V6, among other things. (Important info for me, as I am part of an ever-shrinking small club of MSP owners. That car has other interesting issues of its own

.)

.)Rotary Evolution (Ben Blankenhorn) is a damn good mechanic. His excellent reputation as a rotary engine builder is well-documented in other threads. It's too bad he left California. Fixed my car just before he left, under threats that it would follow him to Las Vegas.

A logical, diagnostic approach will save time and money in the end. Everyone involved started out with a logical troubleshooting process. Later on, this devolved into some combination of experience-based guesswork, assumptions, and maybe even hastiness on occasion.

Pay attention to your data, and check proper function after replacing parts. The injector pulse width measurements taken by Rick's Rotary were valuable clues. Adding the RTek 2.0 gave decent data-collection capabilities; well worth the $450 and would have saved time and money, had I decided to put it in earlier.

With this problem out of the way, the car enjoys a typical streetported powerband. And with the solenoid rack, 6PI, and VDI actuators eliminated, there is very little torque at low and mid-range RPM. Although the intended purpose of the car is road course track days at 5500 to 8000 rpm, I do intend to drive it on the street occasionally, and the absence of low-end torque bothers me a bit. I'm left to wonder if I should just put everything back the way it was (solenoids and the actuators), change gear ratios (Miata gears?), replace the rear end, etc. Or maybe operate the actuators with an ignition switch & small air pump instead of the stock vacuum arrangement. But those are topics for another thread (and probably covered extensively already).

So if YOU have an FC plagued with high-end power loss, you now have another thread to read. Long, tortuous, verbose, but with a happy ending.

#33

the worst part about the whole issue is the rear secondary injector would in fact work when you disconnected the front secondary injector. it took a few hours of head scratching and patching in wires like a hospital patient to get the injectors to work as designed, apparently there is some sort of cross feeding going on in that secondary rear rotor firing circuit wire so the easiest solution was to bypass it completely. it's just a shame that it really only took me about 8 hours of devoted time to figure out the issue where so many others had failed(not tryng to dig on them, it was definitely a strange issue) but i'm glad it finally worked out in the end.

my suggestion is to probably reinstall the rats nest partially to get the VDI functional and install some electrical secondary actuators and ditch the smog pump for additional room and less drag on the motor. there is some write ups on kevin's rotary resurrection website for some rather easy ways to do the secondary port sleeve actuator mods.

-Ben

my suggestion is to probably reinstall the rats nest partially to get the VDI functional and install some electrical secondary actuators and ditch the smog pump for additional room and less drag on the motor. there is some write ups on kevin's rotary resurrection website for some rather easy ways to do the secondary port sleeve actuator mods.

-Ben

#35

A great read. Glad you solved your problem. I have the problem on my ported S5 NA, but I also throw the narrowband TPS code so I want to really dial in or replace my TPS before I try this.

Was this problem caused by factory wire routing? I'm new at rotaries still and definitely the electronics aspect, so knowing where to look and what for will really help me right now.

-Michael

Was this problem caused by factory wire routing? I'm new at rotaries still and definitely the electronics aspect, so knowing where to look and what for will really help me right now.

-Michael

#36

Thread Starter

Joined: Jul 2006

Posts: 383

Likes: 9

From: Haywards 5000

In the throttle range where the issue was most obvious on this s5 (50% to WOT), the narrow range TPS is fully open. The placement of the factory harness doesn't seem to be a factor -- routing the wires away from the alternator had no impact. Ben's fix (secondary injector wire) is still in place and I'm on my 3rd engine since that time, so there has been plenty of movement and jostling of the entire harness.

I've had the full range TPS code (12) on another s5 with no noticeable impact on drivability or acceleration. I installed and adjusted the cheapest TPS I could find from rockauto and the code went away; nothing else changed AFAICT.

Ben's test (swap primary and secondary wiring & attempt to idle the car) was a clear indication that there was a problem with secondary injector operation. You could also monitor pulse width at the injectors with an automotive scope, a "blinking lights" injector tester, or a voltmeter (average voltage increases with duty cycle).

A wideband oxygen sensor would also help you determine / confirm a lean condition at high RPM operation.

I've had the full range TPS code (12) on another s5 with no noticeable impact on drivability or acceleration. I installed and adjusted the cheapest TPS I could find from rockauto and the code went away; nothing else changed AFAICT.

Ben's test (swap primary and secondary wiring & attempt to idle the car) was a clear indication that there was a problem with secondary injector operation. You could also monitor pulse width at the injectors with an automotive scope, a "blinking lights" injector tester, or a voltmeter (average voltage increases with duty cycle).

A wideband oxygen sensor would also help you determine / confirm a lean condition at high RPM operation.

#37

the narrow range is used for decel cut and base ignition timing, if the ECU is thinking that at times the throttle is closed it may go into decel fuel cut on one or both rotors completely and retard ignition timing significantly(idle mode). you can test this by disconnecting the TPS and see if the problem still exists or is better, if so test the TPS or replace it if it fails the sweep test while having a good reference and ground. with the TPS disconnected the engine will backfire(no decel fuel cut) so if you have a cat then it should be a short test.

i basically came to the conclusion that the other shops did not replace the harness even though they said they did. it is just too unlikely that two harnesses would have the same exact issue, luckily i never take anyone's word for work they have done and didn't rule out the harness as the possible cause. i did not dissect it to try and dig out the problem because it was already costing too much to fix the problem so a simple workaround was implemented. dissecting and repairing a harness is well over a full day job and would have cost twice as much on the final bill.

a voltage test at the ECU on the injectors should also show problems with the injector circuits, but i didn't use that test method at the time and found it easier to just swap the injector firing order around. the engine should run close to normally off the secondaries, if it doesn't then they may be problematic(if your problem is normally beyond 4k RPMs).

most problems are extremely simple, finding them is the difficult part. overthinking things just gets you into more trouble.

and thanks for all the kind words Michal.

i basically came to the conclusion that the other shops did not replace the harness even though they said they did. it is just too unlikely that two harnesses would have the same exact issue, luckily i never take anyone's word for work they have done and didn't rule out the harness as the possible cause. i did not dissect it to try and dig out the problem because it was already costing too much to fix the problem so a simple workaround was implemented. dissecting and repairing a harness is well over a full day job and would have cost twice as much on the final bill.

a voltage test at the ECU on the injectors should also show problems with the injector circuits, but i didn't use that test method at the time and found it easier to just swap the injector firing order around. the engine should run close to normally off the secondaries, if it doesn't then they may be problematic(if your problem is normally beyond 4k RPMs).

most problems are extremely simple, finding them is the difficult part. overthinking things just gets you into more trouble.

and thanks for all the kind words Michal.

Last edited by RotaryEvolution; 10-20-13 at 03:56 PM.

#38

Thread Starter

Joined: Jul 2006

Posts: 383

Likes: 9

From: Haywards 5000

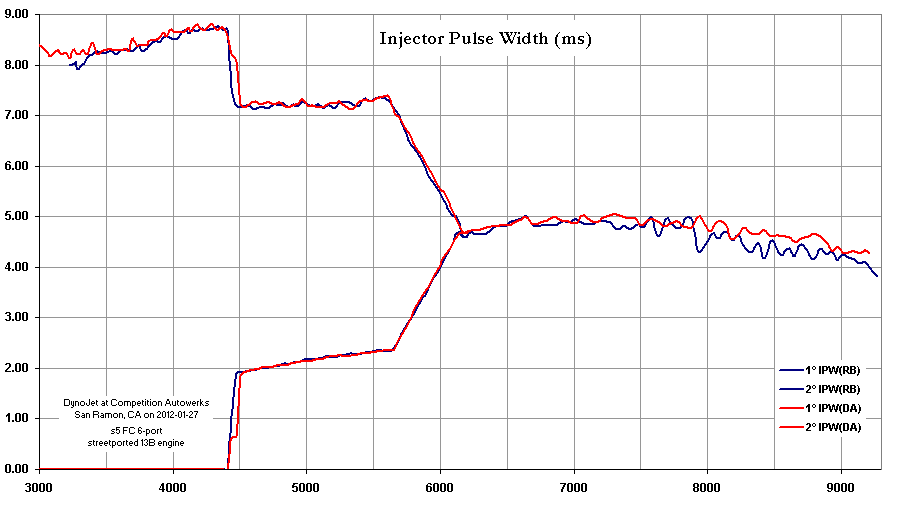

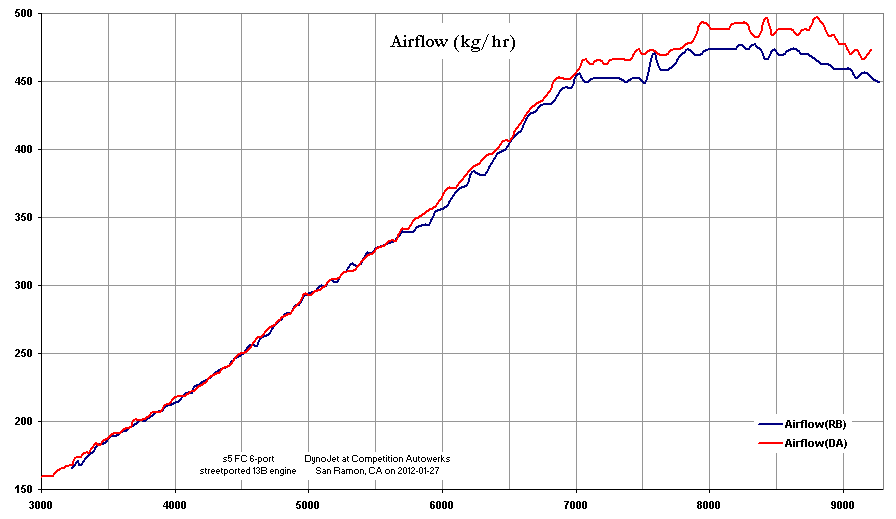

For reference, here are some charts that show injector utilization. These are for WOT operation.

There are two points where the secondaries are "staged":

4400~4500 rpm

5600~6200 rpm

Note that the primaries are dialed back as the secondaries are added in proportion to their flow ratings. If all injectors are the same, the primaries' pulse width is reduced by roughly the same amount as the secondaries' is increased.

After ~6200 RPM, the secondaries are "fully on" and the ECU sends an equal pulse width to all injectors. A problem with one or more injectors will result in a lean condition from this point onwards. If neither of the secondaries is coming on at all, you would likely start seeing problems even earlier as Ben said.

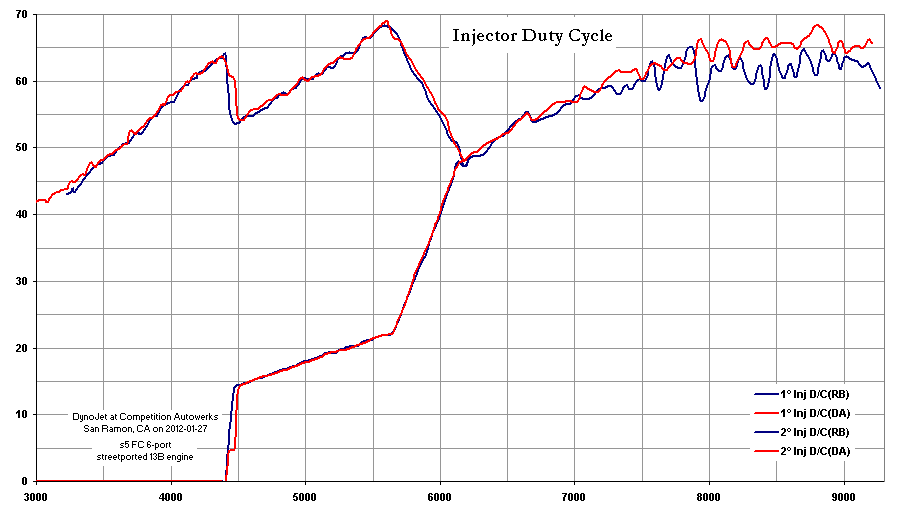

Here are the same data plotted as duty cycle. Mazda seemed to think that 70% is a "safe maximum" for this application (OEM Denso injectors in s5 non-turbo).

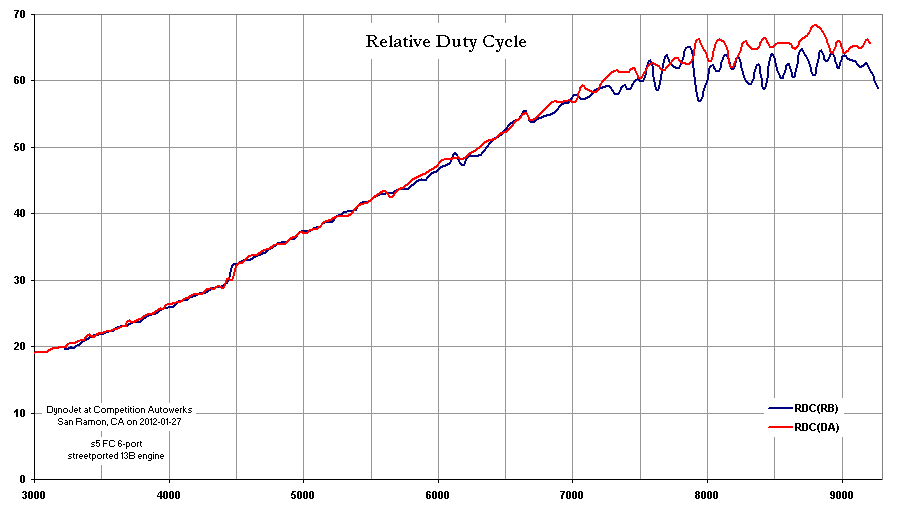

To visualize the contribution of all injectors, I made up an indicator called "relative duty cycle", which aggregates both injector duty cycles and accounts for different flow ratings. Imagine having one large injector for each rotor, instead of a primary and secondary. This is the "duty cycle" of that imaginary injector.

At the first staging point (4400-4500), the ECU bumps up the overall fuel input. Afterwards, it adds fuel fairly smoothly until ~7300 rpm. By that point, the air flow rate into the engine has levelled off (depends on porting, exhaust, restriction by the plungery-style AFM, etc.)

These plots are for a streetported s5 engine with 460cc primary and 550cc secondary injectors (everything operating normally at this point).

There are two points where the secondaries are "staged":

4400~4500 rpm

5600~6200 rpm

Note that the primaries are dialed back as the secondaries are added in proportion to their flow ratings. If all injectors are the same, the primaries' pulse width is reduced by roughly the same amount as the secondaries' is increased.

After ~6200 RPM, the secondaries are "fully on" and the ECU sends an equal pulse width to all injectors. A problem with one or more injectors will result in a lean condition from this point onwards. If neither of the secondaries is coming on at all, you would likely start seeing problems even earlier as Ben said.

Here are the same data plotted as duty cycle. Mazda seemed to think that 70% is a "safe maximum" for this application (OEM Denso injectors in s5 non-turbo).

To visualize the contribution of all injectors, I made up an indicator called "relative duty cycle", which aggregates both injector duty cycles and accounts for different flow ratings. Imagine having one large injector for each rotor, instead of a primary and secondary. This is the "duty cycle" of that imaginary injector.

At the first staging point (4400-4500), the ECU bumps up the overall fuel input. Afterwards, it adds fuel fairly smoothly until ~7300 rpm. By that point, the air flow rate into the engine has levelled off (depends on porting, exhaust, restriction by the plungery-style AFM, etc.)

These plots are for a streetported s5 engine with 460cc primary and 550cc secondary injectors (everything operating normally at this point).

Last edited by 088; 10-20-13 at 05:52 PM. Reason: Reference for Injector Utilization

#39

your staging bar is probably shifted up some, the stock staging point is closer to 3700 rpms. every setup will have optimal staging points, on some turbo engines i lower it for safety since some turbos are hitting near full boost by that RPM and staging is critical in that aspect.

on the n/a engine you can play with the stage point for optimal mid range and smooth transitions.

on the n/a engine you can play with the stage point for optimal mid range and smooth transitions.

Last edited by RotaryEvolution; 10-20-13 at 06:10 PM.

#40

Karack, I dunno if you were thanking me, or 088, but if it was him, I'm Michael too and I totally appreciate your knowledge and the work you've done from the east coast. You are more than welcome.

As I've said before, my only mods are FD rotors and housings, 3mm seals, a big street port and emissions delete, so I have stock ECU, injectors, wiring, etc.

That being said, there are a couple tests I can do to try and pinpoint my problem from what I have gathered from this so far. I don't have any kind of standalone, wideband, nothing like that so I really don't have a way to see the data I feel like I need to be seeing. I need to get a scope too. Like a stethoscope? I have lots of those laying around with nurses and EMT/Paramedics in the fam.

I have seen that I can swap primary and secondary plugs to see if either of them have trouble in the wiring.

Use a lab scope to check[listen for?] pulse width [at the rail or injectors?].

Then, Karack, is your method of unplugging the TPS, I'm assuming at op temp. What am I looking for changewise? My port gives a bit of a lumpy idle anyway, and I periodically make small adjustments to the TPS and IAC based on performance of the car [I know, I know I need to use my multimeter to do this]. Am I looking for a more rough idle and WOT with the TPS unplugged? If it stays the same, my problem is in the TPS?

This is how I'm understanding this as it is, so please feel free to correct me!

I'm going to try this first, and adjust my TPS and IAC back to spec if it's not already there, then try swapping the plugs on the injectors aside from doing some grounding, checking wires, etc.

Since I am NA, Ben, can you tell me about some of the staging?

Man, I really felt like a badass when I was shown how and then built my motor [I'm 8500 miles in and my only problems have been minor ancillary things] but all the electronics involved is complex.

088, I also want to thank you for your RIDICULOUSLY awesome attention to detail in your diagnoses as well as in your explanation of the solution. You and Ben kick *** on this forum and have kept me running in tight spots when I have things go wrong.

-Michael

EDIT: I got EVERYTHING to reground my car via Aaroncake's writeup on his website and will be doing that before my TPS tests so hopefully grounding will not be an issue after that. My grounds are kinda bad as is. I'm hopefully gonna get to that today if I can get the rain to stop.

As I've said before, my only mods are FD rotors and housings, 3mm seals, a big street port and emissions delete, so I have stock ECU, injectors, wiring, etc.

That being said, there are a couple tests I can do to try and pinpoint my problem from what I have gathered from this so far. I don't have any kind of standalone, wideband, nothing like that so I really don't have a way to see the data I feel like I need to be seeing. I need to get a scope too. Like a stethoscope? I have lots of those laying around with nurses and EMT/Paramedics in the fam.

I have seen that I can swap primary and secondary plugs to see if either of them have trouble in the wiring.

Use a lab scope to check[listen for?] pulse width [at the rail or injectors?].

Then, Karack, is your method of unplugging the TPS, I'm assuming at op temp. What am I looking for changewise? My port gives a bit of a lumpy idle anyway, and I periodically make small adjustments to the TPS and IAC based on performance of the car [I know, I know I need to use my multimeter to do this]. Am I looking for a more rough idle and WOT with the TPS unplugged? If it stays the same, my problem is in the TPS?

This is how I'm understanding this as it is, so please feel free to correct me!

I'm going to try this first, and adjust my TPS and IAC back to spec if it's not already there, then try swapping the plugs on the injectors aside from doing some grounding, checking wires, etc.

Since I am NA, Ben, can you tell me about some of the staging?

Man, I really felt like a badass when I was shown how and then built my motor [I'm 8500 miles in and my only problems have been minor ancillary things] but all the electronics involved is complex.

088, I also want to thank you for your RIDICULOUSLY awesome attention to detail in your diagnoses as well as in your explanation of the solution. You and Ben kick *** on this forum and have kept me running in tight spots when I have things go wrong.

-Michael

EDIT: I got EVERYTHING to reground my car via Aaroncake's writeup on his website and will be doing that before my TPS tests so hopefully grounding will not be an issue after that. My grounds are kinda bad as is. I'm hopefully gonna get to that today if I can get the rain to stop.

Last edited by NativeBeggars; 10-22-13 at 11:50 AM.

#41

Thread Starter

Joined: Jul 2006

Posts: 383

Likes: 9

From: Haywards 5000

(In the screenshot -- the 6PI and VDI settings are irrelevant. Aux port sleeves eliminated, intake valve fixed at short runner length, solenoids gone a long time ago.)

#42

interesting, have you talked to digital tuning about it?

NB i would start with the ground kit and clean all the grounds on the engine harness, they're usually the main cause of issues with injector staging.

NB i would start with the ground kit and clean all the grounds on the engine harness, they're usually the main cause of issues with injector staging.

#43

Karack, I did some of them yesterday, but my grounds were a bit different than those on Aaroncake's S4 NA, since mine is S5. I did the ones on the LIM, all the ones around the trailing coils, and the big battery ground on the harness between the shock tower and AC compressor. Are there more I need to do before I move on? Thus far I haven't solved the problem.

Also, do you have any pics of where the grounds are for the injectors? I want to make sure those are solid too.

EDIT: My TPS is probably fucked but $180 for a brand spankin' new one out of the box from RockAuto isn't bad when they go $450+ everywhere else. I don't want a used one unless it's 100% in working order and I can get a good deal on it.

Also, do you have any pics of where the grounds are for the injectors? I want to make sure those are solid too.

EDIT: My TPS is probably fucked but $180 for a brand spankin' new one out of the box from RockAuto isn't bad when they go $450+ everywhere else. I don't want a used one unless it's 100% in working order and I can get a good deal on it.

#44

Worked all day today and just got home so haven't gotten to TPS adjustment yet. Went to pass some people on the way home and instead of hesitation at 6500 I hit a huge dead spot at 5500 rpm.

I need to find my multimeter so I can check these readings, but this is manifesting itself more it seems like. Free rev on shutoff had no problems touching 7000+ but under load it gives.

Any way this makes a big difference in my problem?

I need to find my multimeter so I can check these readings, but this is manifesting itself more it seems like. Free rev on shutoff had no problems touching 7000+ but under load it gives.

Any way this makes a big difference in my problem?

#45

Free reving only uses the primary injectors. You can simulate load on the engine which is required to activate the secondary injectors by unplugging the TPS and removing the vacuum hose to the Pressure Sensor.

Last edited by satch; 10-26-13 at 06:35 PM.

#46

satch please don't take this wrong because iirc even the NAs have a boost sensor, but where the hell would I find it? I need to make a list of things to check once I get a multimeter back in my hands.

Next on my list is checking VDI operation, since it fell on it's face this afternoon at 5500, and then checking the plugs which I'll go do once I finish making some mac n cheese.

Still need a multimeter. Also, since I have a S5 harness, I don't have a ground on my rear rotor, do I?

Just saw your edit. Thanks man. Also, which solenoid plug is for VDI? Is it the grey one?

Next on my list is checking VDI operation, since it fell on it's face this afternoon at 5500, and then checking the plugs which I'll go do once I finish making some mac n cheese.

Still need a multimeter. Also, since I have a S5 harness, I don't have a ground on my rear rotor, do I?

Just saw your edit. Thanks man. Also, which solenoid plug is for VDI? Is it the grey one?

Last edited by NativeBeggars; 10-26-13 at 06:46 PM.

#48

http://s1001.photobucket.com/user/Na...b873f.jpg.html

It's a shitty picture but the plugs are as follows - RT, RL, FT, FL. They have some slight buildup. Rears a little darker than the fronts.

It's a shitty picture but the plugs are as follows - RT, RL, FT, FL. They have some slight buildup. Rears a little darker than the fronts.