Painting Rotor Housings - WHY?

#1

Painting Rotor Housings - WHY?

I'm new to the rx7 scene and am beginning to learn how to rebuild an rx7 13BT motor. I noticed that the vast majority of performance rebuilds on these engines have the intermediate and side housings painted and sometimes have the rotor housings painted as well (less often though).

My question is WHY? I understand that it looks cool but besides that rather moot point does it have any performance benefits? Besides preventing oxidation (rust) it must cause the engine to retain more heat from combustion (which is a bad thing right?)

Any thoughts on this issue are appreciated, if you have technical/logical reasons for or against painting please contribute.

Also, what type of paint is used?

My question is WHY? I understand that it looks cool but besides that rather moot point does it have any performance benefits? Besides preventing oxidation (rust) it must cause the engine to retain more heat from combustion (which is a bad thing right?)

Any thoughts on this issue are appreciated, if you have technical/logical reasons for or against painting please contribute.

Also, what type of paint is used?

#3

it is just for aesthetics, most people don't like going through the trouble of building a motor for it to look raw and rather ugly. why not dress it up some? it isn't just a rotary thing, just about every builder does some sort of engine painting.

the aluminum and cast irons really won't ever look like new no matter how much you scrub them. close but alot of effort for marginal return. painting is just quicker and easier.

the aluminum and cast irons really won't ever look like new no matter how much you scrub them. close but alot of effort for marginal return. painting is just quicker and easier.

Last edited by RotaryEvolution; 05-14-11 at 11:18 PM.

#6

#7

Engine, Not Motor

iTrader: (1)

Joined: Feb 2001

Posts: 29,793

Likes: 119

From: London, Ontario, Canada

Irons and housings are painted during a build because, well, it looks nice. Even a cheesy paint job with minimal masking and cheap spray paint will look much better than the raw metal and last at least a few years.

Most of the engine enamels available at auto parts stores work well if proper prep is followed. With any paint job, prep is the key. In the past I've used VHT caliper enamel, DupliColour MetalCast and POR-15 engine enamel. Media blast following a thorough cleaning (and followed by a cleaning) is the best prep.

Most of the engine enamels available at auto parts stores work well if proper prep is followed. With any paint job, prep is the key. In the past I've used VHT caliper enamel, DupliColour MetalCast and POR-15 engine enamel. Media blast following a thorough cleaning (and followed by a cleaning) is the best prep.

Trending Topics

#10

i generally don't blast anything because it's even more time consuming after doing the degreasing process but it would work for a DIYer for a clean raw aluminum look.

but i also dislike the raw aluminum because it retains dirt easier and is only worsened with any type of blasting process.

but i also dislike the raw aluminum because it retains dirt easier and is only worsened with any type of blasting process.

#12

#16

Why ?

Pride ! Your hard work should look good as long as possible.

Beside the looks it prevents rust on the irons. Some people will tell you that it wont stick on there.

I have seen lots of nice painted rotarys here on the forum and they looked good even years after install.

Steven

Pride ! Your hard work should look good as long as possible.

Beside the looks it prevents rust on the irons. Some people will tell you that it wont stick on there.

I have seen lots of nice painted rotarys here on the forum and they looked good even years after install.

Steven

#18

+1

While waiting for parts....

I've since decided that I don't like the intakes copper and the front cover black....I also tried doing the front cover copper, but didn't like that either. Now I'm just waiting to get parts back from powder coating. Intakes are gloss black. Front cover, cold side of turbo, infini strut bar ends are all going silver...oh TID is going silver also.

BUT it's taking forever for them to do the work. 10 business days has turned into 5 weeks or so. I may go get my parts and not worry about powder coating....I want my engine done!!!

While waiting for parts....

I've since decided that I don't like the intakes copper and the front cover black....I also tried doing the front cover copper, but didn't like that either. Now I'm just waiting to get parts back from powder coating. Intakes are gloss black. Front cover, cold side of turbo, infini strut bar ends are all going silver...oh TID is going silver also.

BUT it's taking forever for them to do the work. 10 business days has turned into 5 weeks or so. I may go get my parts and not worry about powder coating....I want my engine done!!!

#19

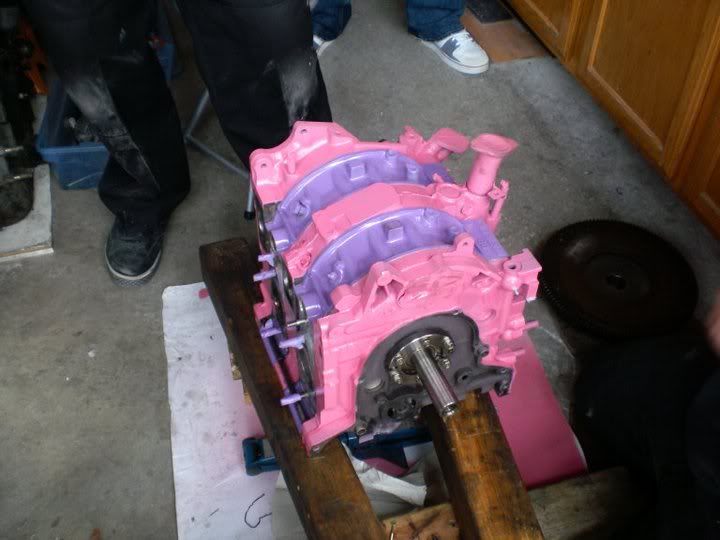

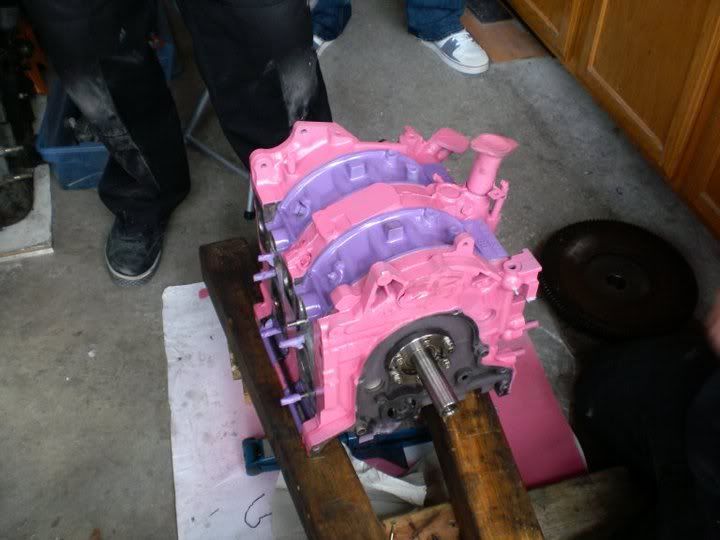

wanted to try somethign never done before... never seen those two colors before! haha

couple pix

with the turbo.

not done yet, but at least i got it bolted in finally!

still need to prolly paint the cas, and then the water pump housing...

dont really feel likg tearing the throttle body apart to paint it... i prolly wouldnt get it back together in 1 peice lol

couple pix

with the turbo.

not done yet, but at least i got it bolted in finally!

still need to prolly paint the cas, and then the water pump housing...

dont really feel likg tearing the throttle body apart to paint it... i prolly wouldnt get it back together in 1 peice lol

#21

"the aluminum and cast irons really won't ever look like new no matter how much you scrub them. close but alot of effort for marginal return. painting is just quicker and easier."[/QUOTE]

not alway true bud.

if that was true then tell me how my 88 s4 22 year d motor looks like NEW ALUMINUM.

not alway true bud.

if that was true then tell me how my 88 s4 22 year d motor looks like NEW ALUMINUM.

#23

i generally don't blast anything because it's even more time consuming after doing the degreasing process but it would work for a DIYer for a clean raw aluminum look.

but i also dislike the raw aluminum because it retains dirt easier and is only worsened with any type of blasting process.

but i also dislike the raw aluminum because it retains dirt easier and is only worsened with any type of blasting process.

Thread

Thread Starter

Forum

Replies

Last Post

cdn

2nd Generation Specific (1986-1992)

14

09-10-15 07:23 AM

cdn

2nd Generation Non-Technical and pictures

0

08-11-15 09:59 PM

..

..