oil metering pump 87 Turbo II

#1

Junior Member

Thread Starter

Join Date: Apr 2011

Location: Miami

Posts: 27

Likes: 0

Received 0 Likes

on

0 Posts

oil metering pump 87 Turbo II

Does anyone know which manual has a diagram of where each line is supposed to go? i have 1 or two that are not connected to anything...

#2

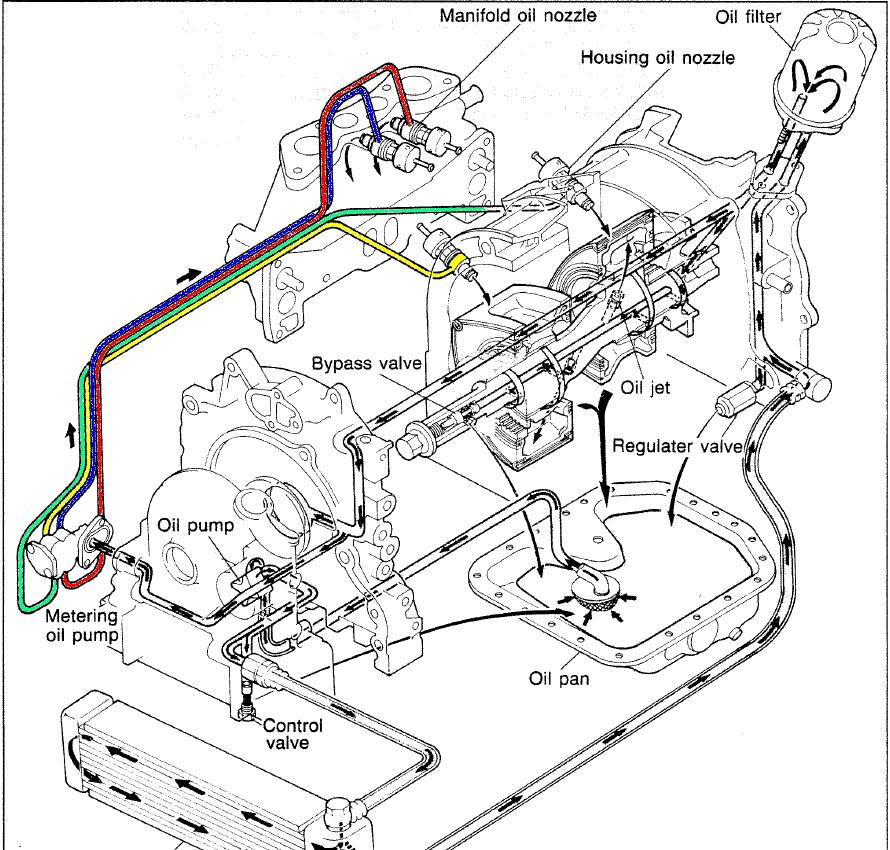

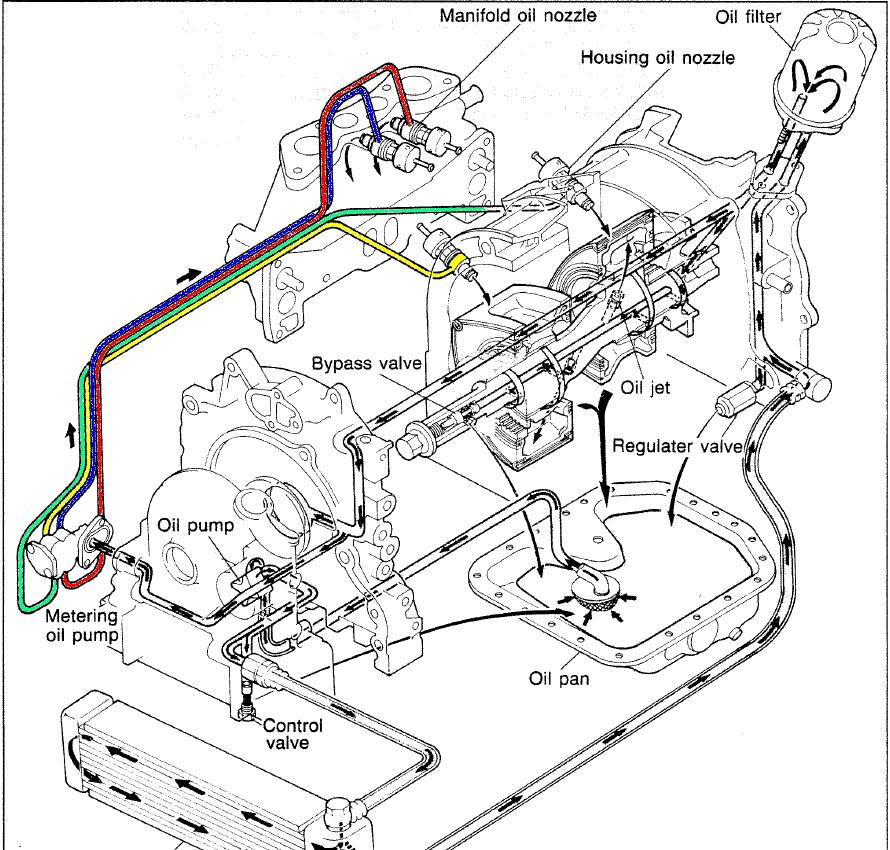

The training manual has a nice diagram: http://mazdarx7.iougs.com/training.shtml (lubrication section). If you have a line or two not connected to oil injectors, you better be premixing. Engine damage will result from a lack of oil for lubrication of the seals.

#4

How important is it to have the line connected like that.

A few weeks ago I noticed I had a couple lines that had cracked, so I made new lines. There was a bit of oil where it had leaked from one of the injector lines, so I know the OMP works. But today I finally got the whole thing back together and fired it up. No oil flowing from the OMP. I am nearly certain that they are connected as depicted in the diagram. Not positive, but I paid attention to how they were run and only removed one at a time.

I don't wanna thread jack but it seems relevant.

A few weeks ago I noticed I had a couple lines that had cracked, so I made new lines. There was a bit of oil where it had leaked from one of the injector lines, so I know the OMP works. But today I finally got the whole thing back together and fired it up. No oil flowing from the OMP. I am nearly certain that they are connected as depicted in the diagram. Not positive, but I paid attention to how they were run and only removed one at a time.

I don't wanna thread jack but it seems relevant.

#6

Rotary Freak

Get the engine fully warmed up.

Idle the car. Go to the engine bay on the left hand side.

Rev the engine to approx 3000 rpm using either the cruise control cable or the throttle linkage while at the same time holding the omp ROD fully up. You can hold the rod up right there at the throttle linkage with whatever it takes. Might even us a zip tie or fingers. Your choice. The ROD will go up thru the hole in the linkage without being hindered by the throttle linkage.

IF you can see the oil in the lines, it will slowly OOOOOCH up the line in little pulsations. It'd take probably ten minutes for it to get all the way up the line from the bottom.

Idle the car. Go to the engine bay on the left hand side.

Rev the engine to approx 3000 rpm using either the cruise control cable or the throttle linkage while at the same time holding the omp ROD fully up. You can hold the rod up right there at the throttle linkage with whatever it takes. Might even us a zip tie or fingers. Your choice. The ROD will go up thru the hole in the linkage without being hindered by the throttle linkage.

IF you can see the oil in the lines, it will slowly OOOOOCH up the line in little pulsations. It'd take probably ten minutes for it to get all the way up the line from the bottom.

#7

Junior Member

Thread Starter

Join Date: Apr 2011

Location: Miami

Posts: 27

Likes: 0

Received 0 Likes

on

0 Posts

i just noticed something messed up too. my lines look like theyre not in the correct order and two of them are cut short reaching up to right under the upper intake manifold. One of the lines is going to the front housing which is good because i was wondering if i could stop pre mixing. Im still wondering about where the second connected line is going to because the color on the diagram isnt matching up with the line thats going to the front housing. one of the cut lines drips oil like my mop is working. how do i make sure oil is getting where it needs to go because im worried to stop pre mixing but its annoying and if my mop works id rather do that.

Trending Topics

#8

Thanks guys, I did all of that and I added a vacuum pump to the vac line that goes to the splitter. The car must have idled for at least ten minutes if not more while I tried to make something happen.

It's not that the oil is moving slowly. It isn't in the lines at all. Only one of the primary lines, that goes down then up, has about 1/2 a drop of oil in the bend (@ lowest point).

I didn't remove the pump, only the intake when I built and installed the lines.

I premixed it at the end of my patients. I'm going to have to go back in under the intake. I it idles high and I'm sure I hear air from the left side of the motor under the plenum. But I don't feel like tackling it now. I know I removed and installed that intake at least 6 times. (I discovered the broken lines while installing a ported/polished intake.)

It's not that the oil is moving slowly. It isn't in the lines at all. Only one of the primary lines, that goes down then up, has about 1/2 a drop of oil in the bend (@ lowest point).

I didn't remove the pump, only the intake when I built and installed the lines.

I premixed it at the end of my patients. I'm going to have to go back in under the intake. I it idles high and I'm sure I hear air from the left side of the motor under the plenum. But I don't feel like tackling it now. I know I removed and installed that intake at least 6 times. (I discovered the broken lines while installing a ported/polished intake.)

#9

The lines going to the oil injectors do not supply vacuum. They supply metered air to help push the oil through. Vacuum would try to suck the oil up. Luckily there are check valves inside the injectors to prevent that. Still, I would reconnect the injectors to the proper metered air source, and check again.

Remove the UIM, and replace your broken lines.

i just noticed something messed up too. my lines look like theyre not in the correct order and two of them are cut short reaching up to right under the upper intake manifold. One of the lines is going to the front housing which is good because i was wondering if i could stop pre mixing. Im still wondering about where the second connected line is going to because the color on the diagram isnt matching up with the line thats going to the front housing. one of the cut lines drips oil like my mop is working. how do i make sure oil is getting where it needs to go because im worried to stop pre mixing but its annoying and if my mop works id rather do that.

#10

Rotary Freak

Thanks guys, I did all of that and I added a vacuum pump to the vac line that goes to the splitter. The car must have idled for at least ten minutes if not more while I tried to make something happen.

It's not that the oil is moving slowly. It isn't in the lines at all. Only one of the primary lines, that goes down then up, has about 1/2 a drop of oil in the bend (@ lowest point).

I didn't remove the pump, only the intake when I built and installed the lines.

I premixed it at the end of my patients. I'm going to have to go back in under the intake. I it idles high and I'm sure I hear air from the left side of the motor under the plenum. But I don't feel like tackling it now. I know I removed and installed that intake at least 6 times. (I discovered the broken lines while installing a ported/polished intake.)

It's not that the oil is moving slowly. It isn't in the lines at all. Only one of the primary lines, that goes down then up, has about 1/2 a drop of oil in the bend (@ lowest point).

I didn't remove the pump, only the intake when I built and installed the lines.

I premixed it at the end of my patients. I'm going to have to go back in under the intake. I it idles high and I'm sure I hear air from the left side of the motor under the plenum. But I don't feel like tackling it now. I know I removed and installed that intake at least 6 times. (I discovered the broken lines while installing a ported/polished intake.)

The oil feed for the OMP is from where the front cover mates with the front housing. There is a small hole that might be ?? 1/16" of diameter that can't be blocked with RTV or whatever if oil is to make its way to the OMP. That small hole is up at the top of the front cover and to the left side a bit.

Like the man said...........there is no vacuum going to the injectors. That line is a metered air line. Any vacuum is from the intake stoke of the rotor and comes from the bottom of the injector.

The OMP PUMPS OIL into the lines. The pressure does NOT come from the engine oil pump. The engine oil pump supplys oil to the OMP and then the OMP takes that oil and pressurized it to flow into the OMP lines.

#11

Rotary Freak

Go to the LUBRICATION section of the FSM and there is a picture showing you how to measure the droppings from the open OMP line. This site won't let me add attachments so I can't do it for you. ATTACHMENTES suck on this forum.

#12

Rotary Freak

Even with a stk car with airpump you can reach down there and undo the banjo bolts. You don't need extra lines and measuring cup as shown in the manual. You could just catch the droppings as they fall from the engine. Messy perhaps but doable. I have extra lines and banjo fittings so I can do it both ways. You really just want to see if the pump is causing oil to drop down on the ground initially. To see if the pump is getting fed oil and is working or not.

Thread

Thread Starter

Forum

Replies

Last Post

trickster

2nd Generation Specific (1986-1992)

25

07-01-23 04:40 PM

LunchboxSA22

2nd Generation Specific (1986-1992)

37

10-26-15 10:53 AM