At my wits end...

#28

There is only one trigger wire at the leading coil/igniter and the leading coil fires both rotors at the same time therefore if one leading plug is firing then the other should as well. So the problem could be the coil but it would be easy to check for spark on both leading plugs. The problem might be more of a fuel delivery problem. With the aid of an LED light you could tell if the ECU is sending the proper signal to fire the injectors, both primary and secondary, to both rotors.

#29

Senior Member

Thread Starter

iTrader: (8)

Join Date: May 2008

Location: RI

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

There is only one trigger wire at the leading coil/igniter and the leading coil fires both rotors at the same time therefore if one leading plug is firing then the other should as well. So the problem could be the coil but it would be easy to check for spark on both leading plugs. The problem might be more of a fuel delivery problem. With the aid of an LED light you could tell if the ECU is sending the proper signal to fire the injectors, both primary and secondary, to both rotors.

#30

The following applies to an S4. Pin 3E (Light Green wire) is the front primary, pin 3C (Light Green/Black) is the rear primary, pin 3H (Light Green/White) is the front secondary and pin 3F (Light Green/Red) is the rear secondary. Use the car battery terminals to figure out which LED wire is positive and which is negative. Then at the ECU to check the front primary injector for example, place the negative LED wire into the back of pin 3E and the positive LED wire into the back of pin 3I (Main relay). With the engine running the light should flash repeatedly. This will tell you if the ECU is doing its part. If the injector itself being tested is not firing it is because the injector clip is loose, the Black/Yellow wire to that clip is w/o voltage, the trigger wire from the ECU is broken or the injector is clogged/damaged in some manner or the fuel is not making it to the fuel rail. To test the secondary injectors the Boost/Pressure sensor vacuum hose needs to be disconnected, plugged and the TPS needs to be unplugged to simulate load which is necessary to activate the secondary injectors.

#31

0

the pins in the injector harness clips have a tendency to push out of the connector on the S4 turbo II's. you either have this or you have a blown motor. oil on the plugs will foul them and cause you to get innacurate spark readings, you may have to change the plugs once you figure out what the real problem is(although, like i said before, there shouldn't be that much oil going through it for there to be ANYTHING coming out on the plugs unburned).

#32

Senior Member

Thread Starter

iTrader: (8)

Join Date: May 2008

Location: RI

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

sounds like a dead rotor, i just ran into a similar issue where a bolt went through a customer's brand new rebuild and pierced the rotor, oil was blowing out the exhaust at an amazing rate.

do the compression test again.

ignore the timing, that isn't your issue. even if the timing was so far off that the engine would barely idle it still wouldn't give that signature sound of a stuck/damaged seal.

if the compression truly is fine then you have a dead primary rear rotor injector. even with a dead injector though, that is too much oil blowby in the exhaust for new oil seals. it may clear up once you fix the issue but it seems like either a seal was cut during installation or the builder used old OEM used oil seals(they do not seal after running the engine so they cannot be reused if the engine had been run on them even once).

do the compression test again.

ignore the timing, that isn't your issue. even if the timing was so far off that the engine would barely idle it still wouldn't give that signature sound of a stuck/damaged seal.

if the compression truly is fine then you have a dead primary rear rotor injector. even with a dead injector though, that is too much oil blowby in the exhaust for new oil seals. it may clear up once you fix the issue but it seems like either a seal was cut during installation or the builder used old OEM used oil seals(they do not seal after running the engine so they cannot be reused if the engine had been run on them even once).

#34

Senior Member

Thread Starter

iTrader: (8)

Join Date: May 2008

Location: RI

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

ok i changed that injector and re stabbed the CAS again but let it spin a bit more and it seems t be running alot smoother. idles at 1k then slowly goes up to its 1.5k. But i figured out thats because of my throttle cables messed up i think. When i put my foot behind the gas petal and lift up the idle goes down. I still have oil in my exhaust. Idk if its timed correctly yet. My issues is and always has been since ive first had the engine before the rebuild is when i let it heat up and run and then shut it off it will not start again still the engine is cooled down, which makes working on this a pain. I know its my cranking fuel and i cant figure out how to get it to start. I'm running rtek 2.1 if that helps. I'm going to work on it now ill keep you all updated

#35

the Rtek has a fuel cut feature, if you hold the throttle wide open while cranking it will attempt to deflood the engine by not turning the injectors on. a fuel cut switch also isn't a bad idea because even the injector fuel cut doesn't always work on severely low compression engines.

you can get a compression test done to get a baseline of where the engine is at now, run the engine for a while and drive it and redo the compression test to see if compression is steadily rising with hours/miles. if the compression is not getting better than your internals are worn too severely for it to have ever been attempted to be rebuilt.

you can get a compression test done to get a baseline of where the engine is at now, run the engine for a while and drive it and redo the compression test to see if compression is steadily rising with hours/miles. if the compression is not getting better than your internals are worn too severely for it to have ever been attempted to be rebuilt.

#36

Senior Member

Thread Starter

iTrader: (8)

Join Date: May 2008

Location: RI

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

the Rtek has a fuel cut feature, if you hold the throttle wide open while cranking it will attempt to deflood the engine by not turning the injectors on. a fuel cut switch also isn't a bad idea because even the injector fuel cut doesn't always work on severely low compression engines.

If any 1 has a cranking fuel tune for the rtek that be great =). Or tell me if i need to add more fuel for warm start or less.

Also did the timing test. It looked to b perfectly timed now after i restabbed it. If i get it running I'm going to take it out for a spin. Not to far tho since it not inspected or insured.

I just want to say Thank you all for posting on here and giving me ideas and sticking with me even tho I'm still not done.

#37

the Rtek has no control over cranking fuel, it is still a preset figure in the hardcoded fuel maps.

if it's having that much difficulty starting then your timing may be wayyy off(try rotating the CAS one tooth at a time and crank it up), you have gobs of fuel leaking into the intake tract after the engine is shut off or you have drastically low compression.

start with the CAS, if it doesn't help then do a compression test. if it comes out something like 60psi then call your builder and setup a cherry picker. if both of those are ok then swap injectors and or your fuel pressure regulator(i have had the FPRs rip internally and dump fuel down the vacuum line into the secondary rotor intake runner), you can test the FPR by disconnecting the vacuum line and prime the fuel system and see if fuel comes out. if you have no spare injectors you can test them by strapping them to the fuel rails and priming the fuel system and watch for leakage for 5 minutes.

if it's having that much difficulty starting then your timing may be wayyy off(try rotating the CAS one tooth at a time and crank it up), you have gobs of fuel leaking into the intake tract after the engine is shut off or you have drastically low compression.

start with the CAS, if it doesn't help then do a compression test. if it comes out something like 60psi then call your builder and setup a cherry picker. if both of those are ok then swap injectors and or your fuel pressure regulator(i have had the FPRs rip internally and dump fuel down the vacuum line into the secondary rotor intake runner), you can test the FPR by disconnecting the vacuum line and prime the fuel system and see if fuel comes out. if you have no spare injectors you can test them by strapping them to the fuel rails and priming the fuel system and watch for leakage for 5 minutes.

#38

Senior Member

Thread Starter

iTrader: (8)

Join Date: May 2008

Location: RI

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

the Rtek has no control over cranking fuel, it is still a preset figure in the hardcoded fuel maps.

if it's having that much difficulty starting then your timing may be wayyy off(try rotating the CAS one tooth at a time and crank it up), you have gobs of fuel leaking into the intake tract after the engine is shut off or you have drastically low compression.

start with the CAS, if it doesn't help then do a compression test. if it comes out something like 60psi then call your builder and setup a cherry picker. if both of those are ok then swap injectors and or your fuel pressure regulator(i have had the FPRs rip internally and dump fuel down the vacuum line into the secondary rotor intake runner), you can test the FPR by disconnecting the vacuum line and prime the fuel system and see if fuel comes out. if you have no spare injectors you can test them by strapping them to the fuel rails and priming the fuel system and watch for leakage for 5 minutes.

if it's having that much difficulty starting then your timing may be wayyy off(try rotating the CAS one tooth at a time and crank it up), you have gobs of fuel leaking into the intake tract after the engine is shut off or you have drastically low compression.

start with the CAS, if it doesn't help then do a compression test. if it comes out something like 60psi then call your builder and setup a cherry picker. if both of those are ok then swap injectors and or your fuel pressure regulator(i have had the FPRs rip internally and dump fuel down the vacuum line into the secondary rotor intake runner), you can test the FPR by disconnecting the vacuum line and prime the fuel system and see if fuel comes out. if you have no spare injectors you can test them by strapping them to the fuel rails and priming the fuel system and watch for leakage for 5 minutes.

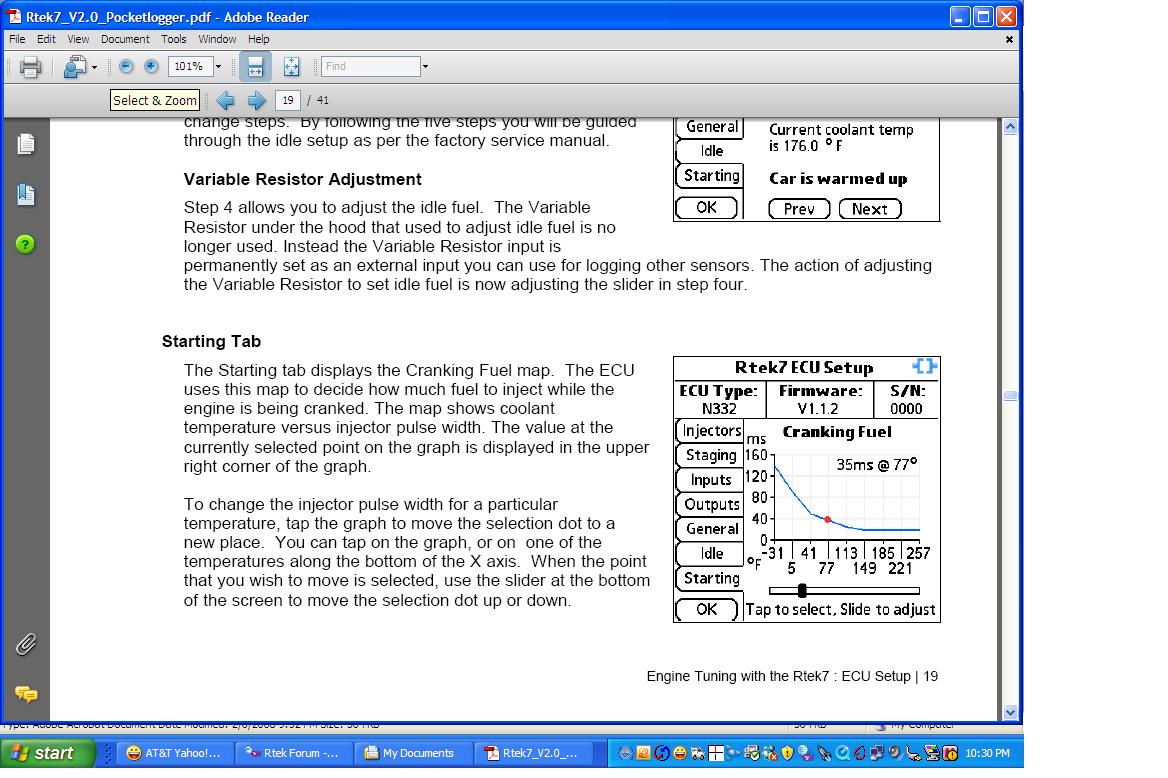

thats what i can do in my Rtek, isnt that adjusting the cranking fuel?

by gobs of fuel what do you mean? Do you think my Maf or w.e its called or the solenoid resistor could be bad? I'm just kinda reaching now

#39

must be a different revision, the ones i have used under that tab stated that it was not supported.

anyways, if it is having trouble starting then it is usually due to being overly rich. jot down the figures and start bringing the figures down linearly. the higher the Ms(millisecond of injector open time) the more fuel is being dumped.

anyways, if it is having trouble starting then it is usually due to being overly rich. jot down the figures and start bringing the figures down linearly. the higher the Ms(millisecond of injector open time) the more fuel is being dumped.

#40

Senior Member

Thread Starter

iTrader: (8)

Join Date: May 2008

Location: RI

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

must be a different revision, the ones i have used under that tab stated that it was not supported.

anyways, if it is having trouble starting then it is usually due to being overly rich. jot down the figures and start bringing the figures down linearly. the higher the Ms(millisecond of injector open time) the more fuel is being dumped.

anyways, if it is having trouble starting then it is usually due to being overly rich. jot down the figures and start bringing the figures down linearly. the higher the Ms(millisecond of injector open time) the more fuel is being dumped.

#44

Senior Member

Thread Starter

iTrader: (8)

Join Date: May 2008

Location: RI

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

Heres a quote from the page. "I ran my vert when it had a Jspec in it with a N338 with no problems at all, for about a year.

But as far as what went lean or not, that I could no tell you, as I never dynoed or had a A/F meter on it.

Other than wiring in the knock box and the scroll control and moving the power steering input to a relay, it was pretty straight forward."

what does he mean on that last part? how would i do that?

#45

whomever said that is full of ****

because the non turbo ecu is not setup to read or adjust for pressure in the intake manifold, it is only setup for vacuum. he may have gotten away with running it out of boost but that's it. what will happen when you do go into boost is anyone's guess.

because the non turbo ecu is not setup to read or adjust for pressure in the intake manifold, it is only setup for vacuum. he may have gotten away with running it out of boost but that's it. what will happen when you do go into boost is anyone's guess.

#46

Senior Member

Thread Starter

iTrader: (8)

Join Date: May 2008

Location: RI

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

whomever said that is full of ****

because the non turbo ecu is not setup to read or adjust for pressure in the intake manifold, it is only setup for vacuum. he may have gotten away with running it out of boost but that's it. what will happen when you do go into boost is anyone's guess.

because the non turbo ecu is not setup to read or adjust for pressure in the intake manifold, it is only setup for vacuum. he may have gotten away with running it out of boost but that's it. what will happen when you do go into boost is anyone's guess.

https://www.rx7club.com/2nd-generation-specific-1986-1992-17/n338-ecu-tii-275423/

#48

Senior Member

Thread Starter

iTrader: (8)

Join Date: May 2008

Location: RI

Posts: 415

Likes: 0

Received 0 Likes

on

0 Posts

ya that is odd. Well the Jspec convertible hada turbo, maybe they got lazy? Idk but now my car wont start up. It starts up then dies right away or its struggling to start will catch for a sec then die and keep on wanting to catch. I'm starting to get really annoyed with this car.