My S4 N/A Nitrous build

#51

So i really didnt want to read all of this, so i got about half way through. I only really wanted to ask if your exhaust manifold racing beat had 2 bungs on each runner? if so are those for o2 seems kinda close, or are those for exhaust gas temp that would be pimp.. anyway now that ive spent like 30 min reading(im a slow reader) i have to add what little 2 sense i have. For the ports dont remove them you ruin airflow, probably why aaron doesnt like them. But pineapple racing does make redesigned sleeve i heard they where really nice, you may want to check them out. As for those talking about reversion i dont know if its muhc of a issue for a rotary we dont have valves that close, we also have a constant power stroke... im not a air dynamics engineer or anything nor can i spell for ****. But i know if we do have reversion it cant be as bad as a piston motor

The problem with a dry shot more on piston motors was the problem with getting equal distrubution of the nitrous. Unless your going full stand alone maybe even using those bunges for EGT and can tune amazing. your cure would be the wet shot or the direct port. If the direct port is angled it shouldnt build up to much on the walls.Thats gonna take some really nice fabvrications. but that would be your advantage of direct port the even distrubuation of nitrous. although theres always problem one jet doesnt spray. injectors clogs who knows. That leads me to another question what size injectors are you using. SOImeone mentioned using an Rtek i havnt looked at the 2.0 but the older ones were only designed for the turbo ECUs might have to try something else.

Some hopefully helpful ideas...

if i was running nitrous i would play it safe, nitrous is like any other power adder. Providing more oxygen. Nitrous does not make power the more fuel it can burn does. So upgrade your fuel system if your shotting for some high numbers. For safty you might want to get some sorth of ECU that can handle the nitrous. you should use a full throttle switch, so nitrous isnt activated at lower RPMs, I always wanted to also hook up a fuel pressure switch may be a little pricing but if the fuels not there, then you dont have nitrous saving you from a blown motor.

o as for propane it yields a higher octane rating. i think 130, maybe 120 but you need more of it then fuel and whereas gas wieghs in at 8pounds a gallon propane is 25 something to think about. personally i think just stick with that gas stuff itll make it less complicated. plus i think ever thinks your trying to push like 500hp, but i dont think you even rebuilt that motor so maybe just 75 extra ponies from the nitrous

The problem with a dry shot more on piston motors was the problem with getting equal distrubution of the nitrous. Unless your going full stand alone maybe even using those bunges for EGT and can tune amazing. your cure would be the wet shot or the direct port. If the direct port is angled it shouldnt build up to much on the walls.Thats gonna take some really nice fabvrications. but that would be your advantage of direct port the even distrubuation of nitrous. although theres always problem one jet doesnt spray. injectors clogs who knows. That leads me to another question what size injectors are you using. SOImeone mentioned using an Rtek i havnt looked at the 2.0 but the older ones were only designed for the turbo ECUs might have to try something else.

Some hopefully helpful ideas...

if i was running nitrous i would play it safe, nitrous is like any other power adder. Providing more oxygen. Nitrous does not make power the more fuel it can burn does. So upgrade your fuel system if your shotting for some high numbers. For safty you might want to get some sorth of ECU that can handle the nitrous. you should use a full throttle switch, so nitrous isnt activated at lower RPMs, I always wanted to also hook up a fuel pressure switch may be a little pricing but if the fuels not there, then you dont have nitrous saving you from a blown motor.

o as for propane it yields a higher octane rating. i think 130, maybe 120 but you need more of it then fuel and whereas gas wieghs in at 8pounds a gallon propane is 25 something to think about. personally i think just stick with that gas stuff itll make it less complicated. plus i think ever thinks your trying to push like 500hp, but i dont think you even rebuilt that motor so maybe just 75 extra ponies from the nitrous

#52

ok this is for Scathcart. I read through almost all of this thread. When I get unbroke, if ever I want to do a pretty decent sized streetport on my s5 na, and want to run nitrous when I feel like having fun or need to dust someone. I want to run a 100 shot, so let me get this straight according to you.

This is what I want to do.

s5 streetport, 6 puck clutch with lightened flywheel, exhuast bolt ons. 100 shot nitrous.

So I should do this according to you if I understand right.

Run a dry shot before the TB, and porting the TB is a good idea. Also use an Rtek to keep my timing good for when I strictly want to run the nitrous it will make the changes accordingly and will only do so when the 5/6 ports are open correct? Then I will be good? what elso should I need?

This is what I want to do.

s5 streetport, 6 puck clutch with lightened flywheel, exhuast bolt ons. 100 shot nitrous.

So I should do this according to you if I understand right.

Run a dry shot before the TB, and porting the TB is a good idea. Also use an Rtek to keep my timing good for when I strictly want to run the nitrous it will make the changes accordingly and will only do so when the 5/6 ports are open correct? Then I will be good? what elso should I need?

#53

Thread Starter

Joined: Mar 2007

Posts: 1,029

Likes: 0

From: Appleton, WI

The experts finally agree on something  Single fogger it is, then.

Single fogger it is, then.

Which FPR should I be looking at?

The RB header came off a fully prepped SCCA car. I had two bungs tapped in, one for the stock o2 sensor and one for EGT. There is a bung tapped where the two pipes join together for a wideband sensor.

Stock. Rtek makes an S4 N/A ecu now. Looks pretty fancy

No I didn't. I really didn't want to spend any more money then I had to on an N/A setup. This should hopefully yield a running RX for another summer...it keeps me wrenching and planning...and it should keep me happy and busy for awhile

Thanks everyone for the input. I'll be home again this weekend. Hopefully should be able to get the rear calipers rebuilt and re-installed and have working brakes. Maybe I'll pull the fuel pump out and see how it looks.

Single fogger it is, then.

Single fogger it is, then. Which FPR should I be looking at?

Thanks everyone for the input. I'll be home again this weekend. Hopefully should be able to get the rear calipers rebuilt and re-installed and have working brakes. Maybe I'll pull the fuel pump out and see how it looks.

#54

Dl: the consensus is to stay away from a dry shot. A wet shot would be more advisable. Also the RTEK will not control nitrous, so you set your timing for nitrous and run down a few hp when you aren't running it. Or go to a full standalone. If you go full standalone you could tune the car to control the nitrous. In other words when you activate the nitrous the computer will automatically drop timing and adjust fueling to compensate for the added oxygen. You could then choose to run a dry shot. This route would likely result in you needing a bigger fuel pump, larger injectors and lots of time on a dyno.

BC

BC

#55

Thats nice EGT is nice i would see can the rtek run a wideband to the ecu as a narrow band. therefore eliminating the need for the narrow band all together and you can runn 2 egt's one for each rotor. instead of only seeing what one rotor is doing you can see both and compare.. think about it.....mmmm

#56

I know the RTEK can log wideband. If you can find a wideband with a controller that will sim a narrowband then you could do both out of one O2 sensor. Finding a wideband and controller that will sim a narrowband 0-1v shouldnt be hard.

BC

BC

#58

Thread Starter

Joined: Mar 2007

Posts: 1,029

Likes: 0

From: Appleton, WI

Dl: the consensus is to stay away from a dry shot. A wet shot would be more advisable. Also the RTEK will not control nitrous, so you set your timing for nitrous and run down a few hp when you aren't running it. Or go to a full standalone. If you go full standalone you could tune the car to control the nitrous. In other words when you activate the nitrous the computer will automatically drop timing and adjust fueling to compensate for the added oxygen. You could then choose to run a dry shot. This route would likely result in you needing a bigger fuel pump, larger injectors and lots of time on a dyno.

BC

BC

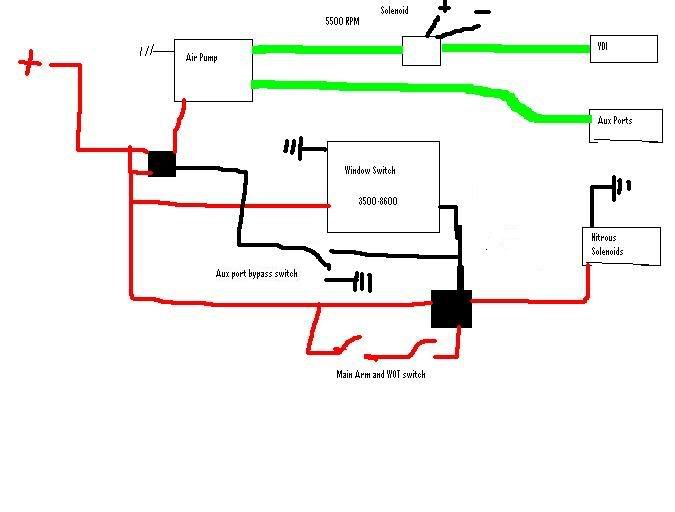

I think I finally figured out how I'm going to wire all this.

Green are vacuum lines

3500 RPM -

Window switch grounds relay for nitrous, activating it.

Window switch grounds relay for air pump, turning it on and opening the aux ports.

5500 RPM -

Using the RTEK, activate the EGR solenoid or other such solenoid which opens air line to VDI, activating it. A bleeder valve will need to be rigged up somewhere in here.

8600 RPM -

Window switch breaks ground to relays, disarming nitrous and turning off the air pump.

The aux port bypass switch will ground the relay and manually override the window switch to turn on the air pump at all time. This way, the aux ports will function normally, but I can manually open them when spraying or beating on the car. (not that I plan on spraying below 3500 anyways, this is just an extra safety measure)

Last edited by The Shaolin; 09-26-07 at 09:08 PM.

#59

If you keep the shot below 75 (100 if you are ballsy) then you should be fine running stock timing maps. If (when) you get bored at 75 then you should start pulling timing. Scath's write up suggests 1* per 25 hp, I have also read 1* per 50. 1* per 25 is safer though

BC

BC

#60

Thread Starter

Joined: Mar 2007

Posts: 1,029

Likes: 0

From: Appleton, WI

Perhaps I shouldn't have been so quick to sell the SAFC. I'm really looking forward to using the Rtek though. I've heard the SAFC actually may retard timing with the way it modifies the AFL readings.

#61

Looks good, a few things to consider...

The manual override switch isn't really necessary, the reason I thought that may have been a good idea is because too much stuff seemed to be happening at once and a failure the 5th and 6th port actuating circuit could mean big problems. I think you would be better off using a mircoswitch on the actuator so if the air pump fails or the vacuum line leaks, or the the ports fail to open for any reason, the kit just won't arm.

The walbro and 5/16" lines will support plenty of power, I have personally made over 500whp with just a walbro running through the stock lines at 58psi with an estimated brake specific fuel consumption of about 0.5lbs.

With the Rtek pulling timing, I would work your way up to a 150shot, might be a good idea to follow scathcarts advice and run a strait elbow off the TB...a backfire is definitely a possibility with this setup, so you'll probably want to take every precaution possible.

Can't resist...

False. Distribution of nitrous will be best with a dry hit, in fact off the bat it will often be as good or better than a direct port in regards to having a consistent AFR between cylinders. The direct port does hold the advantage of having an individual fuel jet for each cylinder, so if certain cylinders are running lean its a jet change away from fixing it.

Would you rather change a few values on your laptop or shut the car off, get out, find a 7/16" and 3/8" open end, reach into a hot *** engine bay, undo the fuel hose at the nozzle, pull the jet out, drop it on the ground, reach in though the engine bay to try to grab the jet, burn yourself on the exhaust, get on your hands and knees and try to kick the jet out so you can reach it, pick it up, grab a bag full of jets and hold them up one by one trying to read the sizes of them stamped on the side, after going through all of them realize you don't have the one you need, push the car off the dyno, go order a jet a pay $5+shipping, wait 3 days...**** fedex doesn't deliver on sundays, make that 4 days....go to slip the jet into the nozzle, drop it on the ground....

You'll need the bigger fuel pump either way, and upgrading injectors isn't a big deal, you can even offset some of the cost because you don't need a fuel solenoid. I understand that because of limited EMS options on these cars a dry shot isn't going to be easy to setup, but don't bash the dry hit...it is the future of nitrous.

The manual override switch isn't really necessary, the reason I thought that may have been a good idea is because too much stuff seemed to be happening at once and a failure the 5th and 6th port actuating circuit could mean big problems. I think you would be better off using a mircoswitch on the actuator so if the air pump fails or the vacuum line leaks, or the the ports fail to open for any reason, the kit just won't arm.

The walbro and 5/16" lines will support plenty of power, I have personally made over 500whp with just a walbro running through the stock lines at 58psi with an estimated brake specific fuel consumption of about 0.5lbs.

With the Rtek pulling timing, I would work your way up to a 150shot, might be a good idea to follow scathcarts advice and run a strait elbow off the TB...a backfire is definitely a possibility with this setup, so you'll probably want to take every precaution possible.

Can't resist...

Dl: the consensus is to stay away from a dry shot. A wet shot would be more advisable. Also the RTEK will not control nitrous, so you set your timing for nitrous and run down a few hp when you aren't running it. Or go to a full standalone. If you go full standalone you could tune the car to control the nitrous. In other words when you activate the nitrous the computer will automatically drop timing and adjust fueling to compensate for the added oxygen. You could then choose to run a dry shot. This route would likely result in you needing a bigger fuel pump, larger injectors and lots of time on a dyno.

You'll need the bigger fuel pump either way, and upgrading injectors isn't a big deal, you can even offset some of the cost because you don't need a fuel solenoid. I understand that because of limited EMS options on these cars a dry shot isn't going to be easy to setup, but don't bash the dry hit...it is the future of nitrous.

#62

Originally Posted by PhantomKid

As for those talking about reversion i dont know if its muhc of a issue for a rotary we dont have valves that close

But i know if we do have reversion it cant be as bad as a piston motor

I have heard a lot of success stories with using N20 on a rotary. Not sure if the reversion wave would cause the N20 to itemize in the air stream very well or not, im leaning more toward not...

I read somewhere that the OP wasn't sure how to make the ports and nitrous work together and though there must have been a reason for why Mazda opens the ports later. Its due to the intake velocity. Personally I would only operate the N20 when the velocity is higher, above 4000rpm. After the Aux ports. Im pretty sure mazda did the same thinking for the secondaries. With the secondaires spraying fuel in the intake runners up high, intake velocity needs to be there to help itemize the fuel with the air intake. Placing them to close may have hurt top end performance since there may not have been enough time for the fuel to itemize in the air stream as well as if they were placed further down the intake.

Having no experience with N20 I can only add little suggestions. I would place the nozzel(s) around where the secondary injectors are. A quick bend and straight down to the ports and you shouldn't have to worry about anything on the walls. You shouldn't have to anyways is you activate the N20 / Fuel at higher rpms where velocity is highest.

Originally Posted by PhantomKid

you should use a full throttle switch, so nitrous isnt activated at lower RPMs

Now you can use both, throttle and rpm so that the N20 is only active during 80-100% throttle at a specific rpm.

Originally Posted by The Shaolin

3500 RPM -

Window switch grounds relay for nitrous, activating it.

Window switch grounds relay for air pump, turning it on and opening the aux ports.

Window switch grounds relay for nitrous, activating it.

Window switch grounds relay for air pump, turning it on and opening the aux ports.

The aux port bypass switch will ground the relay and manually override the window switch to turn on the air pump at all time. This way, the aux ports will function normally, but I can manually open them when spraying or beating on the car. (not that I plan on spraying below 3500 anyways, this is just an extra safety measure)

Using the same air pump is a bad idea. when the VDI kicks in, there could be a substainsul pressure drop and allow the AUX to close a bit and then have both the VDI and AUX open SLOWLY. You need a pretty good air pump if your going to go that route.

I have had the idea of using a 1/4 gallon tank with a small air compressor that would charge the tank to about 6-10 psi and hook the VDI and AUX to the tank using solenoids to activate them and this would cause the ports top open more quickly and not have to worry about air pumps kicking on and possibly overheating and shutting down while operating for long periods like my 2 lumbar air pumps do after 3-5 minutes.

Perhaps I shouldn't have been so quick to sell the SAFC. I'm really looking forward to using the Rtek though. I've heard the SAFC actually may retard timing with the way it modifies the AFL readings.

Last edited by RotaMan99; 09-27-07 at 07:46 AM.

#63

AFAIK any changes in timing made by an SAFC would be completely indirect and therefore pretty much make it into a crapshoot. An SAFC is a half assed way of tuning, you'll be much happier using the Rtek and actually being able to change the values in the computer, instead of trying to figure out the best way to trick it into getting you what you want.

#65

PD, pm scathcart for referense to higher shots. He has topped out at about 400.

Look forward to ITBs and juice by the way. If I stay in the RX7 game long enough that would be a route I would like to go down.

BC

Look forward to ITBs and juice by the way. If I stay in the RX7 game long enough that would be a route I would like to go down.

BC

#66

Thread Starter

Joined: Mar 2007

Posts: 1,029

Likes: 0

From: Appleton, WI

Thank you, everyone, for the feedback on the VDI/Aux ports. This is going to be a giant pain in the ***.

I had taken the pressure drop into consideration, but I was hoping that by giving the aux ports 8 PSI or so, they would snap open, and then 4 psi would still hold them when the vdi opens.

I don't know how else to do it, short of wiring up two air pumps and two RPM switches...trying to keep it simple, but I guess I'll do what it takes to make this work.

I had taken the pressure drop into consideration, but I was hoping that by giving the aux ports 8 PSI or so, they would snap open, and then 4 psi would still hold them when the vdi opens.

I don't know how else to do it, short of wiring up two air pumps and two RPM switches...trying to keep it simple, but I guess I'll do what it takes to make this work.

#67

I wish I was driving!

Joined: Dec 2001

Posts: 5,241

Likes: 84

From: BC, Canada

ok this is for Scathcart. I read through almost all of this thread. When I get unbroke, if ever I want to do a pretty decent sized streetport on my s5 na, and want to run nitrous when I feel like having fun or need to dust someone. I want to run a 100 shot, so let me get this straight according to you.

This is what I want to do.

s5 streetport, 6 puck clutch with lightened flywheel, exhuast bolt ons. 100 shot nitrous.

So I should do this according to you if I understand right.

Run a dry shot before the TB, and porting the TB is a good idea. Also use an Rtek to keep my timing good for when I strictly want to run the nitrous it will make the changes accordingly and will only do so when the 5/6 ports are open correct? Then I will be good? what elso should I need?

This is what I want to do.

s5 streetport, 6 puck clutch with lightened flywheel, exhuast bolt ons. 100 shot nitrous.

So I should do this according to you if I understand right.

Run a dry shot before the TB, and porting the TB is a good idea. Also use an Rtek to keep my timing good for when I strictly want to run the nitrous it will make the changes accordingly and will only do so when the 5/6 ports are open correct? Then I will be good? what elso should I need?

I have no experience with the RTEK. I prefer standalones.

#68

I wish I was driving!

Joined: Dec 2001

Posts: 5,241

Likes: 84

From: BC, Canada

Would you rather change a few values on your laptop or shut the car off, get out, find a 7/16" and 3/8" open end, reach into a hot *** engine bay, undo the fuel hose at the nozzle, pull the jet out, drop it on the ground, reach in though the engine bay to try to grab the jet, burn yourself on the exhaust, get on your hands and knees and try to kick the jet out so you can reach it, pick it up, grab a bag full of jets and hold them up one by one trying to read the sizes of them stamped on the side, after going through all of them realize you don't have the one you need, push the car off the dyno, go order a jet a pay $5+shipping, wait 3 days...**** fedex doesn't deliver on sundays, make that 4 days....go to slip the jet into the nozzle, drop it on the ground....

I'd rather change mechanical jets. Atomization is improved by forcing fuel out through the fogger jet... 950 psi will do that. For equal nitrous jettings, properly optimized, a wet shot will make more power for this reason every time.

As for your scenario...

I'd much rather grab my shiny -AN wrenches, pop the hood, undo each fogger nozzle, grab my organizer filled with jets, and have at 'er. Don't need to worry about dropping **** or burning myself as my mom didn't drink when she was pregnant with me.

Here's my scenario for you:

You've decided to grow a nut and drop your ***** 75 shot for a 150 shot. You pop the hood and change the nitrous jets. You now need to retune the car on nitrous... and hopefully you don't max out your injector duty cycles. ****... now you need new fuel injectors and have to retune the entire car. Then, you decide to grow another nut, and rejet to a 250 shot. Again, you need to retune. *yawn*. With wet, you can establish a baseline jet ratio that gives you your desired AFR, and then just use that same ratio as you move up in power shots. One run to make sure all is good and you're one your way... might need to pull out a fuel jet size here or there as you move up so you don't get too rich. No nerdy laptop, no multiple runs to tune the thing properly... just jet and go.

#69

I wish I was driving!

Joined: Dec 2001

Posts: 5,241

Likes: 84

From: BC, Canada

If you keep the shot below 75 (100 if you are ballsy) then you should be fine running stock timing maps. If (when) you get bored at 75 then you should start pulling timing. Scath's write up suggests 1* per 25 hp, I have also read 1* per 50. 1* per 25 is safer though

BC

BC

#70

I wish I was driving!

Joined: Dec 2001

Posts: 5,241

Likes: 84

From: BC, Canada

Can't I run a nitrous and an N/A tune? I hope there's more than one timing map...just sold my SAFC...

Green are vacuum lines

3500 RPM -

Window switch grounds relay for nitrous, activating it.

Window switch grounds relay for air pump, turning it on and opening the aux ports.

5500 RPM -

Using the RTEK, activate the EGR solenoid or other such solenoid which opens air line to VDI, activating it. A bleeder valve will need to be rigged up somewhere in here.

8600 RPM -

Window switch breaks ground to relays, disarming nitrous and turning off the air pump.

The aux port bypass switch will ground the relay and manually override the window switch to turn on the air pump at all time. This way, the aux ports will function normally, but I can manually open them when spraying or beating on the car. (not that I plan on spraying below 3500 anyways, this is just an extra safety measure)

Green are vacuum lines

3500 RPM -

Window switch grounds relay for nitrous, activating it.

Window switch grounds relay for air pump, turning it on and opening the aux ports.

5500 RPM -

Using the RTEK, activate the EGR solenoid or other such solenoid which opens air line to VDI, activating it. A bleeder valve will need to be rigged up somewhere in here.

8600 RPM -

Window switch breaks ground to relays, disarming nitrous and turning off the air pump.

The aux port bypass switch will ground the relay and manually override the window switch to turn on the air pump at all time. This way, the aux ports will function normally, but I can manually open them when spraying or beating on the car. (not that I plan on spraying below 3500 anyways, this is just an extra safety measure)

#72

Can't resist....

I'd rather change mechanical jets. Atomization is improved by forcing fuel out through the fogger jet... 950 psi will do that. For equal nitrous jettings, properly optimized, a wet shot will make more power for this reason every time.

As for your scenario...

I'd much rather grab my shiny -AN wrenches, pop the hood, undo each fogger nozzle, grab my organizer filled with jets, and have at 'er. Don't need to worry about dropping **** or burning myself as my mom didn't drink when she was pregnant with me.

Here's my scenario for you:

You've decided to grow a nut and drop your ***** 75 shot for a 150 shot. You pop the hood and change the nitrous jets. You now need to retune the car on nitrous... and hopefully you don't max out your injector duty cycles. ****... now you need new fuel injectors and have to retune the entire car. Then, you decide to grow another nut, and rejet to a 250 shot. Again, you need to retune. *yawn*. With wet, you can establish a baseline jet ratio that gives you your desired AFR, and then just use that same ratio as you move up in power shots. One run to make sure all is good and you're one your way... might need to pull out a fuel jet size here or there as you move up so you don't get too rich. No nerdy laptop, no multiple runs to tune the thing properly... just jet and go.

I'd rather change mechanical jets. Atomization is improved by forcing fuel out through the fogger jet... 950 psi will do that. For equal nitrous jettings, properly optimized, a wet shot will make more power for this reason every time.

As for your scenario...

I'd much rather grab my shiny -AN wrenches, pop the hood, undo each fogger nozzle, grab my organizer filled with jets, and have at 'er. Don't need to worry about dropping **** or burning myself as my mom didn't drink when she was pregnant with me.

Here's my scenario for you:

You've decided to grow a nut and drop your ***** 75 shot for a 150 shot. You pop the hood and change the nitrous jets. You now need to retune the car on nitrous... and hopefully you don't max out your injector duty cycles. ****... now you need new fuel injectors and have to retune the entire car. Then, you decide to grow another nut, and rejet to a 250 shot. Again, you need to retune. *yawn*. With wet, you can establish a baseline jet ratio that gives you your desired AFR, and then just use that same ratio as you move up in power shots. One run to make sure all is good and you're one your way... might need to pull out a fuel jet size here or there as you move up so you don't get too rich. No nerdy laptop, no multiple runs to tune the thing properly... just jet and go.

My setup is firing though a hotwire maf, so a once the tune is setup properly I can up the shot size and the maf will compensate for the larger shot without me having to touch anything. If not using a maf you will have to make adjustments to the nitrous fueling map when you change the nitrous jet, you can scale the fuel accordingly and tweak it a little if you need to, then save that tune and use it whenever you switch to that sized shot...sorry if you don't have the means to tune your car properly, but I do.

You should size your injectors to the amount of power you want to make, a little forward thinking solves that "problem".

Guess what these all have in common...

http://videos.streetfire.net/Player....1BD5FBDD33&p=0

http://videos.streetfire.net/player....5-0004B59456E9

http://i161.photobucket.com/albums/t...sBackfire3.jpg

http://www.ls1tech.com/forums/attach...chmentid=44532

Give up? They were all caused by wet kits backfiring. Let me know if you'd like me to find more examples, because there are plenty. Ever experienced this in a car you've worked on?

If you find an engine that was damaged by a properly set up dry hit, it is a tuning mistake or the internals of the engine were simply not strong enough. Even if the solenoid stuck open on a setup going through the maf you'd still be alright because the maf would still compensate. Ever had a fuel solenoid stick open or fail to open? Blown engine. Ever had a nitrous solenoid stick open on a wet kit? Blown engine.

If you seriously think wet kits are a good idea on a modern efi vehicle - not just a compromise, you still have a lot to learn...guess experience isn't everything.

I'll stick with my nerdy laptops and dry hits and you can keep hoping your "*****" are big enough to spray because your awesome wet nitrous kit is capable of starting your car on fire

#73

Thread is interesting.

Not know much about this, why do the wet shots like to backfire? Bad placement?\

I never thought about running dry through the maf. Think it would work with a flapper/cone type AFM?

Not know much about this, why do the wet shots like to backfire? Bad placement?\

I never thought about running dry through the maf. Think it would work with a flapper/cone type AFM?

#74

they tend to backfire beucase you are spraying fuel through a manifold that isnt designed to flow liquid through it. The fuel hits a flat spot and falls out of suspension, or hits a sharp corner, and then gets lit off.

Boom.

BC

Boom.

BC

#75

rosey what are you using to tune? The nitrous on the MAF how accurate is that being that nitrous is very cold i understand the MAF would in turn be tricking thinking more air is going to the engine(which in a wierd way...is) but i just wondering how accurate that could be. Does the MAF get dirty, how often do you have to clean it? i would think that the wire would crack after all it is a heated wire and then your shotting ice cold nitrous the drastic change in temperature doesnt effect the MAF? sorry for all the question im just wondering how your set up works you seem to know alot and i would like to also build a safe powerful set up.