Knock- what you know and what you think you know

#1

Thread Starter

Banned. I got OWNED!!!

iTrader: (1)

Joined: Jun 2006

Posts: 697

Likes: 0

From: Denver

Knock- what you know and what you think you know

In another thread Knock, knock boxes, etc were brought up and I thought its as good a time as any to actually discuss what is out there, what you think you know and what you believe because its internet legend.

First, everyone who wants to have any understanding of knock needs to read this article http://www.streetrodstuff.com/Articl...ne/Detonation/ which is an article that has been reprinted in many many places. It is very very good at explaining detonation, pre-ignition, etc. This link http://sine.ni.com/cs/app/doc/p/id/cs-398 is also pretty useful if you want to design or interpret engine knock.

Next, a couple of things about Knock. It is a harmonic and has a specific bandwith in which it occurs. Because of this, modern ECU's use very sensitive knock sensors to figure out what is and what is not "knock", and so these cars often "run on the knock sensor", advancing timing until the engine knocks, reducing it, then advancing it again. Only a few aftermarket ECU's are capable of this, among those MOTEC M4/6/800, AEM S1 and S2 ecu's, both companies constantly refining thier knock control strategies. I have sucessfully wired in LED's that the AEM has triggered based on its knock definitions and they do work.

I have next to zero faith in "knock boxes" such as the one shown for $50 in BDC's thread. It may work, but I just have no faith in them, mostly because the knock "curve" and engine noise profile of every engine is different. Knock ears do work, but they require you knowing what to listen for.

One of the issues behind a bunch of LED's is that by the time you see them and react, its likely too late, damage done, so it is MUCH better to have the ECU take careof it for you. The reason we wired in LED's to the AEM ECU is so you know you are knocking and that the ECU has retarded timing and you need to see WTF is going on with your car.

Now, I often see people, some of them knowledgable tuners, say they want the knock lights as a safety measure in case they lose a boos hose or have some other failure. Well, thats *** backwards. If you are worried about an overboost condition you need to take care of it in the ECU so it shuts off ignition or fuel or both above a given boost level. If for some reason your ECU doesnt allow this, you probably should not be adjusting boost.

I am sure there are others with a lot to say about this, and I for one welcome discussion on this topic! I hope everyone reads the links posted and gains a useful understanding of what knock is and what causes it and what to do about it.

Cheers!

Don

First, everyone who wants to have any understanding of knock needs to read this article http://www.streetrodstuff.com/Articl...ne/Detonation/ which is an article that has been reprinted in many many places. It is very very good at explaining detonation, pre-ignition, etc. This link http://sine.ni.com/cs/app/doc/p/id/cs-398 is also pretty useful if you want to design or interpret engine knock.

Next, a couple of things about Knock. It is a harmonic and has a specific bandwith in which it occurs. Because of this, modern ECU's use very sensitive knock sensors to figure out what is and what is not "knock", and so these cars often "run on the knock sensor", advancing timing until the engine knocks, reducing it, then advancing it again. Only a few aftermarket ECU's are capable of this, among those MOTEC M4/6/800, AEM S1 and S2 ecu's, both companies constantly refining thier knock control strategies. I have sucessfully wired in LED's that the AEM has triggered based on its knock definitions and they do work.

I have next to zero faith in "knock boxes" such as the one shown for $50 in BDC's thread. It may work, but I just have no faith in them, mostly because the knock "curve" and engine noise profile of every engine is different. Knock ears do work, but they require you knowing what to listen for.

One of the issues behind a bunch of LED's is that by the time you see them and react, its likely too late, damage done, so it is MUCH better to have the ECU take careof it for you. The reason we wired in LED's to the AEM ECU is so you know you are knocking and that the ECU has retarded timing and you need to see WTF is going on with your car.

Now, I often see people, some of them knowledgable tuners, say they want the knock lights as a safety measure in case they lose a boos hose or have some other failure. Well, thats *** backwards. If you are worried about an overboost condition you need to take care of it in the ECU so it shuts off ignition or fuel or both above a given boost level. If for some reason your ECU doesnt allow this, you probably should not be adjusting boost.

I am sure there are others with a lot to say about this, and I for one welcome discussion on this topic! I hope everyone reads the links posted and gains a useful understanding of what knock is and what causes it and what to do about it.

Cheers!

Don

#4

Thread Starter

Banned. I got OWNED!!!

iTrader: (1)

Joined: Jun 2006

Posts: 697

Likes: 0

From: Denver

And Why do you think that?

I KNOW for a fact that the knock control strategies in the AEM ECU work and have saved engines. I also know that the 3R Racing Volvo S-60Rusing MOTEC ran on the knock sensor while making 600awhp under racing conditions, and that it worked flawlessly once it was sorted. So I am very curious as to your statement.

I will say that I do not believe there is a "knock light" that could be used in such a manner, simplt because it relies on the human being to interpret the signal and then react.

I KNOW for a fact that the knock control strategies in the AEM ECU work and have saved engines. I also know that the 3R Racing Volvo S-60Rusing MOTEC ran on the knock sensor while making 600awhp under racing conditions, and that it worked flawlessly once it was sorted. So I am very curious as to your statement.

I will say that I do not believe there is a "knock light" that could be used in such a manner, simplt because it relies on the human being to interpret the signal and then react.

#5

According to Nagao et al., "Present Status and Future View of Rotary Engines," 1986 engine knock mostly occurs in the trailing portion of the rotary combustion chamber:

You can see that the occurrence of knock is related to the temperature of the rotor combustion surface and the ignition timing. Point A is in the middle of the "bath tub" combustion recess. Point B is at the trailing portion of the "bath tub." Point C is at the trailing portion of the rotor face, near the apex seal.

As the ignition timing is advanced further, rotor temperature increases, which makes the engine more prone to knocking. You can especially see that at point B in the graph, the rotor temperature suddenly shoots up as ignition timing goes beyond a particular threshold. Of course this was a test in a lab done 25 years ago and we don't know every detail about it. It does give us a good qualitative understanding of knock in a rotary engine however.

Besides running high grade fuel on modified turbo applications, cooling is critical--intake air, oil temperature, and water temperature. It also means that you need to be very careful with tuning ignition timing, IMO especially on the trailing split (degrees between firing of the leading and trailing plugs). Unfortunately the paper does not explain what the trailing split was in their testing, but we do know that Mazda does tend to use a conservative 15 degrees split under load. So just like idle ignition timing is -5L -20T BTDC, under heavy loads it may be 30L 15T at a particular rpm and load.

I am of the school of thought that trying to gain power by advancing the trailing ignition timing is not worth the risk on street applications with pump fuel. Specifically, in my opinion as you advance the trailing timing relative to the leading you increase the risk of knock faster than you increase horsepower. The marginal risk outweighs the marginal performance benefit. Of course that holds true up to a point. I don't advocate that we all run 20 degrees split on our engines. I run a fixed 12 or 15 degrees split in higher boost levels on almost every turbo engine that I tune.

You can see that the occurrence of knock is related to the temperature of the rotor combustion surface and the ignition timing. Point A is in the middle of the "bath tub" combustion recess. Point B is at the trailing portion of the "bath tub." Point C is at the trailing portion of the rotor face, near the apex seal.

As the ignition timing is advanced further, rotor temperature increases, which makes the engine more prone to knocking. You can especially see that at point B in the graph, the rotor temperature suddenly shoots up as ignition timing goes beyond a particular threshold. Of course this was a test in a lab done 25 years ago and we don't know every detail about it. It does give us a good qualitative understanding of knock in a rotary engine however.

Besides running high grade fuel on modified turbo applications, cooling is critical--intake air, oil temperature, and water temperature. It also means that you need to be very careful with tuning ignition timing, IMO especially on the trailing split (degrees between firing of the leading and trailing plugs). Unfortunately the paper does not explain what the trailing split was in their testing, but we do know that Mazda does tend to use a conservative 15 degrees split under load. So just like idle ignition timing is -5L -20T BTDC, under heavy loads it may be 30L 15T at a particular rpm and load.

I am of the school of thought that trying to gain power by advancing the trailing ignition timing is not worth the risk on street applications with pump fuel. Specifically, in my opinion as you advance the trailing timing relative to the leading you increase the risk of knock faster than you increase horsepower. The marginal risk outweighs the marginal performance benefit. Of course that holds true up to a point. I don't advocate that we all run 20 degrees split on our engines. I run a fixed 12 or 15 degrees split in higher boost levels on almost every turbo engine that I tune.

Last edited by arghx; 01-02-11 at 11:17 PM. Reason: explanation of diagram

#7

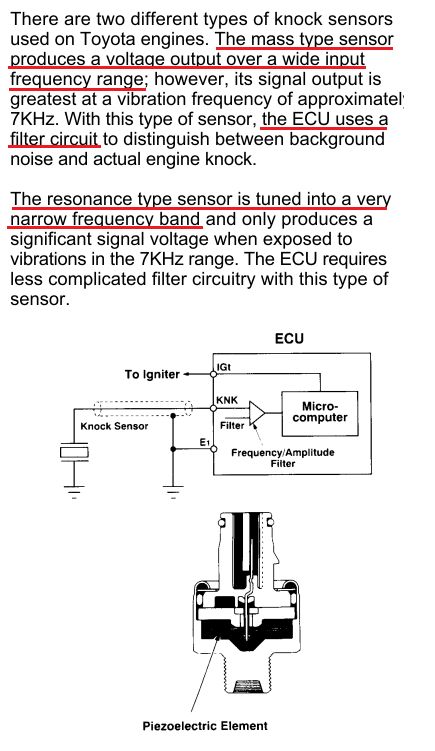

The Toyota/Denso technical manual informs us that there are two basic types of knock sensors. There is the mass-type which produces knocking at one specific frequency. These can work but they are a cheaper design as they don't require sophisticated filtering. This is most likely what you will find on aftermarket external knock warning systems. Personally I suspect that Subarus use this type of sensor from the factory based on my extensive experience with them.

There is also the resonance type. This produces a signal across a wide frequency range and requires the computer to filter out the signal and perform a more sophisticated "learning" process to separate noise from knock. Mitsubishi engines use this type of sensor and so do Rx-7's.

Here is what we know about the factory knock control system on the FC.

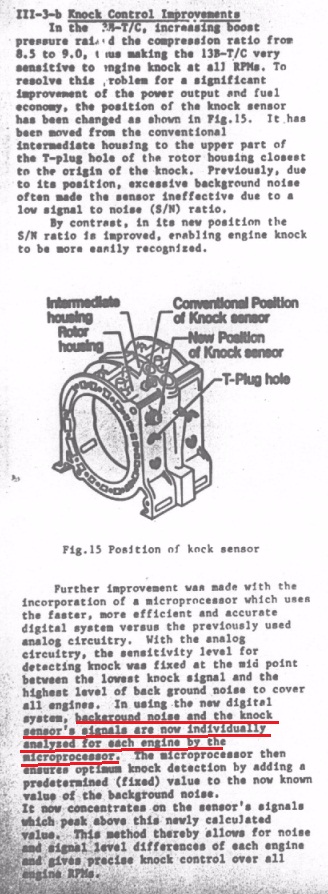

1) the series 4 engines used an external box with analog circuitry and a sensor located in the middle iron

2) the series 5 engines had a much more sophisticated knock control system with a sensor located in the front rotor housing. This system could learn the individual characteristics of each engine.

3) It is possible to log knock control on the Rtek ECU, and it will show knock at least sometimes. To my knowledge few people have done extensive testing with the system so its specific workings and usefulness aren't fully understood.

4) According to the Technical Data document, Mazda lists the knocking frequency in their system as ~3.5 khz

Trending Topics

#8

Thread Starter

Banned. I got OWNED!!!

iTrader: (1)

Joined: Jun 2006

Posts: 697

Likes: 0

From: Denver

I think that is one place many people "have it" while others do not- its the trailing timing vs leading. It seems many tuners, even rotary experts, tend to ignore trailing timing and just sort of leave it in some arbitrary setting.

Anyone have any opinions re trailing split? Any datalogs?

Anyone have any opinions re trailing split? Any datalogs?

#12

Thread Starter

Banned. I got OWNED!!!

iTrader: (1)

Joined: Jun 2006

Posts: 697

Likes: 0

From: Denver

I have the most experience with the Mitsubishi type kock sensors, and of those there are two distinct variations- the "early" sensor which you can basically hit with a hammer before getting a reading, and the "late" which is much more sensitive. Generically I now use the "late" Mitsubishi sensor on all EMS equipped cars, unless there is a compelling reason not to.

On piston cars we have typically established what "knock""looks like" by inducing timing related knock at a light engine load and logging the voltage. We then put the timing back to reasonable and log several "pulls" bothon the dyno and on the street at varying load, speeds etc. and use the hysterisis to determine the engines specific "noise curve". Using these data files, a knock curve is then plotted and inputted into the ECU. This process has changed a bit over the years as we know have more technology, but the basic process can easily be duplicated by virtually anyone. Care must be taken obviously when putting the engine into knock to do it under light load only, and to remember you are only looking for the profile, so there is no reason to do much more than induce knock and get out of it.

Occassionally, issues with the knock sensors themselves come into play, as some aftermarket ECU's cannot process the information in a useful fashion, or the knock sensor itself is simply too blunt to be useful. Other times it is so sensitive as to be a hindrance, on an NSX I supercharged the knock sensor was so sensitive we could see the BOV opening in the log.

On piston cars we have typically established what "knock""looks like" by inducing timing related knock at a light engine load and logging the voltage. We then put the timing back to reasonable and log several "pulls" bothon the dyno and on the street at varying load, speeds etc. and use the hysterisis to determine the engines specific "noise curve". Using these data files, a knock curve is then plotted and inputted into the ECU. This process has changed a bit over the years as we know have more technology, but the basic process can easily be duplicated by virtually anyone. Care must be taken obviously when putting the engine into knock to do it under light load only, and to remember you are only looking for the profile, so there is no reason to do much more than induce knock and get out of it.

Occassionally, issues with the knock sensors themselves come into play, as some aftermarket ECU's cannot process the information in a useful fashion, or the knock sensor itself is simply too blunt to be useful. Other times it is so sensitive as to be a hindrance, on an NSX I supercharged the knock sensor was so sensitive we could see the BOV opening in the log.

#13

I haven't had a chance to really mess with the AEM EMS's knock control capability, just OEM stuff. The OEM Evo knock control system is pretty sick on the factory ECU. From what I've seen it's much more precise than the blunt approach that Subaru uses on the WRX etc.

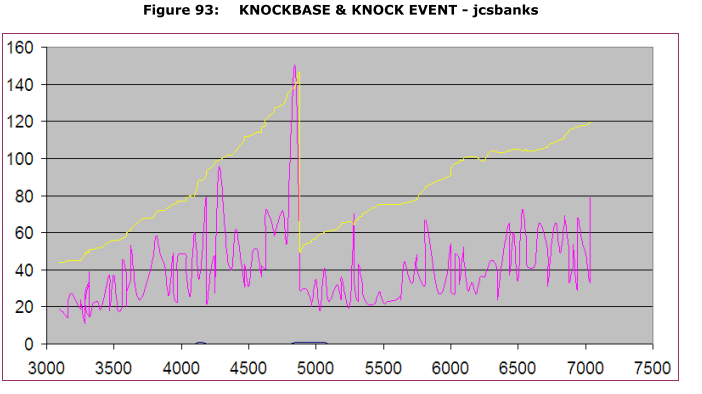

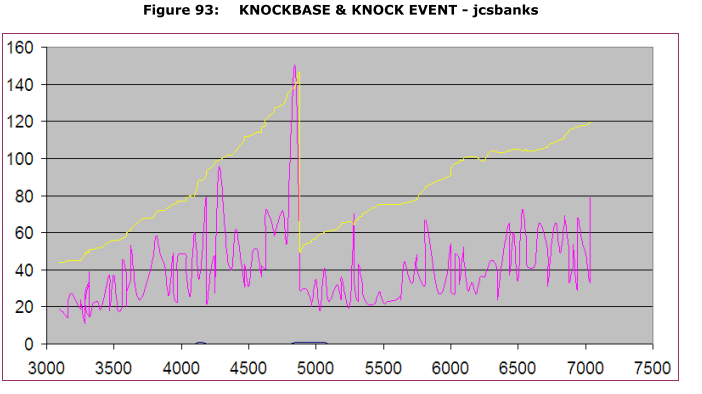

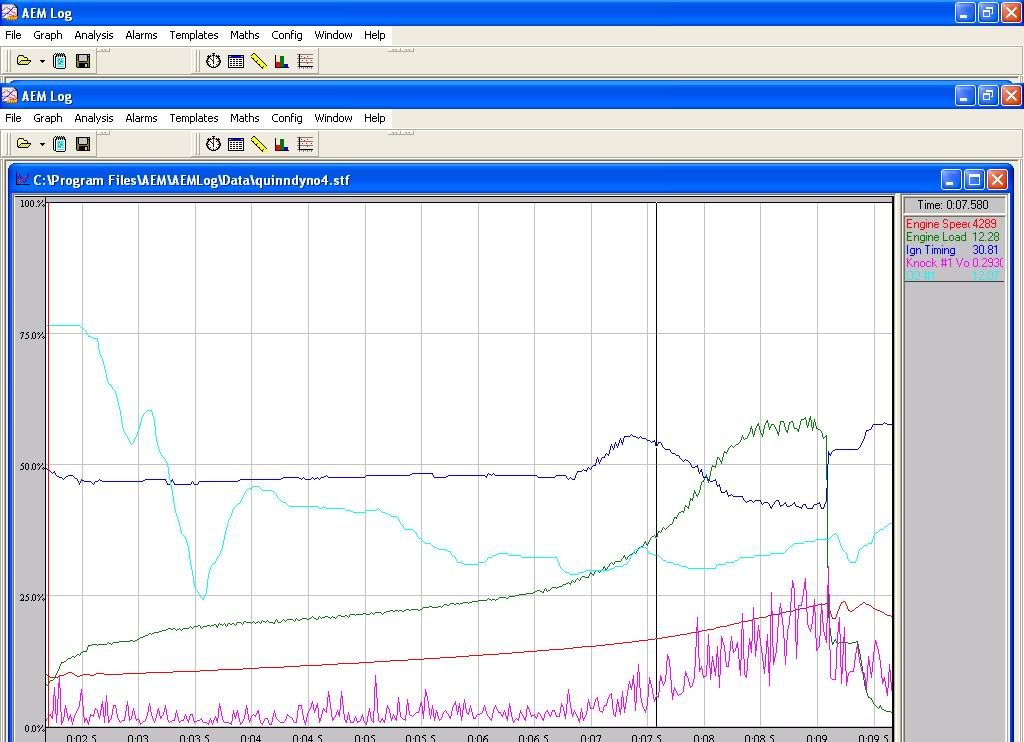

Here you can see that the Mitsu system establishes a type of moving average (yellow line) of the knock sensor signal (purple), with which it can establish a baseline learned noise value. Calculating a baseline noise value lets it adjust to each engine. I suspect that Mazda uses a more primitive version of this approach on the s5 and later rotary engines. I know there's knock control on the Renesis but for the 04-08 engines it is widely considered to not be sensitive/aggressive enough in controlling knock in a boosted application.

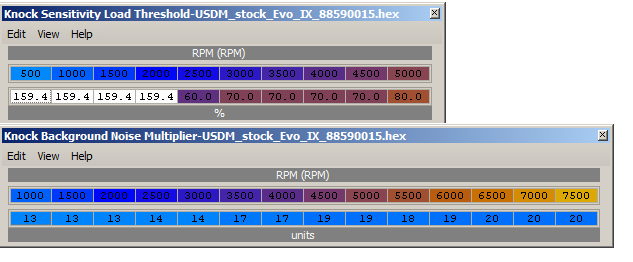

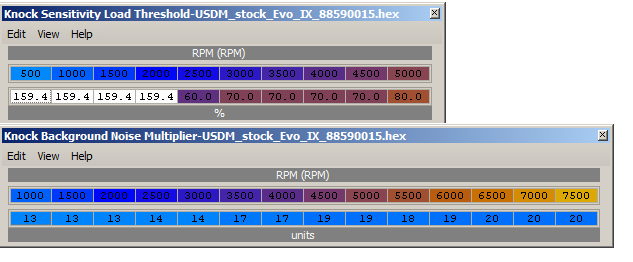

Then you can set the rpm and load points at which the knock control is most active. So in the top map from this default Evo IX calibration, under low rpms the knock sensor isn't active until much higher loads compared to high rpm operation. The second map shown here is a way to adjust the knock sensor noise baseline by prm, in order to get the sensitivity right.

The knock sensor signal provides an immediate knock ignition retard based on the severity of the knock. They call it Burst Knock in GM-speak, or feedback knock correction if you know Subarus. Then that signal is also used to calculate a longer term ignition trim to interpolate between the low and high octane timing maps. That's called Octane number, or dynamic ignition advance, or whatever name the manufacturers/tuners for a particular platform give it.

Here you can see that the Mitsu system establishes a type of moving average (yellow line) of the knock sensor signal (purple), with which it can establish a baseline learned noise value. Calculating a baseline noise value lets it adjust to each engine. I suspect that Mazda uses a more primitive version of this approach on the s5 and later rotary engines. I know there's knock control on the Renesis but for the 04-08 engines it is widely considered to not be sensitive/aggressive enough in controlling knock in a boosted application.

Then you can set the rpm and load points at which the knock control is most active. So in the top map from this default Evo IX calibration, under low rpms the knock sensor isn't active until much higher loads compared to high rpm operation. The second map shown here is a way to adjust the knock sensor noise baseline by prm, in order to get the sensitivity right.

The knock sensor signal provides an immediate knock ignition retard based on the severity of the knock. They call it Burst Knock in GM-speak, or feedback knock correction if you know Subarus. Then that signal is also used to calculate a longer term ignition trim to interpolate between the low and high octane timing maps. That's called Octane number, or dynamic ignition advance, or whatever name the manufacturers/tuners for a particular platform give it.

#14

Thread Starter

Banned. I got OWNED!!!

iTrader: (1)

Joined: Jun 2006

Posts: 697

Likes: 0

From: Denver

Yes for such a knock-prone engine Subarus have pretty stupid knock control. Which actually makes a little sense because of thier "multi-layer adaptive" ECU design which theoretically prevents you from screwing with a signal without the ECU learning around it and more or less putting everything back to stock.

Mitsu on the other hand, has a really good handle on knock control, which might be due to some shared information and development with Porsche/Audi/VW over the years.

Mitsu on the other hand, has a really good handle on knock control, which might be due to some shared information and development with Porsche/Audi/VW over the years.

#15

it's only been recently that AEM has caught up with the curve, but now that they have they may be in the lead for putting out a cheap alternative to the others. looking at the price i may start using them and testing the results.

it's about time that standalones have caught up with OBD3 standards(maybe that's still a stretch)... auto adjusting ECUs have been around in the factory automobile market for at least 10 years now, stock computers for say a GMC learn your throttle tendencies and adjust fuel curves, shift solenoid trim and timing based on driving habits and what the car is doing.

i'm sure there is other alternatives out there for reliable knock boxes that will save the motor as LEDs just won't work because it has to be a quicker reaction than your foot letting off the throttle, same with AFRs if your fuel pump fails. all those safety measures cost money though, the only real alternative is having the ECUs meet the needs of the customers, which so far has only been in the upper tier units.

it's about time that standalones have caught up with OBD3 standards(maybe that's still a stretch)... auto adjusting ECUs have been around in the factory automobile market for at least 10 years now, stock computers for say a GMC learn your throttle tendencies and adjust fuel curves, shift solenoid trim and timing based on driving habits and what the car is doing.

i'm sure there is other alternatives out there for reliable knock boxes that will save the motor as LEDs just won't work because it has to be a quicker reaction than your foot letting off the throttle, same with AFRs if your fuel pump fails. all those safety measures cost money though, the only real alternative is having the ECUs meet the needs of the customers, which so far has only been in the upper tier units.

Last edited by RotaryEvolution; 01-03-11 at 07:51 AM.

#16

Thread Starter

Banned. I got OWNED!!!

iTrader: (1)

Joined: Jun 2006

Posts: 697

Likes: 0

From: Denver

I am not sure thats accurate. The knock control in AEM has always worked and worked pretty well. The biggest "feature" the S2 boxes offered was that the Tuner software makes setting it up initially a lot easier for the novice.

MOTEC actually is the newcomer to knock control, having added it to the M4/6/800 series boxes. Just like everything else they do, it is near OEM in usefulness.

I will post up some logs a bit later of the knock control working in the AEM on various cars. One thing worth mentioning is that on new AEM installs or initial tunes on street cars I frequently make the knock control very aggressive. I mean a 5-10deg ignition retard with a very slow restore rate. This does a couple of things- first, it allows the end user to know when the knock control is working, because you can feel it. That much ignition retard will often feel like the engine is stuttering and most drivers instantly know something is wrong. Second, it allows us to see if there are any issues with the tune that did not show up on the dyno and gives a bit of security in case the tune was a bit close to the edge and now because of a change in fuel, temperature, driving conditions or whatever the timing is too aggressive.

I will post up some screenshots of some logs later today when I have time.

MOTEC actually is the newcomer to knock control, having added it to the M4/6/800 series boxes. Just like everything else they do, it is near OEM in usefulness.

I will post up some logs a bit later of the knock control working in the AEM on various cars. One thing worth mentioning is that on new AEM installs or initial tunes on street cars I frequently make the knock control very aggressive. I mean a 5-10deg ignition retard with a very slow restore rate. This does a couple of things- first, it allows the end user to know when the knock control is working, because you can feel it. That much ignition retard will often feel like the engine is stuttering and most drivers instantly know something is wrong. Second, it allows us to see if there are any issues with the tune that did not show up on the dyno and gives a bit of security in case the tune was a bit close to the edge and now because of a change in fuel, temperature, driving conditions or whatever the timing is too aggressive.

I will post up some screenshots of some logs later today when I have time.

#17

I have never really paid a whole lot of attention to the AEM's knock control features. I need to look back at it. The frustrating thing about the AEM for rotary application is the chicken-and-egg problem of a lack of basemaps. Few people use it because of the price. It costs as much as a Haltech platinum sport, plus you need to buy a Banzai Racing adapter if you want a plug-and-play install on a 2nd gen. Also few people buy it because it lacks a strong knowledge base and set of basemaps. Without people using it, the basemaps and knowledge won't be developed quickly.

The Subaru system is a little different than what I've seen on other manufacturers (granted I haven't seen knock control systems on every single ECU ever made). It has 3 layers of control which is fine, although it is implemented in an unexpected way. I just don't like the fact that you can't adjust the sensitivity of the knock reading. This might be because Subaru uses a narrow-range (resonance type) sensor so there are no filters to adjust.

The cool thing about modern OEM knock control systems is that they are integrated with the boost control, the target AFR tables, the timing maps, the check engine light, etc. So if I am driving an STi and I knock hard enough, the ECU will cut boost back to wastegate spring pressure, richen the mixture to the high knock target AFR table, and significantly retard timing on both an immediate and long-term basis. If I overboost it will throw a check engine light.

The Subaru system is a little different than what I've seen on other manufacturers (granted I haven't seen knock control systems on every single ECU ever made). It has 3 layers of control which is fine, although it is implemented in an unexpected way. I just don't like the fact that you can't adjust the sensitivity of the knock reading. This might be because Subaru uses a narrow-range (resonance type) sensor so there are no filters to adjust.

The cool thing about modern OEM knock control systems is that they are integrated with the boost control, the target AFR tables, the timing maps, the check engine light, etc. So if I am driving an STi and I knock hard enough, the ECU will cut boost back to wastegate spring pressure, richen the mixture to the high knock target AFR table, and significantly retard timing on both an immediate and long-term basis. If I overboost it will throw a check engine light.

#18

there has to be other alternatives to knock retard boxes, but i haven't really done any research on the subject. for example, i'm not going to ditch my LT8s for an AEM when i know my EMS works perfectly fine, it just has 0 safeguards short of boost cut.

#19

Thread Starter

Banned. I got OWNED!!!

iTrader: (1)

Joined: Jun 2006

Posts: 697

Likes: 0

From: Denver

I have never really paid a whole lot of attention to the AEM's knock control features. I need to look back at it. The frustrating thing about the AEM for rotary application is the chicken-and-egg problem of a lack of basemaps. Few people use it because of the price. It costs as much as a Haltech platinum sport, plus you need to buy a Banzai Racing adapter if you want a plug-and-play install on a 2nd gen. Also few people buy it because it lacks a strong knowledge base and set of basemaps. Without people using it, the basemaps and knowledge won't be developed quickly.

and will be posting them to the AEM forum on this site. I also have basemaps for pretty much every other AEM ECU that work with very little tweeking. As far as cost, they can be had for around or under $1300, which is awesome value. No, the harness is not needed from Banzai, as you can swap pins and it will work. I have personally swapped in an AEM ECU into an S5 vert and started the car after simply re-pinning the ecu. If you really feel the need to, AEM themselves make a harness that you can re-pin to fit your needs that is not expensive. If you dont feel comfortable about doing that, simply contact Rich at Autoport Wiring.

and will be posting them to the AEM forum on this site. I also have basemaps for pretty much every other AEM ECU that work with very little tweeking. As far as cost, they can be had for around or under $1300, which is awesome value. No, the harness is not needed from Banzai, as you can swap pins and it will work. I have personally swapped in an AEM ECU into an S5 vert and started the car after simply re-pinning the ecu. If you really feel the need to, AEM themselves make a harness that you can re-pin to fit your needs that is not expensive. If you dont feel comfortable about doing that, simply contact Rich at Autoport Wiring.The Subaru system is a little different than what I've seen on other manufacturers (granted I haven't seen knock control systems on every single ECU ever made). It has 3 layers of control which is fine, although it is implemented in an unexpected way. I just don't like the fact that you can't adjust the sensitivity of the knock reading. This might be because Subaru uses a narrow-range (resonance type) sensor so there are no filters to adjust.

The cool thing about modern OEM knock control systems is that they are integrated with the boost control, the target AFR tables, the timing maps, the check engine light, etc. So if I am driving an STi and I knock hard enough, the ECU will cut boost back to wastegate spring pressure, richen the mixture to the high knock target AFR table, and significantly retard timing on both an immediate and long-term basis. If I overboost it will throw a check engine light.

#20

Thread Starter

Banned. I got OWNED!!!

iTrader: (1)

Joined: Jun 2006

Posts: 697

Likes: 0

From: Denver

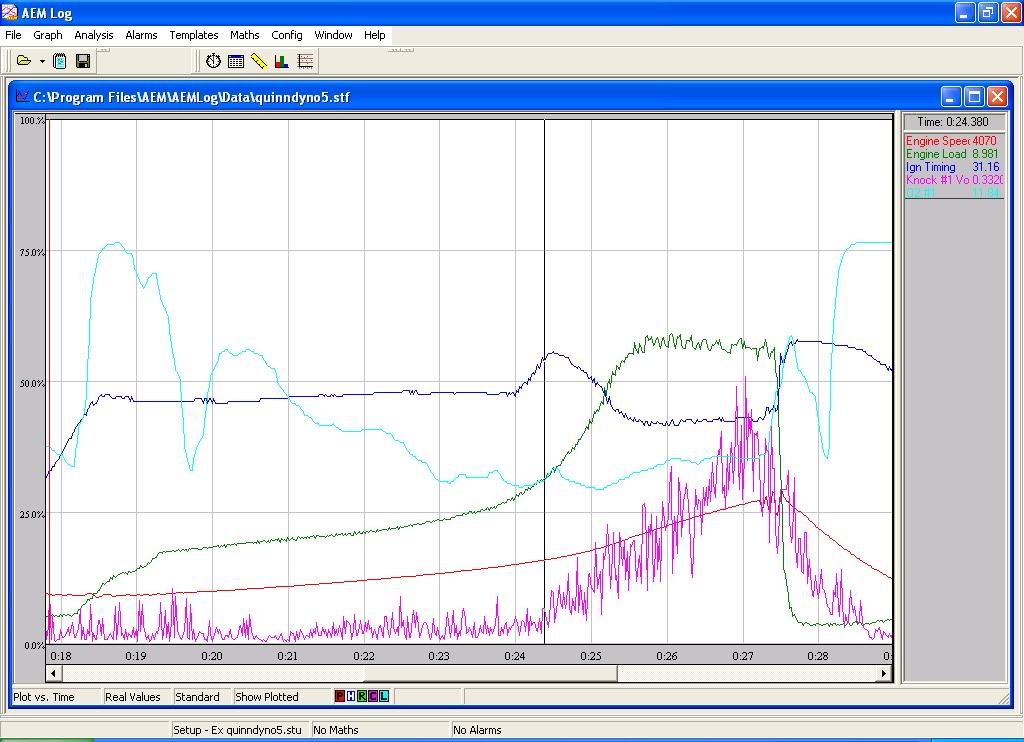

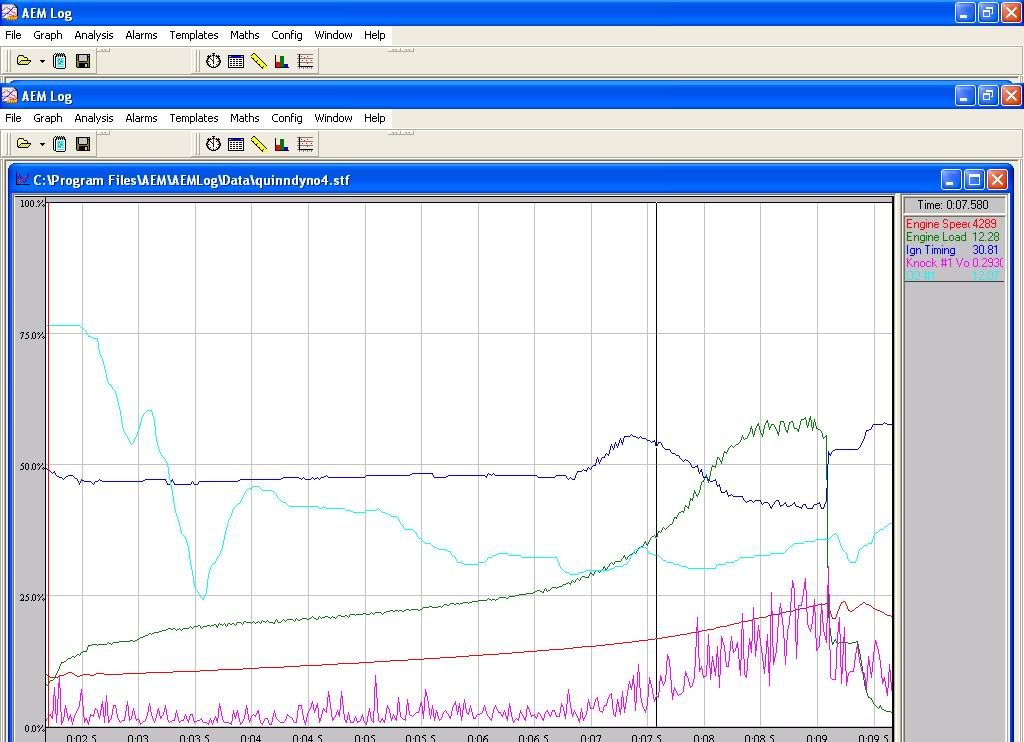

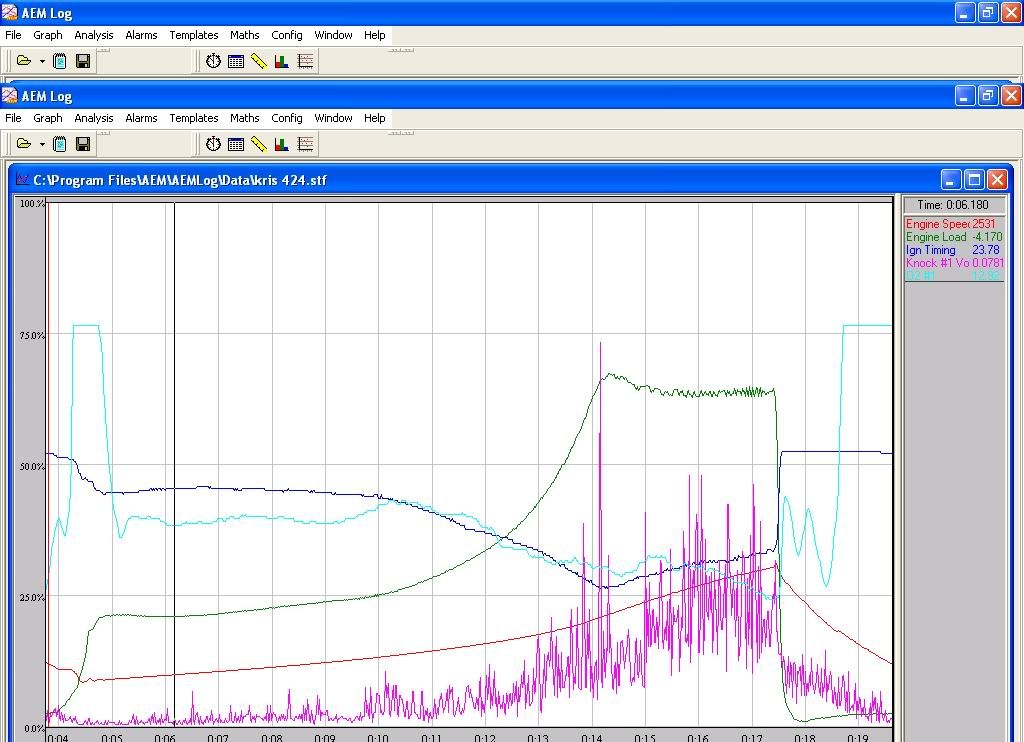

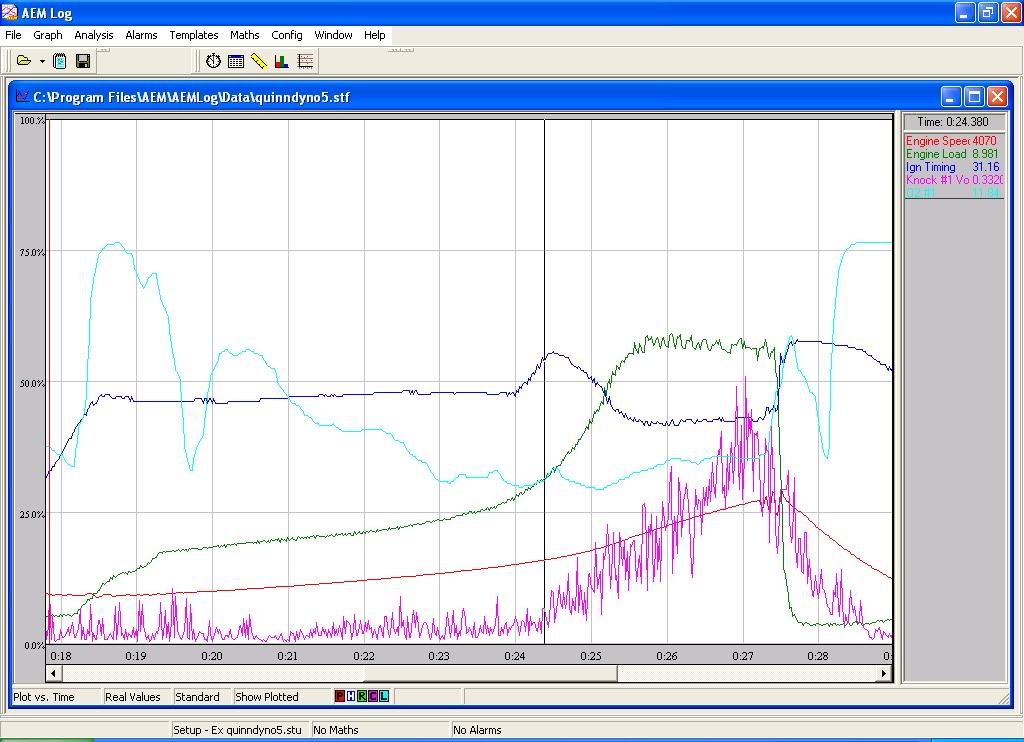

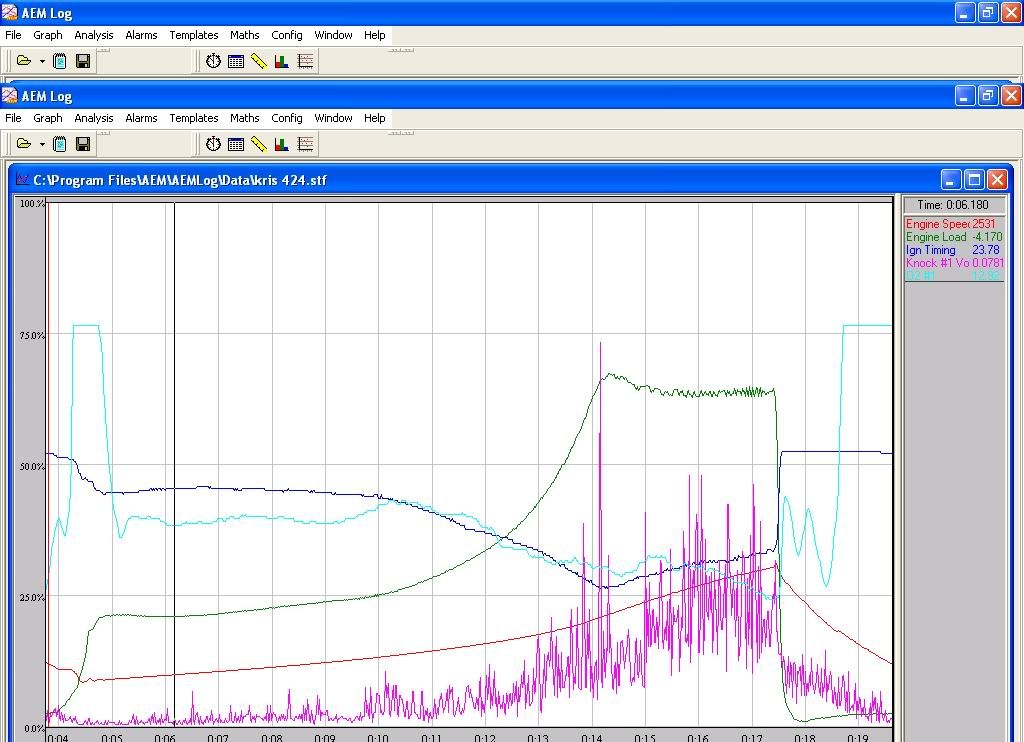

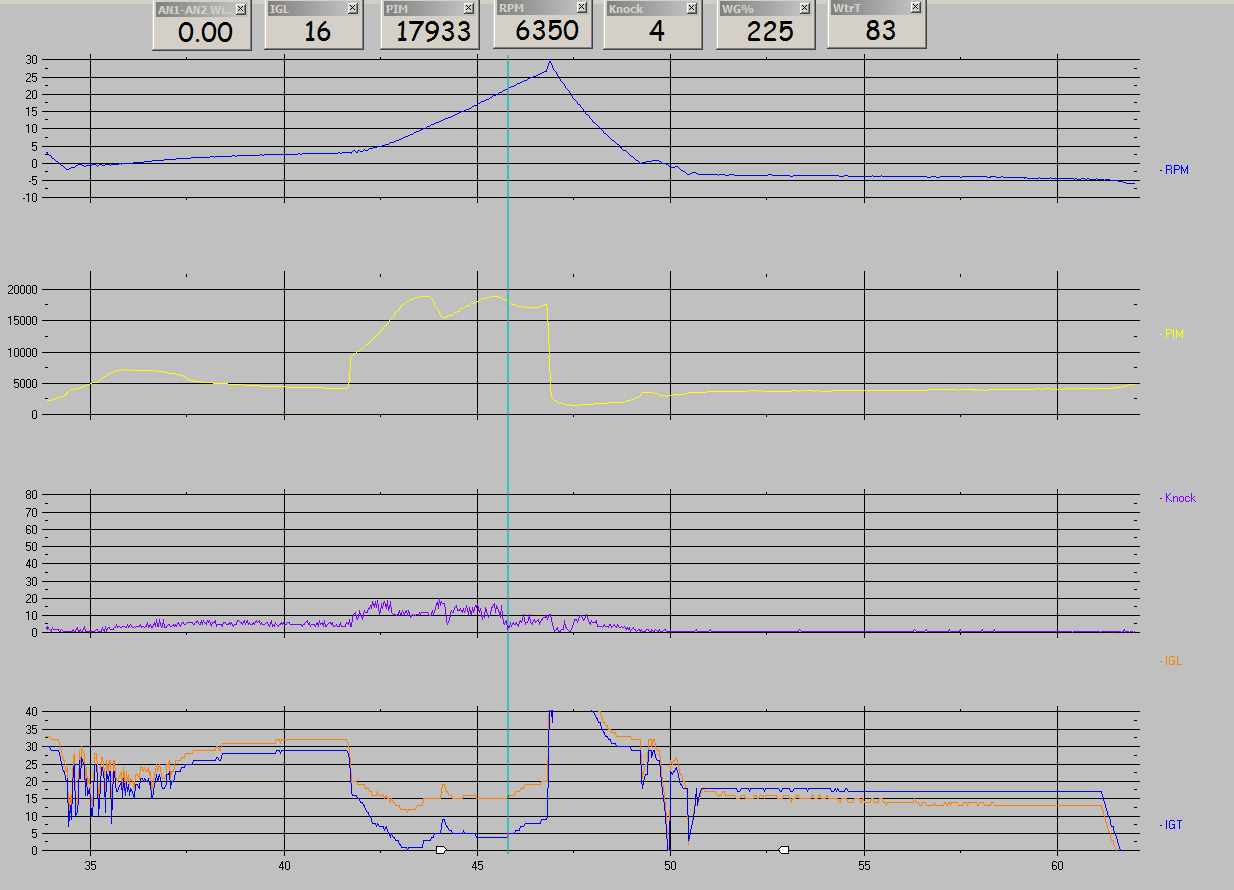

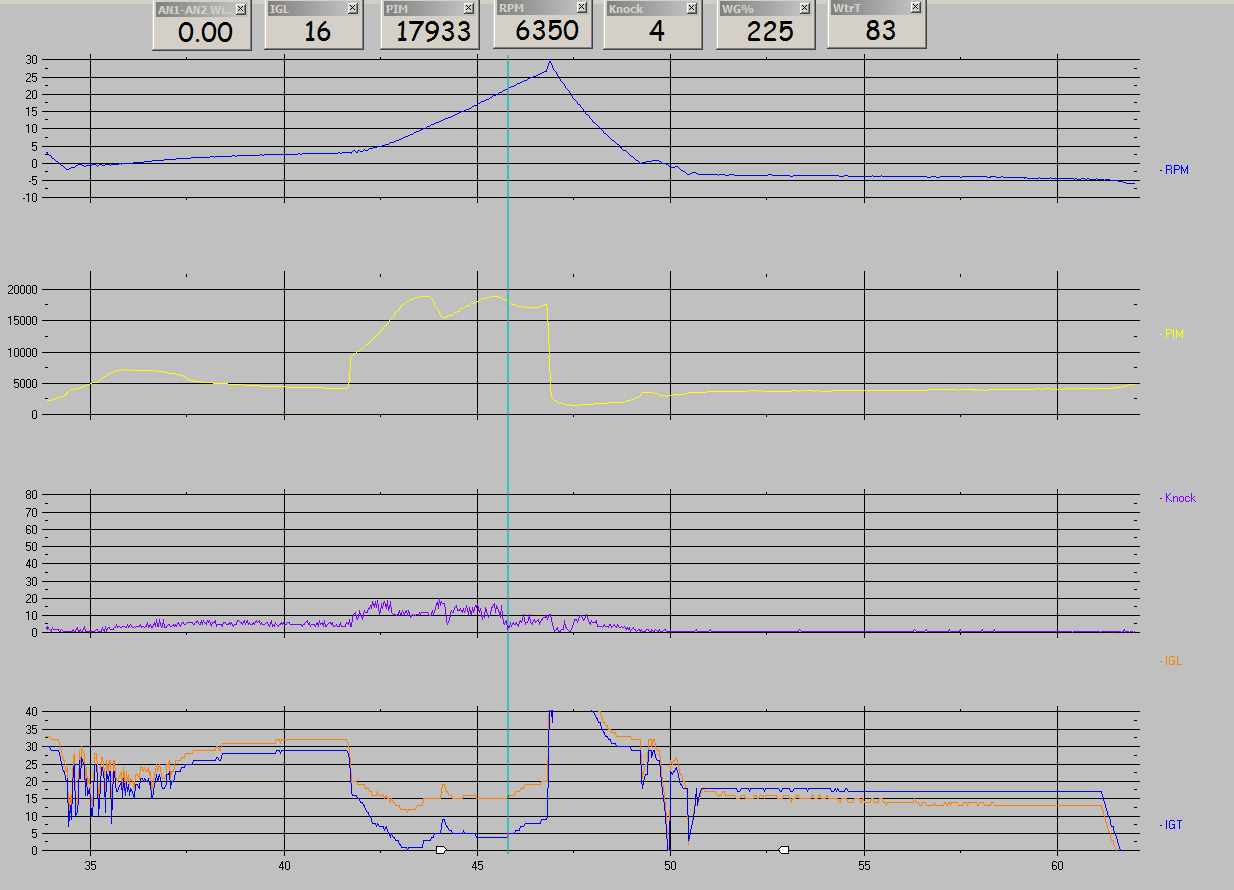

Ok here are some screenshots of a couple of logs using the Mitsubishi knock sensor. Shown is engine load, afr, knock, rpm and ignition timing. Knock is shown as raw voltage, not what the ECU interprets as knock because in these runs we were looking more for engine noise and had knock control off.

First is a Eclipse GSX, 2.4litre, 621whp on e85

This shot shows the engine noise pattern

We see the same pattern here, despite a slight timing change and a 5deg increase in IAT

Here is engine noise with a definite knock in a log from an EVO

An interesting thing about using the Mitsu type knock sensors is that once calibrated they are pretty damned accurate as to what is knock and what is engine noise. Unfortunately the logsfiles with knock control activated are on another laptop so I will upload those shots later, but its easy to see how actively knock can be monitored and controlled.

First is a Eclipse GSX, 2.4litre, 621whp on e85

This shot shows the engine noise pattern

We see the same pattern here, despite a slight timing change and a 5deg increase in IAT

Here is engine noise with a definite knock in a log from an EVO

An interesting thing about using the Mitsu type knock sensors is that once calibrated they are pretty damned accurate as to what is knock and what is engine noise. Unfortunately the logsfiles with knock control activated are on another laptop so I will upload those shots later, but its easy to see how actively knock can be monitored and controlled.

#21

You can do similar analysis with the factory Mazda knock sensor (especially on s5 b/c it is a better sensor location). The stock sensor works with the Power FC and you can see voltage spikes like that once you get an idea of the noise baseline. The problem is that there is no actual automated knock control algorithm with that computer.

#22

Speaking of the stock knock sensor, check out the difference between the baseline noise curve of the s5/FD location (front rotor housing, above the trailing plug) vs the s4 location (middle iron). Here's a dyno pull with an FD:

blue is rpm. yellow is boost where 20000 is ~14psi . the actual "knock" units are unknown but clearly they are related to the raw voltage from the sensor. Orange is leading timing and the second blue line is the trailing timing. Now, compare this to a 1st and 2nd gear run with a series 4 sensor (different car & setup):

You can see how the series 4 signal is much more difficult to interpret. You can see why Mazda relocated the sensor for series 5 and later. Current Rx-8's have two knock sensors, one in the front and one in the rear housing.

blue is rpm. yellow is boost where 20000 is ~14psi . the actual "knock" units are unknown but clearly they are related to the raw voltage from the sensor. Orange is leading timing and the second blue line is the trailing timing. Now, compare this to a 1st and 2nd gear run with a series 4 sensor (different car & setup):

You can see how the series 4 signal is much more difficult to interpret. You can see why Mazda relocated the sensor for series 5 and later. Current Rx-8's have two knock sensors, one in the front and one in the rear housing.

#24

I'm glad to see that people are confirming that ECU's can protect against knock problems.

So what is the main cause of apex seal failure in a turbo rotary application?

Just detonation?

Just pre-ignition?

Or Detonation induced pre-ignition?

And Is pre-ignition easily controllable with colder plugs? Or is that our actual main foe? Even after cold plugs have been installed.

I have also heard of smoothing the spark plug holes where they corner into the combustion chamber to help.

So what is the main cause of apex seal failure in a turbo rotary application?

Just detonation?

Just pre-ignition?

Or Detonation induced pre-ignition?

And Is pre-ignition easily controllable with colder plugs? Or is that our actual main foe? Even after cold plugs have been installed.

I have also heard of smoothing the spark plug holes where they corner into the combustion chamber to help.