Kgparts fuel rail question for FC's

#1

Kgparts fuel rail question for FC's

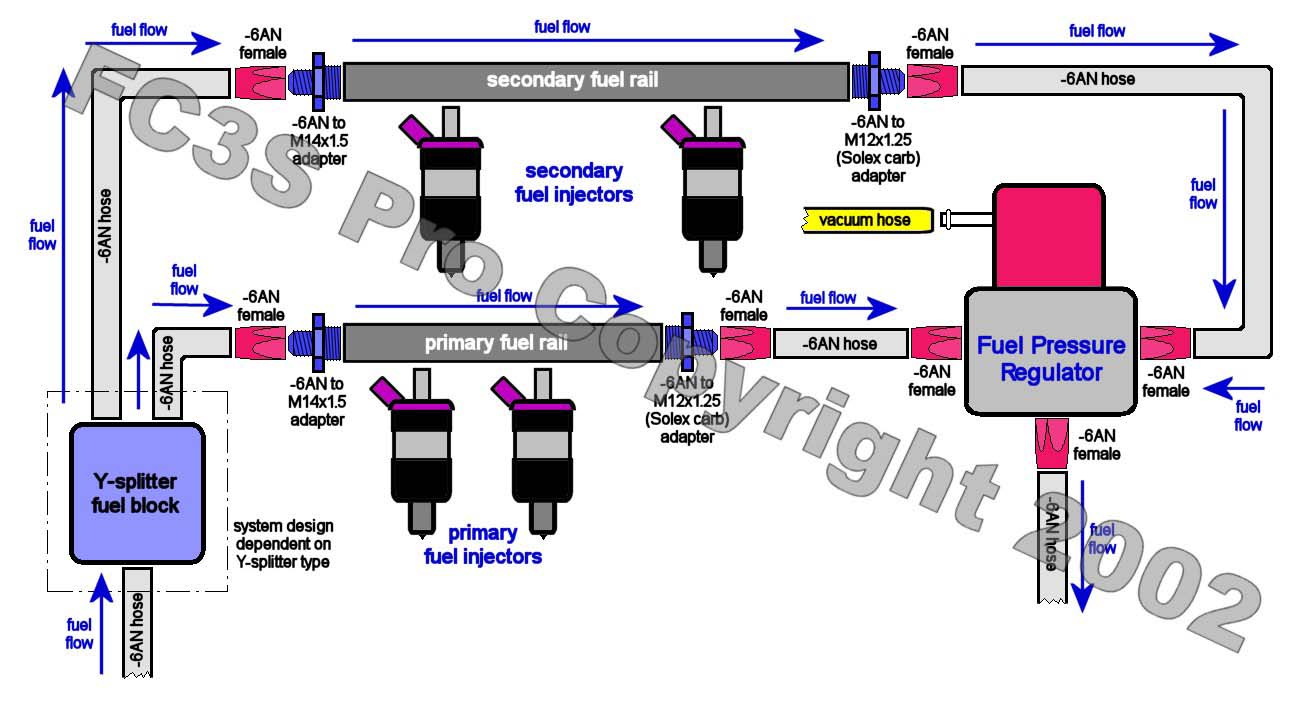

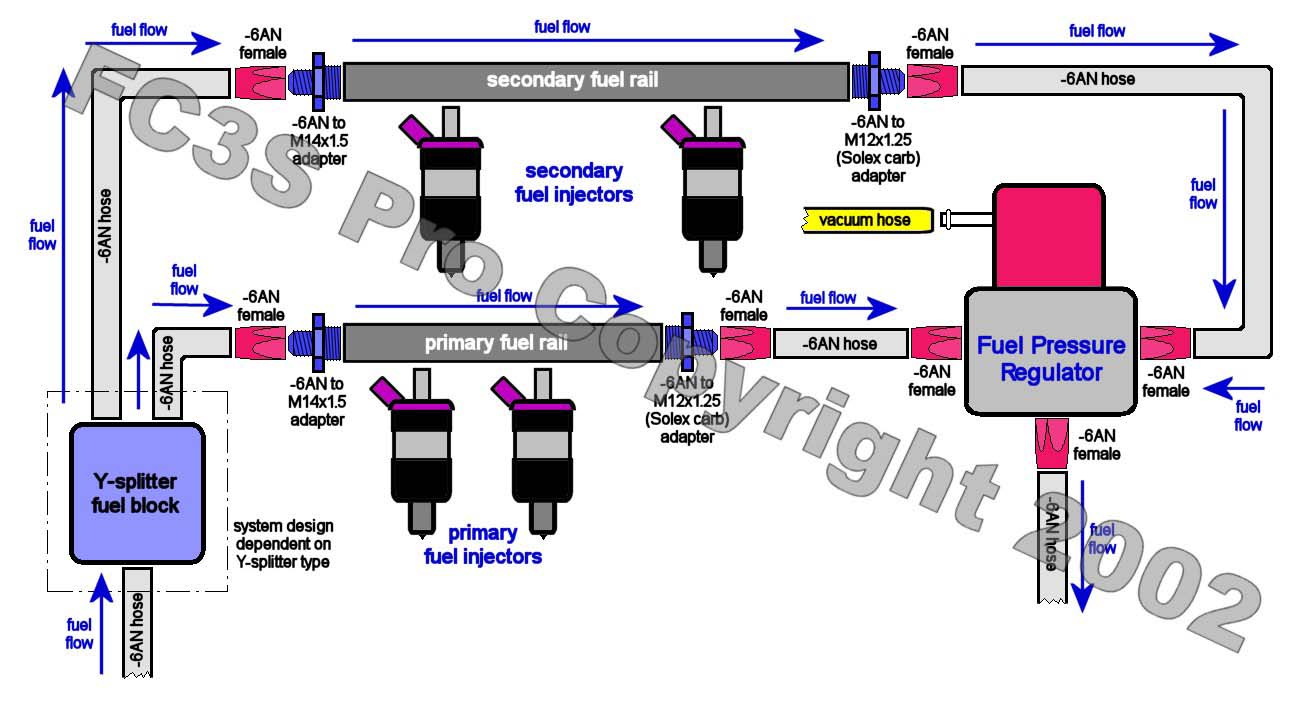

I'm going to be replacing my fuel rails to do a parallel mod (1987 S4 NA) with extra goodies to get ready for my turbo. I'm curious if the KG fuel rails come pre-tapped with any sort of NPT thread. I do not want to cut my stock rails and have fittings welded on. My plan is to run -8 from the filter to a y-block. Then -6's to some fuel coolers mounted to use the brake duct as a cooling portion. then shoot fuel back to the rails, then connect the FPR then return. Any comments on me doing that? (I'm also planning on using the appropriate adapters for the NPT->AN)

#2

I have the KG rail. It is pretapped with something like 1/4 NPT on the ends. I don't remember off the top of my head, just test it with some cheapo plumbing fittings before you buy the AN adapters. The irritating thing about the KG rail is that it did not come with mounting hardware. I'm pretty sure I ended up using two M8 X 1.25 (same thread as stock bolts), 25mm long I think, with two washers stacked between the rail and the manifold. So I think it went: allen bolt head --> rail --> washer --> washer -- manifold. That's on an s4 T2 . Then if you are using the Bosch 1600's you need to install stock injector grommets and s5 pintle caps in order to prevent a vacuum leak. This requires removing the lower o-ring, pintle cap, and orange spacer thingie on the Bosch injector.

I think your overall plan is unncecessarily complex. If you are doing it because that's just what you want to do, you like custom plumbing etc, then fine. But I'll tell you what-- I have an s4 T2 running 20psi on a 60-1 T04S turbo with the stock primary rail and the KG rail (aeromotive FPR @ 40psi base pressure), with a single hotwired Supra TT pump. Fuel lines are in series just like stock, using 6AN line clamped to the stock hardlines on the firewall. If I could go back and do it again, I probably would've used the stock secondary rail and modified it for the Bosch 1600 CC injectors (I'm pretty sure that's possible) and used as many rubber lines as I could. 6AN lines are about the same ID as the stock 5/16" hose. The stock lines can flow more than enough, so can the stock rails. A fuel cooler is cool but it will cost you money, increase complexity and the risk of leaking, and IMO not have a noticeable improvement in performance or reduce the risk of detonation.

I just don't think all the really neato fuel systems are "necessary" for most setups in the sense that having one is not REQUIRED to reliably deliver fuel for 95% of street cars. If it were me, I'd cut back some of those plans at least (run the fuel lines in series like mine) and put the money towards something else, like ignition system or engine management or something.

I think your overall plan is unncecessarily complex. If you are doing it because that's just what you want to do, you like custom plumbing etc, then fine. But I'll tell you what-- I have an s4 T2 running 20psi on a 60-1 T04S turbo with the stock primary rail and the KG rail (aeromotive FPR @ 40psi base pressure), with a single hotwired Supra TT pump. Fuel lines are in series just like stock, using 6AN line clamped to the stock hardlines on the firewall. If I could go back and do it again, I probably would've used the stock secondary rail and modified it for the Bosch 1600 CC injectors (I'm pretty sure that's possible) and used as many rubber lines as I could. 6AN lines are about the same ID as the stock 5/16" hose. The stock lines can flow more than enough, so can the stock rails. A fuel cooler is cool but it will cost you money, increase complexity and the risk of leaking, and IMO not have a noticeable improvement in performance or reduce the risk of detonation.

I just don't think all the really neato fuel systems are "necessary" for most setups in the sense that having one is not REQUIRED to reliably deliver fuel for 95% of street cars. If it were me, I'd cut back some of those plans at least (run the fuel lines in series like mine) and put the money towards something else, like ignition system or engine management or something.

Last edited by arghx; 05-07-08 at 09:48 AM. Reason: AN fittings get real expensive, real fast

#3

To support arghx, I'm running stock S4 TII rails with 750 RC's and 1600 bosch injectors. Rails have AN adapters and I'm running parallel plumbing.

As far as the direct question, yes the KG's are tapped with (some size) of NPT thread

As for a fuel cooler, head to the junk yard. I variety of different cars have either transmisson (ford focus has a nice one) or power steering coolers that are single or double lines with decent cooling fins around them. One of those babies mounted under the car will pull a fair amount of heat from the system, but again, necessity is debatable.

As far as the direct question, yes the KG's are tapped with (some size) of NPT thread

As for a fuel cooler, head to the junk yard. I variety of different cars have either transmisson (ford focus has a nice one) or power steering coolers that are single or double lines with decent cooling fins around them. One of those babies mounted under the car will pull a fair amount of heat from the system, but again, necessity is debatable.

#4

Engine, Not Motor

iTrader: (1)

Joined: Feb 2001

Posts: 29,793

Likes: 119

From: London, Ontario, Canada

Pretty sure that the primary fuel rail in your S4 NA is already tapped with M12 x 1.25.

The secondary will have one tapped port (maybe M14?) and then all you need to do is tap out the port used for the fuel pressure regulator.

Mounting fuel coolers in the brake ducts is a bit of overkill. Just mounting it along the frame rail will do the job nicely.

The secondary will have one tapped port (maybe M14?) and then all you need to do is tap out the port used for the fuel pressure regulator.

Mounting fuel coolers in the brake ducts is a bit of overkill. Just mounting it along the frame rail will do the job nicely.

#6

Sorry I didn't ask about that prior I was a little low on sleep when I posed the first question.

Mounting fuel coolers in the brake ducts is a bit of overkill. Just mounting it along the frame rail will do the job nicely.

#7

the stock rails and fuel lines will handle 600 hp easy. the fuel pressure regulator will have to be ditched in lue of a stand alone one, and then the fuel pump will need to be upgraded. the standard rail can fit 1600(they will max out at 600hp or so) but they have to be machined to fit the stock rails.

thats how i went. its cheaper overall.

thats how i went. its cheaper overall.

Trending Topics

#8

So just for clarification purposes:

The stock fuel rails on the S4 do not need to have the fittings welded in? I say this because I do not want to take apart the fuel system then have to pay some one to weld them up (I do not trust my brazing skills). The only portion that needs work on the stock rails is the secondary rail and that would just need to be tapped for a M14x1.5? I can then cut off the FPR tabs and install the rising rate FPR ya?

The Aeromotive FPR also has a built in PD correct? If not how would I managae to integrate the stand alone PD on a parallel set up? the only way I can imagine it is to either get two or put a Y block prior to it and then feed it into the PD and then back to the FPR (Nullifying one of the inputs).

The original questions concerning the KG fuel rails was to bypass the need for me to weld the fittings in. If I do not need to weld the fitting in but mearly tap and thread in the adapters then that's what I'll plan on doing. I do not wish to make more than 500hp at the moment so the stock fuel rails will do fine.

Of another consequence would installing an in-line fuel filter after the stock fuel filter be of any benefit (IE: a 10 micron -6 threaded hi-pressure fuel filter)? I don't really think it would be... but maybe I'm just being too cynical and trusting of the OEM fuel filter.

I've looked around for some fuel/fluid coolers that could accept -8 or bigger or by use of some adapter become -8, but what I have found are just too big for the applications space. I think the only way to accomplish the fuel cooler the way I invision is to put it through the brake duct (by which I mean alter the brake duct to scoop air up and into the cooler). Here are the one's I saw that had potential. Nothing really caught my fancy, and the one that is already -8 acceptable doesn't look all that effcient at its job.

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

Beyond those is there anything else I should consider for the fuel set up?

The stock fuel rails on the S4 do not need to have the fittings welded in? I say this because I do not want to take apart the fuel system then have to pay some one to weld them up (I do not trust my brazing skills). The only portion that needs work on the stock rails is the secondary rail and that would just need to be tapped for a M14x1.5? I can then cut off the FPR tabs and install the rising rate FPR ya?

The Aeromotive FPR also has a built in PD correct? If not how would I managae to integrate the stand alone PD on a parallel set up? the only way I can imagine it is to either get two or put a Y block prior to it and then feed it into the PD and then back to the FPR (Nullifying one of the inputs).

The original questions concerning the KG fuel rails was to bypass the need for me to weld the fittings in. If I do not need to weld the fitting in but mearly tap and thread in the adapters then that's what I'll plan on doing. I do not wish to make more than 500hp at the moment so the stock fuel rails will do fine.

Of another consequence would installing an in-line fuel filter after the stock fuel filter be of any benefit (IE: a 10 micron -6 threaded hi-pressure fuel filter)? I don't really think it would be... but maybe I'm just being too cynical and trusting of the OEM fuel filter.

I've looked around for some fuel/fluid coolers that could accept -8 or bigger or by use of some adapter become -8, but what I have found are just too big for the applications space. I think the only way to accomplish the fuel cooler the way I invision is to put it through the brake duct (by which I mean alter the brake duct to scoop air up and into the cooler). Here are the one's I saw that had potential. Nothing really caught my fancy, and the one that is already -8 acceptable doesn't look all that effcient at its job.

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

http://store.summitracing.com/partde...5&autoview=sku

Beyond those is there anything else I should consider for the fuel set up?

#10

s4 rails have threaded fittings, just like in the FC3S parallel fuel mod posted above. Remove the stock FPR, it is threaded in there too I believe. The Aeromotive FPR is supposed to have an integral PD... I didn't know that a year ago so I went and bought a brand new OEM one. Oh well.

Extra fuel filters and especially fuel coolers are such a waste of money for your application. You can't find ANYTHING else to spend that money and time on?l

Extra fuel filters and especially fuel coolers are such a waste of money for your application. You can't find ANYTHING else to spend that money and time on?l

#11

s4 rails have threaded fittings, just like in the FC3S parallel fuel mod posted above. Remove the stock FPR, it is threaded in there too I believe. The Aeromotive FPR is supposed to have an integral PD... I didn't know that a year ago so I went and bought a brand new OEM one. Oh well.

Extra fuel filters and especially fuel coolers are such a waste of money for your application. You can't find ANYTHING else to spend that money and time on?l

#12

Cooler fuel temps would hopefully reduce the chance of pre-ignition, but who knows how much. I don't see it directly increasing power.

If it were me, I would run as simple of a fuel setup as possible and save the money to build a sick V-mount intercooler setup. Now that will increase reliability from the enhanced cooling capacity.

If it were me, I would run as simple of a fuel setup as possible and save the money to build a sick V-mount intercooler setup. Now that will increase reliability from the enhanced cooling capacity.

#13

Cooler fuel temps would hopefully reduce the chance of pre-ignition, but who knows how much. I don't see it directly increasing power.

If it were me, I would run as simple of a fuel setup as possible and save the money to build a sick V-mount intercooler setup. Now that will increase reliability from the enhanced cooling capacity.

If it were me, I would run as simple of a fuel setup as possible and save the money to build a sick V-mount intercooler setup. Now that will increase reliability from the enhanced cooling capacity.

I wouldn't count the fuel coolers as improving the ability of dissolving the pre-ignition problems that much as they would only be most efficeint when the car is at highway speeds. I suppose that's probably the time you have the most boost though... I guess it's something to think about.

#14

Engine, Not Motor

iTrader: (1)

Joined: Feb 2001

Posts: 29,793

Likes: 119

From: London, Ontario, Canada

So just for clarification purposes:

The stock fuel rails on the S4 do not need to have the fittings welded in? I say this because I do not want to take apart the fuel system then have to pay some one to weld them up (I do not trust my brazing skills). The only portion that needs work on the stock rails is the secondary rail and that would just need to be tapped for a M14x1.5? I can then cut off the FPR tabs and install the rising rate FPR ya?

The stock fuel rails on the S4 do not need to have the fittings welded in? I say this because I do not want to take apart the fuel system then have to pay some one to weld them up (I do not trust my brazing skills). The only portion that needs work on the stock rails is the secondary rail and that would just need to be tapped for a M14x1.5? I can then cut off the FPR tabs and install the rising rate FPR ya?

The Aeromotive FPR also has a built in PD correct? If not how would I managae to integrate the stand alone PD on a parallel set up? the only way I can imagine it is to either get two or put a Y block prior to it and then feed it into the PD and then back to the FPR (Nullifying one of the inputs).

Of another consequence would installing an in-line fuel filter after the stock fuel filter be of any benefit (IE: a 10 micron -6 threaded hi-pressure fuel filter)? I don't really think it would be... but maybe I'm just being too cynical and trusting of the OEM fuel filter.

Beyond those is there anything else I should consider for the fuel set up?

#15

The advantage of the V-mount intercooler is increased airflow to the radiator versus the front mount design, not necessarily a more efficient intercooler itself. I'm not sure how different a v-mount and an front mount are in terms of the intercooler's efficiency (I'd imagine it depends on the setup somewhat), but the cooling benefits of the V-mount are well known.