Hijacker's Paradise - the Alcohol Injection/AFR edition...

#1

BDC Motorsports

Thread Starter

Thread created to clean up build thread, pulld text below from EA's quote....mar3, SuperModerator

Last edited by mar3; 07-30-10 at 10:21 PM.

#2

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 110 Likes

on

93 Posts

That seems awfully rich. Not having any experience with AI, I thought it would have allowed you to run a much better ratio? Mid 10s just seems like a LOT of fuel and is probably leaving quite a bit of power and turbo response on the floor. Hell, I run 11:1 at 16 PSI on a GT40R with 9.4:1 rotors.

Last edited by mar3; 07-30-10 at 10:20 PM. Reason: Killd quote since reply was back-to-back to post in question...

#3

BDC Motorsports

Thread Starter

It's the difference in properties alcohol has over gasoline that affords a richer ratio. It goes against the normal grain of what guys like you and I are accustomed to when tuning AFR's on 100% gasoline alone (which comprises 99% of the setups out there). It's why it throws people off. The alcohols don't carbon up the plugs like gasolines will and don't have anywhere near the tendency to blow spark out. Therefore, you can lean more on it and run more of it, and use the extra cc/min as a chamber coolant. The composition of the "base fuel" (a term I use in a post in the AI section I wrote called "Alcohol and Water vs. Gasoline...") is changed when mixing two fuels like this especially in the kinds of heavier alcohol to gasoline ratios that I'm using.

B

B

Last edited by mar3; 07-30-10 at 09:15 PM. Reason: Killd quote since reply was back-to-back to post in question...

#4

Banned. I got OWNED!!!

That seems awfully rich. Not having any experience with AI, I thought it would have allowed you to run a much better ratio? Mid 10s just seems like a LOT of fuel and is probably leaving quite a bit of power and turbo response on the floor. Hell, I run 11:1 at 16 PSI on a GT40R with 9.4:1 rotors.

FWIW I run about .82L or ~12:1 under 15psi of twin hitachi HT-12's...... you know, the same turbo's that everyone claims are a backpressure nightmare, the one's that pump out nothing but superheated air with no CFM's to make over 350rwhp reliably

Internet parrots with no data whatsoever.

Internet parrots with no data whatsoever.The other thing that I have noticed about this build is that with the wonderfully awesome chemical cooling that alcohol gives, it still doesn't match what my intercooler can do. I've logged charge temps in the 270*F range, yet my AIT's remain a few degrees above ambient. Even while sitting on the dyno on a 75* day, I was seeing AIT's in the low 80's.

I've thought about methanol to cool the EGT's only becuase I may NEED to do that becuase of a choice in poweradder, so how awesome would that be? 270* down to 80* without methanol, what would my AIT's be with it?

So, knowing what a properly designed/ducted/built air to air intercooler can do, why would you choose to not run one? According to my math, my intercooler will take out more heat than your alcohol yet you're choosing not to run one at all.......why?

Last edited by mar3; 07-30-10 at 09:47 PM. Reason: Killd coolant text prior to move to new thread...

#5

Rotorhead

Join Date: Feb 2001

Location: Charlottesville, Virginia, USA

Posts: 9,136

Likes: 0

Received 39 Likes

on

33 Posts

That seems awfully rich. Not having any experience with AI, I thought it would have allowed you to run a much better ratio? Mid 10s just seems like a LOT of fuel and is probably leaving quite a bit of power and turbo response on the floor. Hell, I run 11:1 at 16 PSI on a GT40R with 9.4:1 rotors.

Last edited by mar3; 07-30-10 at 10:00 PM. Reason: Killd coolant/trigger text prior to move to new thread...

#6

BDC Motorsports

Thread Starter

While the best power AFR for unleaded pump gas is around 12:1, the best power AFR for ethanol is about 6.5:1, and for methanol it is about 4.5:1. The specific gravity of various fuels also confuses the issue, as the engine AFR is actually a mass rato as opposed to the volume ratio used by the EMS and/or the person mixing the fuel. Additionally, O2 sensors detect lambda rather than AFR, and the gauge converts this to an AFR number based on a fixed variable which is usually not correct. These are just some of the many reasons why real tuners tune by trends rather than indicated numerical AFR values.

B

#7

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 110 Likes

on

93 Posts

It's the difference in properties alcohol has over gasoline that affords a richer ratio. It goes against the normal grain of what guys like you and I are accustomed to when tuning AFR's on 100% gasoline alone (which comprises 99% of the setups out there). It's why it throws people off. The alcohols don't carbon up the plugs like gasolines will and don't have anywhere near the tendency to blow spark out. Therefore, you can lean more on it and run more of it, and use the extra cc/min as a chamber coolant. The composition of the "base fuel" (a term I use in a post in the AI section I wrote called "Alcohol and Water vs. Gasoline...") is changed when mixing two fuels like this especially in the kinds of heavier alcohol to gasoline ratios that I'm using.

B

B

FWIW I run about .82L or ~12:1 under 15psi of twin hitachi HT-12's...... you know, the same turbo's that everyone claims are a backpressure nightmare, the one's that pump out nothing but superheated air with no CFM's to make over 350rwhp reliably  Internet parrots with no data whatsoever.

Internet parrots with no data whatsoever.

Internet parrots with no data whatsoever.

Internet parrots with no data whatsoever.

I run about 11.5 - 11.7 under 15 PSI and only go into the high 10s around 16 PSI (I taper down to low 11s approaching 15 PSI).

I run about 11.5 - 11.7 under 15 PSI and only go into the high 10s around 16 PSI (I taper down to low 11s approaching 15 PSI). That is the only way I could get capacitors for my Tesla coils without spending a load of money. Alternate layers of aluminium foil and glass.

Trending Topics

#8

BDC Motorsports

Thread Starter

As a pure gasoline ratio, I'd agree with you 100%. There are a lot of people (and I'm not pointing the finger at anyone in this thread) that seem to have the blanket "rich = good, lean = bad" mentality. Not realizing that rich misfires create pressure spikes just as lean misfires do.

That's more like it.  I run about 11.5 - 11.7 under 15 PSI and only go into the high 10s around 16 PSI (I taper down to low 11s approaching 15 PSI).

I run about 11.5 - 11.7 under 15 PSI and only go into the high 10s around 16 PSI (I taper down to low 11s approaching 15 PSI).

I run about 11.5 - 11.7 under 15 PSI and only go into the high 10s around 16 PSI (I taper down to low 11s approaching 15 PSI).

I run about 11.5 - 11.7 under 15 PSI and only go into the high 10s around 16 PSI (I taper down to low 11s approaching 15 PSI).

B

#9

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 110 Likes

on

93 Posts

This opens up the whole subject as to why the common tuning paradigm on these motors for boost is to run so rich (on gasolines, mind you) even though for ideal power AFR's may be closer to 13:1-13.5:1. Makes ya wonder.

I have been doing some reading in the AI forum about tuning AFRs with AI. From all the threads I have read, it seems that one tunes to an AFR assuming pure gasoline. So low to mid 10s still seems pretty rich to me.

#10

Banned. I got OWNED!!!

with almost twice the boost, meth injected, blah blah blah is only 10-25% more power? Seems like there's a ton of power being left on the abortion table from tuning.

with almost twice the boost, meth injected, blah blah blah is only 10-25% more power? Seems like there's a ton of power being left on the abortion table from tuning.But oh wait, MoTeC already solved that with thier Dual Half-Bridge, but at the cost of more than what most FC owners spend one thier ECU, I doubt anyone here will use it outside of a select few.

Because at AFRs in the 13s the engine would blow up due to detonation. Even FI piston engines don't generally run 13s under boost. Chamber cooling by the richer ratios is needed...which leads me to...

I have been doing some reading in the AI forum about tuning AFRs with AI. From all the threads I have read, it seems that one tunes to an AFR assuming pure gasoline. So low to mid 10s still seems pretty rich to me.

I have been doing some reading in the AI forum about tuning AFRs with AI. From all the threads I have read, it seems that one tunes to an AFR assuming pure gasoline. So low to mid 10s still seems pretty rich to me.

#11

BDC Motorsports

Thread Starter

Because at AFRs in the 13s the engine would blow up due to detonation. Even FI piston engines don't generally run 13s under boost. Chamber cooling by the richer ratios is needed...which leads me to...

I have been doing some reading in the AI forum about tuning AFRs with AI. From all the threads I have read, it seems that one tunes to an AFR assuming pure gasoline. So low to mid 10s still seems pretty rich to me.

The rules of tuning change when the characteristics of the base fuel changes. 10's seems dubiously rich because it strikes at the tuning paradigm (from AFR's to ignition advance curves) we've all been adjusted to since day 1 in this community because we've always used 100% gasoline as that base fuel. There's nothing magical or set-in-stone about an AFR like 11.5:1, 11.2:1, etc.

B

#12

Senior Member

Join Date: Nov 2008

Location: Czech republic

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

At high water to fuel ratios( up to 150%), its different.

Very high power with best knock protection can be made at rich mixtures, 10s to 11s, but slightly higher figures, again with best knock protection, can be made at LEAN mixtures - anywhere from 16,5-18s AFR, but with increased boost ---> airflow. For example, airflow is increased by 27,7% but power goes up by only 8%

BSFC, of course, is decreased, in this particular example by 17%

BSFC, of course, is decreased, in this particular example by 17%

#13

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 110 Likes

on

93 Posts

Yup, doing the math my intercooler is still more effeicient than this meth alternative. Seems like yours is too. Amazing the performance you can get when you don't build your car through flea-bay or china. I see no need for AI with my car which is putting down 400+RWHP on a mild street port, stock twins, and an intercooler. And the goals for this Spec C bridgeport  with almost twice the boost, meth injected, blah blah blah is only 10-25% more power? Seems like there's a ton of power being left on the abortion table from tuning.

with almost twice the boost, meth injected, blah blah blah is only 10-25% more power? Seems like there's a ton of power being left on the abortion table from tuning.

with almost twice the boost, meth injected, blah blah blah is only 10-25% more power? Seems like there's a ton of power being left on the abortion table from tuning.

with almost twice the boost, meth injected, blah blah blah is only 10-25% more power? Seems like there's a ton of power being left on the abortion table from tuning.

I agree, not to mention that you're adding how many more points of failure?

I understand. I like the "turn key" thing myself. However, the truth unfortunately is we've got an engine that produces a crap ton of heat that we're trying to make big power with on a deficient fuel that we're literally soaking the internals of the engine with in a vain attempt to keep it cool. We could ideally run in the 13's if we looked at the role of gasoline as the essential part of internal combustion.

But as a counterpoint, if one designs a system that is more efficient all around, then it isn't a huge issue. As an example, my daily driver setting is 13 PSI on a GT4088R 1.06, 9.4:1 rotors, weak S4 NA block, small bridgeport, decently sized (but not huge) intercooler, 91 octane and around 11.5:1 AFRs under boost. No real issues for 4 years at over wheel HP on that boost level. As you know, over 400HP on an FC is largely bragging rights anyway since that is very difficult to get to the ground on street tires anyway. While I have not dyno'd the 16 PSI setting (where I bring AFRs down into the high 10s), I'd say it's around 500HP judging by injector times. Why would I want to run AFRs into the 13s in this case? Would I gain power? Certainly. Do I care? Not really.

But as a counterpoint, if one designs a system that is more efficient all around, then it isn't a huge issue. As an example, my daily driver setting is 13 PSI on a GT4088R 1.06, 9.4:1 rotors, weak S4 NA block, small bridgeport, decently sized (but not huge) intercooler, 91 octane and around 11.5:1 AFRs under boost. No real issues for 4 years at over wheel HP on that boost level. As you know, over 400HP on an FC is largely bragging rights anyway since that is very difficult to get to the ground on street tires anyway. While I have not dyno'd the 16 PSI setting (where I bring AFRs down into the high 10s), I'd say it's around 500HP judging by injector times. Why would I want to run AFRs into the 13s in this case? Would I gain power? Certainly. Do I care? Not really.  In a sense it would be an artificial victory if I have to rely on something other then what is already in the car (ie. AI) to achieve it. Again, this is just a philosophical disagreement and in no way am I saying that your work is somehow substandard.

In a sense it would be an artificial victory if I have to rely on something other then what is already in the car (ie. AI) to achieve it. Again, this is just a philosophical disagreement and in no way am I saying that your work is somehow substandard.

The rules of tuning change when the characteristics of the base fuel changes. 10's seems dubiously rich because it strikes at the tuning paradigm (from AFR's to ignition advance curves) we've all been adjusted to since day 1 in this community because we've always used 100% gasoline as that base fuel. There's nothing magical or set-in-stone about an AFR like 11.5:1, 11.2:1, etc.

B

B

#14

BDC Motorsports

Thread Starter

That is sort of the crux of the matter for me; another system to maintain. It is one of the reasons I dislike premix as well (even though I am currently premixing my car). For a weekend warrior, it probably isn't a big deal. But I drive my car all the time without reservations of driving a few hundred KM to a town of 15 people to replace a printer, so I don't think I could or should rely on any chemical intercooling.

I see your point on this, I really do.  But as a counterpoint, if one designs a system that is more efficient all around, then it isn't a huge issue. As an example, my daily driver setting is 13 PSI on a GT4088R 1.06, 9.4:1 rotors, weak S4 NA block, small bridgeport, decently sized (but not huge) intercooler, 91 octane and around 11.5:1 AFRs under boost. No real issues for 4 years at over wheel HP on that boost level. As you know, over 400HP on an FC is largely bragging rights anyway since that is very difficult to get to the ground on street tires anyway.

But as a counterpoint, if one designs a system that is more efficient all around, then it isn't a huge issue. As an example, my daily driver setting is 13 PSI on a GT4088R 1.06, 9.4:1 rotors, weak S4 NA block, small bridgeport, decently sized (but not huge) intercooler, 91 octane and around 11.5:1 AFRs under boost. No real issues for 4 years at over wheel HP on that boost level. As you know, over 400HP on an FC is largely bragging rights anyway since that is very difficult to get to the ground on street tires anyway.

But as a counterpoint, if one designs a system that is more efficient all around, then it isn't a huge issue. As an example, my daily driver setting is 13 PSI on a GT4088R 1.06, 9.4:1 rotors, weak S4 NA block, small bridgeport, decently sized (but not huge) intercooler, 91 octane and around 11.5:1 AFRs under boost. No real issues for 4 years at over wheel HP on that boost level. As you know, over 400HP on an FC is largely bragging rights anyway since that is very difficult to get to the ground on street tires anyway.

But as a counterpoint, if one designs a system that is more efficient all around, then it isn't a huge issue. As an example, my daily driver setting is 13 PSI on a GT4088R 1.06, 9.4:1 rotors, weak S4 NA block, small bridgeport, decently sized (but not huge) intercooler, 91 octane and around 11.5:1 AFRs under boost. No real issues for 4 years at over wheel HP on that boost level. As you know, over 400HP on an FC is largely bragging rights anyway since that is very difficult to get to the ground on street tires anyway.

While I have not dyno'd the 16 PSI setting (where I bring AFRs down into the high 10s), I'd say it's around 500HP judging by injector times. Why would I want to run AFRs into the 13s in this case? Would I gain power? Certainly. Do I care? Not really.  In a sense it would be an artificial victory if I have to rely on something other then what is already in the car (ie. AI) to achieve it. Again, this is just a philosophical disagreement and in no way am I saying that your work is somehow substandard.

In a sense it would be an artificial victory if I have to rely on something other then what is already in the car (ie. AI) to achieve it. Again, this is just a philosophical disagreement and in no way am I saying that your work is somehow substandard.

In a sense it would be an artificial victory if I have to rely on something other then what is already in the car (ie. AI) to achieve it. Again, this is just a philosophical disagreement and in no way am I saying that your work is somehow substandard.

In a sense it would be an artificial victory if I have to rely on something other then what is already in the car (ie. AI) to achieve it. Again, this is just a philosophical disagreement and in no way am I saying that your work is somehow substandard.

B

#15

I hope to eventually run some form of AI when cash flow allows me to. It really is great to see people trying new things, without it we would never learn. Out of curiosity, what is the formula you were using on another forum (found a link to your post in the AI section somewhere and I can't find it anymore) to get the AFR for X% of pump gas and Y% of alcohol? Also how much gap do you use when tuning at those levels?

Alcohol isn't merely to reduce IAT's, it also increases fuel octane rating (based on percentage of mixture I'm guessing) something an intercooler can't do. Just because you don't agree with it or feel the need not to doesn't mean he can't. He's doing some really great stuff here and I'm enjoying the read. Everyone is allowed to do there own thing.

Edit: found that thread I was talking about (http://forum.teamfc3s.org/showthread.php?t=50684). What is that huge list of numbers?

Alcohol isn't merely to reduce IAT's, it also increases fuel octane rating (based on percentage of mixture I'm guessing) something an intercooler can't do. Just because you don't agree with it or feel the need not to doesn't mean he can't. He's doing some really great stuff here and I'm enjoying the read. Everyone is allowed to do there own thing.

Edit: found that thread I was talking about (http://forum.teamfc3s.org/showthread.php?t=50684). What is that huge list of numbers?

Last edited by mar3; 07-30-10 at 10:02 PM.

#17

BDC Motorsports

Thread Starter

Yep, that's it. The chart sounded nice in the beginning but it turned out we were wrong about using it for tuning AFR's with alcohol.

B

B

Last edited by mar3; 07-30-10 at 09:27 PM. Reason: Killd quote since reply was back-to-back to post in question...

#18

Banned. I got OWNED!!!

I actually have a China intercooler core. It is one of the better bar and plate coolers that actually includes internal finning (shocking how many of these China intercoolers don't). The original end tanks were poorly cast and didn't include turbulators but I made better tanks last year. What I've also done is sized my turbo so that it makes the power that I want at sane boost levels. I'm not saying there is anything particularly wrong with running 20+ PSI, but I wouldn't build my car to run those pressures.

That is sort of the crux of the matter for me; another system to maintain. It is one of the reasons I dislike premix as well (even though I am currently premixing my car). For a weekend warrior, it probably isn't a big deal. But I drive my car all the time without reservations of driving a few hundred KM to a town of 15 people to replace a printer, so I don't think I could or should rely on any chemical intercooling.

directly into the chamber, and then I toss in about 1/4 oz/gallon into the tank. I have my reasons. Regardless, that little 1.5qtr resevoir in the bay is still a hassel. I've just gotten into the habit of checking all fluids at each gas up.

directly into the chamber, and then I toss in about 1/4 oz/gallon into the tank. I have my reasons. Regardless, that little 1.5qtr resevoir in the bay is still a hassel. I've just gotten into the habit of checking all fluids at each gas up.I see your point on this, I really do.  But as a counterpoint, if one designs a system that is more efficient all around, then it isn't a huge issue. As an example, my daily driver setting is 13 PSI on a GT4088R 1.06, 9.4:1 rotors, weak S4 NA block, small bridgeport, decently sized (but not huge) intercooler, 91 octane and around 11.5:1 AFRs under boost. No real issues for 4 years at over wheel HP on that boost level. As you know, over 400HP on an FC is largely bragging rights anyway since that is very difficult to get to the ground on street tires anyway. While I have not dyno'd the 16 PSI setting (where I bring AFRs down into the high 10s), I'd say it's around 500HP judging by injector times. Why would I want to run AFRs into the 13s in this case? Would I gain power? Certainly. Do I care? Not really.

But as a counterpoint, if one designs a system that is more efficient all around, then it isn't a huge issue. As an example, my daily driver setting is 13 PSI on a GT4088R 1.06, 9.4:1 rotors, weak S4 NA block, small bridgeport, decently sized (but not huge) intercooler, 91 octane and around 11.5:1 AFRs under boost. No real issues for 4 years at over wheel HP on that boost level. As you know, over 400HP on an FC is largely bragging rights anyway since that is very difficult to get to the ground on street tires anyway. While I have not dyno'd the 16 PSI setting (where I bring AFRs down into the high 10s), I'd say it's around 500HP judging by injector times. Why would I want to run AFRs into the 13s in this case? Would I gain power? Certainly. Do I care? Not really.  In a sense it would be an artificial victory if I have to rely on something other then what is already in the car (ie. AI) to achieve it. Again, this is just a philosophical disagreement

In a sense it would be an artificial victory if I have to rely on something other then what is already in the car (ie. AI) to achieve it. Again, this is just a philosophical disagreement

But as a counterpoint, if one designs a system that is more efficient all around, then it isn't a huge issue. As an example, my daily driver setting is 13 PSI on a GT4088R 1.06, 9.4:1 rotors, weak S4 NA block, small bridgeport, decently sized (but not huge) intercooler, 91 octane and around 11.5:1 AFRs under boost. No real issues for 4 years at over wheel HP on that boost level. As you know, over 400HP on an FC is largely bragging rights anyway since that is very difficult to get to the ground on street tires anyway. While I have not dyno'd the 16 PSI setting (where I bring AFRs down into the high 10s), I'd say it's around 500HP judging by injector times. Why would I want to run AFRs into the 13s in this case? Would I gain power? Certainly. Do I care? Not really.

But as a counterpoint, if one designs a system that is more efficient all around, then it isn't a huge issue. As an example, my daily driver setting is 13 PSI on a GT4088R 1.06, 9.4:1 rotors, weak S4 NA block, small bridgeport, decently sized (but not huge) intercooler, 91 octane and around 11.5:1 AFRs under boost. No real issues for 4 years at over wheel HP on that boost level. As you know, over 400HP on an FC is largely bragging rights anyway since that is very difficult to get to the ground on street tires anyway. While I have not dyno'd the 16 PSI setting (where I bring AFRs down into the high 10s), I'd say it's around 500HP judging by injector times. Why would I want to run AFRs into the 13s in this case? Would I gain power? Certainly. Do I care? Not really.  In a sense it would be an artificial victory if I have to rely on something other then what is already in the car (ie. AI) to achieve it. Again, this is just a philosophical disagreement

In a sense it would be an artificial victory if I have to rely on something other then what is already in the car (ie. AI) to achieve it. Again, this is just a philosophical disagreementLast edited by mar3; 07-30-10 at 09:28 PM. Reason: Killd text referring to deleted posts before move into new thread...

#21

As far as low 10's being rich... well there is the gas and methanol blend as BDC points out. But still, those AFR's are rich relative to aftermarket tunes. That's a pretty standard range on turbo piston engines from the factory. Part of the reason is for keeping catalytic converter temps under control. So there are a gazillion engines running that rich for 100k+ miles. Anecdotal evidence also indicates that Rx-7's are like that too, as FD owners with very few mods are seeing around 10:1 AFR at WOT (stock boost levels) on the stock ECU. I had a dedicated thread on this in the 3rd gen section:

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/fds-dont-run-rich-895499/

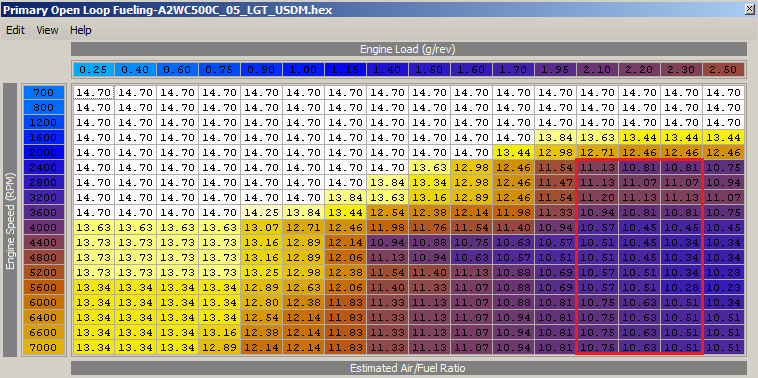

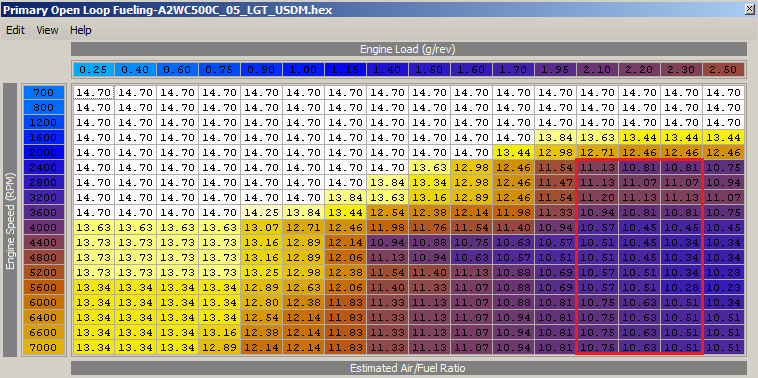

Here are some factory target AFR tables (which are actually close to the measured AFR), taken out of disassembled ECU's. Subaru Legacy 2.5 turbo:

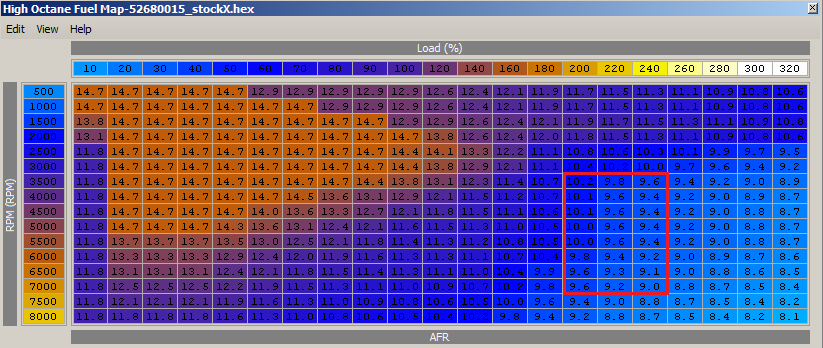

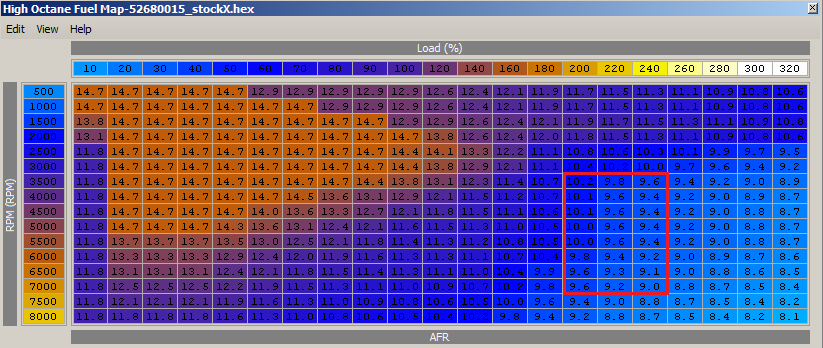

Evo X:

in both cases the x axis "load" column is proportional to the MAF sensor voltage... I won't go through the formulas they are using for load calculations here

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/fds-dont-run-rich-895499/

Here are some factory target AFR tables (which are actually close to the measured AFR), taken out of disassembled ECU's. Subaru Legacy 2.5 turbo:

Evo X:

in both cases the x axis "load" column is proportional to the MAF sensor voltage... I won't go through the formulas they are using for load calculations here

#23

Racing Rotary Since 1983

iTrader: (6)

thanks mar3 for all the work you did in cleaning up what is actually a good thread.

BDC and i go back a number of years together with our interest and appreciation for AI. we both read thru the 200 pages of threads on the Turbobuick AI section and gained an appreciation for the long journey they started many years ago.

the rotary is little different.

perhaps the manner in which the FD and Buick are used is different however. all the Buicks are quarter mile drag cars. most, of course not all, of our FDs are more dual purpose leaning towards road racing where throttle modulation under boost is important.

while i understand that many have various concerns re AI and have resolved to get along without it, which is fine w me of course, please consider:

the FD as delivered makes 255 flywheel hp according to mazda.

our motors have 59 cubic inches but since they function as 2 cycles, i e every time the combustion chamber passes the sparkplug we have a power event, they should be doubled as to displacement when compared to a 4 cycle...

so let's use 159 cubic inches.

255 flywheel hp from 159 cubic inches or 1.60 hp per cubic inch.

now let's compare our stock rotary to the latest and greatest.

the 2011 twin turbo intercooled direct injected Mercedes M157 4 valve V8.

336 cubic inches 563 flywheel hp.... 1.67 hp per cubic inch

the 2021 SL65AMG twin turbo 4 valve titanium rodded etc

365 cu inches 661 flywheel hp 1.81 hp per cu inch

the 2010 Corvette ZR1 supercharged, intercooled, dry sumped, titanium rods

376 cu inches 638 flywheel hp 1.69 hp per cu inch

it is important to understand that these 3 powerplants are engineered in every aspect to the MAX that the factory figured could live on the street. this most probably includes closed loop interactive timing and fuel relating to monitored knock.

uh, we don't have that...

nevertheless, our 1986 T2-1995 turbo'd rotaries in stock configuration are very close to these mega-dollar 21st century monsters....

and it is so easy for us to add what we consider a "mid to small" sized GT35 turbo and make a "moderate" amount of additional hp.

nothing crazy like 500-600...

say, 375... that would be a modest upgrade.

right?

do the math here.

375 rear wheel is 431 flywheel.

431/ 159 cu inches is 2.71 hp per cubic inch!

and that is considered moderate within our community.

please pardon the above as while it is a touch off track i think it makes the case for doing whatever we can to calm things down in our combustion chambers which surely contain too much heat and pressure. (CCP)

it also explains why we have so many broken rotaries. it isn't necessarily the motors fault, it is that we are pumping them up w so much air and fuel that they can't cope w the heat/pressure. it is so easy to do w a turbo.

Brian and i both like alcohol as the fix... actually methanol.

here's why:

fuel has BTUs in it.

nothing new to you of course.

However... there are BTUs of energy AND there are BTUs of COOLING. (by another tag, latent heat)

here's how they stack up and it is an eye opener.

BTUs of energy/gallon

Gasoline (includes racegas) 116,090

Ethanol (alcohol) 76,330

Methanol (alcohol) 57,250

BTUs of COOLING

Gasoline (includes racegas) 952

Ethanol (alcohol) 2398

Methanol (alcohol) 3136

while it is evident that the alcohols do not possess the energy per gallon of gasoline (you just run more volume) they do deliver vastly more cooling. note the significantly greater cooling of methanol V ethanol.... that's why methanol, not ethanol, is used in many higher output motors when the rules allow.

finally there is the autoignition advantage.

Gasoline (including racegas) 495 F

Methanol 867 F

Ethanol 793 F

autoignition is the temp where a fuel ignities w no outside influence (i e spark).

when we talk BTUs cooling, latent heat, it is important to understand that the cooling is not necessarily represented by measuring the intake air temperature. while alcohol does "flash" atomise more than gasoline or water and thereby does cool the IAT a bit. it is in the combustion chamber where it produces it's primary effect.

if you read the TurboBuick AI section you will quickly realise that much of the tuning is done by measuring KNOCK.

that is exactly how i tune. (not to say other things get seriously looked at but KNOCK is primary focus.) i am of course aware that the FC and FD are a bit different here but if i had an FC i sure would be using some sort of knock logging equipment.

not having knock logged and trying to tune would be exactly like trying to dial in your suspension on a road course without a pyrometer. you would be blind.

knock will tell you where the motor likes to run AFR-wise. being a rotary and being highly stressed due to small cu inches and great flowing ports, you need to be very careful to sneak up on knock. take it slowly w re to timing and fuel.

last year i ran two 700 CC/Min methanol injectors and found the motor at 507 rwhp SAE (3.66 hp per cu inch!) was very happy along w 93 octane pump gas. my Power FC knock was under 10 at max power. that was around 11.3 AFR on the mix. this year i will be running two 1000 CC/Min injectors so i am slightly upping my meth.

back to BDC and his IC-less experiments. as most know, many drag racers don't run intercoolers. that is primarily because most run 100% methanol. my friend makes over 1000 rwhp from his all meth two rotor drag car. he runs 14 injectors. given the amount of methanol and it's cooling properties he just doesn't need an IC.

given the fact i run pump gas and meth i like the idea of the additional 130 F degrees removed from my charge air. i don't doubt that BDC's setup will work fine, i just think it could work fin-er w an IC.

there is something to be said for eliminating 25 pounds and probably a couple of psi boost drag so it might work well for BDC. i certainly won't be worrying about his motor from a CCP aspect given all the meth envolved.

carry on Brian

howard

BDC and i go back a number of years together with our interest and appreciation for AI. we both read thru the 200 pages of threads on the Turbobuick AI section and gained an appreciation for the long journey they started many years ago.

the rotary is little different.

perhaps the manner in which the FD and Buick are used is different however. all the Buicks are quarter mile drag cars. most, of course not all, of our FDs are more dual purpose leaning towards road racing where throttle modulation under boost is important.

while i understand that many have various concerns re AI and have resolved to get along without it, which is fine w me of course, please consider:

the FD as delivered makes 255 flywheel hp according to mazda.

our motors have 59 cubic inches but since they function as 2 cycles, i e every time the combustion chamber passes the sparkplug we have a power event, they should be doubled as to displacement when compared to a 4 cycle...

so let's use 159 cubic inches.

255 flywheel hp from 159 cubic inches or 1.60 hp per cubic inch.

now let's compare our stock rotary to the latest and greatest.

the 2011 twin turbo intercooled direct injected Mercedes M157 4 valve V8.

336 cubic inches 563 flywheel hp.... 1.67 hp per cubic inch

the 2021 SL65AMG twin turbo 4 valve titanium rodded etc

365 cu inches 661 flywheel hp 1.81 hp per cu inch

the 2010 Corvette ZR1 supercharged, intercooled, dry sumped, titanium rods

376 cu inches 638 flywheel hp 1.69 hp per cu inch

it is important to understand that these 3 powerplants are engineered in every aspect to the MAX that the factory figured could live on the street. this most probably includes closed loop interactive timing and fuel relating to monitored knock.

uh, we don't have that...

nevertheless, our 1986 T2-1995 turbo'd rotaries in stock configuration are very close to these mega-dollar 21st century monsters....

and it is so easy for us to add what we consider a "mid to small" sized GT35 turbo and make a "moderate" amount of additional hp.

nothing crazy like 500-600...

say, 375... that would be a modest upgrade.

right?

do the math here.

375 rear wheel is 431 flywheel.

431/ 159 cu inches is 2.71 hp per cubic inch!

and that is considered moderate within our community.

please pardon the above as while it is a touch off track i think it makes the case for doing whatever we can to calm things down in our combustion chambers which surely contain too much heat and pressure. (CCP)

it also explains why we have so many broken rotaries. it isn't necessarily the motors fault, it is that we are pumping them up w so much air and fuel that they can't cope w the heat/pressure. it is so easy to do w a turbo.

Brian and i both like alcohol as the fix... actually methanol.

here's why:

fuel has BTUs in it.

nothing new to you of course.

However... there are BTUs of energy AND there are BTUs of COOLING. (by another tag, latent heat)

here's how they stack up and it is an eye opener.

BTUs of energy/gallon

Gasoline (includes racegas) 116,090

Ethanol (alcohol) 76,330

Methanol (alcohol) 57,250

BTUs of COOLING

Gasoline (includes racegas) 952

Ethanol (alcohol) 2398

Methanol (alcohol) 3136

while it is evident that the alcohols do not possess the energy per gallon of gasoline (you just run more volume) they do deliver vastly more cooling. note the significantly greater cooling of methanol V ethanol.... that's why methanol, not ethanol, is used in many higher output motors when the rules allow.

finally there is the autoignition advantage.

Gasoline (including racegas) 495 F

Methanol 867 F

Ethanol 793 F

autoignition is the temp where a fuel ignities w no outside influence (i e spark).

when we talk BTUs cooling, latent heat, it is important to understand that the cooling is not necessarily represented by measuring the intake air temperature. while alcohol does "flash" atomise more than gasoline or water and thereby does cool the IAT a bit. it is in the combustion chamber where it produces it's primary effect.

if you read the TurboBuick AI section you will quickly realise that much of the tuning is done by measuring KNOCK.

that is exactly how i tune. (not to say other things get seriously looked at but KNOCK is primary focus.) i am of course aware that the FC and FD are a bit different here but if i had an FC i sure would be using some sort of knock logging equipment.

not having knock logged and trying to tune would be exactly like trying to dial in your suspension on a road course without a pyrometer. you would be blind.

knock will tell you where the motor likes to run AFR-wise. being a rotary and being highly stressed due to small cu inches and great flowing ports, you need to be very careful to sneak up on knock. take it slowly w re to timing and fuel.

last year i ran two 700 CC/Min methanol injectors and found the motor at 507 rwhp SAE (3.66 hp per cu inch!) was very happy along w 93 octane pump gas. my Power FC knock was under 10 at max power. that was around 11.3 AFR on the mix. this year i will be running two 1000 CC/Min injectors so i am slightly upping my meth.

back to BDC and his IC-less experiments. as most know, many drag racers don't run intercoolers. that is primarily because most run 100% methanol. my friend makes over 1000 rwhp from his all meth two rotor drag car. he runs 14 injectors. given the amount of methanol and it's cooling properties he just doesn't need an IC.

given the fact i run pump gas and meth i like the idea of the additional 130 F degrees removed from my charge air. i don't doubt that BDC's setup will work fine, i just think it could work fin-er w an IC.

there is something to be said for eliminating 25 pounds and probably a couple of psi boost drag so it might work well for BDC. i certainly won't be worrying about his motor from a CCP aspect given all the meth envolved.

carry on Brian

howard

#24

Senior Member

Join Date: Nov 2008

Location: Czech republic

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

255 flywheel hp from 159 cubic inches or 1.60 hp per cubic inch.

now let's compare our stock rotary to the latest and greatest.

the 2011 twin turbo intercooled direct injected Mercedes M157 4 valve V8.

336 cubic inches 563 flywheel hp.... 1.67 hp per cubic inch

the 2021 SL65AMG twin turbo 4 valve titanium rodded etc

365 cu inches 661 flywheel hp 1.81 hp per cu inch

the 2010 Corvette ZR1 supercharged, intercooled, dry sumped, titanium rods

376 cu inches 638 flywheel hp 1.69 hp per cu inch

now let's compare our stock rotary to the latest and greatest.

the 2011 twin turbo intercooled direct injected Mercedes M157 4 valve V8.

336 cubic inches 563 flywheel hp.... 1.67 hp per cubic inch

the 2021 SL65AMG twin turbo 4 valve titanium rodded etc

365 cu inches 661 flywheel hp 1.81 hp per cu inch

the 2010 Corvette ZR1 supercharged, intercooled, dry sumped, titanium rods

376 cu inches 638 flywheel hp 1.69 hp per cu inch

BTW, these Mercedes examples are shameful. Why donīt mention EVOs, STIs and small displacement European engines? Not only with much more HP/cu.inch(meaningless), but mainly with much more torque - literally with more torque than stock 13B-REW with 60% of capacity

(BMW 1,6).

(BMW 1,6).I want to add that Iīm trying to understand what such high ratios of pure methanol to gasoline are really doing, since from 1940s, it has been usually used in 50:50 ratio with water. Methanol, despite many claims has really low octane number, but it is masked by immense cooling properties together with amount needed to reach stoichiometry(well, actually much richer than this).

What I think is, that running such high ratios of pure methanol with gas effectively lowering octane number. And running 20-30% of it against base fuel is just trying to mask it by cooling.

For real, "jdmfantasy" is running over 600 rwhp with around 300 cc of methanol and pump gas and is fine with it. So where is need for 2000 cc??

#25

The Big Ugly!

Well in comparison the motors that have been used were in factory form & the Rotary example is in an modded state so @ 375hp. Remember those motors can also be upgaded with bolt ons & tuning thus changing your comparison. Try this a, 4G63 stock bottom end, Bolt ons & GT35R @ 610.61 awhp with 120 ci = 5.08841 hp per inch to the wheels (a friends car). Even though in stock form the rotary is no slouch the sad thing is stock for stock you are saying nothing. With your Rotary converison of 159 ci @ 255 hp = 1.60377 per inch & a stock 4G63 of 120 ci @ 210 hp = 1.75 per inch. For some reason I'm lost to the reason of the engine comparisons when not directly associated with Alcohol Injection, even more so since none of the motors listed use AI.

Thread

Thread Starter

Forum

Replies

Last Post

edmcguirk

NE RX-7 Forum

3

05-30-18 06:50 PM

Captain_Panic

Alternative Fuels

9

09-16-15 02:06 PM