DIY engine stand adapter help?

#1

Thread Starter

Joined: Mar 2006

Posts: 1,174

Likes: 1

From: Elkhorn, WI/ N.A.S. JAX

DIY engine stand adapter help?

I was wondering if anyone had any plans or designs for a DIY stand adapter? I want to tear down my blown engine. Plus I need a reason to weld something up when i go home.

#3

1/4" plate about 4" x 8" to 10" long(i forgot how long i made it lol), and some 1/4" 2" x 8" to 10" angle iron and drill holes where needed on the A/C bracket studs, and for the engine stand head. When you have the material in front of you its common sense what needs to be drilled and you can use your existing head stand with out the "fingers".

If this is still confusing i can snap some pictures of mine, literally took me 5 minutes to make. A drill press, tape measure, and a center punch make drilling quick and accurate.

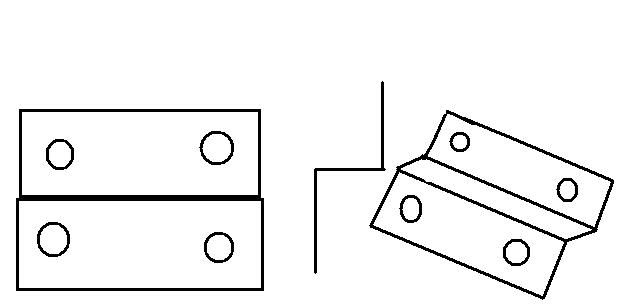

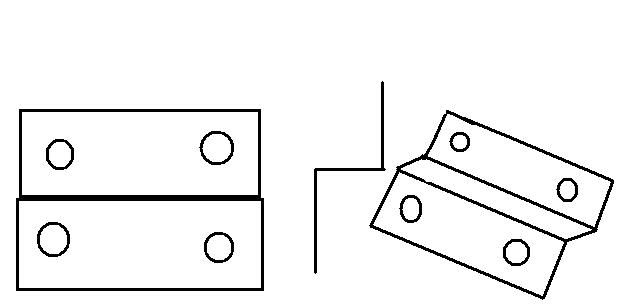

Here is a very crude, not to spec, just a reference, MS paint drawing, looking dead on, from the side, and at a angle.

If this is still confusing i can snap some pictures of mine, literally took me 5 minutes to make. A drill press, tape measure, and a center punch make drilling quick and accurate.

Here is a very crude, not to spec, just a reference, MS paint drawing, looking dead on, from the side, and at a angle.

Last edited by lim_fc3c; 04-25-11 at 08:41 PM.

#4

no need for adapters

just drill straight into the stand for three points so as to mount the front plate from the PS/aircon fixing points

if you wish to weld something,,

note the last pic where you can see i have added a bottle jack that allows me to lift the crank

-to allow fitting of the centre plate with one man and also allows check for endfloat

#7

This is the best pic I have of mine. Just a saw cut chunk of cold rolled, sort of trapezoidal in shape, and some thick walled tubing welded to it that fit my engine stand. I made a spacer with the same bolt pattern from some other scrap to clear the center iron. I just traced the bolt pattern off the engine.

Last edited by TonyD89; 04-25-11 at 11:07 PM.