Alternator belt tensioner (pictures!)

#1

Thread Starter

Trunk Ornament

iTrader: (11)

Joined: Sep 2006

Posts: 3,054

Likes: 2

From: Goose Creek, SC

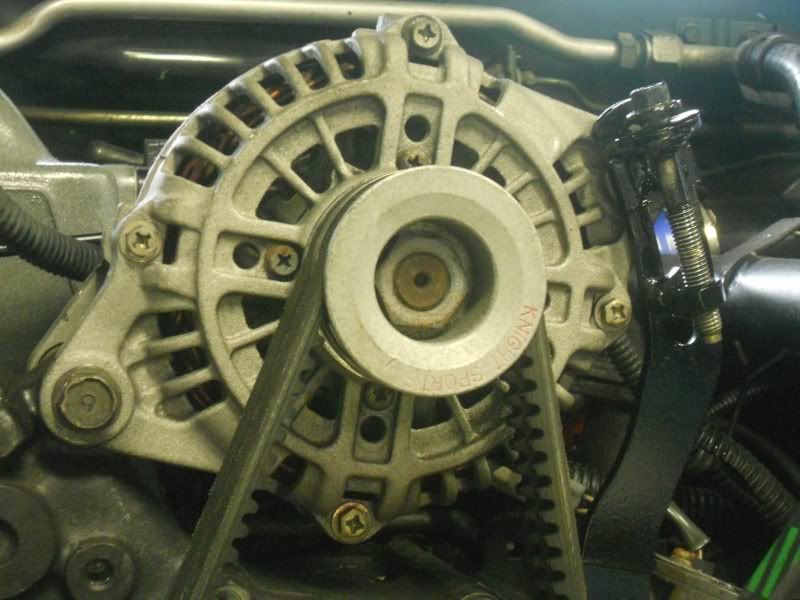

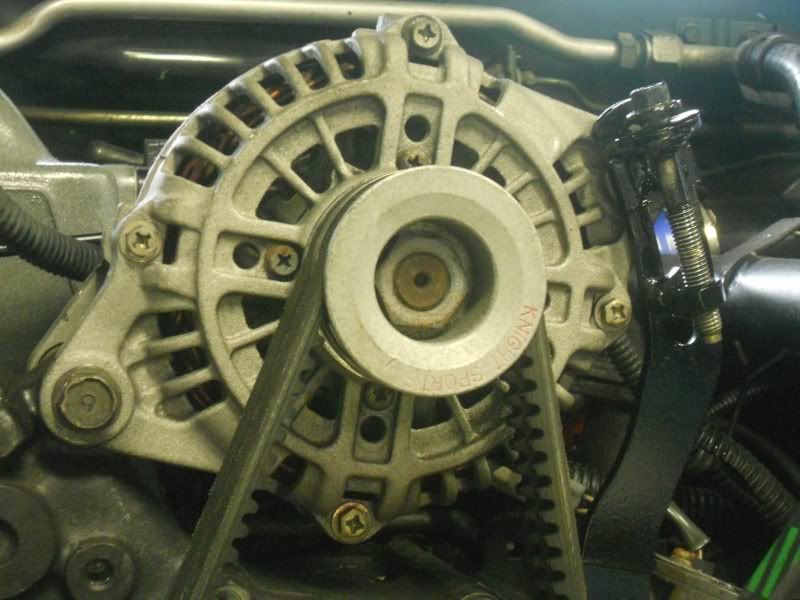

Alternator belt tensioner (pictures!)

You know you want one now

I got tired of trying to hold the prybar with the "proper" tension while tightening the nut. Stupid design, when RIGHT NEXT TO IT is the same design tensioner. Why couldn't Mazda have done this in the first place??

The design is simple. I started with an old air pump bracket, because I just had one lying around (as do alot of people). I bent the end and cut it off. This part slides up and down the alt bracket. I welded a bolt to that, such that the bolt goes through the alt bracket, through the ear on the alternator, and tightens down with a nut in the back. I then modified a long bolt by putting it in through the top of the now L-shaped bracket, then making it "captive" by welding a washer pretty close to the top. This way, you turn the bolt counter clockwise and it pulls the L-bracket up. Then, I welded a nut to the alternator bracket for the long modified bolt.

Here are more pictures:

Enjoy

I got tired of trying to hold the prybar with the "proper" tension while tightening the nut. Stupid design, when RIGHT NEXT TO IT is the same design tensioner. Why couldn't Mazda have done this in the first place??

The design is simple. I started with an old air pump bracket, because I just had one lying around (as do alot of people). I bent the end and cut it off. This part slides up and down the alt bracket. I welded a bolt to that, such that the bolt goes through the alt bracket, through the ear on the alternator, and tightens down with a nut in the back. I then modified a long bolt by putting it in through the top of the now L-shaped bracket, then making it "captive" by welding a washer pretty close to the top. This way, you turn the bolt counter clockwise and it pulls the L-bracket up. Then, I welded a nut to the alternator bracket for the long modified bolt.

Here are more pictures:

Enjoy

#4

It makes TOO MUCH SENSE! Stop it!

I would spin another nut onto the bottom threads of that bolt to lock it in place once the tension is set. I know it probably won't move over time but another nut would make me stop worrying.

I would spin another nut onto the bottom threads of that bolt to lock it in place once the tension is set. I know it probably won't move over time but another nut would make me stop worrying.

#5

Thread Starter

Trunk Ornament

iTrader: (11)

Joined: Sep 2006

Posts: 3,054

Likes: 2

From: Goose Creek, SC

With the water pump bolt and slide bolt on the tensioner bracket tight (which has been enough for Mazda for 20+ years) it's not going anywhere.

I'm thinking about re-doing this now, and instead of having to weld it to my tensioner bracket, just make the bottom nut bolt on instead. That way, it's removable if I ever feel like taking it off for whatever reason...

That also makes it just a straight bolt-on kit for anyone who wants me to make them one in the future.

I'm thinking about re-doing this now, and instead of having to weld it to my tensioner bracket, just make the bottom nut bolt on instead. That way, it's removable if I ever feel like taking it off for whatever reason...

That also makes it just a straight bolt-on kit for anyone who wants me to make them one in the future.

#6

Call me a hill billy but I still love my big *** pry bar a quick turn of the socket.

Trending Topics

#8

Driving RX7's since 1979

iTrader: (43)

Joined: Aug 2001

Posts: 6,096

Likes: 9

From: So Cal where the OC/LA/SB counties meet

Can the FD alternator tensioner be fitted onto an FC? Showing my FD ignorance having never owned or worked on one, also my jealousy of the superior design. Perhaps as a compliment to the ever popular FD alternator into and FC.

#9

the arm would likely have to be bent which would affect the throw. the FD water pump is basically about an inch or so thicker than the FC setup which mounts the arm to the same location. the FD also uses a support brace bolted to the a/c+p/s bracket to help support it which isn't present on the FC.

short answer, probably not an easy adaptation to do.

short answer, probably not an easy adaptation to do.

#11

Driving RX7's since 1979

iTrader: (43)

Joined: Aug 2001

Posts: 6,096

Likes: 9

From: So Cal where the OC/LA/SB counties meet

Cut and welding the top part of an FD bracket to an FC bracket would be an interesting experiment, and perhaps a more simple approach to a nobel end. Both would be a dime a dozen, so little pocket book damage. Finding that additional bracket support otherwise provided by the FD's a/c + p/s bracket would be the challenge. Can't ignore that some Mazda engineer felt it was needed.

#14

Cut and welding the top part of an FD bracket to an FC bracket would be an interesting experiment, and perhaps a more simple approach to a nobel end. Both would be a dime a dozen, so little pocket book damage. Finding that additional bracket support otherwise provided by the FD's a/c + p/s bracket would be the challenge. Can't ignore that some Mazda engineer felt it was needed.

the FD uses a slightly different approach with a simple L bend at the top of the bracket with a hole in it for the tensioner. the pull bolt is threaded and then goes through the alternator. this ones a pusher bolt instead. the FD bracket does have better resolution though with seemingly more swing before hitting the wall in either direction.

interesting and a good idea nonetheless. i never liked the prybar method of tensioning.

Last edited by RotaryEvolution; 11-23-11 at 06:27 PM.

#15

Thread Starter

Trunk Ornament

iTrader: (11)

Joined: Sep 2006

Posts: 3,054

Likes: 2

From: Goose Creek, SC

Thanks everyone.

I sometimes sit around looking at my car going "WTF were they thinking?"

This is the same reason the individual camber links for the rear were designed. Can't understand why they went through so much detail for these cars, giving it awesomeness (for 1988) such as 4 piston brakes up front, disc brakes all around, independent rear suspension, distributorless ignition (some manufacturers used distributors until quite recently), a pioneer CD player, etc., yet you had to tension the alternator by by a neanderthal method.

Not sure yet. I need to do a couple more prototypes and I'll probably go through a couple revisions before I decide on selling them. I may have to get "vendor" status to do this too, I need to read up on the rules first.

I sometimes sit around looking at my car going "WTF were they thinking?"

This is the same reason the individual camber links for the rear were designed. Can't understand why they went through so much detail for these cars, giving it awesomeness (for 1988) such as 4 piston brakes up front, disc brakes all around, independent rear suspension, distributorless ignition (some manufacturers used distributors until quite recently), a pioneer CD player, etc., yet you had to tension the alternator by by a neanderthal method.

Not sure yet. I need to do a couple more prototypes and I'll probably go through a couple revisions before I decide on selling them. I may have to get "vendor" status to do this too, I need to read up on the rules first.

Thread

Thread Starter

Forum

Replies

Last Post

LunchboxCritter

2nd Generation Specific (1986-1992)

15

01-03-16 05:11 PM

rotor_veux

2nd Generation Specific (1986-1992)

7

08-31-15 08:49 PM