Lets talk engine paints

#26

powder coating is the most durable hands down.

all paints that i have used start to melt off if you even point a can of carb cleaner at them. basic rebuilds i just use dupont 500*F ceramic engine paint, it still flakes off easily and isn't very chemical or fuel resistant(even though it sais it is) but there isn't much better without much more work.

all paints that i have used start to melt off if you even point a can of carb cleaner at them. basic rebuilds i just use dupont 500*F ceramic engine paint, it still flakes off easily and isn't very chemical or fuel resistant(even though it sais it is) but there isn't much better without much more work.

#27

Not that u guys probably have access to it but I got the painters at work to paint some of my **** in polyurethane (work on aircraft) although I only get a choice in red, black, tan or green it seems to hold up really well. Painted my brakes with it and they still look like a million dollars, also did my inlet manifold. Went to repaint it while the engine was out and couldn't sandblast it off. Painting is much better then polishing, it stays better for longer

#28

I have used the DupliColor 500 or whatever deree paint with the ceramic and it holds up pretty damned well honestly. Once its actually cured (after the engine has run a few times) its fairly chemical resistant- gas wont faze it, brake clean wont take it off and even carb cleaner has a rough time. Chipping is more about how think your putting it on than the paint itself really. 90% of it is in the prep, and its very hard to get the parts prepped right at home or without the right stuff.

Powdercoat is fairly durable, but be warned its not all the same, and I had some wheels and calipers done a few years back and brake clean would soften it right up.

I have also painted engines and parts using urethane, polyurethane, and acrillic urethane automotive paints, and this is hit or miss really. It is durable stuff once cured, but a PITA to deal with and any urethane is cancer in a can, and the clearcoats are even worse, so full gear is required. Also bodyshop paints tend to not be as heat resistant as actual engine paints, and you can get browning or other signs of scorching. One day I might try the new waterborne paint system I used to paint the car itself on an engine, I just have some doubts about the amount of heat the paints will take before discoloring or just flaking off.

Powdercoat is fairly durable, but be warned its not all the same, and I had some wheels and calipers done a few years back and brake clean would soften it right up.

I have also painted engines and parts using urethane, polyurethane, and acrillic urethane automotive paints, and this is hit or miss really. It is durable stuff once cured, but a PITA to deal with and any urethane is cancer in a can, and the clearcoats are even worse, so full gear is required. Also bodyshop paints tend to not be as heat resistant as actual engine paints, and you can get browning or other signs of scorching. One day I might try the new waterborne paint system I used to paint the car itself on an engine, I just have some doubts about the amount of heat the paints will take before discoloring or just flaking off.

#29

im fairly good with spray cans.. painted furniture when i was young, r/c cars, pc tower case, to recenly painting my bike, stripped, primer, wet sand, than paint , wet sand, then clear coat.

http://sphotos.ak.fbcdn.net/hphotos-..._3092591_n.jpg

http://sphotos.ak.fbcdn.net/hphotos-..._3092591_n.jpg

http://sphotos.ak.fbcdn.net/hphotos-..._3092591_n.jpg

http://sphotos.ak.fbcdn.net/hphotos-..._3092591_n.jpg

#31

spraying a part with brake cleaner and spray bombing it comparing it to sandblasted/PC.

its not as much the powdercoat as it is the fact it was sandblasted.

blast, prime, paint- follow flash times, dont do it in a 40 degree garage- and it will last

spraying with a spray gun- well any 2 part catalyzed paint will be far more durable then air dry enamel

its all how crazy you want to go

its not as much the powdercoat as it is the fact it was sandblasted.

blast, prime, paint- follow flash times, dont do it in a 40 degree garage- and it will last

spraying with a spray gun- well any 2 part catalyzed paint will be far more durable then air dry enamel

its all how crazy you want to go

#33

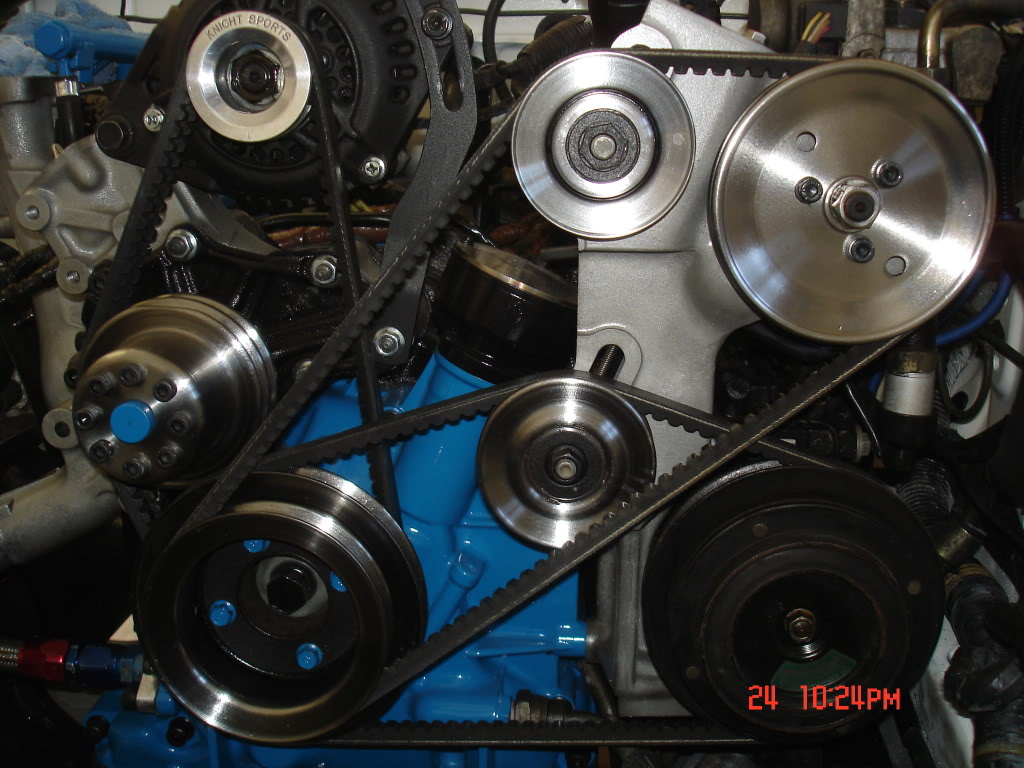

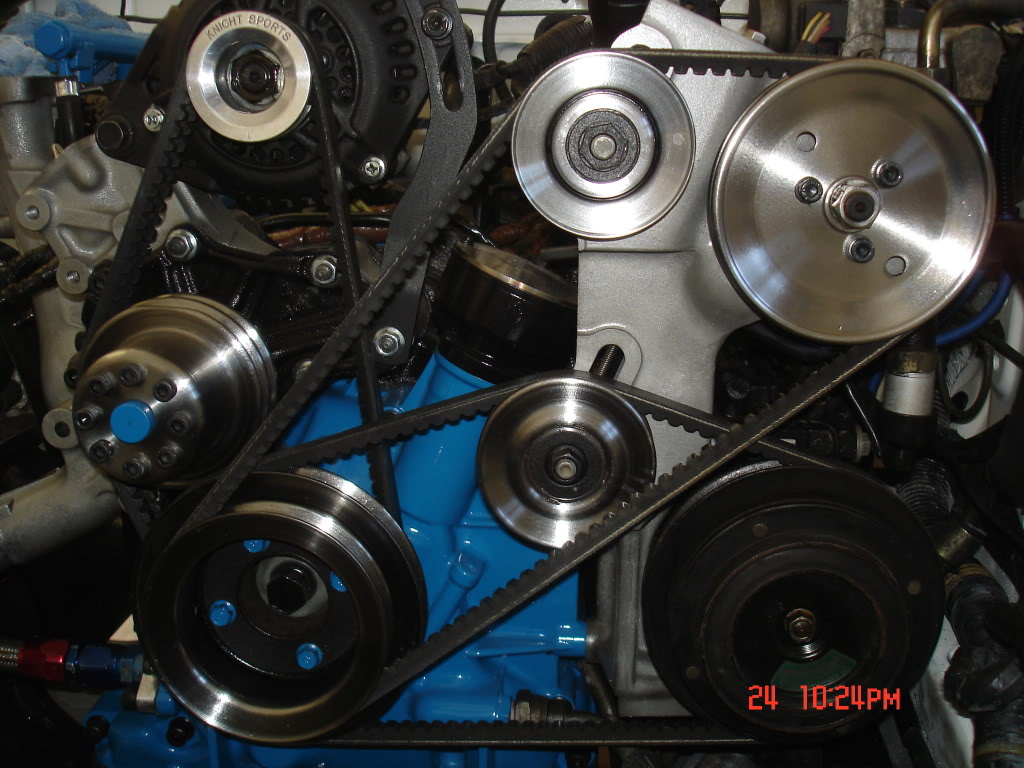

i am dam good with a spray can a decent with a gun. heres some pics of what i did in my bay.

in the engine bay i sprayed with a gun and cleared it with a quality spray clear.

the block like others i used duplicolor high heat paint. it holds up to heat and normal use well, but dont let gas where near it.

on my intake manifolds i bead blasted them and used spray clear on them, gave me the look i wanted.

I took my pulleys to a lathe and polished them with multiple grits of sand paper and then cleared them.

everything is holding up great and looks awesome imo.

in the engine bay i sprayed with a gun and cleared it with a quality spray clear.

the block like others i used duplicolor high heat paint. it holds up to heat and normal use well, but dont let gas where near it.

on my intake manifolds i bead blasted them and used spray clear on them, gave me the look i wanted.

I took my pulleys to a lathe and polished them with multiple grits of sand paper and then cleared them.

everything is holding up great and looks awesome imo.

#36

Engine, Not Motor

iTrader: (1)

Joined: Feb 2001

Posts: 29,793

Likes: 119

From: London, Ontario, Canada

Regular POR-15 is almost impossible to damage if it is applied properly as well. It isn't designed for top coating but is fine for that purpose as long as it isn't constantly exposed to sunlight. Sun just discolours it but doesn't affect the paint otherwise. It only comes in a few colours though so unless you like silver, black or grey, then it might not be the choice. However, it is very, very strong. The only way to remove it is with a grinder. No chemical method will take it off, and it doesn't really blast off either (much to the annoyance of a local blaster when I brought in my subframe to be cleaned up...the incidental POR-15 coverage that happened when I painted the bottom of the car would not come off). It is also heat resistant to any temperatures you would find in the engine bay except exhaust manifolds.

The POR-15 company also makes a two part paint called "Hardnose" which shares all of the toughness of POR-15 but is designed for topcoats and thus is available in a far wider range of colours and doesn't fade. Abrasive methods are the only way to remove it when properly applied (either to VERY CLEAN blasted metal or to an undercoat of POR-15) and it will just barely blast off (with a lot of pressure and effort).

The nice thing about the POR-15 coatings is that they can be brushed on fairly easily and lay down flat. Prep is a bit annoying as engines really should be blasted but as long as the metal is clean and has some tooth, it should stick. Just make sure to follow their instructions and BUY SOME SOLVENT when you buy the paing. Don't let it dry on your skin.

On my Cosmo engine, as mentioned, I used POR-15s engine enamel. While it has not seen service yet, initial impressions are optimistic as it laid down flat, feels very tough and has a nice gloss to it. In other words, it feels like any other POR-15 product. The only annoyance is the 24 hour recoat time and the 6 day cure.

The POR-15 company also makes a two part paint called "Hardnose" which shares all of the toughness of POR-15 but is designed for topcoats and thus is available in a far wider range of colours and doesn't fade. Abrasive methods are the only way to remove it when properly applied (either to VERY CLEAN blasted metal or to an undercoat of POR-15) and it will just barely blast off (with a lot of pressure and effort).

The nice thing about the POR-15 coatings is that they can be brushed on fairly easily and lay down flat. Prep is a bit annoying as engines really should be blasted but as long as the metal is clean and has some tooth, it should stick. Just make sure to follow their instructions and BUY SOME SOLVENT when you buy the paing. Don't let it dry on your skin.

On my Cosmo engine, as mentioned, I used POR-15s engine enamel. While it has not seen service yet, initial impressions are optimistic as it laid down flat, feels very tough and has a nice gloss to it. In other words, it feels like any other POR-15 product. The only annoyance is the 24 hour recoat time and the 6 day cure.

#37

Regular POR-15 is almost impossible to damage if it is applied properly as well. It isn't designed for top coating but is fine for that purpose as long as it isn't constantly exposed to sunlight. Sun just discolours it but doesn't affect the paint otherwise. It only comes in a few colours though so unless you like silver, black or grey, then it might not be the choice. However, it is very, very strong. The only way to remove it is with a grinder. No chemical method will take it off, and it doesn't really blast off either (much to the annoyance of a local blaster when I brought in my subframe to be cleaned up...the incidental POR-15 coverage that happened when I painted the bottom of the car would not come off). It is also heat resistant to any temperatures you would find in the engine bay except exhaust manifolds.

The POR-15 company also makes a two part paint called "Hardnose" which shares all of the toughness of POR-15 but is designed for topcoats and thus is available in a far wider range of colours and doesn't fade. Abrasive methods are the only way to remove it when properly applied (either to VERY CLEAN blasted metal or to an undercoat of POR-15) and it will just barely blast off (with a lot of pressure and effort).

The nice thing about the POR-15 coatings is that they can be brushed on fairly easily and lay down flat. Prep is a bit annoying as engines really should be blasted but as long as the metal is clean and has some tooth, it should stick. Just make sure to follow their instructions and BUY SOME SOLVENT when you buy the paing. Don't let it dry on your skin.

On my Cosmo engine, as mentioned, I used POR-15s engine enamel. While it has not seen service yet, initial impressions are optimistic as it laid down flat, feels very tough and has a nice gloss to it. In other words, it feels like any other POR-15 product. The only annoyance is the 24 hour recoat time and the 6 day cure.

The POR-15 company also makes a two part paint called "Hardnose" which shares all of the toughness of POR-15 but is designed for topcoats and thus is available in a far wider range of colours and doesn't fade. Abrasive methods are the only way to remove it when properly applied (either to VERY CLEAN blasted metal or to an undercoat of POR-15) and it will just barely blast off (with a lot of pressure and effort).

The nice thing about the POR-15 coatings is that they can be brushed on fairly easily and lay down flat. Prep is a bit annoying as engines really should be blasted but as long as the metal is clean and has some tooth, it should stick. Just make sure to follow their instructions and BUY SOME SOLVENT when you buy the paing. Don't let it dry on your skin.

On my Cosmo engine, as mentioned, I used POR-15s engine enamel. While it has not seen service yet, initial impressions are optimistic as it laid down flat, feels very tough and has a nice gloss to it. In other words, it feels like any other POR-15 product. The only annoyance is the 24 hour recoat time and the 6 day cure.

#43

Engine, Not Motor

iTrader: (1)

Joined: Feb 2001

Posts: 29,793

Likes: 119

From: London, Ontario, Canada

If you are going to do that, have them nickle plated and then clear them. Maintaining any sort of polished finish is a chore. You can just polish then clear and shown earlier in this thread, but the nickle would add corrosion protection much more so than the clear.

Thread

Thread Starter

Forum

Replies

Last Post