GordiniRX7's 87 TII Build Thread

#78

Today, when I had a moment, I bit the bullet, grabbed a pair of vise grips and got the injectors off. So now I can clean those up and attatch the new lines. then I need to delete the pulsation dampener, clean up/repair some of the wire harness; then I'll be able to mount the UIM. I need a coupler and an elbow to mount the intercooler, and find the bolts that bolt it down. I'll go to the junk yard soon and get a O2 sensor, since I'm poor, some wire harness connectors, a seat, and whatever else I see that I might need.

Last night I replaced my clutch master, slave, and soft line, then bled the system so now my clutch works! I need the little bump stop because the pedal doesn't engage the clutch sensor thing. I also got my shift **** mounted.

Today I got some exhaust nuts from pineapple. Put those where they need to be.

I'm going to tap the starter bolt hole a size bigger and see how that works.

I still have a little ways to go still. But this car's future is deffinatly looking brighter.

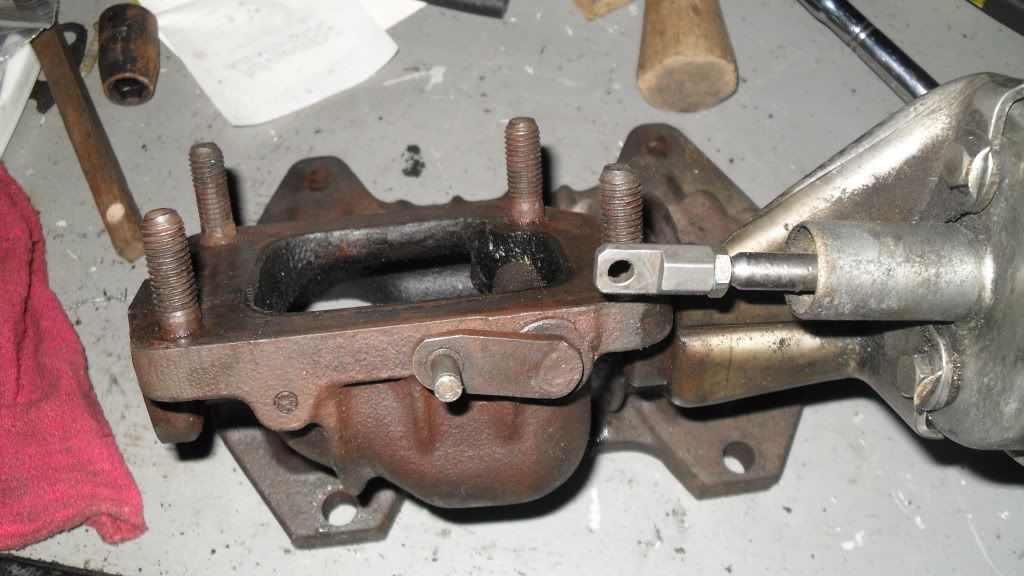

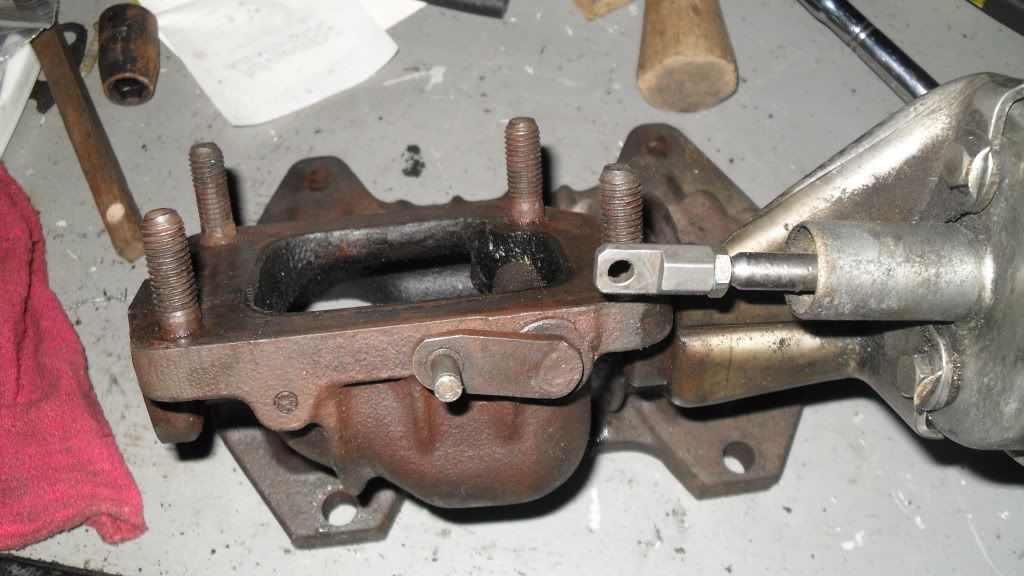

I'm trying to figure out what I can do here. I know they don't attatch directly to eachother, and that there's supposed to be a little clip here. Can someone tell me what I can do?

Last night I replaced my clutch master, slave, and soft line, then bled the system so now my clutch works! I need the little bump stop because the pedal doesn't engage the clutch sensor thing. I also got my shift **** mounted.

Today I got some exhaust nuts from pineapple. Put those where they need to be.

I'm going to tap the starter bolt hole a size bigger and see how that works.

I still have a little ways to go still. But this car's future is deffinatly looking brighter.

I'm trying to figure out what I can do here. I know they don't attatch directly to eachother, and that there's supposed to be a little clip here. Can someone tell me what I can do?

#80

Thats not the wastegate, thats the twin scroll actuator and door. there's supposed to be an inch or so long connector peice connecting the two. Is there a safe way to rig it? Say with a paper clip and said "E" clips?

#81

I wouldn't suggest anything with a paper clip around the turbo. You should be able to make something out of some sort of metal. The FSM shows something similar to a small piece of angle (an angle bracket).

I believe I have a cheap ebay silicone coupler/elbow. Will 2.5" work?

I believe I have a cheap ebay silicone coupler/elbow. Will 2.5" work?

#82

No, it's a 2" pipe. DRAMA has a coupler and elbow that I might get.

I didn't even think of the heat the turbine puts out...

I found a MIG welder at pep boys. I'm going to try and get it. Maybe I can try welding a little peice together. I'll check out the FSM again.

Or, just a small, 1.5" x 3/8" x 1/8" peice of metal, with two holes drilled into it. Nut/bolt on one side and eclip on the other. I think That would work.

I didn't even think of the heat the turbine puts out...

I found a MIG welder at pep boys. I'm going to try and get it. Maybe I can try welding a little peice together. I'll check out the FSM again.

Or, just a small, 1.5" x 3/8" x 1/8" peice of metal, with two holes drilled into it. Nut/bolt on one side and eclip on the other. I think That would work.

#83

When you're making the connections for the sensors, injectors, grounds, etc, take as many pictures as possible. I think it will help out others doing Turbo II swaps or putting motors in rollers. And to comment on your turbo oil and coolant line routing, it looked upside down. Your top coolant line should be on the bottom and the other one with the flange goes on top and bolts onto the LIM. The oil drain with the flex piece goes on the bottom while the feed line with the fitting on it goes to the top. Hope this helps! I'm still trying to get mine running as well.

#84

When you're making the connections for the sensors, injectors, grounds, etc, take as many pictures as possible. I think it will help out others doing Turbo II swaps or putting motors in rollers. And to comment on your turbo oil and coolant line routing, it looked upside down. Your top coolant line should be on the bottom and the other one with the flange goes on top and bolts onto the LIM. The oil drain with the flex piece goes on the bottom while the feed line with the fitting on it goes to the top. Hope this helps! I'm still trying to get mine running as well.

And in regards to the turbo, I got all that sorted out finnaly. I'm just waiting on some gaskets to mount everything.

I just rode my bike to Lowes (it's 35* by the way) and got this while the idea was fresh in my brain.

It's a 1/8" x 1/2" x 3' peice of aluminum(hope it wont melt).

I figure Ill cut a 1-2" peice off and drill a 1/4" hole into both sides. And throw some loctite on the the bolt.

#85

I'm still working on trying to figure out the wireing. I've been reading and scanning the FSM.

These are just ideas. I need to get to the car and look to see what the wire colors are and how they fit onto the engine and where they reach.

The big connector, I have confirmed that it goes to the BAC.

the big single cut wire next to it, I belive that it may be to the O2 sensor.

The black connector, is broken, that extra female end goes to it, and there are three wires going to it. So i'm still a little confused about that one, I'll replace it.

The really thin single cut wire I know for sure goes to the fan switch relay, which I have to replace.

I'm not sure where the two short-cut wires go.

I suppose I should wait until Im with the car to figure all the wiring out.

Edit*

I was browsing Mazdatrix for anything that had wires connected to it, and found that the ACV has TWO connectors so I think its safe to say that the broken clip and two short cut wires are for that.

Anybody disagree?

These are just ideas. I need to get to the car and look to see what the wire colors are and how they fit onto the engine and where they reach.

The big connector, I have confirmed that it goes to the BAC.

the big single cut wire next to it, I belive that it may be to the O2 sensor.

The black connector, is broken, that extra female end goes to it, and there are three wires going to it. So i'm still a little confused about that one, I'll replace it.

The really thin single cut wire I know for sure goes to the fan switch relay, which I have to replace.

I'm not sure where the two short-cut wires go.

I suppose I should wait until Im with the car to figure all the wiring out.

Edit*

I was browsing Mazdatrix for anything that had wires connected to it, and found that the ACV has TWO connectors so I think its safe to say that the broken clip and two short cut wires are for that.

Anybody disagree?

#86

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

First, my bad on the twin scroll, it looks a lot like a wg on a phone screen lol. Ditching that crap for an S5 manifold would be the best route though.

There are many wires there that you prolly won't need, I have a bundle the size of a thumb of terminated wires all wrapped up in that area that you're talking about. Looks like you've already found the important ones, BAC, O2, Fan switch, I think those are the only ones I have left. pics tomorrow... hooray for removing useless crap!

There are many wires there that you prolly won't need, I have a bundle the size of a thumb of terminated wires all wrapped up in that area that you're talking about. Looks like you've already found the important ones, BAC, O2, Fan switch, I think those are the only ones I have left. pics tomorrow... hooray for removing useless crap!

#87

I plan on doing that a little later on. I can't afford it right now, loosing my job and all.

I'm guessing that I might need to put the BAC back on... But I already plugged the hole in the rear housing and the waterpump housing...

I'm guessing that I might need to put the BAC back on... But I already plugged the hole in the rear housing and the waterpump housing...

#88

Hopefully plugged as in capped. When removing the BAC/Thermowax/TB coolant you should run a bypass hose from the rear iron port to the back of the waterpump housing to keep circulation. I think this may have been the circulation issue on the motor I bought.

#89

I only went off of the information on Rotary Resurection and filled the holes with black RTV sealant or whatever, then a large vacuum cap, and a hose clamp. Could I safely drill it out somehow?

#91

My understanding was to run the bypass. Maybe it would work? My motor would push coolant into the resevior and not return. It was never overheated though. I found the port on the rear iron and the heater port by the oil pressure switch blocked and filled. So I'm thinking it's a possibility it wasn't being allowed to circulate correctly. Possbile toasted coolant seals but who knows

#92

Well whenever your water/coolant is pushed into your resevior, and not pulled back, theres a leak in your cooling system. Not a circulation problem. Bad hoses or plugs that wont hold pressue. I won't waste your time and explain it. lol

#93

Yeah, we're just working on theories since I haven't really been able to get it running yet to see what the motor is actually doing. All I have to go on is what I was told when I bought the motor LOL

#94

Well, if those ports are sealed up tight, you shouldn't have a problem there. If one of your water seals are weak and won't hold pressure, then the cooling system wont be able to create vacuum and pull the water back in after it cools down. Also bad hoses, leak in the radiator, and stuff like that.

#95

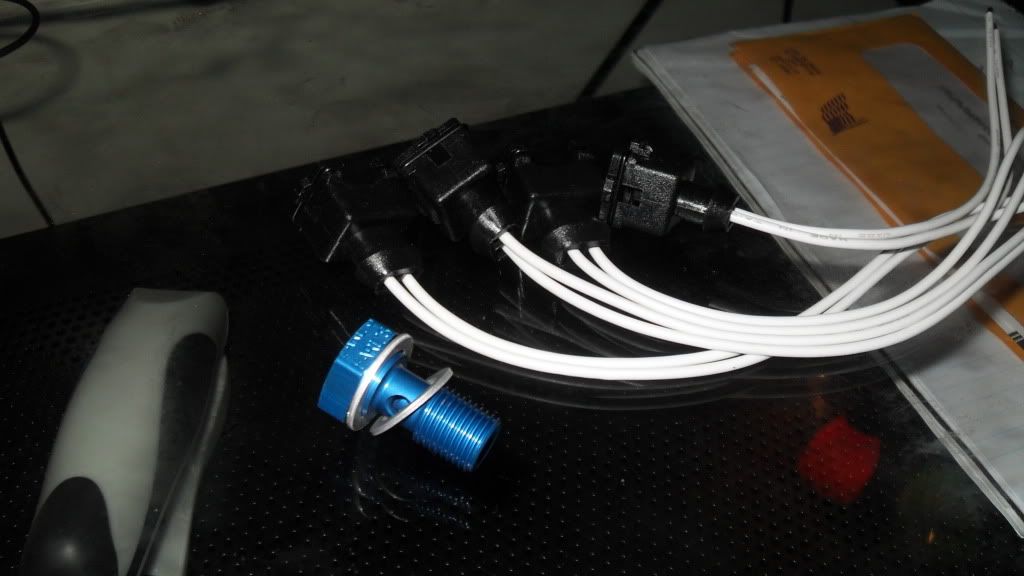

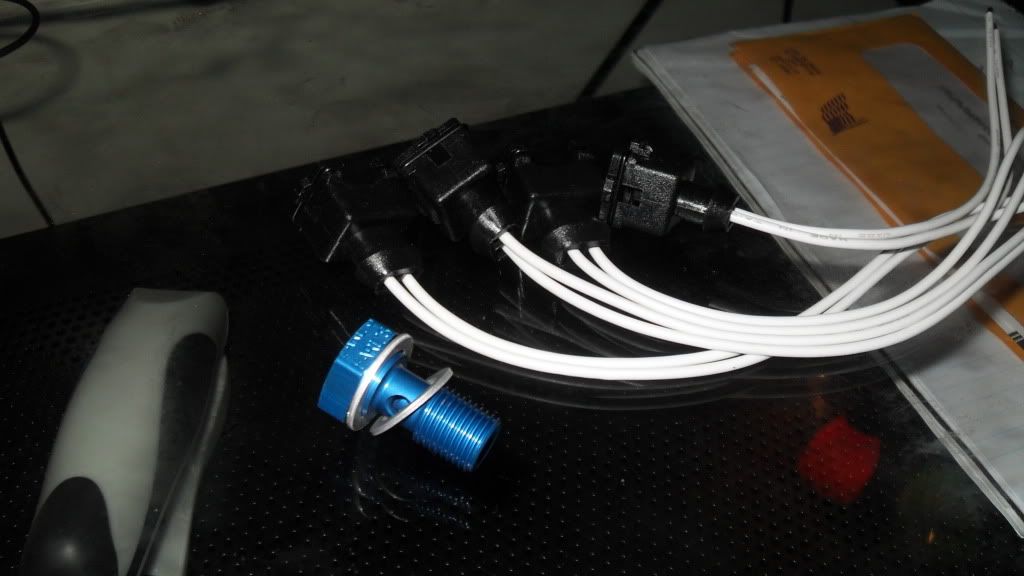

I got some more parts in the mail today(or yesterday?).

I know yesterday I got my thermostat and waterneck gasket from atkins rotary. And a cheapo steering wheel hub for a steering wheel I had from some of our old corvettes. I was in a daze yesterday so, for whatever reason, I didn't take pictures.

But today I got my pulsation dampener eliminator bolt from (I forgot) and some fuel injector wire clips. I have to drop by advanced some time and get some wire connectors and fuses.

I know yesterday I got my thermostat and waterneck gasket from atkins rotary. And a cheapo steering wheel hub for a steering wheel I had from some of our old corvettes. I was in a daze yesterday so, for whatever reason, I didn't take pictures.

But today I got my pulsation dampener eliminator bolt from (I forgot) and some fuel injector wire clips. I have to drop by advanced some time and get some wire connectors and fuses.

#96

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

Good items to have!

I ended up getting a spare S4 fuel rail for less than what that bolt costs new, but at least you have a little bling in the engine bay

The wiring clips are likewise a great idea, mine were in TERRIBLE shape. The insulation had come off one, and the PO had a toothpick wedged between the bare wires to keep them from touching...

You mentioned "wire connectors" . I hope by that you mean adhesive lined shrink wrapped connectors. That is not a very hospitable environment, and unprotected electrical inadequately protected electrical connections could cause headaches down the road.

I ended up getting a spare S4 fuel rail for less than what that bolt costs new, but at least you have a little bling in the engine bay

The wiring clips are likewise a great idea, mine were in TERRIBLE shape. The insulation had come off one, and the PO had a toothpick wedged between the bare wires to keep them from touching...

You mentioned "wire connectors" . I hope by that you mean adhesive lined shrink wrapped connectors. That is not a very hospitable environment, and unprotected electrical inadequately protected electrical connections could cause headaches down the road.

#97

I got one of them installed.

I apologize for the ultra crappy picture. I left my camera at my girlfriends house...

Do I need the little boots like the factory ones? And should I heat shrink over the connections? I got the little blue 16-14 ga insulated butt connectors. Is this good?

I apologize for the ultra crappy picture. I left my camera at my girlfriends house...

Do I need the little boots like the factory ones? And should I heat shrink over the connections? I got the little blue 16-14 ga insulated butt connectors. Is this good?

#98

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

The boots near the connectors are optional, the stock style connector was pretty open so w/o the boot debris could have easily found its way into places it shouldn't. The newer connectors (at least the ones I got...which look similar to yours) have a much better seal around the wire.

I would heat shrink over the connectors, not only does it provide an extra layer of protections from shorts and debris, but it physically strengthens the connection in case it gets pulled on.

I would heat shrink over the connectors, not only does it provide an extra layer of protections from shorts and debris, but it physically strengthens the connection in case it gets pulled on.

#100

That car looks like one from TN I saw a while ago... Keep a close eye on your car, the rear wheel is turned out (driver's side) the door has bondo, the cut in the floor board, and the twist in the front bumper, I hate to say this but it all points to the fact that your car was smacked hard at some point..

I commend you on your efforts, good learning experience.

I would pull the front bumper and matte black the whole car just to make it presentable. . Good luck with the project.

I commend you on your efforts, good learning experience.

I would pull the front bumper and matte black the whole car just to make it presentable. . Good luck with the project.