Fully Blown Electric Auxilliary Port Activation...

#27

Originally posted by HAILERS

For what its worth....the 89 manual, online, pages FI 81 and FI 71, say the sixport solenoid is open at 3800 and closed below that.

For what its worth....the 89 manual, online, pages FI 81 and FI 71, say the sixport solenoid is open at 3800 and closed below that.

On a series four(wifes stock car), I've ridden around with a spare lower intake manifold in the front seat, with its vac(pressure) hose tee'd into the one on the engines lower intake manifold. While driving, I saw the actuators begin to open around 3500 and would finally fully open around 5000. That was a completly stock car.

It makes more sense that Mazda would engineer the 6PI system to gradually open, eliminating any rapid changes in port velocity that could affect the engines smoothness (manufacturers things like that remember).

#28

Thread Starter

Moderator

iTrader: (1)

Joined: Mar 2002

Posts: 7,592

Likes: 5

From: Toronto, Corporate Canada

[QUOTE]Originally posted by HAILERS

[B]For what its worth....the 89 manual, online, pages FI 81 and FI 71, say the sixport solenoid is open at 3800 and closed below that.

I don't remember seeing that In the S4 manual. Can the same be said about the s4?

[B]For what its worth....the 89 manual, online, pages FI 81 and FI 71, say the sixport solenoid is open at 3800 and closed below that.

I don't remember seeing that In the S4 manual. Can the same be said about the s4?

#29

I've never seen a reference in the series four manual about when they open. Since the series five uses a solenoid, they make a remark about when the solenoid opens and is closed.

That said, I'm using, on a series four, a solenoid that is supplied from the same point (as best I can tell from the series five manual) as the series five. Mine flip open instantly when the solenoid is opened. There might be a difference in the spring in the actuators i.e series four vs series five. Maybe a stiffer spring in the series five??? Maybe not

Again, I'm not knocking anybodys method of opening the things in any manner. Never entered my mind. Right now I'm making a home made, rpm activated switching device designed by ZUB. Gonna use it to open my ports at any darn rpm I desire. The 3800 rpm signal for the Relief solenoid isn't as reliable as I previously thought. Theres times it comes on prior to 3800. I think its load related combined with rpm. Just rambling.

That said, I'm using, on a series four, a solenoid that is supplied from the same point (as best I can tell from the series five manual) as the series five. Mine flip open instantly when the solenoid is opened. There might be a difference in the spring in the actuators i.e series four vs series five. Maybe a stiffer spring in the series five??? Maybe not

Again, I'm not knocking anybodys method of opening the things in any manner. Never entered my mind. Right now I'm making a home made, rpm activated switching device designed by ZUB. Gonna use it to open my ports at any darn rpm I desire. The 3800 rpm signal for the Relief solenoid isn't as reliable as I previously thought. Theres times it comes on prior to 3800. I think its load related combined with rpm. Just rambling.

#30

Thread Starter

Moderator

iTrader: (1)

Joined: Mar 2002

Posts: 7,592

Likes: 5

From: Toronto, Corporate Canada

I'm still debating on when I'm going to have my Auxilliary Ports open. Perhaps I'm looking to hard Into the fact that the Air Compressor cranks out 7-8psi. I'll have to see you It responds to my custom setup.

#31

Originally posted by HAILERS

Right now I'm making a home made, rpm activated switching device designed by ZUB. Gonna use it to open my ports at any darn rpm I desire. The 3800 rpm signal for the Relief solenoid isn't as reliable as I previously thought. Theres times it comes on prior to 3800. I think its load related combined with rpm. Just rambling.

Right now I'm making a home made, rpm activated switching device designed by ZUB. Gonna use it to open my ports at any darn rpm I desire. The 3800 rpm signal for the Relief solenoid isn't as reliable as I previously thought. Theres times it comes on prior to 3800. I think its load related combined with rpm. Just rambling.

I had thought the Relief soleniod had more variables controling it than RPM. It makes me wonder what that does to the people using the air that vents from the ACV.

While on the topic. Where does the series 5 take the air from the air pump to route to the 6port actuators? I know it goes from the airpump to the solenoid but where does the line attach to? Is there an attachement in the hose to the ACV or is there a line out of the ACV or Intake manifold

Last edited by Thaniel; 10-16-02 at 01:14 PM.

#32

Thread Starter

Moderator

iTrader: (1)

Joined: Mar 2002

Posts: 7,592

Likes: 5

From: Toronto, Corporate Canada

FWIW, I hooked up the Air Compressor today along with my RPM Switch. Man does that Air Compressor belch out some air! I have so It Is activated around 3850 rpm. I did It this way to work around the random hesitation I get from time to time. (not dealing with the new electric setup but rather with the Infamous 3800 hesitation). The Auxilliary ports open Instantaniously creating a mild supercharging effect with no hiccups or harsh hesitations. I believe the PR Inserts have alot to do with this.

Doing this I eliminated the Air Pump, Air Control Valve and Split Air Pipe. My only dillema Is finding the optimum rpm setting to run my new set up.

Doing this I eliminated the Air Pump, Air Control Valve and Split Air Pipe. My only dillema Is finding the optimum rpm setting to run my new set up.

#34

For what its worth......I put a Autometer boost gauge (the sensing line), in the hose b/t the airpump and the acv. I never ever saw more than 4 to 4 1/2 psi. Full throttle to idle, no more than the above. Fifteen year old airpump, but I don't think it did any better when new.

Curious about where SilverRotor got his rpm switch . Part number etc, and approx price. Using it with a aftermarket ignition or the stock?

Curious about where SilverRotor got his rpm switch . Part number etc, and approx price. Using it with a aftermarket ignition or the stock?

#35

Thread Starter

Moderator

iTrader: (1)

Joined: Mar 2002

Posts: 7,592

Likes: 5

From: Toronto, Corporate Canada

I got It from Summitracing, summit part number #SUM-830449, $45. Great little Black box. I set the dip switches to 3800. Although that wasn't the output It was giving me (I guess due to Piston configuration). No big deal. The box also came with a "fine adjustment" phillips head screw, on the circuit board, that allowed me to rotate It to give me precise desired rpms. Worked out beautifully.

Oh, you could barely hear the Air Compressor over my whailing exhaust as NZ suggested . I have It wedged b'n the Charcoal Canister and the sidewall fender.

. I have It wedged b'n the Charcoal Canister and the sidewall fender.

Oh, you could barely hear the Air Compressor over my whailing exhaust as NZ suggested

. I have It wedged b'n the Charcoal Canister and the sidewall fender.

. I have It wedged b'n the Charcoal Canister and the sidewall fender.

Last edited by silverrotor; 10-25-02 at 08:04 PM.

#36

silverrotor I bought the same switch. I'm having problems. I connected it to the bullet connector at the trail coil and then the bullet connector at the lead coil. Can't get it to come on except at 50000 rpm. Lowest setting on the dip switch is 2000 and thats where I have mine set. Where did you connect your white wire?????

EDIT: Above, I'm trying to say I tried both coil assy, one at a time. Not both at the same time.

EDIT: Above, I'm trying to say I tried both coil assy, one at a time. Not both at the same time.

#38

Thread Starter

Moderator

iTrader: (1)

Joined: Mar 2002

Posts: 7,592

Likes: 5

From: Toronto, Corporate Canada

Oops, I'm wrong. Shoot me. I too have It set on the lowest setting @ 2000 w/ the help of the screw I keep mentioning.

I too have It set on the lowest setting @ 2000 w/ the help of the screw I keep mentioning.

BTW, why Is It suggested to use a relay In conjunction w/ the Air Compressor and RPM Switch?

I too have It set on the lowest setting @ 2000 w/ the help of the screw I keep mentioning.

I too have It set on the lowest setting @ 2000 w/ the help of the screw I keep mentioning.BTW, why Is It suggested to use a relay In conjunction w/ the Air Compressor and RPM Switch?

#41

Yo. I have the same unit. I had to use the lead coil assy bullet to make it work at the lowest setting. I'll do the fine adjust tomorrow and maybe I can get it to go down lower than 5000 for the trip. I use the yellow wire to lite a LED inside the car so I could tell if the darn thing was working. I took a look at the IC inside the box. The long black one. Its a LM2074 I believe, the same type I was thinking about using on a home made switch. Its for frequency sensing.

Just a side note on my use of the Relief solenoids 3800 rpm signal to switch the solenoid for the aux actuators. It works right about 85 percent of the time. The times it does not work, is when the car is cold and other times at cruise. Such as driving at 70mph in fifth gear. Car is at 3000 rpm, but the solenoid has the actuators open, when they should be shut.It switches to open the actuators when they should not really be open. But just driving around town, on the whole they open at 3800 and close below.

Thanks for the reply. I was wondering about where I might be going wrong. And for anybody elses info, that rpm switch from Summit has no adjustment for four, six or twelve cylinder cars. The advertisement should have stated that it was for a 8?????? cylinder only.

EDIT: On the *why a relay*? I'm just guessing, but maybe they don't think their unit should be used as a grounding path. Maybe too much current. I dunno. I'm using it with a spare solenoid off a RX. The type that looks like the orange solenoid for the fpr. Its a 69ohm outfit. Maybe I should think about using a cheap auto relay instead, and then use the relay to operate the RX solenoid.

Just a side note on my use of the Relief solenoids 3800 rpm signal to switch the solenoid for the aux actuators. It works right about 85 percent of the time. The times it does not work, is when the car is cold and other times at cruise. Such as driving at 70mph in fifth gear. Car is at 3000 rpm, but the solenoid has the actuators open, when they should be shut.It switches to open the actuators when they should not really be open. But just driving around town, on the whole they open at 3800 and close below.

Thanks for the reply. I was wondering about where I might be going wrong. And for anybody elses info, that rpm switch from Summit has no adjustment for four, six or twelve cylinder cars. The advertisement should have stated that it was for a 8?????? cylinder only.

EDIT: On the *why a relay*? I'm just guessing, but maybe they don't think their unit should be used as a grounding path. Maybe too much current. I dunno. I'm using it with a spare solenoid off a RX. The type that looks like the orange solenoid for the fpr. Its a 69ohm outfit. Maybe I should think about using a cheap auto relay instead, and then use the relay to operate the RX solenoid.

Last edited by HAILERS; 10-25-02 at 09:31 PM.

#44

Heck yes! The small pot under the cover, which faces the wall and can't be turned by a screwdriver due to no room to access it, did the job. Had to drill a hole thru the side so I could put a screwdriver on it. Drill bit hit the pot, The pot laid over facing straight up. The center pin came unsoldered. Had to resolder, but screwing it made a major difference and I decided to set my solenoid to go off at four grand. I'm not using a relay. Ain't gonna use a relay. May pay for it someday, who knows.

I've got too many other things to do right now, but I suspect the unit isn't being calibrated at the factory properly. I would have thought the small pot would only make a fifty rpm change. Wrong again. Anyway, if it fails, I've got a LED coming off it going to the dash, so if that ceases to function I'll know the aux ports are not working.

Yes, I'm just guessing, but I think their recommendation for using a relay is to protect their unit. Sorry world, I'll take my chances.

AS a side note, ZUB, is making a home made rpm switching device out of readily available parts from the electonic stores such as JAMECO. I plan on tossing the Summit unit and using the homemade device. Like homemade stuff. More of an adventure.

I've got too many other things to do right now, but I suspect the unit isn't being calibrated at the factory properly. I would have thought the small pot would only make a fifty rpm change. Wrong again. Anyway, if it fails, I've got a LED coming off it going to the dash, so if that ceases to function I'll know the aux ports are not working.

Yes, I'm just guessing, but I think their recommendation for using a relay is to protect their unit. Sorry world, I'll take my chances.

AS a side note, ZUB, is making a home made rpm switching device out of readily available parts from the electonic stores such as JAMECO. I plan on tossing the Summit unit and using the homemade device. Like homemade stuff. More of an adventure.

#46

Thread Starter

Moderator

iTrader: (1)

Joined: Mar 2002

Posts: 7,592

Likes: 5

From: Toronto, Corporate Canada

Hailers///After rereading your last post, I'm wondering howcome you are drilling to get to the adjustment screw. With the cover off, that screw Is very accessable. I dunno know, am I missing something?

#47

Thread Starter

Moderator

iTrader: (1)

Joined: Mar 2002

Posts: 7,592

Likes: 5

From: Toronto, Corporate Canada

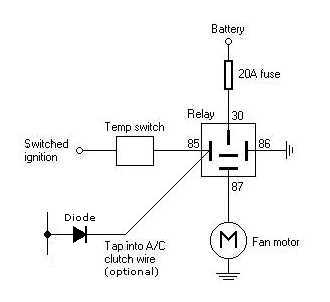

Perhaps this pic could simplify how I In corporated the use of a relay In my Fully Blown Electric Auxilliary Ports project.

Pic courtesy of NZConvertible

Note! A few changes must be made If you are to follow this schematic.

-Substitute the Temp Switch with the RPM Switch

-Substitute the Fan Motor with the Air Compressor

-Under 87 Terminal, positive charge It rather than ground It. I wired It directly to the Battery.

Pic courtesy of NZConvertible

Note! A few changes must be made If you are to follow this schematic.

-Substitute the Temp Switch with the RPM Switch

-Substitute the Fan Motor with the Air Compressor

-Under 87 Terminal, positive charge It rather than ground It. I wired It directly to the Battery.

Last edited by Icemark; 11-30-03 at 12:44 PM.

#48

SILVERROTOR......The little tiny trim pot on mine, faced the wall of the case, whereas it should have been facing straight up in you face when you take the top off. I could have tried to bend it over to face straight up, but I was sure it would have broken off at the base. So I thought I'd just drill a 3/16 hole in the side of the box and stick a screwdriver thru the hole to do the adjustment. Well I wasn't as skilled as I thought, and pushed the drill thru to hit the trim pot, which in turn bent it over. To the straight up position! of all things. But the center conductor pulled out of its hole in the pcb, and I had to resolder it (if it was ever really soldered). Was your trim pot facing you as you opened the case????? Real small pot on mine. About 3/16 square.

#49

Thread Starter

Moderator

iTrader: (1)

Joined: Mar 2002

Posts: 7,592

Likes: 5

From: Toronto, Corporate Canada

Yea, It was facing me right on, square In the face. Begging me to adjust, to better suit the RPM's needed to zero In my Auxilliary Ports. Without It, the RPM Switch Is no good (RPM's were way too high).

A good point that NZ brought up, Is to do 2 runs. One with Ports wide open and the other closed. Compare graphs and where the 2 lines Intersect, would be a good starting point to have them "permently" open.

Considering my na Is severly modded, I don't think the Mazda settings, on the opening/closing of the Auxilliary Ports,will compliment maximum efficiency of this feature found In na's. However, a Dyno will prove valid. I'll keep you guys posted...

A good point that NZ brought up, Is to do 2 runs. One with Ports wide open and the other closed. Compare graphs and where the 2 lines Intersect, would be a good starting point to have them "permently" open.

Considering my na Is severly modded, I don't think the Mazda settings, on the opening/closing of the Auxilliary Ports,will compliment maximum efficiency of this feature found In na's. However, a Dyno will prove valid. I'll keep you guys posted...

#50

Thread Starter

Moderator

iTrader: (1)

Joined: Mar 2002

Posts: 7,592

Likes: 5

From: Toronto, Corporate Canada

I extracted an Idea from you Hailers. I have a LED Light tapped Into the **** pit that I wired up to the Ground Wire of the RPM Switch. By doing this, I am constantly tuned In to the set up. So 3850rpm (at current) the light goes off and so does my car!

Perhaps this Is an overkill, considering I would feel the sleeves rotating rather than depending on the light to go off. But than again, I'm not always flooring It. I think this has to do with my multiple Gauges I just Installed. More like a Gauge fetish.

Perhaps this Is an overkill, considering I would feel the sleeves rotating rather than depending on the light to go off. But than again, I'm not always flooring It. I think this has to do with my multiple Gauges I just Installed. More like a Gauge fetish.