Myth about the 20B exhaust sleeves

#1

Myth about the 20B exhaust sleeves

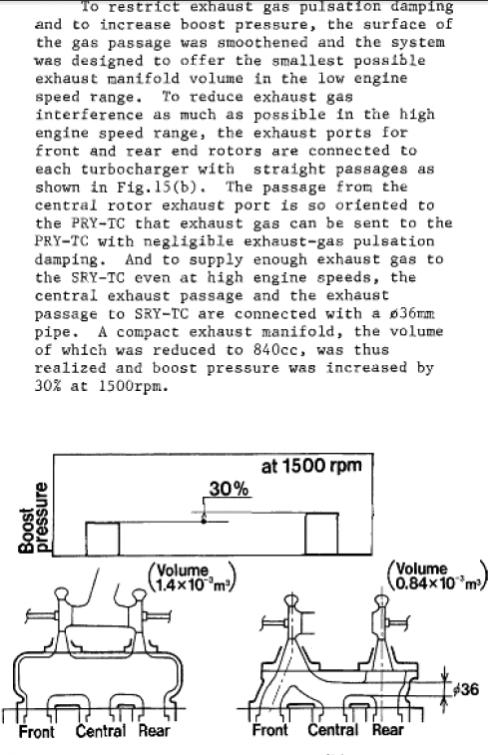

A lot of people think that the 20B exhaust sleeves are restrictive for noise reduction. This is not true. They were designed this way for specifically for spool and low end torque. Mazde specifically engineered them to have a narrow opening in order to work with the narrow exhaust manifold:

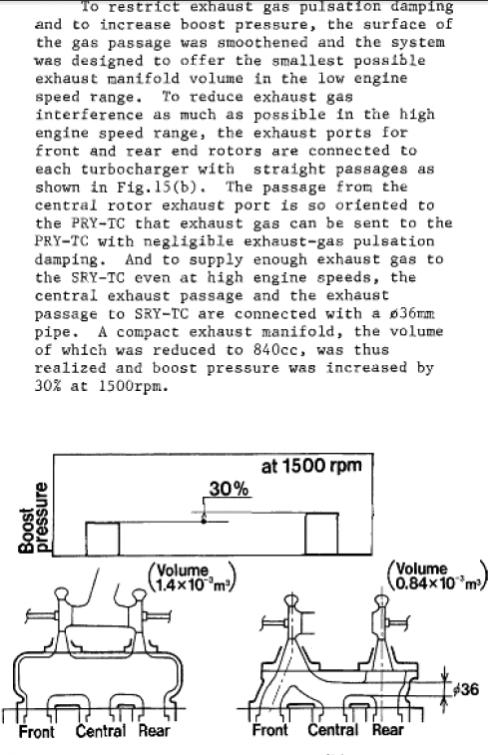

This helped Mazda achieve their targets for boost response and low-end torque:

That doesn't mean you shouldn't swap sleeves. It just means that Mazda used the narrow sleeves for a specific performance-oriented reason: they wanted a torque curve that could compete with the V8's (or twin turbo 6 cylinders) of the time.

This helped Mazda achieve their targets for boost response and low-end torque:

That doesn't mean you shouldn't swap sleeves. It just means that Mazda used the narrow sleeves for a specific performance-oriented reason: they wanted a torque curve that could compete with the V8's (or twin turbo 6 cylinders) of the time.

#4

20b Tinkerer

iTrader: (1)

Join Date: Jan 2002

Location: TX

Posts: 240

Likes: 0

Received 0 Likes

on

0 Posts

Ack! Can't edit.

I'm curious if this translates to use on a modern tubular exhaust system to the same degree. Also, I'm curious if it matters where you shave the volume.

Since in a tubular manifold, we are relying on the gentle bends to guide the exhaust, I think the volume is the only variable. Supposing a 20b manifold with equal length, 50mm, 18" runners, we could expect a volume, excluding the collector, of ((pi*25mm^2) * 475.2mm * 3) = 2797740mm^3

Shrinking to 44mm runners ((pi*22mm^2) * 475.2mm * 3) = 2797740mm^3 = 2166569.85mm^3

33% reduction as opposed to Mazda's 40%, hmm. I'm not sure people are seeing gains like Mazda.

Also, if volume reduction has such a significant effect, why are people against quick spool valves when we (20b users) can't get a fully divided manifold? Aren't we effectively reducing the volume of the exhaust system (inside the turbo pre-turbine, albeit with leaks) by half for that portion? Is this section less effective per unit of volume reduced than say the sleeve or manifold area?

I'm curious if this translates to use on a modern tubular exhaust system to the same degree. Also, I'm curious if it matters where you shave the volume.

Since in a tubular manifold, we are relying on the gentle bends to guide the exhaust, I think the volume is the only variable. Supposing a 20b manifold with equal length, 50mm, 18" runners, we could expect a volume, excluding the collector, of ((pi*25mm^2) * 475.2mm * 3) = 2797740mm^3

Shrinking to 44mm runners ((pi*22mm^2) * 475.2mm * 3) = 2797740mm^3 = 2166569.85mm^3

33% reduction as opposed to Mazda's 40%, hmm. I'm not sure people are seeing gains like Mazda.

Also, if volume reduction has such a significant effect, why are people against quick spool valves when we (20b users) can't get a fully divided manifold? Aren't we effectively reducing the volume of the exhaust system (inside the turbo pre-turbine, albeit with leaks) by half for that portion? Is this section less effective per unit of volume reduced than say the sleeve or manifold area?

#5

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,989

Received 2,688 Likes

on

1,903 Posts

it probably does matter where you shave the volume, but its pretty obvious what and why mazda did theirs

#8

20b Tinkerer

iTrader: (1)

Join Date: Jan 2002

Location: TX

Posts: 240

Likes: 0

Received 0 Likes

on

0 Posts

I'm quite familiar. As far as I know, there is no 3 way divided turbine housing to allow a 20b to run a true, fully divided, fully separated manifold all the way to the turbine blades. By having 3 runners, we are forced to run collected or semi-divided. The divided workaround I've seen is to split the center exhaust runner, but I'm curious how much energy is lost having exhaust expand into both chambers vs. closing off volume to make up for the collection.

#12

Here's how the triple-scroll turbo worked. On a 5 cylinder you've got an oddball firing order and weird pulsation effects that can cause backpressure problems. This is due to the fact that a 5 cylinder has a 144 crank degree firing interval. So on the three scrolls it worked like this

scroll 1) single cylinder

scroll 2) two cylinders

scroll 3) two cylinders

At low rpm/load, they are all divided up among the three scrolls like that. At high rpm, two valves open to connect scroll #2 and #3 with the single cylinder scroll #1. That effectively turns it into an undivided manifold with less pulsation in order to improve turbine efficiency. The whole point of this configuration was to ultimately reduce smoke emissions on marine diesels (as part of an overall optimzation program). That sums up the 22 page paper.

scroll 1) single cylinder

scroll 2) two cylinders

scroll 3) two cylinders

At low rpm/load, they are all divided up among the three scrolls like that. At high rpm, two valves open to connect scroll #2 and #3 with the single cylinder scroll #1. That effectively turns it into an undivided manifold with less pulsation in order to improve turbine efficiency. The whole point of this configuration was to ultimately reduce smoke emissions on marine diesels (as part of an overall optimzation program). That sums up the 22 page paper.

#15

All of this is made obsolete by VG turbos, which basically have an infinitely adjustable scroll point instead of distinct scrolls with a switch. I have considered adapting one to a rotary, the control scheme can be made pretty simple.

VG turbos are not super popular right now because the diesel manufacturers pioneered them, but the advantages are less obvious on a diesel where low end power is abundant anyway, so many are electing to ditch the VG turbos in favor of a simplified setup, or, interestingly, sequential twins....

VG turbos are not super popular right now because the diesel manufacturers pioneered them, but the advantages are less obvious on a diesel where low end power is abundant anyway, so many are electing to ditch the VG turbos in favor of a simplified setup, or, interestingly, sequential twins....

#16

VG turbos are not super popular right now because the diesel manufacturers pioneered them, but the advantages are less obvious on a diesel where low end power is abundant anyway,

so many are electing to ditch the VG turbos in favor of a simplified setup, or, interestingly, sequential twins....

#17

Registered User

Join Date: Dec 2001

Location: Chicago

Posts: 428

Likes: 0

Received 0 Likes

on

0 Posts

This is a actual twin scroll turbo. Unlike how everyone always claims a divided turbine housing is a twin scroll.

Thread

Thread Starter

Forum

Replies

Last Post