E shaft stregnthening ideas.

#1

YOUR TRIANGLE NIGHTMARE

Thread Starter

iTrader: (6)

Join Date: Mar 2006

Location: automotive purgatory

Posts: 807

Likes: 0

Received 0 Likes

on

0 Posts

E shaft stregnthening ideas.

I've been up all night trying to get my house ready for family coming in town, so bare with me maybe im just going nuts. I started thinking about the breaking point of the E shaft, I hear about everyone trying to make a stronger shaft but I started thinking. Maybe if we put less stress on the shaft by using a lighter rotors it wouldnt break as easily. This and a combination of the other modifications we are aware of might help. Also maybe another motor mount on the front of motor might help to keep the rotating assembly more stable by keeping the motor more firmly planted. scratch:

#2

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 31,127

Received 2,791 Likes

on

1,977 Posts

i agree, breaking the shaft is a symptom

#4

roto moto

Join Date: Dec 2004

Location: middlesbrough, england

Posts: 13

Likes: 0

Received 0 Likes

on

0 Posts

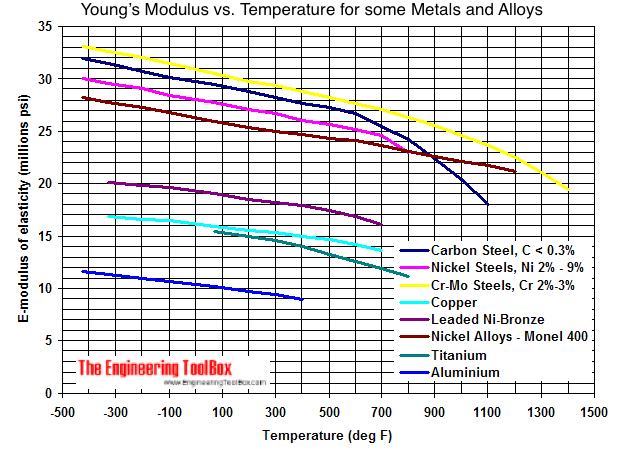

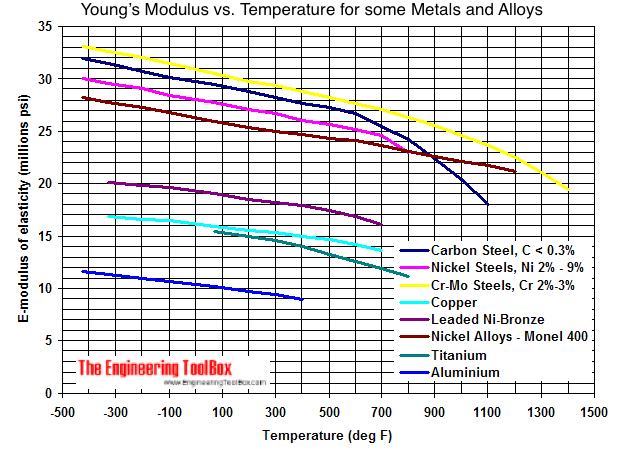

titanium rotors would never work, titanium is really soft when exposed to high heat.

we had ti pipe work on our plant at work and above 400 degrees the pipework was prone to rupture. i nthe end we exchanged it all for hastelloy

we had ti pipe work on our plant at work and above 400 degrees the pipework was prone to rupture. i nthe end we exchanged it all for hastelloy

#5

HA! you might be shocked with what some deep pockets came up with.

an interesting tidbit i read:

Titanium burns in air when heated to 1200 °C (2,200 °F) and in pure oxygen when heated to 610 °C (1,130 °F) or higher, forming titanium dioxide

#7

Beryllium-Aluminum Alloy is basically the perfect material for making rotors.

Commonly used in the aerospace industry, it's lighter than Aluminum, high strength, and has great thermal stability.

Problem is it's extremely expensive, $600 per pound, complex to machine, and the dust given off during machining is highly toxic, but once installed in an engine would pose no more harm then anything else coming out your exhaust.

Commonly used in the aerospace industry, it's lighter than Aluminum, high strength, and has great thermal stability.

Problem is it's extremely expensive, $600 per pound, complex to machine, and the dust given off during machining is highly toxic, but once installed in an engine would pose no more harm then anything else coming out your exhaust.

Trending Topics

#8

Beryllium-Aluminum Alloy is basically the perfect material for making rotors.

Commonly used in the aerospace industry, it's lighter than Aluminum, high strength, and has great thermal stability.

Problem is it's extremely expensive, $600 per pound, complex to machine, and the dust given off during machining is highly toxic, but once installed in an engine would pose no more harm then anything else coming out your exhaust.

Commonly used in the aerospace industry, it's lighter than Aluminum, high strength, and has great thermal stability.

Problem is it's extremely expensive, $600 per pound, complex to machine, and the dust given off during machining is highly toxic, but once installed in an engine would pose no more harm then anything else coming out your exhaust.

#10

KM48 Burnout

iTrader: (4)

Join Date: Nov 2001

Location: Ventura County, CA

Posts: 1,692

Likes: 0

Received 0 Likes

on

0 Posts

Titanium is a great metal to use. Here's the trick. Plasma spray the Ti rotors with Cubic Zirconia.

http://en.wikipedia.org/wiki/Cubic_zirconia

http://www.insaco.com/MatPages/mat_display.asp?M=CZ

Light, Strong, Heat Resistant.

http://en.wikipedia.org/wiki/Cubic_zirconia

http://www.insaco.com/MatPages/mat_display.asp?M=CZ

Light, Strong, Heat Resistant.

#11

The rotors wouldn't be that heavy, it's easy enough to work out with a bit of ruff maths:

Steel has a density of about 0.28 lb/cu

Beryllium Aluminum Alloy has a density of 0.076 lb/cu

Stock steel rotors weigh 9.5 lb.

9.5 / 0.28 = 33.93 (volume of a stock rotor in cubic inchs)

33.93 * 0.076 = 2.58 lb (now that presuming there is no change in the rotor design)

2.58 x 600 = $1548 per rotor (and that don't allow for manufacturing, waste etc).

Like I said extremely expensive, but the rotors would be less than a third the weigh of the stock items.

Steel has a density of about 0.28 lb/cu

Beryllium Aluminum Alloy has a density of 0.076 lb/cu

Stock steel rotors weigh 9.5 lb.

9.5 / 0.28 = 33.93 (volume of a stock rotor in cubic inchs)

33.93 * 0.076 = 2.58 lb (now that presuming there is no change in the rotor design)

2.58 x 600 = $1548 per rotor (and that don't allow for manufacturing, waste etc).

Like I said extremely expensive, but the rotors would be less than a third the weigh of the stock items.

#12

Senior Member

iTrader: (2)

Join Date: Mar 2005

Location: St. Simons Island, Georgia

Posts: 319

Likes: 0

Received 0 Likes

on

0 Posts

Sent the shaft to Liberty Transmissions and have them do there metal enhancement process. They have a 3 step process of shot peening, Heat stress relieving and cryo treatment. That would be an economical, incremental help.

#13

YOUR TRIANGLE NIGHTMARE

Thread Starter

iTrader: (6)

Join Date: Mar 2006

Location: automotive purgatory

Posts: 807

Likes: 0

Received 0 Likes

on

0 Posts

does anyone think that maybe just using lighter rotors would be a good route to go(if possible) and anchoring the motor with a 3rd mount up front at the front cover or iron?

#14

KM48 Burnout

iTrader: (4)

Join Date: Nov 2001

Location: Ventura County, CA

Posts: 1,692

Likes: 0

Received 0 Likes

on

0 Posts

#15

Scott Howard

what about a titanium E shaft with Lightened rotors? What kind of heat is the E shaft exposed to?

I like the sound of the 2.58lb rotors. $3500 for a pair of ultra light rotors would be worth it, especially if it increased reliability and hp. Tight tollerances and low weight.....

I like the sound of the 2.58lb rotors. $3500 for a pair of ultra light rotors would be worth it, especially if it increased reliability and hp. Tight tollerances and low weight.....

#17

Titanium is an unsuitable material to make a eccentric shaft out of, titanium is about half as stiff as steel, so an eccentric shaft bad out of titanium would flex to much to be usable.

The best material to make an eccentric shaft from is chromoly steel, as it's extremely stiff yet strong, I not sure what the factory items are made from but I know a couple of the aftermarket eccentric shafts are made from chomoly.

The best material to make an eccentric shaft from is chromoly steel, as it's extremely stiff yet strong, I not sure what the factory items are made from but I know a couple of the aftermarket eccentric shafts are made from chomoly.

#18

Scott Howard

so how about this:

1. chromoly steel e-shaft,

2. Beryllium-Aluminum Alloy rotors,

3. 13B PP combined with side bridge ports (we can call it the super duper port) JK

4. we need a NA 13B with 450+ engine hp

1. chromoly steel e-shaft,

2. Beryllium-Aluminum Alloy rotors,

3. 13B PP combined with side bridge ports (we can call it the super duper port) JK

4. we need a NA 13B with 450+ engine hp

#21

Half Life

Join Date: Mar 2004

Location: No fixed Address. Any city worldwide. I live out of a bag!

Posts: 46

Likes: 0

Received 0 Likes

on

0 Posts

Where is the oil passage in the rotors for oil cooling. If this thing is made out of block aluminum, then it must be as heavy as the original iron rotor... and probably heavier too.

#23

KM48 Burnout

iTrader: (4)

Join Date: Nov 2001

Location: Ventura County, CA

Posts: 1,692

Likes: 0

Received 0 Likes

on

0 Posts

wish they mentioned how much it weighed. I'd rather have it hard anodized instead of a machined surface finish though.

#24

It should still have some oil cooling though if its meant to be used on the street. Heat resistant isn't the same as heat proof. Heat resistant just means it takes longer for heat soak to take effect. If its thermal coated it could get by with a lot less but it still needs something to carry heat it abosrbs away.

#25

KM48 Burnout

iTrader: (4)

Join Date: Nov 2001

Location: Ventura County, CA

Posts: 1,692

Likes: 0

Received 0 Likes

on

0 Posts

It should still have some oil cooling though if its meant to be used on the street. Heat resistant isn't the same as heat proof. Heat resistant just means it takes longer for heat soak to take effect. If its thermal coated it could get by with a lot less but it still needs something to carry heat it abosrbs away.