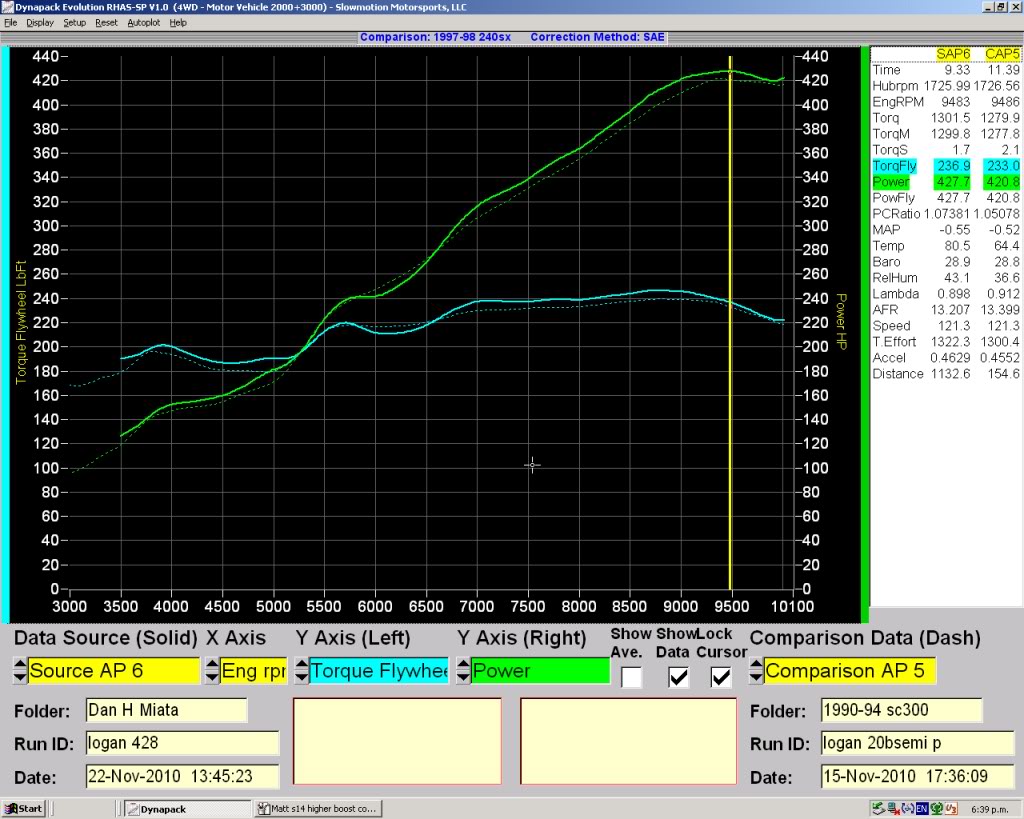

Defined N/a 20b semi p-port. 421rwhp

#26

Look at the video again. It's a dyno dynamic dyno which reads from the rear axle. Personally I too am curious as to how much power is actually being put down with tires actually mounted.

#27

It will be around 415-430rwhp on a roller. I have taken many cars from this dyno to rollers and depending on which shop I go to, most read 2-5% higher. And one place reads pretty much identical.

#31

Did you do the exhaust and intake adjustments at the same time or did you separate them to see where your gains where? I bet you'll get even better results if you furture radius those throttles body at the top and or fab up some velocity stacks for your PP throttle bodies. Smoothing the air flow entry will always help things. I've personally made my own out of fiberglass and bondo.  It's great that your reaching your peak at a lower rpm range.

It's great that your reaching your peak at a lower rpm range.

It's great that your reaching your peak at a lower rpm range.

It's great that your reaching your peak at a lower rpm range.

#32

Did you do the exhaust and intake adjustments at the same time or did you separate them to see where your gains where? I bet you'll get even better results if you furture radius those throttles body at the top and or fab up some velocity stacks for your PP throttle bodies. Smoothing the air flow entry will always help things. I've personally made my own out of fiberglass and bondo.  It's great that your reaching your peak at a lower rpm range.

It's great that your reaching your peak at a lower rpm range.

It's great that your reaching your peak at a lower rpm range.

It's great that your reaching your peak at a lower rpm range.

#34

Its mechanical. After half throttle there is a aux cable that pulls open the p-port throttle bodies. I was going to make it come on at a certain rpm. But after testing, the p-ports did not remove any torque open at any rpm. So it was just added complexity and a point of failure using electronic devices. The injectors on the p-ports however are ran by the electromotive, and come on at low vaccum to 0 vaccum.

#35

do u think it would benefit a stock port motor?

does it reduce the overall height of the motor vs stock intake? (my bonnet doesn't quite close at the moment)

how impossible is it to tune yourself using a PS2k using only TPS input since ITBs have no vacuume?

and finally of course.. whats the damage gonna cost :p

#36

That depends,

do u think it would benefit a stock port motor?

does it reduce the overall height of the motor vs stock intake? (my bonnet doesn't quite close at the moment)

how impossible is it to tune yourself using a PS2k using only TPS input since ITBs have no vacuume?

and finally of course.. whats the damage gonna cost :p

do u think it would benefit a stock port motor?

does it reduce the overall height of the motor vs stock intake? (my bonnet doesn't quite close at the moment)

how impossible is it to tune yourself using a PS2k using only TPS input since ITBs have no vacuume?

and finally of course.. whats the damage gonna cost :p

- $1990.00

- $1990.00

#37

Benefit a stock port motor..... yes. Reduce overall height..... yes, a good amount. How impossible to tune.... not impossible. The ITB's I have ran had plenty of vacuum to use a MAP based system. But if you want to tune TPS that isn't difficult either. Damage... a good amount  - $1990.00

- $1990.00

- $1990.00

- $1990.00do u make the long runners the wrap up and over the motor? or are they shorties that point straight up like a carb setup?

2k cover everthing u need to install? or is there something extra?

are the injectors stand off? any more info?

(sorry I realized I'm shitting on ur thread, make a new thread? switch to PM? or leave it here?)

thanks

#38

vacuume really? that's good news.. I always thought they pulled zero vacuume and were tough to tune... i'm glad to hear that

do u make the long runners the wrap up and over the motor? or are they shorties that point straight up like a carb setup?

2k cover everthing u need to install? or is there something extra?

are the injectors stand off? any more info?

(sorry I realized I'm shitting on ur thread, make a new thread? switch to PM? or leave it here?)

thanks

do u make the long runners the wrap up and over the motor? or are they shorties that point straight up like a carb setup?

2k cover everthing u need to install? or is there something extra?

are the injectors stand off? any more info?

(sorry I realized I'm shitting on ur thread, make a new thread? switch to PM? or leave it here?)

thanks

It wraps over the engine, so the ITB's will be on top. 1990 will be everything except the injectors. Price may vary a little depending on material and machining costs. Setup for the standard metric top feed injectors. Just like the FC and 20b use for secondaries. Can be made for american o-ring if requested. You will have to fit a TPS as well.

It wraps over the engine, so the ITB's will be on top. 1990 will be everything except the injectors. Price may vary a little depending on material and machining costs. Setup for the standard metric top feed injectors. Just like the FC and 20b use for secondaries. Can be made for american o-ring if requested. You will have to fit a TPS as well.

#39

This is what I do testing for, to manufacture and sell products  It wraps over the engine, so the ITB's will be on top. 1990 will be everything except the injectors. Price may vary a little depending on material and machining costs. Setup for the standard metric top feed injectors. Just like the FC and 20b use for secondaries. Can be made for american o-ring if requested. You will have to fit a TPS as well.

It wraps over the engine, so the ITB's will be on top. 1990 will be everything except the injectors. Price may vary a little depending on material and machining costs. Setup for the standard metric top feed injectors. Just like the FC and 20b use for secondaries. Can be made for american o-ring if requested. You will have to fit a TPS as well.

It wraps over the engine, so the ITB's will be on top. 1990 will be everything except the injectors. Price may vary a little depending on material and machining costs. Setup for the standard metric top feed injectors. Just like the FC and 20b use for secondaries. Can be made for american o-ring if requested. You will have to fit a TPS as well.

It wraps over the engine, so the ITB's will be on top. 1990 will be everything except the injectors. Price may vary a little depending on material and machining costs. Setup for the standard metric top feed injectors. Just like the FC and 20b use for secondaries. Can be made for american o-ring if requested. You will have to fit a TPS as well.have you made any before? would I be able to put a box around it? (i live in a dusty dessert climate)

do you have any pics?

you've caught my interest...

#41

Logan can better answer this question...

#42

Blast from the past

Using the old method

Using the old method

#43

Like Chris said, most likely you will spend a little more. But it really depends on what goals you have in mind. Once you have a semi p-port setup and ITB's with a custom header, the cost is going to be higher than just tossing in a stock port 20b with the stock intake, and making a quick steel header for it.

#45

Yeah I keep going back and forth on mine. Should I boost it or shouldnt I? You don't need a lot of power in a 1st gen but I doubt I'll make my power goal of 300 with streetports and stock rotors+ stock intake manifolds and a quick steel header.

It's an early engine #756 so what can I do with it? Keep it NA? Or go for the gusto and get the same cheap turbo stevesimon got from cxracing and keep the boost low. Kinda wish I didn't port it now if it's boosted.

I wonder how much power an early engine can really take before the shaft or one of the plates lets go. 350? 400?

It's an early engine #756 so what can I do with it? Keep it NA? Or go for the gusto and get the same cheap turbo stevesimon got from cxracing and keep the boost low. Kinda wish I didn't port it now if it's boosted.

I wonder how much power an early engine can really take before the shaft or one of the plates lets go. 350? 400?

#46

Yeah I keep going back and forth on mine. Should I boost it or shouldnt I? You don't need a lot of power in a 1st gen but I doubt I'll make my power goal of 300 with streetports and stock rotors+ stock intake manifolds and a quick steel header.

It's an early engine #756 so what can I do with it? Keep it NA? Or go for the gusto and get the same cheap turbo stevesimon got from cxracing and keep the boost low. Kinda wish I didn't port it now if it's boosted.

I wonder how much power an early engine can really take before the shaft or one of the plates lets go. 350? 400?

It's an early engine #756 so what can I do with it? Keep it NA? Or go for the gusto and get the same cheap turbo stevesimon got from cxracing and keep the boost low. Kinda wish I didn't port it now if it's boosted.

I wonder how much power an early engine can really take before the shaft or one of the plates lets go. 350? 400?

#47

When is the last time I heard of one failing as the result of shear power (no pun intended)? Never in recent memory. The only shaft related problems that come to mind were mentioned by Zero R about storing the shaft incorrectly, causing it to bend. Whether over time or immediatly as soon as you lay it down on its side, I don't know.

That threw up a red flag. Honestly, how can a robust, well engineered piece of steel bend over time just lying on its side? Maybe after a thousand years but not in just a few months. He said he stores his shafts upright in a wooden fixture and says if they're stored improperly, will cause the center stationary bearing to wear prematurely which is hard to tell at first but then makes itself known after a while.

The engineer in me can't wrap his head around that one. I probably jarred the shaft a lot more just separating the front journal section (heat with BFH and crowbar method), since I don't have a puller, than anything that could happen to it just happily lying on a piece of cardboard supported at three places. Both journals and the long end are contacting the carboard with no weight on top of it anywhere. Just a plastic bag to protect it from dust.

I'm sure if my shaft survived the separation, it will be perfect to throw right back in the engine come spring time or whenever I can get back to work on it. Heck I once applied something like 600 - 800 foot pounds to a front 19mm nut that someone had locktited on a 76 Cosmo 13B. I bent a counterweight stopper (angle iron) and then decided to take a 1" hole saw and cut (drilled) around the 19mm hex allowing the flat part to relax until it could be removed by my impact wrench. I didn't have any propane or mapp gas at the time. This shaft survived and ran fine and smooth during test firing in my REPU which had hockey puck motor mounts (they let you really feel the engine). This engine is now in my rotary baja project just waiting for a few things before I can drive it.

Carlos Lopez is awesome. I talked to him a few years ago and he recognized me from my website. That was pretty cool. This is before forums really took off. Anyway you guys both have a lot more 20B experience than me, and if he's done over 500rwhp, and you say it should be safe if properly tuned, then 500 is my new goal. I was just going on what everyone around here (this forum) says about the early engines; they're weak, only run them NA or low boost etc.

I was just going on what everyone around here (this forum) says about the early engines; they're weak, only run them NA or low boost etc.

You know, with my port job, I think 500 will be achievable at 14psi. The ports look like a Judge Ito/Rice Racing/Blake Qualley job. Similar closing shape and similar opening timing. I could close them a little later like a typical Judge Ito/Rice Racing port, but with boost, the power is in the turbo and not so much just in the ports. Blake was doing a lot more NA work, but mine open similar to his and Rice's at 11.3mm (primary) and 10.9mm (secondary) from the coolant seal groove.

Thanks. Your post has really helped me out.

That threw up a red flag. Honestly, how can a robust, well engineered piece of steel bend over time just lying on its side? Maybe after a thousand years but not in just a few months. He said he stores his shafts upright in a wooden fixture and says if they're stored improperly, will cause the center stationary bearing to wear prematurely which is hard to tell at first but then makes itself known after a while.

The engineer in me can't wrap his head around that one. I probably jarred the shaft a lot more just separating the front journal section (heat with BFH and crowbar method), since I don't have a puller, than anything that could happen to it just happily lying on a piece of cardboard supported at three places. Both journals and the long end are contacting the carboard with no weight on top of it anywhere. Just a plastic bag to protect it from dust.

I'm sure if my shaft survived the separation, it will be perfect to throw right back in the engine come spring time or whenever I can get back to work on it. Heck I once applied something like 600 - 800 foot pounds to a front 19mm nut that someone had locktited on a 76 Cosmo 13B. I bent a counterweight stopper (angle iron) and then decided to take a 1" hole saw and cut (drilled) around the 19mm hex allowing the flat part to relax until it could be removed by my impact wrench. I didn't have any propane or mapp gas at the time. This shaft survived and ran fine and smooth during test firing in my REPU which had hockey puck motor mounts (they let you really feel the engine). This engine is now in my rotary baja project just waiting for a few things before I can drive it.

Carlos Lopez is awesome. I talked to him a few years ago and he recognized me from my website. That was pretty cool. This is before forums really took off. Anyway you guys both have a lot more 20B experience than me, and if he's done over 500rwhp, and you say it should be safe if properly tuned, then 500 is my new goal.

I was just going on what everyone around here (this forum) says about the early engines; they're weak, only run them NA or low boost etc.

I was just going on what everyone around here (this forum) says about the early engines; they're weak, only run them NA or low boost etc.You know, with my port job, I think 500 will be achievable at 14psi. The ports look like a Judge Ito/Rice Racing/Blake Qualley job. Similar closing shape and similar opening timing. I could close them a little later like a typical Judge Ito/Rice Racing port, but with boost, the power is in the turbo and not so much just in the ports. Blake was doing a lot more NA work, but mine open similar to his and Rice's at 11.3mm (primary) and 10.9mm (secondary) from the coolant seal groove.

Thanks. Your post has really helped me out.

#48

Like Chris said, most likely you will spend a little more. But it really depends on what goals you have in mind. Once you have a semi p-port setup and ITB's with a custom header, the cost is going to be higher than just tossing in a stock port 20b with the stock intake, and making a quick steel header for it.

I agree here, that's why I am so interested. For my build, I am still up in the air on a 20b versus a built LS7 (hide's behind computer screen to dodge flying tomatoes). For around 20k I can get a Katech built LS7 with about 550rwhp and 500rwtq, but it just doesn't have the uniqueness, killer sound and high-rev fun as a 10k rpm n/a 20b. While the rwhp of this killer n/a 20b posted here is nice, the rwtq is only about half of a good LS7 setup. Not to make this a versus thread, but it's a hard decision!

#49

^ The N/A 20B is honestly just something you have to want, all for illogical reasons. Dollar for dollar, you aren't going to even come close to the LSx engine for power output. Logan and others have made incredible progress lately on this front, but as we all know 450-500whp from even an LS1 is only a cam and heads upgrade away. As you said, the sound, feel and uniqueness of the 20B is what lures the few of us in, but in racing and to be financially sane, none of that really matters.

#50

Aren't all rotaries fuel injected? With FI I mean forced induction.

For my build I am looking to go no higher than 20-25k for the engine. A forced induction 20b would barely squeak in there if built by a shop. If a n/a 20b costs even more, it would cost too much for me.

I agree here, that's why I am so interested. For my build, I am still up in the air on a 20b versus a built LS7 (hide's behind computer screen to dodge flying tomatoes). For around 20k I can get a Katech built LS7 with about 550rwhp and 500rwtq, but it just doesn't have the uniqueness, killer sound and high-rev fun as a 10k rpm n/a 20b. While the rwhp of this killer n/a 20b posted here is nice, the rwtq is only about half of a good LS7 setup. Not to make this a versus thread, but it's a hard decision!

For my build I am looking to go no higher than 20-25k for the engine. A forced induction 20b would barely squeak in there if built by a shop. If a n/a 20b costs even more, it would cost too much for me.

I agree here, that's why I am so interested. For my build, I am still up in the air on a 20b versus a built LS7 (hide's behind computer screen to dodge flying tomatoes). For around 20k I can get a Katech built LS7 with about 550rwhp and 500rwtq, but it just doesn't have the uniqueness, killer sound and high-rev fun as a 10k rpm n/a 20b. While the rwhp of this killer n/a 20b posted here is nice, the rwtq is only about half of a good LS7 setup. Not to make this a versus thread, but it's a hard decision!

and then give me a ride damn-it! lol

and then give me a ride damn-it! lol

Last edited by GtoRx7.; 11-28-10 at 01:45 AM.