CMonakar Mandeville 20B GT42R Project

#1

CMonakar Mandeville 20B GT42R Project

As most of you already know I've been working on a 20b swap for the last 2 years. Since the car is getting close to done I figured it was time to post some information.

Chassis

-93 black touring

-New firewall/tunnel layout constructed with chrome alloy and seam welded

-Custom X brace subframe

-The drivetrain has been moved back 6.8" and down 1" compared to the FD.

-The entire shell was stripped to the bare metal and is being repainted black with Eikkens paint and lots and lots of polish work

-Stock red interior

-OEM 99 front bumper and rebar, Type RS wheels, steering wheel, rear lights.

-94 dash with pas side airbag (because I care )

)

Motor

-Low mileage D-series core modified by Mandeville

-Large street port

-Dynamically balanced rotating assembly

-Modified bearings

-Modified oil pump

-Custom 55mm oil pan with RX8 oil level sensor (Installed by GTORX7)

-Blue printed with the all part specs and condition logged

-New rear iron

Turbo

-102mm GT42R with 1.15 T6 exhaust (ceramic coated)

-V-band compressor outlet

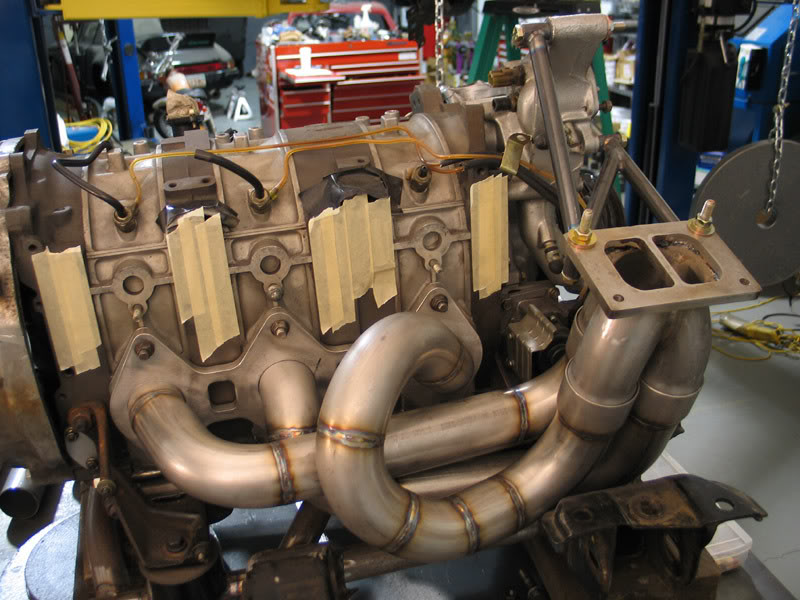

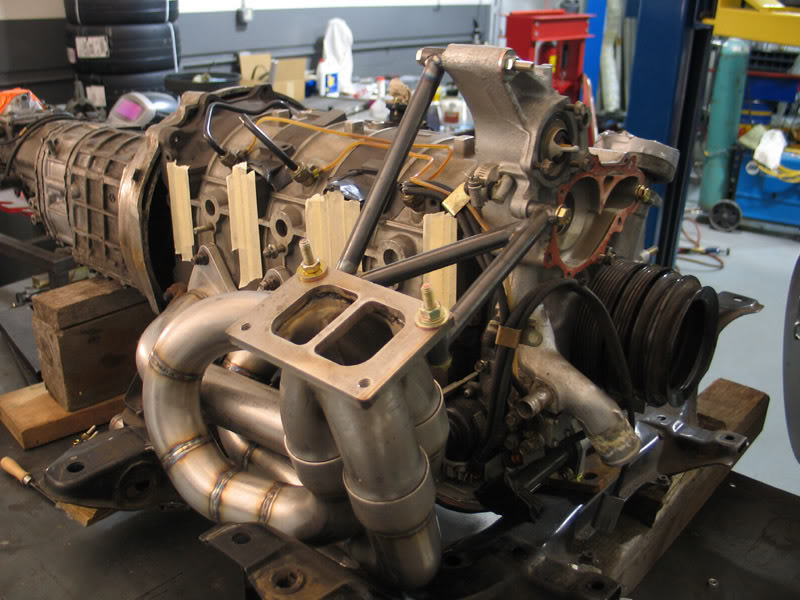

Turbo Manifold

-Custom built nearly equal length

-321 stainless tubing & flanges

-Custom Burns Stainless double slip fit collector

-3 egt bungs

-Ceramic coated

Wastegate

-HKS GTII 60mm v-band wastegate with the world's most expensive dump tube routed back into the exhaust system

exhaust

-4" stainless tubing purchased from Wolf Aircraft.

-Hollow stainless steel exhaust hangers and mounting brackets

-Full v-band system

-Ceramic coated downpipe

Fuel System

-83lb primaries injectors

-160lb secondary injectors

-New stock injector diffusers

-KGParts polished primary and secondary rails

-Twin -6AN feed lines (to be installed)

-Twin Earls in-line filters

-Twin supra TT pumps

-Milspec fuel tank cap electrical connection with heavy duty pump wiring.

-SX regulator

ECU

-Pectel SQ6 with 20A on board coil drivers, traction control, boost control, 2 built in widebands, 2 built in K-series TC amps, driveby wire ready, *stepper motor control in development. Motorola MPC565 56MHz processor

-Pi Research Toolbox datalogging software

-60-2 timing wheel, 5/8" Motec Mag sensor all run by the SQ6's FPGA for true real-time position detection.

-034 Motorsports proprietary inductive ignition coils

Drivetrain

-Custom chrome alloy driveshaft with rebuildable joints

-Custom machined gear selector shaft linkage (90% complete)

TBD/Pending

-IC/Radiator: something different that I have been working on.

-Clutch/FW: Carbonetic full face carbon twinplate

-Oil Coolers: Yes

-Custom filter relocation adaptor

-Pettit Flares/more rubber: Couldn't bring myself to have the body shop cut the rear 1/4s, but I may revisit that after I get the car on the road.

-20b 5/8" timing sensor bracket

-Additional insurance coverage

-Earplugs

-Bankruptcy

Chassis

-93 black touring

-New firewall/tunnel layout constructed with chrome alloy and seam welded

-Custom X brace subframe

-The drivetrain has been moved back 6.8" and down 1" compared to the FD.

-The entire shell was stripped to the bare metal and is being repainted black with Eikkens paint and lots and lots of polish work

-Stock red interior

-OEM 99 front bumper and rebar, Type RS wheels, steering wheel, rear lights.

-94 dash with pas side airbag (because I care

)

)Motor

-Low mileage D-series core modified by Mandeville

-Large street port

-Dynamically balanced rotating assembly

-Modified bearings

-Modified oil pump

-Custom 55mm oil pan with RX8 oil level sensor (Installed by GTORX7)

-Blue printed with the all part specs and condition logged

-New rear iron

Turbo

-102mm GT42R with 1.15 T6 exhaust (ceramic coated)

-V-band compressor outlet

Turbo Manifold

-Custom built nearly equal length

-321 stainless tubing & flanges

-Custom Burns Stainless double slip fit collector

-3 egt bungs

-Ceramic coated

Wastegate

-HKS GTII 60mm v-band wastegate with the world's most expensive dump tube routed back into the exhaust system

exhaust

-4" stainless tubing purchased from Wolf Aircraft.

-Hollow stainless steel exhaust hangers and mounting brackets

-Full v-band system

-Ceramic coated downpipe

Fuel System

-83lb primaries injectors

-160lb secondary injectors

-New stock injector diffusers

-KGParts polished primary and secondary rails

-Twin -6AN feed lines (to be installed)

-Twin Earls in-line filters

-Twin supra TT pumps

-Milspec fuel tank cap electrical connection with heavy duty pump wiring.

-SX regulator

ECU

-Pectel SQ6 with 20A on board coil drivers, traction control, boost control, 2 built in widebands, 2 built in K-series TC amps, driveby wire ready, *stepper motor control in development. Motorola MPC565 56MHz processor

-Pi Research Toolbox datalogging software

-60-2 timing wheel, 5/8" Motec Mag sensor all run by the SQ6's FPGA for true real-time position detection.

-034 Motorsports proprietary inductive ignition coils

Drivetrain

-Custom chrome alloy driveshaft with rebuildable joints

-Custom machined gear selector shaft linkage (90% complete)

TBD/Pending

-IC/Radiator: something different that I have been working on.

-Clutch/FW: Carbonetic full face carbon twinplate

-Oil Coolers: Yes

-Custom filter relocation adaptor

-Pettit Flares/more rubber: Couldn't bring myself to have the body shop cut the rear 1/4s, but I may revisit that after I get the car on the road.

-20b 5/8" timing sensor bracket

-Additional insurance coverage

-Earplugs

-Bankruptcy

Last edited by CMonakar; 11-29-06 at 10:07 PM.

#4

Thanks. The car is in Charlotte, but may spend some time up north this spring. I am going to tune it. However, if I was going to hire someone to tune it Neel would be my first choice. I have been working with him and Pectel for several months to setup a rotary-compatible profile for the SQ6. He has a tremendous amount of experience tuning everything from Moto GP bikes to powerboats, and a strong understanding of the theory behind it all. I believe my car will be the first rotary to use the SQ6. I think it's a great alternative to the Motec M800.

#5

thats awsome...from what I have seen of the pectel it looks very nice good to see someone trying new stuff. I was just curious about neel since he did all the data for a GA team I used to work for and was curious if he was going to try his hand at the triangle .

.

what are your plans for the car?

.

.what are your plans for the car?

#7

I replaced the original hot side with one that has a 4" outlet. The compressor outlet size for both is the same size.

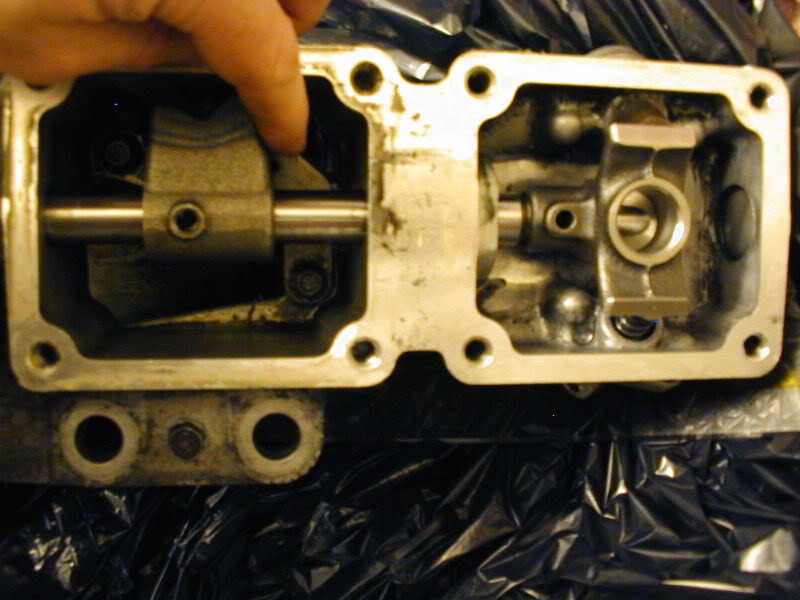

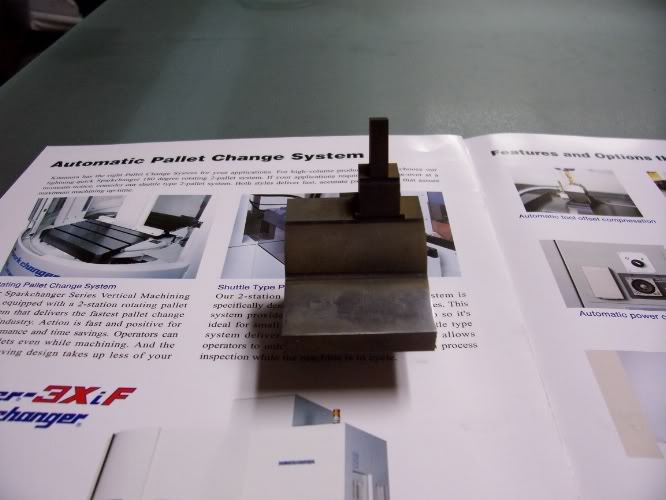

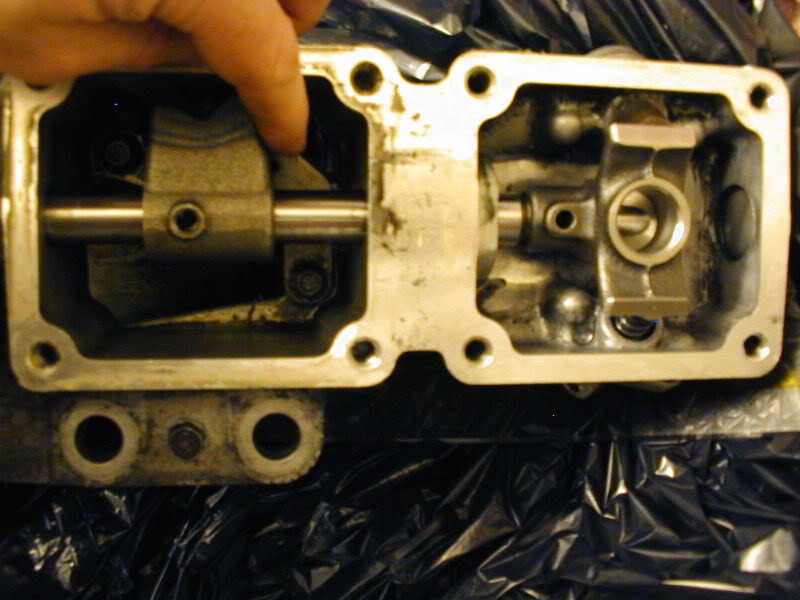

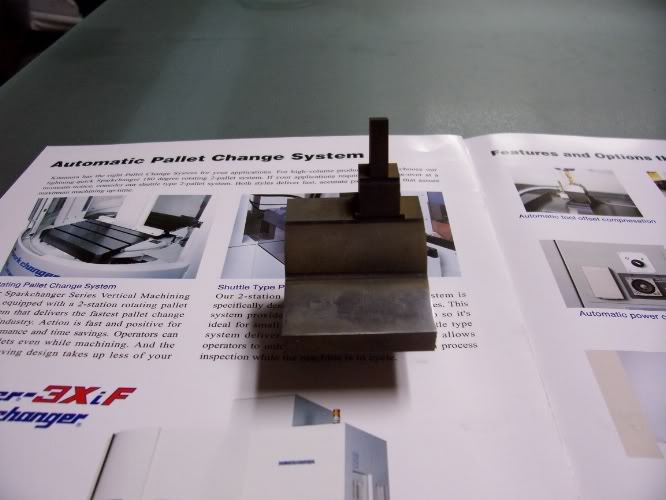

Re. the gearbox mod, we created a linkage that would allow the shifter to be mounted in the front window and repositioning the shifter further forward in the window by reversing the top cap.

There a single shaft running through both windows. The linkage in the rear window serves two purposes (1) gear selection (2) centers the shifter (that's what the wings and pistons are for). The linkage in the front window is connected to the reverse lockout (3).

To preserve all 3 functions a custom linkage part had to be created that accomplished (1) and (3). The stock shifter linkage will be retained in the rear window to take care of (2). The shaft diameter in the front window is slightly larger than the rear window. We tried to keep the height of where the shifter connects to the shaft as close to stock as possible. The end result is that the shifter is about 1" further back than with the stock drivetrain.

Here is a shot of the work in progress:

The part should be done any day now.

Re. the gearbox mod, we created a linkage that would allow the shifter to be mounted in the front window and repositioning the shifter further forward in the window by reversing the top cap.

There a single shaft running through both windows. The linkage in the rear window serves two purposes (1) gear selection (2) centers the shifter (that's what the wings and pistons are for). The linkage in the front window is connected to the reverse lockout (3).

To preserve all 3 functions a custom linkage part had to be created that accomplished (1) and (3). The stock shifter linkage will be retained in the rear window to take care of (2). The shaft diameter in the front window is slightly larger than the rear window. We tried to keep the height of where the shifter connects to the shaft as close to stock as possible. The end result is that the shifter is about 1" further back than with the stock drivetrain.

Here is a shot of the work in progress:

The part should be done any day now.

Trending Topics

#8

Are you planning on some slick way to integrate the 3 EGT sensors into the 2 ECU inputs, use a selector switch, or average the three sensor outputs into one ECU input? Or, are you just going to forget the fancy stuff and simply hook the EGT senors up to 3 gauges and/or 3 ECU aux inputs?

Please elaborate on the wastegate dump tube.

Please elaborate on the wastegate dump tube.

#11

Originally Posted by Evil Aviator

Are you planning on some slick way to integrate the 3 EGT sensors into the 2 ECU inputs, use a selector switch, or average the three sensor outputs into one ECU input? Or, are you just going to forget the fancy stuff and simply hook the EGT sensors up to 3 gauges and/or 3 ECU aux inputs?

The manifold was built based on my specs and general layout for the runners. Because the turbo weighs 40lbs we added a mini Chrome alloy control style bracket to support it independently of the runners using the air pump mounting points. FYI the manifold weighs 19lbs and the 60mm wastegate is 4.5. Grand total =63.5lbs

Please elaborate on the wastegate dump tube.

One of the biggest challenges of this project was finding room for everything. Unless you see it in person it is hard to appreciate how much energy went into not compromising function while still making everything fit. No matter where you look on the hot side of the motor there is something else within .5"

-subframe to runners (they come down very low)

-dump tube to frame rail

-turbo to chassis (had to reverse box part of the frame rail)

-turbo to motor

-downpipe to firewall

-downpipe to motor mount (had to cut the mount bracket and drop the height of the motor to create enough space for the downpipe to pass between it and the firewall.

-front runner and oil metering pump

-turbo and hood.

The one notable exception is the distance between the downpipe/turbine housing and the intake manifold.

The further along the project went the more limited the options became. Eg, dropping the motor another .5" would have made it easier to fit the downpipe, but then the front runner would be dangerously close to the subframe. We could cut the mount down and tilt the motor back, but then intake manifold would make contact with the firewall. If we twisted the motor a few degrees the turbo made contact with the pas side fender. If we pushed the entire motor further to the driver side the transmission made contact with the tunnel (remember the tunnel gets narrower as it goes back and the gearbox has been moved 6"+) . . .

#12

^ God Damn nice header!!

hey if your intersted I am making some k-type T/C amps as we speak, I bought enough stuff to make three incase i screwed one up and well as long as i don't screw one up you can buy the third for cost ( around $30) in a couple weeks when i get them built and tested.... I just hate to see someone pay Motec they're super stupid inflated prices

or go here http://www.simplecircuitboards.com/Thermocouples.html same thing i'm building

hey if your intersted I am making some k-type T/C amps as we speak, I bought enough stuff to make three incase i screwed one up and well as long as i don't screw one up you can buy the third for cost ( around $30) in a couple weeks when i get them built and tested.... I just hate to see someone pay Motec they're super stupid inflated prices

or go here http://www.simplecircuitboards.com/Thermocouples.html same thing i'm building

#14

Originally Posted by rarson

Just curious, why are you using a divided turbine housing?

Originally Posted by sereneseven

sereneseven ^ God Damn nice header!! hey if your intersted I am making some k-type T/C amps as we speak, I bought enough stuff to make three incase i screwed one up and well as long as i don't screw one up you can buy the third for cost ( around $30) in a couple weeks when i get them built and tested.... I just hate to see someone pay Motec they're super stupid inflated prices

or go here http://www.simplecircuitboards.com/Thermocouples.html same thing i'm building

or go here http://www.simplecircuitboards.com/Thermocouples.html same thing i'm building

#15

CMonakar, I completely understand what you went through with your header, I had all the same issues. My solution as fas as the wastegate dump was to just vent it to atmosphere. I also have a 1.15 but I went ahead and removed the divider. I also used Iconel to build my header. Here are some pics of the header off the car waiting to be shipped the HPC to be termal coated along with the downpipe, wastegate and exhaust housing. Sorry about the quality pics where taken with my cell

#16

Originally Posted by CMonakar

I believe it can even be configured to trim fuel/ignition to the rotors individually based on the each sensor.

Originally Posted by CMonakar

I wasn't happy with that answer, so I hired a new one and he managed to prove the other guy wrong.

Originally Posted by CMonakar

The manifold was built based on my specs and general layout for the runners.

#18

Awesome project! It's hard to even imagine the amount of work you've put into your car and this design.

Just a few quick questions though: Regarding your secondary fuel rail, does KG Parts sell 20B rails that fit with top feed injectors? Was this a custom order or will I also be able to place one? Finally, how much was the cost for only the secondary rail?

I'd like to run 1680cc Injectors on my setup as well and right now I'm trying to figure out where I can purchase a rail that will work. I would definitely prefer to purchase a rail already made, otherwise I will have to go the custom route = expensive route .

.

Let me know please.

Thanks,

Rizwan

Just a few quick questions though: Regarding your secondary fuel rail, does KG Parts sell 20B rails that fit with top feed injectors? Was this a custom order or will I also be able to place one? Finally, how much was the cost for only the secondary rail?

I'd like to run 1680cc Injectors on my setup as well and right now I'm trying to figure out where I can purchase a rail that will work. I would definitely prefer to purchase a rail already made, otherwise I will have to go the custom route = expensive route

.

.Let me know please.

Thanks,

Rizwan

#20

Nice progress CC.

Just a few quick questions though: Regarding your secondary fuel rail, does KG Parts sell 20B rails that fit with top feed injectors? Was this a custom order or will I also be able to place one? Finally, how much was the cost for only the secondary rail?

I'd like to run 1680cc Injectors on my setup as well and right now I'm trying to figure out where I can purchase a rail that will work.

Yes they are available. Currently redesigning the primary mounts, but should be done by the end of the week. (CC actually informed me of a small imperfection once installing.) We didnt have the problem on Tom's local 20B car, but the new design should fix Chris's problem.

**If anyone has the old primary brackets and has/had trouble, DO NOT Hesitate to contact us for a trade/replacement set for no charge.

Chris, yours will be in the mail ASAP.

Originally Posted by str8ryd

Just a few quick questions though: Regarding your secondary fuel rail, does KG Parts sell 20B rails that fit with top feed injectors? Was this a custom order or will I also be able to place one? Finally, how much was the cost for only the secondary rail?

I'd like to run 1680cc Injectors on my setup as well and right now I'm trying to figure out where I can purchase a rail that will work.

**If anyone has the old primary brackets and has/had trouble, DO NOT Hesitate to contact us for a trade/replacement set for no charge.

Chris, yours will be in the mail ASAP.

#23

Originally Posted by Evil Aviator

I have seen lesser roll cages posted on this forum.

Too funny.

Too funny.

Originally Posted by rxrotary2_7

Nice progress CC.

Here's a shot of Keith's rails after I spent the better part of a day sanding and polishing them.

I don't think I will pick up another piece of sand paper for a few years. I'm not sure what I am going to do with the manifold yet. A red crackle finish with polished letters and a polished TB might look neat . . .

I ordered a Carbonetic (http://www.carbonetic.net/)twin plate full face carbon clutch from TitanMotorsports (http://www.titanmotorsports.com/)today. It cost as much as the reman I bought a few years ago for the 2-rotor did

. I wanted something that was as light as possible, relatively streetable, and could hold 600+ rwhp. I'm still having trouble getting over the price, but I think it will prove to be a good choice.

. I wanted something that was as light as possible, relatively streetable, and could hold 600+ rwhp. I'm still having trouble getting over the price, but I think it will prove to be a good choice.

Last edited by CMonakar; 12-05-06 at 06:56 PM.

#24

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

Damn Chris, those fuel rails look friggin' great. Maybe I am sending my stuff to the wrong place to be polished......do you work for the labor wages of a typical third world country  ?

?

?

?