Wheel stuck on hub - Ideas?

#1

Wheel stuck on hub - Ideas?

This is probably an easy one, but I have an '81 GSL (stock alloys) that the PO stored outside for a few years. The rear drivers wheel is stuck on the hub (yes- all wheel studs removed). The rear passengers wheel came off easily. There is a little surface rust on the hub, but not bad. I've tried WD40, pulling and smacking with a hammer. My next attempt will be to gently lower the floor jack to put a little pressure on the wheel and maybe break it free from the hub. I'm sure somebody has a better way. Ideas?

#2

Sit on your butt and kick it on one side, then on the other. If that doesn't do it, you'll have to get creative.

I had one car that was so bad, I had to put a jack on the inside of the opposite wheel and run a 2x4 to the other wheel. Then I "raised" the jack to press the wheel off.

I had one car that was so bad, I had to put a jack on the inside of the opposite wheel and run a 2x4 to the other wheel. Then I "raised" the jack to press the wheel off.

#3

put the studs on kinda tight and drive the car lol, back your car out of your driveway that normally works XD. Uhm hit the tires with a sledgehammer (don't hit your rim) and other than that im not sure

#4

DO NOT hit the tire with a sledgehammer..it can bounce back and hit you, someone or something else. sit on your butt, put your hands on the ground for support and kick the tire on the left or right side and alternate sides. usually will break free in one or two kicks. the wheels, being aluminum, oxidize to the steel brake rotor and bond slightly due to the oxidation. once the wheel is off, clean the rotor hub area where the wheel sits witha wire wheel and do the same on the hub portion of the wheel.

#5

DO NOT hit the tire with a sledgehammer..it can bounce back and hit you, someone or something else. sit on your butt, put your hands on the ground for support and kick the tire on the left or right side and alternate sides. usually will break free in one or two kicks. the wheels, being aluminum, oxidize to the steel brake rotor and bond slightly due to the oxidation. once the wheel is off, clean the rotor hub area where the wheel sits witha wire wheel and do the same on the hub portion of the wheel.

#6

sit and kick either side of the tire. rotate the tire and kick more. if this doesn't work, put on the lugs *almost* tight, and rev/dump the clutch (very quick dump, squawk the tires for <1 sec, depress clutch pedal). It should only take one dump for the parts to free themselves.

#7

Thanks for the input. Unfortunately, driving it is out of the question since I'm in the middle of a full brake job, so I'll try to kick the snot out of it tonight! I'll let you guys know what happens.

Trending Topics

#8

rubber mallet on the rim, not on the tire. it won't damage the aluminum, and it should help breaking it free.

#10

raise the rear end enough where you can easily reach the backside of the wheel, use a piece of 2x4 or something and put one end against the inside of the wheel and hit the other end as hard as **** with a mallet or something. just make sure you use wood or something else so you don't bend your wheels.

#13

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,196

Likes: 2,825

From: https://www2.mazda.com/en/100th/

i like kenetsu's idea. i would put a stud or two back on loosely though so when it does pop off the car doesnt end up on the ground.

also when you do get it apart, make sure to smear some grease on the hub

also when you do get it apart, make sure to smear some grease on the hub

#15

Alright, here are the results. Since so many people contributed, I decided to try a few different methods:

1. Lightly threaded wheel stud and smacked with hammer.

2. Hit the rim with heavy rubber mallet.

3. Put my a$$ kicking boots on, sat down in front of the wheel, and kicked the $hit out of it

It's not exactly the scientific method, but by far the best method after a stressful day at work. Thanks again to everyone who responded so quickly. This board has been a great asset for me, from little stuff like this to the big stuff. Cheers.

1. Lightly threaded wheel stud and smacked with hammer.

2. Hit the rim with heavy rubber mallet.

3. Put my a$$ kicking boots on, sat down in front of the wheel, and kicked the $hit out of it

It's not exactly the scientific method, but by far the best method after a stressful day at work. Thanks again to everyone who responded so quickly. This board has been a great asset for me, from little stuff like this to the big stuff. Cheers.

#16

thanks for saying what worked, cuz i have the same problem, tried to pry it with a steel rod, mallet, wd40 everything you cann imagine and that son of a gun has not budged. will try the sit on your *** and kick the hell out of it. thanks

#18

I have a rotary addiction

iTrader: (18)

Joined: Jun 2006

Posts: 4,815

Likes: 24

From: Columbia, Tennessee

Put 4 lug nuts bak on the wheel, but do not tighten them. Keep them turned out a couple turns. Have someone else hold a bock of wood across the entire inside of the wheel to make an insulator between the hammer and wheel. Beat the block of wood with a sledge hammer as hard as you can. With the block of wood on you will not bend the rim of the wheel. With the lug nuts loosely installed the wheel will not fly off.

I did this to a 79 in the junkyard.

I did this to a 79 in the junkyard.

#21

Rear wheels and calipers are off, but the rotors are stuck (they spin freely, but won't come off the hub). Any tricks to getting the rear rotors off (1981 GSL stock)? I didn't find anything through the search function and all the Haynes manual says is to remove the two philips head screws, which I did. Is there anything else (besides rust) holding the rotor on?

#22

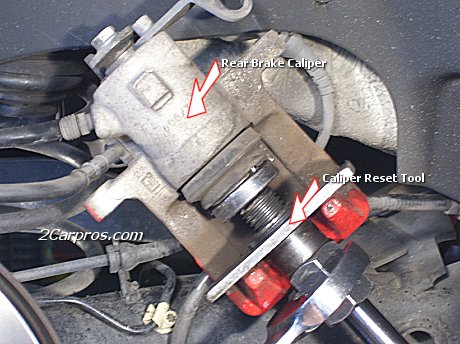

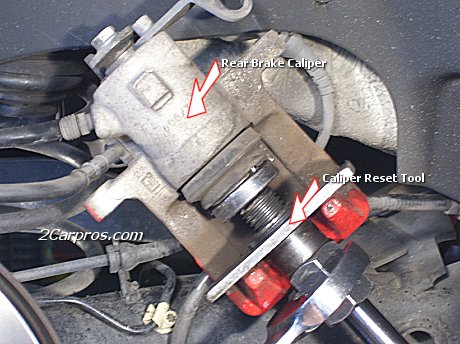

Wait a minute, an '81 with rear discs? Sounds like someone swapped an '84-85 gsl rear end in??? They were limited slip too, does it posi? As far as getting the rotor off, about all I can suggest is liberal amounts of patience and gentle tapping on the hub area, not the rotor surface, unless you are replacing the rotors. You will also need a special tool to reset the caliper, it's gotta screw back in and that 6" C clamp we all use just wont work. Then after you rotate that piston, you will need to adjust the E-brake. Also make sure the notch on the piston is rotated to match up with the bump on the pad. Clean up the hub surface and hub areas of the rotor on front and back, so that it won't glue the wheel and rotor onto the car again. Good luck and have fun.

#25

81 GSL's came standard with rear disc brakes and LSD - I think it was the first year for the rear discs and LSD. I was able to use channel locks to rotate the caliper piston without damaging the piston, although I did pick up a caliper tool for $20 that I'll try on the other side. My big problem, though, is getting the blasted rotor off the hub. (BTW, your calipers look a heck of a lot better than mine!) Thanks for the input.