Some tips on fabbing header/intake heat shield?

#1

Senior Member

Thread Starter

Join Date: Sep 2008

Location: Seattle, WA

Posts: 622

Likes: 0

Received 0 Likes

on

0 Posts

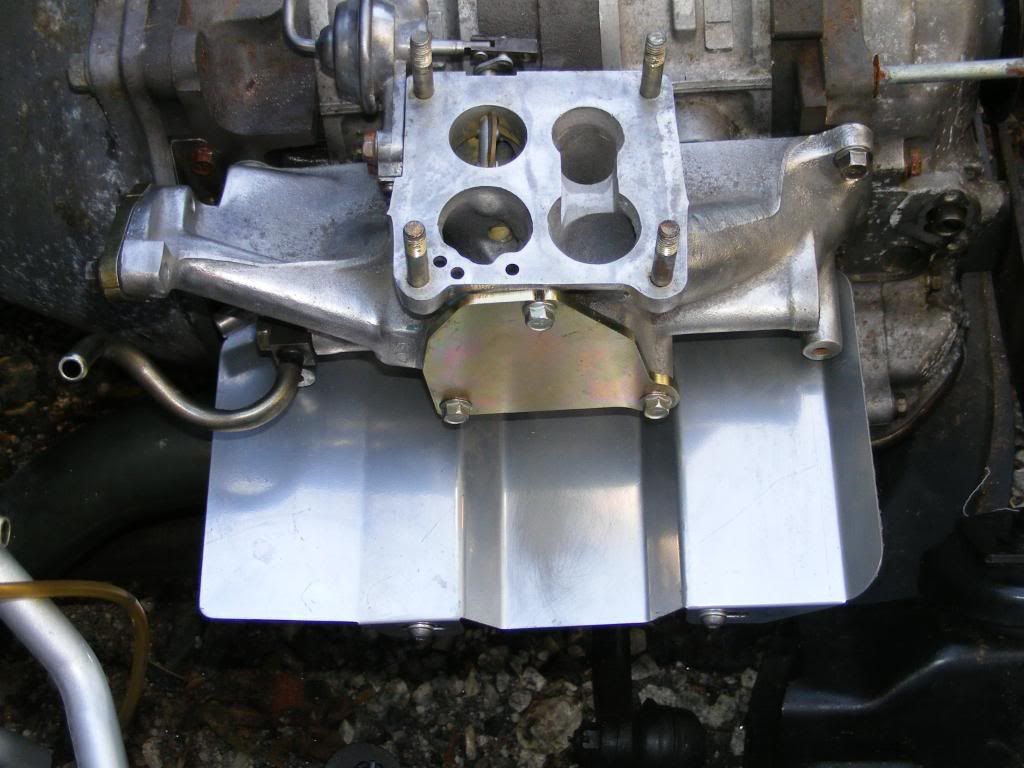

Some tips on fabbing header/intake heat shield?

What are good materials for that and how to make it most efficient? I was thinking about just bending a sheet of aluminum, but that seems kind of flimsy.

Another option is to do ceramic coating on the headers, but I don't know how effective that would be, and frankly that's not really in the budget anymore. At least for now.

Another option is to do ceramic coating on the headers, but I don't know how effective that would be, and frankly that's not really in the budget anymore. At least for now.

#2

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 31,140

Received 2,797 Likes

on

1,979 Posts

ideally you want something like steel that will block the heat and not absorb it.

back in the day we used to use steel and line it with header wrap, you can sew it on with safety wire

back in the day we used to use steel and line it with header wrap, you can sew it on with safety wire

#3

Jegs has header wrap if you wanted to wrap the header. If that doesn't drop the temp to your liking use steel for the shield, aluminum will act as a heat sink and transfer it directly to your floor.

#5

Senior Member

Thread Starter

Join Date: Sep 2008

Location: Seattle, WA

Posts: 622

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, I was thinking about how the stock shielding is aluminum. But I also think ultimately the idea is to reflect heat down to the ground, away from the intake manifold. Since the sheet of metal would be fairly thin, its conductivity might be a lesser factor. In that regard the metal itself might not even be as crucial as the surface facing the heat source. The more heat it reflects, the less it's going to heat up. Now, I'm not a physics major, so I don't really know what surface finish or coating would be most effective at that. I imagine something shiny would do a better job than something dull, but that's about it. In fact, if the side facing the intake manifold could absorb heat, that'd be even better.

As far as ceramic coating, IIRC the local place that does it coats both inside and outside. It's been a while since I've had them coat a set of headers, so I don't remember, but I think that's how it goes. Two things that concern me regarding the ceramic coating vs. heat shield are first that coating would trap the heat inside the exhaust, making the exhaust ports hotter, instead of dissipating heat away from the engine, and second that it's quite pricey.

And no, I'm not going to do header wrap.

As far as ceramic coating, IIRC the local place that does it coats both inside and outside. It's been a while since I've had them coat a set of headers, so I don't remember, but I think that's how it goes. Two things that concern me regarding the ceramic coating vs. heat shield are first that coating would trap the heat inside the exhaust, making the exhaust ports hotter, instead of dissipating heat away from the engine, and second that it's quite pricey.

And no, I'm not going to do header wrap.

#6

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 31,140

Received 2,797 Likes

on

1,979 Posts

what shields are aluminum? all of the ones around hot things are steel, with insulation

Trending Topics

#10

In that regard the metal itself might not even be as crucial as the surface facing the heat source. The more heat it reflects, the less it's going to heat up. Now, I'm not a physics major, so I don't really know what surface finish or coating would be most effective at that. I imagine something shiny would do a better job than something dull, but that's about it. In fact, if the side facing the intake manifold could absorb heat, that'd be even better.

As far as ceramic coating, IIRC the local place that does it coats both inside and outside. It's been a while since I've had them coat a set of headers, so I don't remember, but I think that's how it goes. Two things that concern me regarding the ceramic coating vs. heat shield are first that coating would trap the heat inside the exhaust, making the exhaust ports hotter, instead of dissipating heat away from the engine.

As far as ceramic coating, IIRC the local place that does it coats both inside and outside. It's been a while since I've had them coat a set of headers, so I don't remember, but I think that's how it goes. Two things that concern me regarding the ceramic coating vs. heat shield are first that coating would trap the heat inside the exhaust, making the exhaust ports hotter, instead of dissipating heat away from the engine.

The hotter one can keep the exhaust gas, the more velocity it maintains. Cooling allows the gases to expand which in turn slows them down, thus reducing hp.

Unless I'm having a major brain fart, some of the shielding is aluminum. I recall seeing both steel and aluminum shielding. Even the large insulated one over the main cat.

#12

My 7 is my girlfriend.

iTrader: (5)

Join Date: Feb 2006

Location: London, Ontario, Canada

Posts: 3,162

Likes: 0

Received 1 Like

on

1 Post

Header wrap does a great job of reducing the underhood temps. I can touch my header while the is car running with the wrap on. It's also fairly cheap. I think I payed $30 or so for the amount of wrap I used, although the shop I bought it from takes back what I don't use.

#13

Senior Member

Thread Starter

Join Date: Sep 2008

Location: Seattle, WA

Posts: 622

Likes: 0

Received 0 Likes

on

0 Posts

I think the explanation could be that in humid climates there's moisture in the air, and it would condensate on header wrap and seep through to the metal and get trapped. And since most of the time the car is off, rather than on, the header is cold and does not force the moisture to evaporate.

#14

Junior Member

Join Date: Dec 2009

Location: Central Washington

Posts: 39

Likes: 0

Received 0 Likes

on

0 Posts

84 Stock, I think you're on the right track. As I was reading this, I was thinking that you need to fab a shield from two thinner sheets of metal with an air gap between them (metal standoffs strategically placed to maintain space); but the Air Bakes did that already - brilliant!

Modded Air Bake baking sheet - now that's right thinking. What you need is an air layer between two sheets - that's what Air Bake baking sheets give you. The hot side stays hot, the cool side stays cool.

No matter what your heat shield is made of, it will absorb some heat. I believe that steel will heat soak (and stay hot), whereas aluminum will quickly dissipate it (cool quickly). Why not have that cooling air layer to interrupt heat transfer?

Modded Air Bake baking sheet - now that's right thinking. What you need is an air layer between two sheets - that's what Air Bake baking sheets give you. The hot side stays hot, the cool side stays cool.

No matter what your heat shield is made of, it will absorb some heat. I believe that steel will heat soak (and stay hot), whereas aluminum will quickly dissipate it (cool quickly). Why not have that cooling air layer to interrupt heat transfer?

#17

Senior Member

Thread Starter

Join Date: Sep 2008

Location: Seattle, WA

Posts: 622

Likes: 0

Received 0 Likes

on

0 Posts

84 Stock, I think you're on the right track. As I was reading this, I was thinking that you need to fab a shield from two thinner sheets of metal with an air gap between them (metal standoffs strategically placed to maintain space); but the Air Bakes did that already - brilliant!

Modded Air Bake baking sheet - now that's right thinking. What you need is an air layer between two sheets - that's what Air Bake baking sheets give you. The hot side stays hot, the cool side stays cool.

No matter what your heat shield is made of, it will absorb some heat. I believe that steel will heat soak (and stay hot), whereas aluminum will quickly dissipate it (cool quickly). Why not have that cooling air layer to interrupt heat transfer?

Modded Air Bake baking sheet - now that's right thinking. What you need is an air layer between two sheets - that's what Air Bake baking sheets give you. The hot side stays hot, the cool side stays cool.

No matter what your heat shield is made of, it will absorb some heat. I believe that steel will heat soak (and stay hot), whereas aluminum will quickly dissipate it (cool quickly). Why not have that cooling air layer to interrupt heat transfer?

#18

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 31,140

Received 2,797 Likes

on

1,979 Posts

#20

Senior Member

Thread Starter

Join Date: Sep 2008

Location: Seattle, WA

Posts: 622

Likes: 0

Received 0 Likes

on

0 Posts

I can't use the Re-Speed shield, because I'm running stock intake manifold with actuators and all that. Billy used to have the shield that works with stock manifold, but it's no longer available due to manufacturing costs.

Oh yeah, and further on the header wrap issue. Seems another reason that it damages headers is because it prevents metal from shedding some of the heat, and as such the header reaches much higher temperatures and corrodes and breaks down a lot quicker. Especially on rotaries and their massively hot exhaust. Naturally if moisture gets in there and causes rust, excessive heat accelerates the rusting process as well. So ultimately it's better to let the header breathe and dissipate some of that heat - that way it'll last longer.

Oh yeah, and further on the header wrap issue. Seems another reason that it damages headers is because it prevents metal from shedding some of the heat, and as such the header reaches much higher temperatures and corrodes and breaks down a lot quicker. Especially on rotaries and their massively hot exhaust. Naturally if moisture gets in there and causes rust, excessive heat accelerates the rusting process as well. So ultimately it's better to let the header breathe and dissipate some of that heat - that way it'll last longer.

Thread

Thread Starter

Forum

Replies

Last Post

Turblown

Vendor Classifieds

12

10-17-20 03:25 PM