P-port project

#1

P-port project

engine and gearbox taken out last week. perfectly working rebuilt street port motor with 173rwhp. anyone interested in following this project ? am happy to post pics of p port housings. these will be cut by a local engineering shop here in cape town, south africa and ported by my builder. my builder will also fabricate an intake manifold. he will also cut my 48IDA to 51mm. And finally i will be more than happy to share my jetting info and eventual dyno run. In terms of jets at this stage I'm thinking 46 chokes, 240 main, 110 air, F8 emulsion, 300 needle and seat to get me started. Am looking for 235rwhp, a 35% increase. am running stock flywheel, stock omp to IDA, tii gearbox and copper button clutch. Mazdatrix short shifter. custom driveshaft and stock rx7 diff.

#2

Of course you should document the build and post pics, lol. There have been a rare few in the 2nd gen section and over at NoPistons that have tried this with mixed results. Iirc, Judge Ito did a peri-port on his drag car with insane results, but it's not what one would call streetable. Scalliwag was trying to build a p-port from scratch using stock housing, but he flaked out and disappeared, taking other members money with him.

#3

Originally Posted by craigw1

engine and gearbox taken out last week. perfectly working rebuilt street port motor with 173rwhp. anyone interested in following this project ? am happy to post pics of p port housings. these will be cut by a local engineering shop here in cape town, south africa and ported by my builder. my builder will also fabricate an intake manifold. he will also cut my 48IDA to 51mm. And finally i will be more than happy to share my jetting info and eventual dyno run. In terms of jets at this stage I'm thinking 46 chokes, 240 main, 110 air, F8 emulsion, 300 needle and seat to get me started. Am looking for 235rwhp, a 35% increase. am running stock flywheel, stock omp to IDA, tii gearbox and copper button clutch. Mazdatrix short shifter. custom driveshaft and stock rx7 diff.

#4

My attempt: http://www.nopistons.com/forums/inde...&hl=Peripheral

Current home is in my racecar/garagequeen Thought about slamming it in the streetcar, but it scares me

Thought about slamming it in the streetcar, but it scares me  and everybody in a 5 mile radius

and everybody in a 5 mile radius

No that aint me in the last picture, its OC94RX7 having his way with the Bridgeport

Current home is in my racecar/garagequeen

Thought about slamming it in the streetcar, but it scares me

Thought about slamming it in the streetcar, but it scares me  and everybody in a 5 mile radius

and everybody in a 5 mile radiusNo that aint me in the last picture, its OC94RX7 having his way with the Bridgeport

#5

Originally Posted by pportnosgsl

My Peripheral Port makes 280 @ wheels racingbeat housings 51 IDA 46 chokes,230 main,don't remember off the top of my head what air bleeds or emulsion tubes,but it is very streetable,i can drive around town in 4th gear @ 2200 rpm and it purs like a kitten,no jerks or bucks.i love it.

#6

2 changes you may wish to make from your current configuration. Iirc, you're running S5 TII rotors, those should be changed out to the higher compression NA ones, and you will need to go with the carbon apex seals for the 9000+ rpm you will be running with a p-port.

Good luck with your build.

Good luck with your build.

#7

have got them carbon apex seals :-)

no na rotors available locally. but i've heard the higher comp doesn't really make that much of a difference....anyone care to post any comment on this ??

no na rotors available locally. but i've heard the higher comp doesn't really make that much of a difference....anyone care to post any comment on this ??

Trending Topics

#9

Originally Posted by trochoid

2 changes you may wish to make from your current configuration. Iirc, you're running S5 TII rotors, those should be changed out to the higher compression NA ones, and you will need to go with the carbon apex seals for the 9000+ rpm you will be running with a p-port.

Good luck with your build.

Good luck with your build.

#11

Originally Posted by pportnosgsl

My Peripheral Port makes 280 @ wheels racingbeat housings 51 IDA 46 chokes,230 main,don't remember off the top of my head what air bleeds or emulsion tubes,but it is very streetable,i can drive around town in 4th gear @ 2200 rpm and it purs like a kitten,no jerks or bucks.i love it.

#12

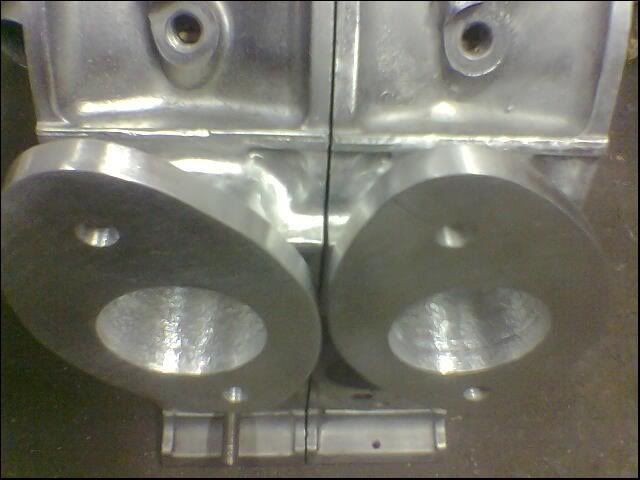

well chaps, winter has nearly passed and we've been working away. September 1 is start of spring here and I intend to get the baby running shortly. The carb has been cut to 51mm and just needs to be re assembled. The housings have been sleeved and have now been ported. The metal bits have arrived for the intake manifold and that will now be made up. Here is a pic of the two housings side by side. Its taken from the inside of the housings. The one on the left is as it was received from the machine shop with the sleeve. The one on the right is when it has been ported by my builder. All done by hand. I can see 280 rwhp written all over it !!

sorry for poor quality pic, it was taken with a mobile phone

sorry for poor quality pic, it was taken with a mobile phone

#17

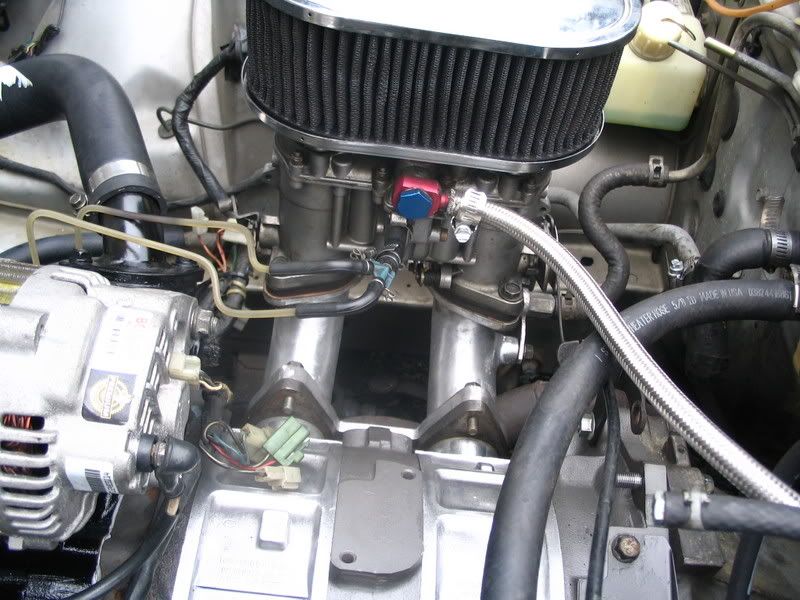

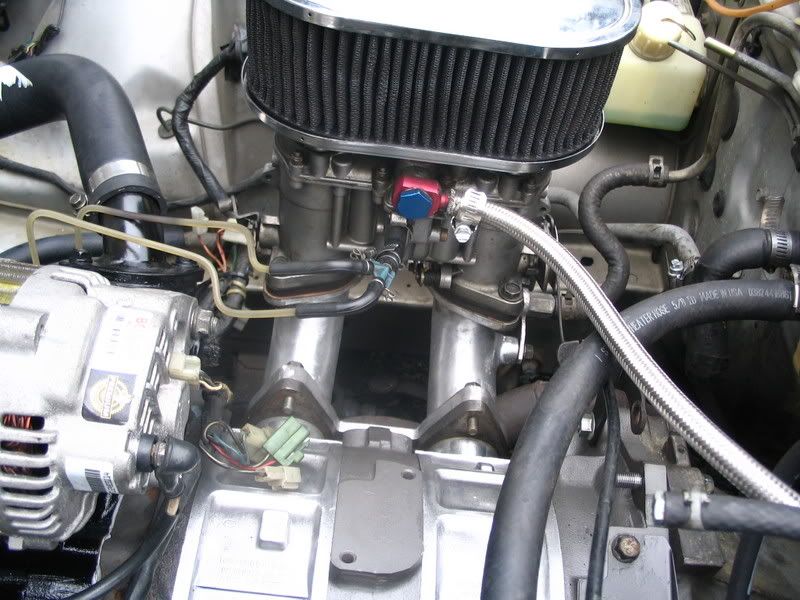

I still have a little work to get my 13B-PP to make some good hp numbers. I have to get a good exhaust system on there then i need to tune my weber. I love the engine and can't wait till i throw a microtech some ceramic seals, fuel injection and nitrous into it. My housings are from 1974 and have only seen steel seals twice in its life other than that its been carbon.

here are some pics of her.

here are some pics of her.

#19

mine or craigw1's. Mine were done by a local rotary shop here in the early 80's. They have the insert with the flange built on but not attached. The flange rotates around the intake pipe. The flange is the same bolt pattern as the factory mazda housings. Hence why I'm using a factory mazda weber intake. My wife's father has a old rotary book with my intake in it but it is using a vw bosch style fuel injection.

#24

wow ! a mazda factory intake for a p port ! that must be quite rare. Have to build our own here. I will post some pics. you guys are lucky too that your brake booster is on the left....ours are on the right, so our intake manifold has a sharper bend upwards. is it true that you get better torque with a longer/taller intake manifold ?