Oil pan gasket replacement - se 13b

#27

keep it original!!

iTrader: (3)

Joined: Oct 2005

Posts: 1,329

Likes: 8

From: SF Bay Area, California

PLEASE HELP ME! I AM STUCK!! PICS.... i want the car to be running for rotary fest!!!

on top... arethose the four bolts??? im sucha newb..

any ideas yet?

i tried taking off the cotter pins/ bolts but that didnt do anything... crap

please help my baby.. I CANNOT THANK YOU ENOUGH! and this is just a oil pan re-gasket.. think about in the future me doing a full restoration... my baby's my inspiration and u all are my guidance. i hope everyone had a fantastic fathers day and have a great week! im gonna get some sleep and start fresh tomorrow and see if i can get the pan out!

on top... arethose the four bolts??? im sucha newb..

any ideas yet?

i tried taking off the cotter pins/ bolts but that didnt do anything... crap

please help my baby.. I CANNOT THANK YOU ENOUGH! and this is just a oil pan re-gasket.. think about in the future me doing a full restoration... my baby's my inspiration and u all are my guidance. i hope everyone had a fantastic fathers day and have a great week! im gonna get some sleep and start fresh tomorrow and see if i can get the pan out!

#28

I absolutely agree with those who have said to omit the oil pan gasket. We NEVER use them. All stock rotary oil pans leak sooner or later, simply due to the "working" of the engine (flexing). The gasket just makes what would otherwise be a small leak a major one. Any high quality RTV will work.

It's also a good idea to dig out old silicone sealant from the bolt holes, chase them out with a tap and blow them clean with compressed air (just one of those "air in a can" dusters is fine). I also like to use brand new Cad-plated, flange-head M6x1.0x12mm bolts without a "nose" (unthreaded starter section). Proper torque for a 6mm bolt is 7-10 ft. lbs. Helicoil any suspect bolt holes. Anything that helps the bolts seat properly and at the correct torque is a Good Thing (TM) in leak management.

I am having some Stainless Steel oil pan re-inforcement pieces (similar to what the Rotary Truck had stock) CNC laser cut to go between the bolt and the pan. I think that will help even out the pressure and make even a slightly bent pan do it's duty. We will make them for all the oil pans, from '74 on up. Rob and I have also been talking about doing a somewhat thicker "windage tray" (horizontal baffle between pan and engine) with O-rings on either side. We have had great success with O-rings on our aluminum oil pans, but there are no plans for a 1st gen or earlier pan at this time, so something like this might fit the bill. Let me know if there is any interest and perhaps we can get it off the back burner.

It's also a good idea to dig out old silicone sealant from the bolt holes, chase them out with a tap and blow them clean with compressed air (just one of those "air in a can" dusters is fine). I also like to use brand new Cad-plated, flange-head M6x1.0x12mm bolts without a "nose" (unthreaded starter section). Proper torque for a 6mm bolt is 7-10 ft. lbs. Helicoil any suspect bolt holes. Anything that helps the bolts seat properly and at the correct torque is a Good Thing (TM) in leak management.

I am having some Stainless Steel oil pan re-inforcement pieces (similar to what the Rotary Truck had stock) CNC laser cut to go between the bolt and the pan. I think that will help even out the pressure and make even a slightly bent pan do it's duty. We will make them for all the oil pans, from '74 on up. Rob and I have also been talking about doing a somewhat thicker "windage tray" (horizontal baffle between pan and engine) with O-rings on either side. We have had great success with O-rings on our aluminum oil pans, but there are no plans for a 1st gen or earlier pan at this time, so something like this might fit the bill. Let me know if there is any interest and perhaps we can get it off the back burner.

#31

You should be able to unbolt the engine mounts and jack up the engine/tranny like in Wackey's pics. That should give you enough clearance to get the pan out. The other option is to take apart the steering. Just do the jacking technique. Wackey laid out the whole procedure a couple posts up. Good luck.

Kent

Kent

#32

Originally Posted by boyee

ok so how can i get my pan out?? good tips tho thanks!

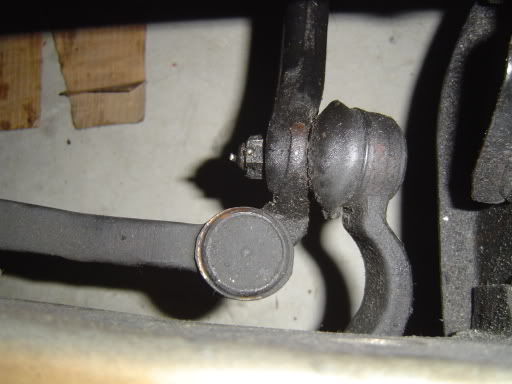

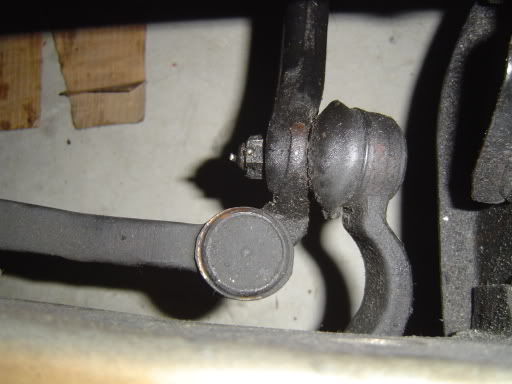

This is a GIF animation I did of an idler arm with bad bushings. It should help you identify the idler arm and perhaps convince you to replace those bushings as long as you're down there. They are about $6 each (2 required). In that case, you take the nut off the top idler arm assembly and pull it out, giving you access to the bushings and clearing the way for the oil pan removal. If you don't want to bother with the bushings at this time, then just unbolt the idler arm assemby from the chassis and drop the whole thing down.

The following users liked this post:

Savage99 (03-09-21)

#33

keep it original!!

iTrader: (3)

Joined: Oct 2005

Posts: 1,329

Likes: 8

From: SF Bay Area, California

thanks man! finally a pic of the idler arm.. got it out real easy with that thing off.. now clean... rinse... have my friend supervise me re-rtving it and bolting it back on and putting on the omp gasket on correcly this time so nothing leaks anymore!! i hate oil

#34

After SO many people saying not to use a gasket.. I may just be convinced.. but i just grew up always using a gasket, and i know how to tighten it properly. Since the gasket costs $30 anyway..

Will the stock bolts get tight enough without a gasket? Or will they bottom out? I hear people talking about different bolts..

Will the stock bolts get tight enough without a gasket? Or will they bottom out? I hear people talking about different bolts..

#37

2 Questions for Wacky

Wackyracer, your instructions did not specify to remove the Nuts from the transmission mount bolts. If the Transmission is jacked up without removing those, won't the transmission mount be torn or damaged?

Second, why do you remove the four bolts from the mount bracket instead of the two nuts from the motor mounts? Thank you.

Second, why do you remove the four bolts from the mount bracket instead of the two nuts from the motor mounts? Thank you.

#38

Bump...

I need to replace my oil pan gasket, it's got a slow leak. I read this entire thread, it seems easier to remove the idler rather than jack up the engine/trans. The reason I say that is I don't see how much higher the transmission can rise, or does it have some pivot ability at the transmission mount? I think just removing one idler from the chassis might be the fastest way.

Any new thoughts or experience on this? I don't have a lift to work off of so I'll be using jack stands. I might just time this with replacing all the suspension bushing/boots anyways, in that case I guess it's a non-issue anyways.

But for discussion sake, what do you lot recommend? Raise the engine or move the steering linkage?

I need to replace my oil pan gasket, it's got a slow leak. I read this entire thread, it seems easier to remove the idler rather than jack up the engine/trans. The reason I say that is I don't see how much higher the transmission can rise, or does it have some pivot ability at the transmission mount? I think just removing one idler from the chassis might be the fastest way.

Any new thoughts or experience on this? I don't have a lift to work off of so I'll be using jack stands. I might just time this with replacing all the suspension bushing/boots anyways, in that case I guess it's a non-issue anyways.

But for discussion sake, what do you lot recommend? Raise the engine or move the steering linkage?

Thread

Thread Starter

Forum

Replies

Last Post