Motor Harness... 12A - 13B swap.

#1

Motor Harness... 12A - 13B swap.

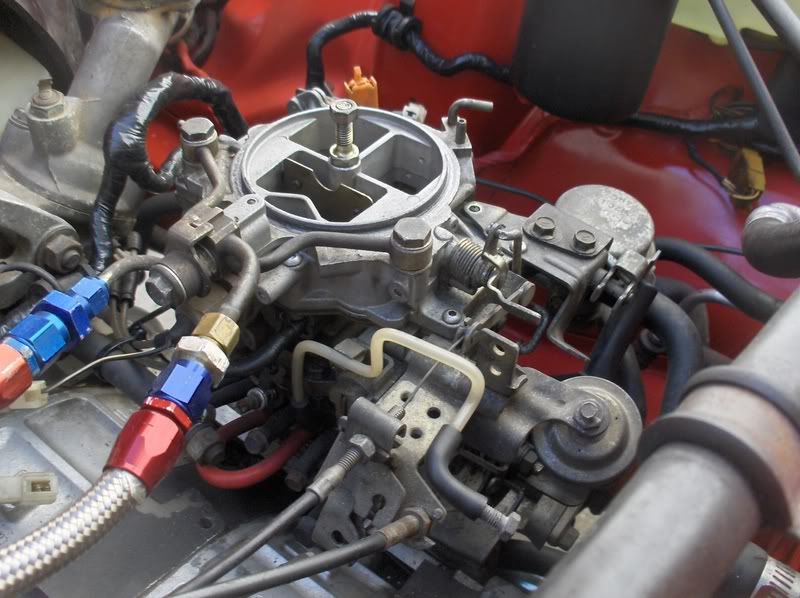

I swapped over from a completly stock 85 12A to a older style 13B, 74 maybe...? I believe that's the year, but I could easily find out for sure if need be. Here's a quick pic to show you just how stock the 12A really was:

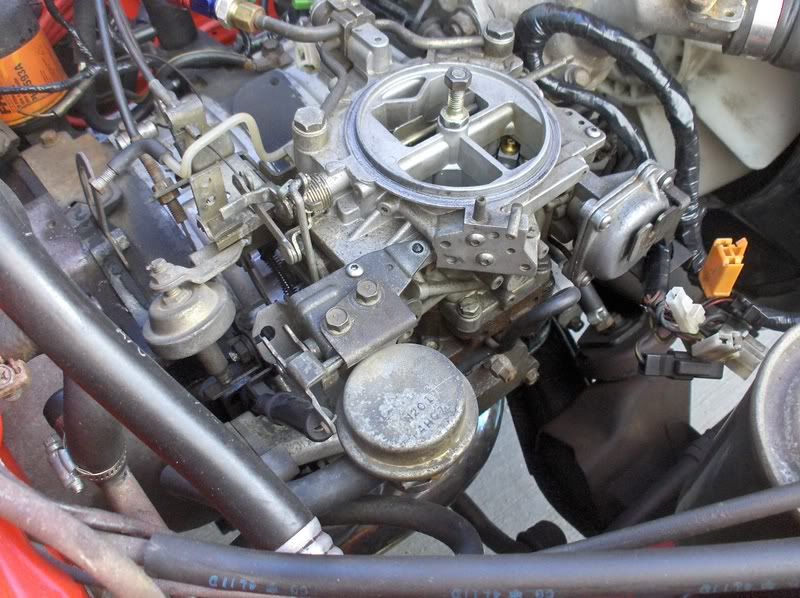

Anyways... When I pulled the 12A engine, I left the harness intact to the motor by only unplugging the one main yellow connector at the passanger side firewall. I dropped in the 13B which is now sitting pretty, but alternator's not charging, no oil pressure reading, no coolant temp reading, etc... Here's a quick pic of 13B installed (via no engine harness) to keep the pics flowing:

Now my reason for posting is... I would now like to get the orginal harness back onto the car from the pulled 12A motor to the installed 13B. I did already remove the harness from the 12A, taking a pic of every single connector that was undone as a reference.

Photobucket is acting funny right now...??? So as soon as I figure out how to upload, I'll post pics of all the connectors that were unplugged as reference for what is important and what is not. Hopefully I can learn a thing or two.

My question is pretty simple... do I just plug whatever can be plugged back in and that's it...???

The 13B does have a YAW nikki so the carbs are the same, although the YAW is missing ALOT of components that I guess aren't needed besides to pass emissions.

The rest of the connectors that now have nowhere to go just sit there doing nothing...?? Is that OK..???

Anyways... When I pulled the 12A engine, I left the harness intact to the motor by only unplugging the one main yellow connector at the passanger side firewall. I dropped in the 13B which is now sitting pretty, but alternator's not charging, no oil pressure reading, no coolant temp reading, etc... Here's a quick pic of 13B installed (via no engine harness) to keep the pics flowing:

Now my reason for posting is... I would now like to get the orginal harness back onto the car from the pulled 12A motor to the installed 13B. I did already remove the harness from the 12A, taking a pic of every single connector that was undone as a reference.

Photobucket is acting funny right now...??? So as soon as I figure out how to upload, I'll post pics of all the connectors that were unplugged as reference for what is important and what is not. Hopefully I can learn a thing or two.

My question is pretty simple... do I just plug whatever can be plugged back in and that's it...???

The 13B does have a YAW nikki so the carbs are the same, although the YAW is missing ALOT of components that I guess aren't needed besides to pass emissions.

The rest of the connectors that now have nowhere to go just sit there doing nothing...?? Is that OK..???

#2

Unbolt the rat's nest from the top of the 12A. Strip the wiring harness from it. Don't cut any wires or connectors off (in case you were thinking of doing that). Clean it up (degrease or just wipe it with a rag), lay it across the engine the way it was on the 12A and start connecting things. You really can't screw this part up unless you're a total retard, which I highly doubt since you got a 13B in there. Good job.

#5

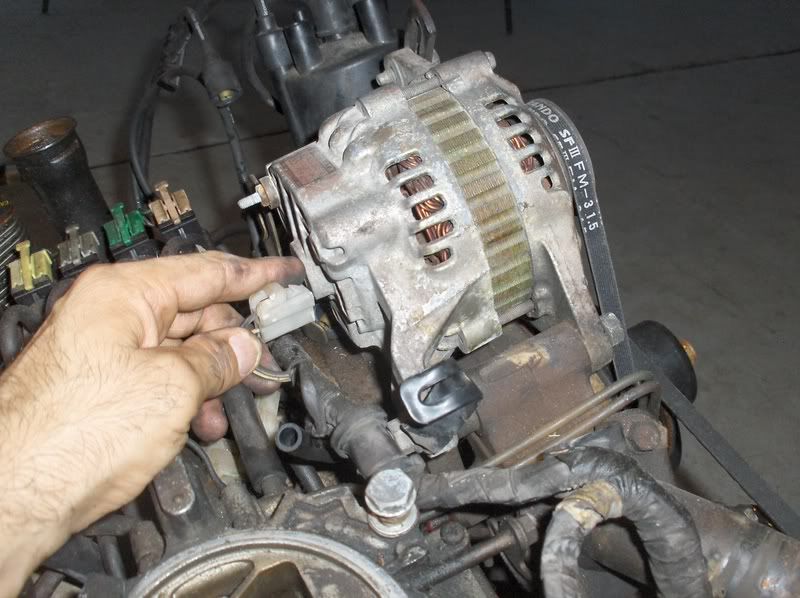

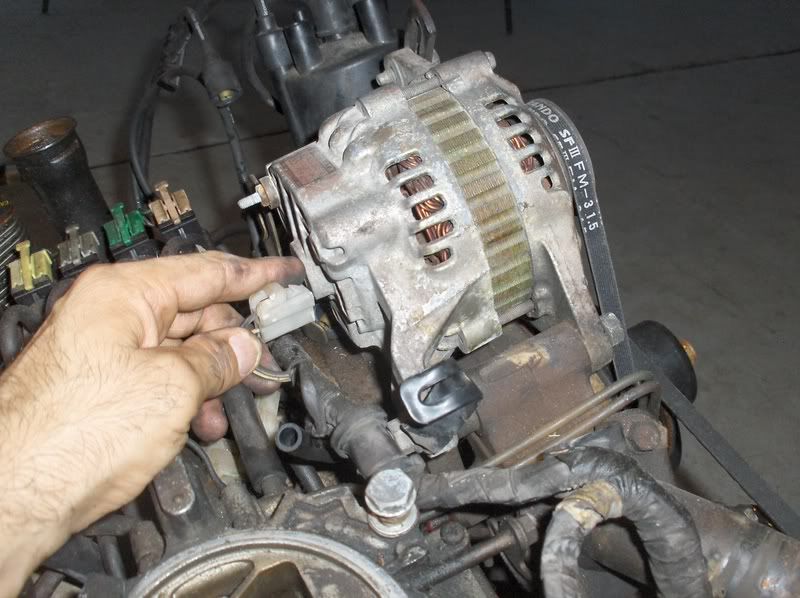

^ The 13B transplant has a 2nd gen alternator from a 87 TII.

Jeff, looking at the dirty oil ridden 12A, removing the harness was easier then I thought. I did clean it up and re-tape the entire harness before dropping it back in the car. Dropping the harness back in also seemed tooo easy.

So here's pics of what I did connect back:

1: The alternator. Plug fit even though it was a 2nd gen alt.

2: The fuel bowl boil thinggie.... (don't know the name)

3: Something to do with the ground...

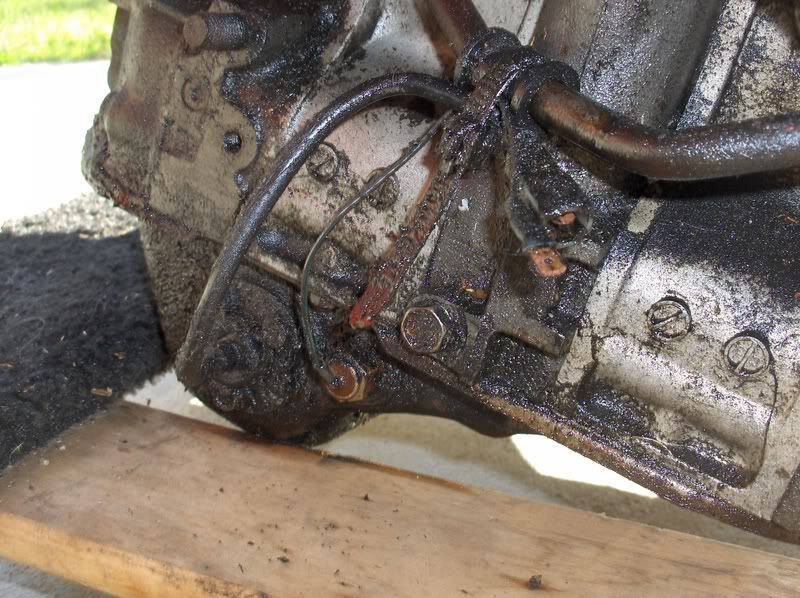

4: Driver's side lower portion / end of harness. Oil pressure and coolant temp.

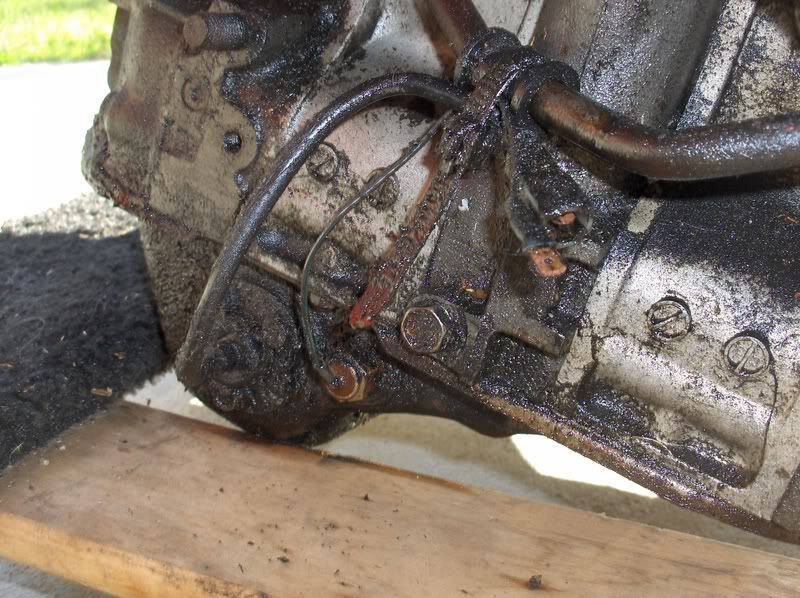

5: The oil pan on the 12A has two parts that the harness connected to... The 13B only has the bigger one on the left, oil level..?? (hard to see w/all the grimmeyness) what's the smaller right side one...??

Jeff, looking at the dirty oil ridden 12A, removing the harness was easier then I thought. I did clean it up and re-tape the entire harness before dropping it back in the car. Dropping the harness back in also seemed tooo easy.

So here's pics of what I did connect back:

1: The alternator. Plug fit even though it was a 2nd gen alt.

2: The fuel bowl boil thinggie.... (don't know the name)

3: Something to do with the ground...

4: Driver's side lower portion / end of harness. Oil pressure and coolant temp.

5: The oil pan on the 12A has two parts that the harness connected to... The 13B only has the bigger one on the left, oil level..?? (hard to see w/all the grimmeyness) what's the smaller right side one...??

#7

Hey,that stuff all looks very familiar........heh,heh.

Long time, no talk Devil.

I take it thats still my old 76 RX-4 engine and Yaw carb?

The carb really doesnt need any electrical stuff ran to it since its stripped.The ECU controls the rats nest solenoids and relays,so theres very little need for any of that stuff.The float bowl vent solenoid isnt really needed,its more for vapor(smog) control.I dont remember if the Yaw used one,or if it was just vented to atmosphere all the time.

3 wires to the alternator.

A few wires from the distributor to the coils.

1 wire from the oil sending unit to the gauge.

1 wire from the water temp sending unit to the gauge.

1 wire to the oil level sender unit.

Thats all I ever ran on that engine.The crankcase ventilation system is all vucuum and valves,no electrical there.And if you dont use the choke for more than just startup,you wont need the electrical sensor on the back of the waterpump.

Long time, no talk Devil.

I take it thats still my old 76 RX-4 engine and Yaw carb?

The carb really doesnt need any electrical stuff ran to it since its stripped.The ECU controls the rats nest solenoids and relays,so theres very little need for any of that stuff.The float bowl vent solenoid isnt really needed,its more for vapor(smog) control.I dont remember if the Yaw used one,or if it was just vented to atmosphere all the time.

3 wires to the alternator.

A few wires from the distributor to the coils.

1 wire from the oil sending unit to the gauge.

1 wire from the water temp sending unit to the gauge.

1 wire to the oil level sender unit.

Thats all I ever ran on that engine.The crankcase ventilation system is all vucuum and valves,no electrical there.And if you dont use the choke for more than just startup,you wont need the electrical sensor on the back of the waterpump.

Trending Topics

#8

Subzero fluid motor activator..? Hmmmm, how does that thing work..?? I'd guess a temp reading off the oil...???

Steve, of course that is your old motor/set-up. I baby that thing. Except it doesn't have the MSD's and no lightweight flywheel for now. I'm wanted to see how the 12A transmission with the stock flywheel feels vs the TII transmission with the lightweight fly.

The YAW most certianly uses the float bowl vent solenoid... I went through a hair pulling experience trying to figure that one out. I thought the secondaries weren't working, clogged exhaust, clogged fuel filter... the car would act extremly funny out of nowhere. I even thought it was running on one rotor, checked ignition, etc. I was ready to drive the thing off a cliff. I even payed a local rotary shop for 3 hrs diagnostic time to try to figure it out. Sterling was like "Give the Fuel bowl vent solenoid 12V ignition power." and bam, problem SOLVED. I'll never forget what that thing does ever...! haha

And that is exactly why I don't want to overlook anything on this install.

My next question was actually going to be about the plug that connected to the sensor on the back of the water pump. I was wondering what that was if the coolant temp sensor was on the rear iron / housing. I do plan on getting the choke to work correctly again... that'll be the next thread. So I take it that means I'll be need to hook that sensor back up.

Thanks for the help as always..!!!

Steve, of course that is your old motor/set-up. I baby that thing. Except it doesn't have the MSD's and no lightweight flywheel for now. I'm wanted to see how the 12A transmission with the stock flywheel feels vs the TII transmission with the lightweight fly.

The YAW most certianly uses the float bowl vent solenoid... I went through a hair pulling experience trying to figure that one out. I thought the secondaries weren't working, clogged exhaust, clogged fuel filter... the car would act extremly funny out of nowhere. I even thought it was running on one rotor, checked ignition, etc. I was ready to drive the thing off a cliff. I even payed a local rotary shop for 3 hrs diagnostic time to try to figure it out. Sterling was like "Give the Fuel bowl vent solenoid 12V ignition power." and bam, problem SOLVED. I'll never forget what that thing does ever...! haha

And that is exactly why I don't want to overlook anything on this install.

My next question was actually going to be about the plug that connected to the sensor on the back of the water pump. I was wondering what that was if the coolant temp sensor was on the rear iron / housing. I do plan on getting the choke to work correctly again... that'll be the next thread. So I take it that means I'll be need to hook that sensor back up.

Thanks for the help as always..!!!

#9

I used to just give the choke a pull to get it started,then let the **** slap back in once she fired.It doesnt get very cold here in CA,so having the sensor that keeps the choke **** "hold" magnet energized while warming up,wasnt really essencial.I imagine youll have more need to make that work,than I did.

The YAW didnt even have a choke when I got it,I had to re-install it after a couple weeks of hard starting.Living in Arizona,Paul probably doesnt ever need a choke on his cars,but I still needed a little to get her lit up on those cold mornings.

I so glad your still running that engine/carb.The Yaw is still one of my favorite mods I ever made to my car,it was so responsive and sharp.And that 13B......when I first spotted it in the wrecking yard,I would have never though it would run again,let alone be the jewel it turned out to be.

Keep us informed!

The YAW didnt even have a choke when I got it,I had to re-install it after a couple weeks of hard starting.Living in Arizona,Paul probably doesnt ever need a choke on his cars,but I still needed a little to get her lit up on those cold mornings.

I so glad your still running that engine/carb.The Yaw is still one of my favorite mods I ever made to my car,it was so responsive and sharp.And that 13B......when I first spotted it in the wrecking yard,I would have never though it would run again,let alone be the jewel it turned out to be.

Keep us informed!

#10

Wow, you just cleard up another question I had. I definatly need the choke... but when I pull the **** out it doesn't stay so I would wedge a nickle in there to keep the RPM's at 3Kish while she warmed up. I always wanted to get it working correctly again... We do have some cold days here... Nice.

I searched my old posts to find the one where I was having problems with the float bowl vent solenoid and Sterling did say it was weird that solenoid was even there if I had a YAW carb...? b/c YAW did whatver was necessary to remove those..?? Which just got me to thinking maybe the shop who tried to figure out my problem changed the top portion of my carb w/out my knowledge...??? but after you now saying you did put the choke back... that could also be the reason it's still there...????

I do want to eventually run some n20... I'm thinking of building a scrappy 12A to experiment with that not to mess this motor up... but that rite now is definatly waaaay down the road.

I searched my old posts to find the one where I was having problems with the float bowl vent solenoid and Sterling did say it was weird that solenoid was even there if I had a YAW carb...? b/c YAW did whatver was necessary to remove those..?? Which just got me to thinking maybe the shop who tried to figure out my problem changed the top portion of my carb w/out my knowledge...??? but after you now saying you did put the choke back... that could also be the reason it's still there...????

I do want to eventually run some n20... I'm thinking of building a scrappy 12A to experiment with that not to mess this motor up... but that rite now is definatly waaaay down the road.

#11

If the factory designed the carb body with a float bowl vent solenoid to provide atmosphere to the bowls,then YAW might not have had any choice other than to keep the solenoid.

Even disregarding the smog control side of that component,theres another need to keep it.If the valve is removed and the passage left wide open as a vent,then dirt and debris can get into the bowls.This is a huge problem on some of the equipment I work on,since they see a LOT of dirt.On a carb without the solenoid,the vent passage is usually convoluted or filtered to keep things clean inside.The solenoid doesnt really hurt anything being there,and its just a simple 12V "power on" item,so YAW probably didnt see any reason to off it.

I didnt change out the whole airhorn,I just popped the lid,slid the choke shaft and butterfly back into the airhorn and hooked up the extra linkage needed to operate it.Im pretty sure that the solenoid was always there,although it has been many years now.I had the airhorn off that carb lots of times changing jets and making minor adjustments,especially after I changed over to the 13B,from my old 12A.I wasnt concerned with the small airflow restriction the choke produced like YAW was,I just wanted to make cold starts easier.

Even disregarding the smog control side of that component,theres another need to keep it.If the valve is removed and the passage left wide open as a vent,then dirt and debris can get into the bowls.This is a huge problem on some of the equipment I work on,since they see a LOT of dirt.On a carb without the solenoid,the vent passage is usually convoluted or filtered to keep things clean inside.The solenoid doesnt really hurt anything being there,and its just a simple 12V "power on" item,so YAW probably didnt see any reason to off it.

I didnt change out the whole airhorn,I just popped the lid,slid the choke shaft and butterfly back into the airhorn and hooked up the extra linkage needed to operate it.Im pretty sure that the solenoid was always there,although it has been many years now.I had the airhorn off that carb lots of times changing jets and making minor adjustments,especially after I changed over to the 13B,from my old 12A.I wasnt concerned with the small airflow restriction the choke produced like YAW was,I just wanted to make cold starts easier.

#14

This is what I was lead to believe from gathering bits of information here and there after I knew the fuel bowl vent solenoid was the root of my troubles...

It has a plunger inside that closes when given 12V power. The 12V has to be ran off ignition not constant for 2 reasons... 1: It will drain the battery by having the 12V constantly hold the plunger shut. And 2: If it constantly held shut then it will not do it's job... which is to actually vent the fuel bowls to prevent them from boiling on a hot day.

If left open... or no 12V power source provided... it will cause a major vacuum leak which was making the car drive complelty retarded.

Here is a picture of it again for anyone who is not familar w/ it... My finger is pointing to it and it has a one wire connector coming off it. It's located top of carb drivers side.

It has a plunger inside that closes when given 12V power. The 12V has to be ran off ignition not constant for 2 reasons... 1: It will drain the battery by having the 12V constantly hold the plunger shut. And 2: If it constantly held shut then it will not do it's job... which is to actually vent the fuel bowls to prevent them from boiling on a hot day.

If left open... or no 12V power source provided... it will cause a major vacuum leak which was making the car drive complelty retarded.

Here is a picture of it again for anyone who is not familar w/ it... My finger is pointing to it and it has a one wire connector coming off it. It's located top of carb drivers side.

#16

I believe you can mod something about the vent solenoid so it allows the bowls to be vented and doesn't require a switched 12V source. It will be like the older carbs that had a simple venting system (when the charcoal canister was attatched to the upper air cleaner cover) except the rubber hose should still be connected over to the charcoal canister on the passenger inner fender.

There's gotta be a way to do this. I just haven't bothered because I used the stock rat's nest harness and connected the 12V switched wire and never had a float bowl venting problem.

It's not even a problem to run an extra wire in a non-stock engine bay such as a project car or whatever. It's faster than engineering a vent bypass... maybe.

There's gotta be a way to do this. I just haven't bothered because I used the stock rat's nest harness and connected the 12V switched wire and never had a float bowl venting problem.

It's not even a problem to run an extra wire in a non-stock engine bay such as a project car or whatever. It's faster than engineering a vent bypass... maybe.