Making my own Pre-Silencers

#1

Making my own Pre-Silencers

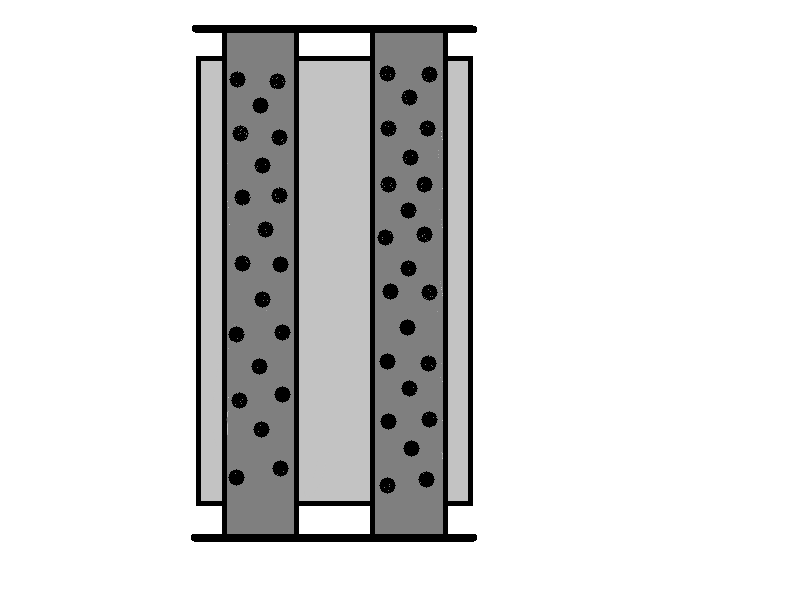

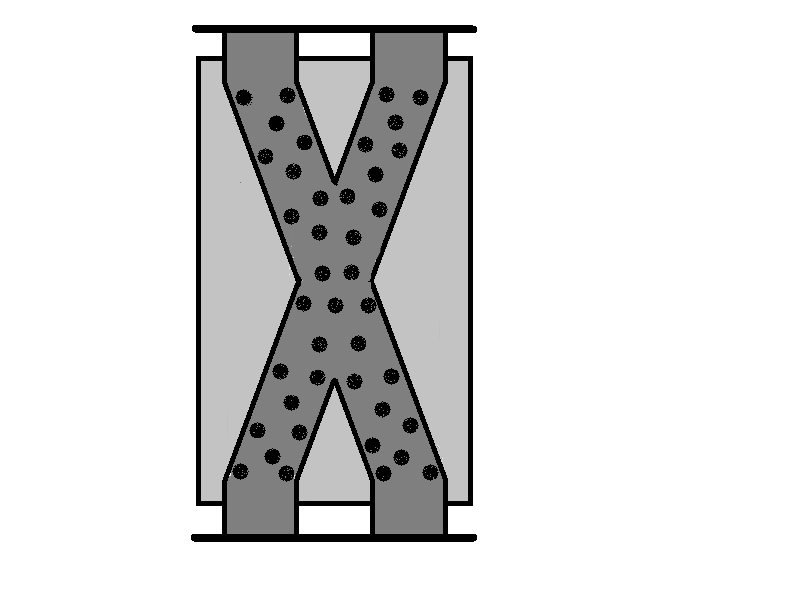

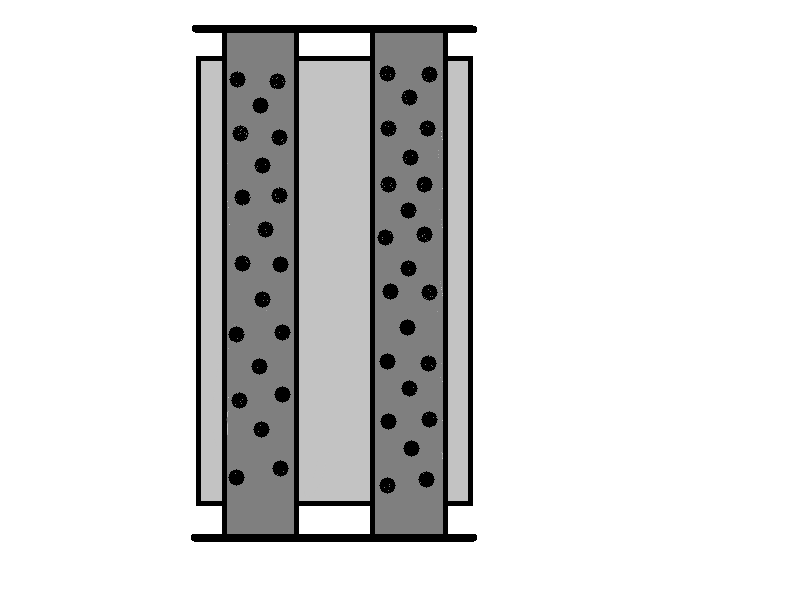

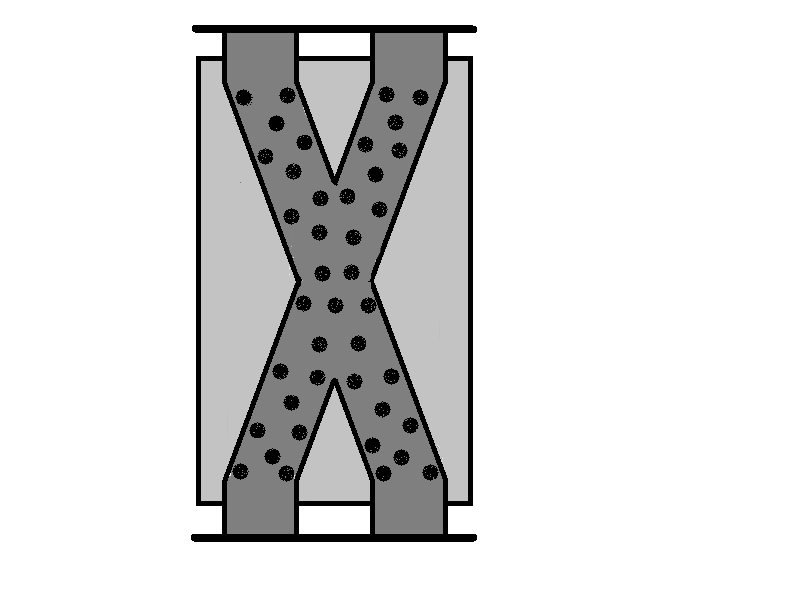

I'm going to be making my own exhaust system for my 83 and I wanted to get peoples opinions on a couple different designs for a pre-silencer. I'm no expert on exhaust systems so I was hoping to get some help from more knowledgeable individuals. Here are 2 quick drawings I did of a couple of my ideas.

The first is a single housing with both pipes running parallel. Dual in and Dual out.

The second is like above but with an X pipe design.

My other idea is like the Racing Beat Street Port Center Section with 2 staggered pre-silencers. I didn't bother drawing a picture.

http://www.racingbeat.com/RX7-1975-1...ems/16398.html

Any advantages or disadvantages of my designs?

-Kyle

The first is a single housing with both pipes running parallel. Dual in and Dual out.

The second is like above but with an X pipe design.

My other idea is like the Racing Beat Street Port Center Section with 2 staggered pre-silencers. I didn't bother drawing a picture.

http://www.racingbeat.com/RX7-1975-1...ems/16398.html

Any advantages or disadvantages of my designs?

-Kyle

#2

the best flowing setup is for each rotor to have its own pipe for free flowing exhaust. the trick is to get the presilencers long enough and be packed with the appropriate material to effectively dampen the sound...while being able to stand up to the heat.... simple fiberglass packing will melt. with the money in custom fab work you will have in this project, the best bet may be to bite the bullet and buy the RB pre silencer setup.

#3

the best flowing setup is for each rotor to have its own pipe for free flowing exhaust. the trick is to get the presilencers long enough and be packed with the appropriate material to effectively dampen the sound...while being able to stand up to the heat.... simple fiberglass packing will melt. with the money in custom fab work you will have in this project, the best bet may be to bite the bullet and buy the RB pre silencer setup.

#4

The whole system will be dual 2", thick wall tubing with mandrel bends. The Pre-Silencers will be made out of pretty thick material as well and be filled with stainless steel wool. I dont have my notes so I dont remember the gauges. I'm going to be using a slightly shortened RB Street Port header. I got it from the junk yard for $10.00 but the lower flange was cut off when they took the cat. I'm just gonna re-flange it. But because its shorter than original the RB pipe wont fit. Plus I like to do things I've never done before.  I'm not sure about the muffler yet. I might try to get a used RB street port muffler and just fabricate the mid pipe. This is still a ways off. I have to get the car running first. I love to experiment, but it all cost money. The idea behind the X pipe design was to help with scavenging. It works with piston motors. Probably wont work as well when the pipes are full of holes though. lol.

I'm not sure about the muffler yet. I might try to get a used RB street port muffler and just fabricate the mid pipe. This is still a ways off. I have to get the car running first. I love to experiment, but it all cost money. The idea behind the X pipe design was to help with scavenging. It works with piston motors. Probably wont work as well when the pipes are full of holes though. lol.

I'm not sure about the muffler yet. I might try to get a used RB street port muffler and just fabricate the mid pipe. This is still a ways off. I have to get the car running first. I love to experiment, but it all cost money. The idea behind the X pipe design was to help with scavenging. It works with piston motors. Probably wont work as well when the pipes are full of holes though. lol.

I'm not sure about the muffler yet. I might try to get a used RB street port muffler and just fabricate the mid pipe. This is still a ways off. I have to get the car running first. I love to experiment, but it all cost money. The idea behind the X pipe design was to help with scavenging. It works with piston motors. Probably wont work as well when the pipes are full of holes though. lol.

#5

I haven't tested my two repacked (rebuilt) RB presilencers yet. But keep in mind if you do make your own presilencer(s), be sure to use at least 14 gauge for the shell and make sure the cores have a slip-fit feature to allow them to expand with heat when the engine first starts. The cores will get hot quickly while the insulated shell stays cool for a while. They will buckle like a typical cheap muffler used on a rotary. Ask hyper4mance2k.

I wonder how my presilencers will perform compared to RB. The cores of mine were wrapped in pot scrubbers first (you just spread them out like putting socks on a little kid). Then I built up the rest of the thickness with coarse stainless wool purchased from a wood refinishing company until 4" thick. Then I slipped the 14 guage tubing on and tacked it in place. Had to wrap masking tape on the wool to keep it in place and spray some WD40-like lube spray (it was silicone based lol) to get the tube on. Seems it is packed well enough, not too tight but not too loose.

I started with two dead RB presilencers. The shells were rusted thin, dented, road rashed (scraped through at one edge), and the core material of one had turned completely into orange dust and disappeared. The other was still packed so I got to see what RB used.

The other was still packed so I got to see what RB used.

Pot scrubbing material only. They look like big industrial size Andre the Giant pot scrubbers.

Their job is to only take out the high frequncy metalic noise. They honestly do not work as mufflers (we tried it once, oh the noise was out of this world). Their shells are also 14 gauge to prevent noise from leaking out. I'm hoping the way I packed mine will act more like mini mufflers and hopefully not allow any more noise out than the genuine RB. So I replaced my dead tubing with new 14 gauge 409 stainless as it should have a similar expansion rate to the original mild steel shells. Good luck finding 304 SS or mild in 14 gauge. I only found 409 in that thickness on amazon.

Oh and make sure your main muffler is really, really good if doing any kind of long primary system. The trick with street driven rotaries to keep them quiet is to join the two pulses as soon as possible. When you have a stock exhaust manifold, they join right as they leave the exhaust ports. These work really well to premuffle about 30-40%, taking some of the burden off the cat(s) and allowing the stock muffler to only barely muffler (they sound awful when used with a header and presilencer because of this).

Now think of how well a turbo muffles things. Pretty close to 50% and again it joins the pulses either inside the exhaust manifold if stock or if using a tubular aftermarket manifold that's fully divided, same thing when they mix together pushing the turbine wheel.

Now we come to a collected header. This can easily be used on the street without being loud because the collector is still sort of close to the engine compared to a long primary system. The only thing you gotta do is make sure to use one RB presilencer and one RB main muffler (the powerpulse one) because anything else most likely won't muffle well enough. The RB one does it without bing too restrictive when using their standard .120 wall 2" pipe RB designed the system to use. Problem is I think a single 2" pipe is way too small on any 13B or a ported 12A.

Lastly the long primary collects back there, and is kinda loud. RB uses the same muffler except its inlet pipe is 2.375"OD which has the same ID of 2.25" as a thickwall 2.5" OD pipe. Thickwall being 1/8" or .120 or 11 gauge. (all interchangeable terms). The end result is a louder system that will raise eyebrows but is still safe on the street. 84stock will tell you it's the very best exhaust for a 1st gen. I'd have to agree because it's quiet at low RPM and idle, but will get loud when you get on it. It lasts for 20 years or longer. It is compatible with a Camden supercharger, or any NA carbed setup. Not sure about bridge and PP though. Some have even used the muffler only in a turbo setup. That Steve guy used one with a 3" pipe feeding it (had to go from 3" to 2.375") on his S5 T2 swapped california car and passes emissions. It makes 300HP and is quiet. As for 84stock, he recently set a horse power record with his 7" Camden and a full RB system.

If I were you, I'd go with the full RB Street Port system, unless you're dying to experiment and build your own presilencers. The worst that happens is they are super loud and you wasted time building them. Heck my first couple of exhaust systems made with some old rotary engineering glasspacks turned out less than stellar, but they worked as a temp setup. Gave me some much needed experience so now I can step it up to some next-level stuff and experiment with my repacked RB presilencers and some Magnaflow mufflers on the REPU. The goal is to sound like an RB Street Port system, flow like an RB Street Port system, but fit under the REPU where their powerpulse main muffler and staggered presilencers wouldn't. I've got some room under the bed but the main muffler is kind of the wrong shape. I'm hoping two 2.5" magnaflows will suffice.

I wonder how my presilencers will perform compared to RB. The cores of mine were wrapped in pot scrubbers first (you just spread them out like putting socks on a little kid). Then I built up the rest of the thickness with coarse stainless wool purchased from a wood refinishing company until 4" thick. Then I slipped the 14 guage tubing on and tacked it in place. Had to wrap masking tape on the wool to keep it in place and spray some WD40-like lube spray (it was silicone based lol) to get the tube on. Seems it is packed well enough, not too tight but not too loose.

I started with two dead RB presilencers. The shells were rusted thin, dented, road rashed (scraped through at one edge), and the core material of one had turned completely into orange dust and disappeared.

The other was still packed so I got to see what RB used.

The other was still packed so I got to see what RB used.Pot scrubbing material only. They look like big industrial size Andre the Giant pot scrubbers.

Their job is to only take out the high frequncy metalic noise. They honestly do not work as mufflers (we tried it once, oh the noise was out of this world). Their shells are also 14 gauge to prevent noise from leaking out. I'm hoping the way I packed mine will act more like mini mufflers and hopefully not allow any more noise out than the genuine RB. So I replaced my dead tubing with new 14 gauge 409 stainless as it should have a similar expansion rate to the original mild steel shells. Good luck finding 304 SS or mild in 14 gauge. I only found 409 in that thickness on amazon.

Oh and make sure your main muffler is really, really good if doing any kind of long primary system. The trick with street driven rotaries to keep them quiet is to join the two pulses as soon as possible. When you have a stock exhaust manifold, they join right as they leave the exhaust ports. These work really well to premuffle about 30-40%, taking some of the burden off the cat(s) and allowing the stock muffler to only barely muffler (they sound awful when used with a header and presilencer because of this).

Now think of how well a turbo muffles things. Pretty close to 50% and again it joins the pulses either inside the exhaust manifold if stock or if using a tubular aftermarket manifold that's fully divided, same thing when they mix together pushing the turbine wheel.

Now we come to a collected header. This can easily be used on the street without being loud because the collector is still sort of close to the engine compared to a long primary system. The only thing you gotta do is make sure to use one RB presilencer and one RB main muffler (the powerpulse one) because anything else most likely won't muffle well enough. The RB one does it without bing too restrictive when using their standard .120 wall 2" pipe RB designed the system to use. Problem is I think a single 2" pipe is way too small on any 13B or a ported 12A.

Lastly the long primary collects back there, and is kinda loud. RB uses the same muffler except its inlet pipe is 2.375"OD which has the same ID of 2.25" as a thickwall 2.5" OD pipe. Thickwall being 1/8" or .120 or 11 gauge. (all interchangeable terms). The end result is a louder system that will raise eyebrows but is still safe on the street. 84stock will tell you it's the very best exhaust for a 1st gen. I'd have to agree because it's quiet at low RPM and idle, but will get loud when you get on it. It lasts for 20 years or longer. It is compatible with a Camden supercharger, or any NA carbed setup. Not sure about bridge and PP though. Some have even used the muffler only in a turbo setup. That Steve guy used one with a 3" pipe feeding it (had to go from 3" to 2.375") on his S5 T2 swapped california car and passes emissions. It makes 300HP and is quiet. As for 84stock, he recently set a horse power record with his 7" Camden and a full RB system.

If I were you, I'd go with the full RB Street Port system, unless you're dying to experiment and build your own presilencers. The worst that happens is they are super loud and you wasted time building them. Heck my first couple of exhaust systems made with some old rotary engineering glasspacks turned out less than stellar, but they worked as a temp setup. Gave me some much needed experience so now I can step it up to some next-level stuff and experiment with my repacked RB presilencers and some Magnaflow mufflers on the REPU. The goal is to sound like an RB Street Port system, flow like an RB Street Port system, but fit under the REPU where their powerpulse main muffler and staggered presilencers wouldn't. I've got some room under the bed but the main muffler is kind of the wrong shape. I'm hoping two 2.5" magnaflows will suffice.

Trending Topics

#8

This might be interesting for you. https://www.rx7club.com/v-8-powered-rx-7s-299/new-exhaust-build-946369/#post10529995

#10

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,197

Likes: 2,825

From: https://www2.mazda.com/en/100th/

the dual in dual out, is like the RB FC center section. so that should work just fine. i'd think it could be more compact too.

the X pipe isn't a bad idea, ive actually seen a couple of mufflers like that, i do not know how it works, or what it does to tuning, a V8 is different than, well everything else

the X pipe isn't a bad idea, ive actually seen a couple of mufflers like that, i do not know how it works, or what it does to tuning, a V8 is different than, well everything else

#11

I'm thinking I might have to build both of the pre-silencers so I can see if there are any differences. They shouldn't cost too much to make. j9fd3s do you have any good sources for materials like the perforated tubing? I could always cannibalize a couple cheap cherry bombs if I have to.

#12

The x-pipe will give the best performance if you know what you are doing. I've used this one in the past: http://drgas.mybisi.com/product/xscream-tandem-x-overs

However, I don't think you want it perforated as it will defeat the scavanging properties that make it benificial. I would make the dual parallel runs behind the x-pipe if it were my project.

Make sure to use heavy steel. SS is preferred but expensive. Make the parallel runs as long as possible. A divider separating the two chambers will help with noise reduction. The runs do need to be isolated from each other, but you can still utilize one big oval can with the divider down the middle. Good luck and make sure to post pics.

However, I don't think you want it perforated as it will defeat the scavanging properties that make it benificial. I would make the dual parallel runs behind the x-pipe if it were my project.

Make sure to use heavy steel. SS is preferred but expensive. Make the parallel runs as long as possible. A divider separating the two chambers will help with noise reduction. The runs do need to be isolated from each other, but you can still utilize one big oval can with the divider down the middle. Good luck and make sure to post pics.

#13

I was thinking that by leaving it undivided that it might be quieter than a divided one due to the sound waves canceling each other out. Just a thought, like I said before I'm no expert. I think I might save some money and instead of building multiple units I can just make it re-packable like in the link Jeff provided. Then I can just make the internals replaceable to do some testing. I would like to incorporate a X pipe in the system, so maybe right after the header then have it go into the pre-silencer. I'll be able to see my car this weekend and get some measurements and a good idea of how I want things laid out.

#14

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,197

Likes: 2,825

From: https://www2.mazda.com/en/100th/

I'm thinking I might have to build both of the pre-silencers so I can see if there are any differences. They shouldn't cost too much to make. j9fd3s do you have any good sources for materials like the perforated tubing? I could always cannibalize a couple cheap cherry bombs if I have to.

i was looking at the star mazda cars this weekend, and they use an oval borla muffler. it looked like they had cut em in half to repack em, and they were just clamped together.

Thread

Thread Starter

Forum

Replies

Last Post

ray green

1st Gen General Discussion

2

09-02-15 06:35 AM

rx8volks

Canadian Forum

0

09-01-15 11:02 PM

rx8volks

Canadian Forum

0

09-01-15 10:46 PM