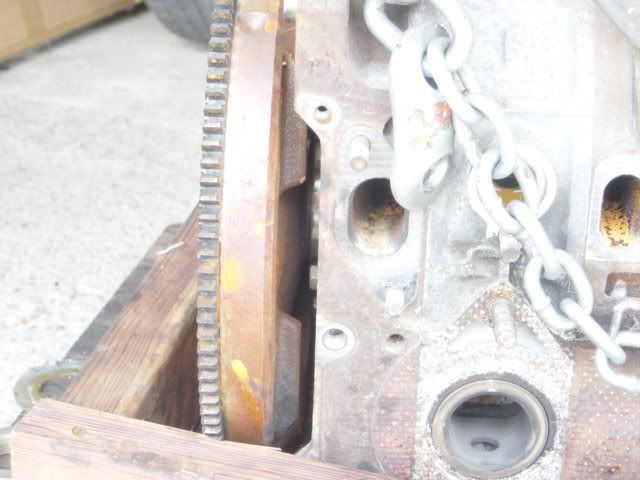

main pully and timing

#1

Thread Starter

wheres the water goin?

iTrader: (9)

Joined: May 2005

Posts: 1,586

Likes: 0

From: Nor Cal

main pully and timing

i changed my water pump today on my 84 SE ( the old was a cheap design) and i pulled my main pully off without thinknig about it and im not too sure i put it back on correctly. i pulled it and took a look at it to find the timing marks and i was curseing myself when i didnt mark it 4 i pulled it off. heres my question how do i know if i put it back on right i put it back to how i thought i pulled it off, and then i rotated the pully 90 degrees and it still went on find so i put it back on the way that i thought that i pulled it off. how do i do this right bc i would like to play alil with my timing in the near future. can you guys help

thanks

charles

thanks

charles

#2

I have had this exact problem before, but on a 12a... I think the solution may be the same, take the flywheel inspection plate off (just above the exhaust, on the edge of the tranny bellhousing), and when the skinny part of the flywheel lines up with the inspection plate you put the pulley on so that the timing marks line up with the indicator pin on the front of the motor.

#5

Certified Old Fart

Joined: Oct 2004

Posts: 490

Likes: 0

From: Inkerman, On, South of Ottawa, the 2nd coldest Capital in the World

Nice job Wacky. You saved 2988 words with your post, and explained better than most any one of us could.

#6

Im just glad to be able to give something back to the community. BTW,keep in mind that the above pix are for 12-A motor. Remember, once you have the flywheel lined up with the rear housing, one of the pulley bolts is your 0 as long as it is or near the 12 oclock position.

#7

Thread Starter

wheres the water goin?

iTrader: (9)

Joined: May 2005

Posts: 1,586

Likes: 0

From: Nor Cal

so just take the cover off where the eng and trans meet turn the pully till i see that divit in the flywheel and at that point i should postion the pully the leading mark is at 12 o'clock and im good to go?

Trending Topics

#9

not on torque plate but on the rear counterweight which is kinda hard to see when installed. look at the e-shaft's key in the pix below. it will keep ya the idea. if not, let me know and I will look at the flex plate in my pile of junks

#12

Originally Posted by 3rd and final 7

so just take the cover off where the eng and trans meet turn the pully till i see that divit in the flywheel and at that point i should postion the pully the leading mark is at 12 o'clock and im good to go?

'Cause you know those balancing holes can be located in different places on different flywheels, depending on the individual flywheel and where the holes need to be drilled to balance it. So you can't use them as a TDC reference.

#15

Rotoholic Moderookie

iTrader: (4)

Joined: May 2002

Posts: 5,962

Likes: 33

From: Ottawa, Soviet Canuckistan

Originally Posted by Wankelguy

Wait a minute, are you talking about the little balancing hole when you say "divot"?

'Cause you know those balancing holes can be located in different places on different flywheels, depending on the individual flywheel and where the holes need to be drilled to balance it. So you can't use them as a TDC reference.

'Cause you know those balancing holes can be located in different places on different flywheels, depending on the individual flywheel and where the holes need to be drilled to balance it. So you can't use them as a TDC reference.

Archived! (wacky now you can't say I don't archive your stuff when I see it!)

Jon

Thread

Thread Starter

Forum

Replies

Last Post

trickster

2nd Generation Specific (1986-1992)

25

07-01-23 04:40 PM