Has anyone gotten the vacuum advance to work right with an aftermarket carb?

#26

With the stock setup (at least the SEs), it is really manifold vac, but they add a solenoid to vent to atmoshphere under idle conditions. This means no vac advance at idle, but just above idle you'll see it kick in if you rev the engine a bit looking at it with the timing light.

For an aftermarket carb, you'll want to use the ported source if available. If a ported source is not available, you can connect to manifold vac (drill and tap a fitting if needed) and use the stock solenoid that controls vac advance (assuming that your emissions control unit is still in place).

For an aftermarket carb, you'll want to use the ported source if available. If a ported source is not available, you can connect to manifold vac (drill and tap a fitting if needed) and use the stock solenoid that controls vac advance (assuming that your emissions control unit is still in place).

Just trying to get a more realistic, more accurate ignition advance. Right now vacuum advancd is disconnected and I am using 25L 15T max timing via centrifugal advance only. For the REPU.

Anyone have the part number for the stock GSL-SE distributor? I might try and see if they're available New Old Stock.

#27

The part number for the SE dizzy is N304-18-200B. I don't even want to think about Mazda will charge for that! Your best bet is probably get a used one. The 12A one will do as well, but the advance curve is a bit different.

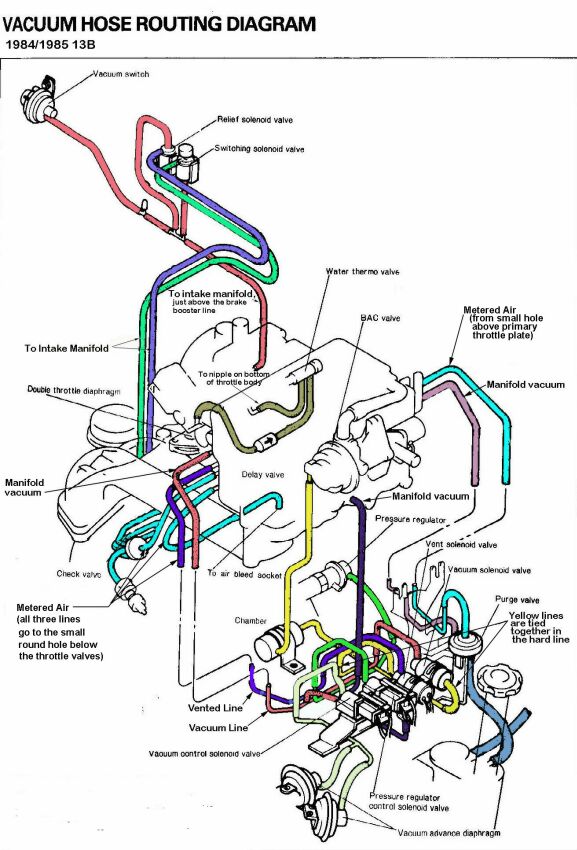

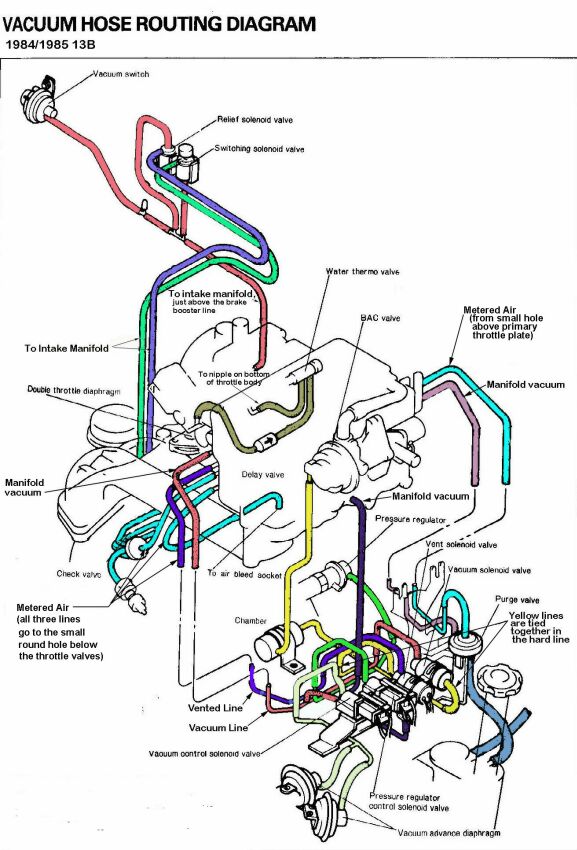

On the SE at least, the solenoid is marked green. It is controlled by the ECU. It looks like it cuts vacuum under idle and under decel. Otherwise, it is manifold vac. I have attach a diagram of the 13B setup. It is the solenoid closest to the front. Probably for your puposes, I bet you could probably set up something simple instead of hooking up the ECU and wiring get to get that control. I bet you could use a microswitch or TPS of somekind, a relay, and that solenoid. Set the swicth/TPS to only be ON (of OFF) at idle (the stock setup adds the vac advance in after about 1000 RPM). You'll have max vac advance on decel, but that shouldn't be a prob. You could also add a vacuum switch at some point if you wanted to kill the vac advance on decel (probably only helps emissions, though)

Hope this helps. Let me know if you need any help setting this up. The easiest would be just connected to ported vacuum if your carb has such a fitting (no extra solenoids and stuff to deal with). I also seem to remember a device you can get to make manifold vac behave like ported. I'll see if I can remember more or find out about that option.

Kent

On the SE at least, the solenoid is marked green. It is controlled by the ECU. It looks like it cuts vacuum under idle and under decel. Otherwise, it is manifold vac. I have attach a diagram of the 13B setup. It is the solenoid closest to the front. Probably for your puposes, I bet you could probably set up something simple instead of hooking up the ECU and wiring get to get that control. I bet you could use a microswitch or TPS of somekind, a relay, and that solenoid. Set the swicth/TPS to only be ON (of OFF) at idle (the stock setup adds the vac advance in after about 1000 RPM). You'll have max vac advance on decel, but that shouldn't be a prob. You could also add a vacuum switch at some point if you wanted to kill the vac advance on decel (probably only helps emissions, though)

Hope this helps. Let me know if you need any help setting this up. The easiest would be just connected to ported vacuum if your carb has such a fitting (no extra solenoids and stuff to deal with). I also seem to remember a device you can get to make manifold vac behave like ported. I'll see if I can remember more or find out about that option.

Kent

#28

Lives on the Forum

Drivefast7; Do you have any vacuum ports on the carb at all? If you can find one that shows no vacuum at idle, and that does shows vacuum with throttle, you should be all set...

#31

Full Member

iTrader: (3)

Join Date: May 2005

Location: Pennsylvania

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

i'd just like to add to inform you, that if you do not use the factory solenoid that vents the vacuum advance to atmospheric at idle, you may experience a poor idle. If you can get that vacuum switching valve and connect it correctly to the ECU, you can use manifold vacuum and it should run just fine.

#33

DriveFast - There is also a SE dizzy in the 1st gen 4 sale section currently. $45 shipped If you were interested in trying out the 13B advance curve.

The REPU may have someting like that solenoid. I honestly don't know enough about REPU to know for sure. All of the 1st gens have that solenoid, though. If that doesn't pan out, I'll help you figure out a switch/relay setup for it. I may even have one of those solenoids that you could have. Just need to find a way to control it, though.

The REPU may have someting like that solenoid. I honestly don't know enough about REPU to know for sure. All of the 1st gens have that solenoid, though. If that doesn't pan out, I'll help you figure out a switch/relay setup for it. I may even have one of those solenoids that you could have. Just need to find a way to control it, though.

#34

Lives on the Forum

Hey, the nipple for the ported vacuum does not necessarily need to be above the throttle plates. Check each available nipple (if there are any) and find one with no vac at idle. Even on the Nikki, the ported vacuum is from a nipple right next to all the others at the base of the carb. The routing is internal... I'd be willing to bet that you have one, you'll just have to verify the function of each one until you find the right one. Good luck...

#35

Junior Member

Join Date: Sep 2007

Location: Alberta, Canada

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

That's almost right Revhead. The idea behind this is, as soon as you tip into the throttle the ignition will advance, giving you a tad more power.

If you set it up with manifold vacuum (assuming that the emissions have been removed) then once you tip into the throttle, the ignition will retard, resulting in less power.

One point though, even at wide open throttle, there will be vacuum above the throttle plates. This will be based off of the flow of air over the port. It provides a sort of siphoning effect to produce the vacuum...

If you set it up with manifold vacuum (assuming that the emissions have been removed) then once you tip into the throttle, the ignition will retard, resulting in less power.

One point though, even at wide open throttle, there will be vacuum above the throttle plates. This will be based off of the flow of air over the port. It provides a sort of siphoning effect to produce the vacuum...

I believe what Kentetsu is talking about is the venturi effect - The same thing that is used to draw fuel into the air stream in the carb. Power steering flow control valves use this effect too. When a fluid moves past a port, a vacuum is created in the port. I don't know for sure if this effect is significant enough or not to make any measurable difference in the vacuum advance or not (never bothered to look into it). Regardless, theoretically I think he makes a good point.

#37

Hunting Skylines

Join Date: Apr 2001

Location: Brisbane, Queensland, Australia.

Posts: 3,431

Likes: 0

Received 3 Likes

on

3 Posts

I believe what Kentetsu is talking about is the venturi effect - The same thing that is used to draw fuel into the air stream in the carb. Power steering flow control valves use this effect too. When a fluid moves past a port, a vacuum is created in the port. I don't know for sure if this effect is significant enough or not to make any measurable difference in the vacuum advance or not (never bothered to look into it). Regardless, theoretically I think he makes a good point.

#38

Lives on the Forum

I helped my cousing drain his waterbed one time. He bought a simple device that hooked up to the faucet on the bath tub. Once it was hooked up, he turned on the water. The water flowed past the opening of a hose, which led to the waterbed. This created a draw that pulled the water out of the bed and emptied it. This was an example of a fluid flowing past a port and creating a vacuum, so don't tell me this is impossible...

#39

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,993

Received 2,691 Likes

on

1,905 Posts

i put a boost/vacuum guage on my stock 83 limited once, just to see what it did.

when the throttle was closed, vacuum to the dizzy was off. the rest of the time, it was manifold vacuum.

we've run the rx8 with the IDS hooked up to it, and it does the same exact thing. zero throttle = -5btdc L

when the throttle was closed, vacuum to the dizzy was off. the rest of the time, it was manifold vacuum.

we've run the rx8 with the IDS hooked up to it, and it does the same exact thing. zero throttle = -5btdc L

#40

Junior Member

Join Date: Sep 2007

Location: Alberta, Canada

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, I guess you're right REVHEAD. Port vacuum source would be located too far away from the venturi for it to have any effect. But I was thinking, if the throttle plates suddenly open, then the air below the venturi would be able to suddenly dump into the engine and if replenishing air is delayed in any way through the venturi to catch up with the increased air volume demand, then it may be possible that a momentary negative pressure may be created above the throttle plates. Not sure if this actually happens though and if it does, it would probably be far too short and too weak to have any effect on the advance diaphragm. I'm not a carb guy, and I'll admit I don't know everything about them, just trying to consider all possibilities.

#41

Hunting Skylines

Join Date: Apr 2001

Location: Brisbane, Queensland, Australia.

Posts: 3,431

Likes: 0

Received 3 Likes

on

3 Posts

I helped my cousing drain his waterbed one time. He bought a simple device that hooked up to the faucet on the bath tub. Once it was hooked up, he turned on the water. The water flowed past the opening of a hose, which led to the waterbed. This created a draw that pulled the water out of the bed and emptied it. This was an example of a fluid flowing past a port and creating a vacuum, so don't tell me this is impossible...

Last edited by REVHED; 11-05-07 at 01:55 AM.

#42

Junior Member

Join Date: Sep 2007

Location: Alberta, Canada

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Kentetsu, I've never seen one of those hose things to empty a water bed so I can't tell you for sure, but I'm betting that the port leading to the water bed connects into a venturi in the hose running from the faucet.

#44

found this post on using manifold vacuum instead of port vacuum. which really is the best?

and, anyone ever buy a remanufactured distributor? kragen sells them for 199 + 50 core by cardone, or the beck arnley brand reman 261 no core.

and, anyone ever buy a remanufactured distributor? kragen sells them for 199 + 50 core by cardone, or the beck arnley brand reman 261 no core.

From everything I've read in regards to traditional piston motors, it's more beneficial to run manifold vacuum. Is it different for rotors?

Kev

From a GM Engineer in regards to HEI ignitions.....

As many of you are aware, timing and vacuum advance is one of my favorite subjects, as I was involved in the development of some of those systems in my GM days and I understand it. Many people don't, as there has been very little written about it anywhere that makes sense, and as a result, a lot of folks are under the misunderstanding that vacuum advance somehow compromises performance. Nothing could be further from the truth. I finally sat down the other day and wrote up a primer on the subject, with the objective of helping more folks to understand vacuum advance and how it works together with initial timing and centrifugal advance to optimize all-around operation and performance. I have this as a Word document if anyone wants it sent to them - I've cut-and-pasted it here; it's long, but hopefully it's also informative.

TIMING AND VACUUM ADVANCE 101

The most important concept to understand is that lean mixtures, such as at idle and steady highway cruise, take longer to burn than rich mixtures; idle in particular, as idle mixture is affected by exhaust gas dilution. This requires that lean mixtures have "the fire lit" earlier in the compression cycle (spark timing advanced), allowing more burn time so that peak cylinder pressure is reached just after TDC for peak efficiency and reduced exhaust gas temperature (wasted combustion energy). Rich mixtures, on the other hand, burn faster than lean mixtures, so they need to have "the fire lit" later in the compression cycle (spark timing retarded slightly) so maximum cylinder pressure is still achieved at the same point after TDC as with the lean mixture, for maximum efficiency.

The centrifugal advance system in a distributor advances spark timing purely as a function of engine rpm (irrespective of engine load or operating conditions), with the amount of advance and the rate at which it comes in determined by the weights and springs on top of the autocam mechanism. The amount of advance added by the distributor, combined with initial static timing, is "total timing" (i.e., the 34-36 degrees at high rpm that most SBC's like). Vacuum advance has absolutely nothing to do with total timing or performance, as when the throttle is opened, manifold vacuum drops essentially to zero, and the vacuum advance drops out entirely; it has no part in the "total timing" equation.

At idle, the engine needs additional spark advance in order to fire that lean, diluted mixture earlier in order to develop maximum cylinder pressure at the proper point, so the vacuum advance can (connected to manifold vacuum, not "ported" vacuum - more on that aberration later) is activated by the high manifold vacuum, and adds about 15 degrees of spark advance, on top of the initial static timing setting (i.e., if your static timing is at 10 degrees, at idle it's actually around 25 degrees with the vacuum advance connected). The same thing occurs at steady-state highway cruise; the mixture is lean, takes longer to burn, the load on the engine is low, the manifold vacuum is high, so the vacuum advance is again deployed, and if you had a timing light set up so you could see the balancer as you were going down the highway, you'd see about 50 degrees advance (10 degrees initial, 20-25 degrees from the centrifugal advance, and 15 degrees from the vacuum advance) at steady-state cruise (it only takes about 40 horsepower to cruise at 50mph).

When you accelerate, the mixture is instantly enriched (by the accelerator pump, power valve, etc.), burns faster, doesn't need the additional spark advance, and when the throttle plates open, manifold vacuum drops, and the vacuum advance can returns to zero, retarding the spark timing back to what is provided by the initial static timing plus the centrifugal advance provided by the distributor at that engine rpm; the vacuum advance doesn't come back into play until you back off the gas and manifold vacuum increases again as you return to steady-state cruise, when the mixture again becomes lean.

The key difference is that centrifugal advance (in the distributor autocam via weights and springs) is purely rpm-sensitive; nothing changes it except changes in rpm. Vacuum advance, on the other hand, responds to engine load and rapidly-changing operating conditions, providing the correct degree of spark advance at any point in time based on engine load, to deal with both lean and rich mixture conditions. By today's terms, this was a relatively crude mechanical system, but it did a good job of optimizing engine efficiency, throttle response, fuel economy, and idle cooling, with absolutely ZERO effect on wide-open throttle performance, as vacuum advance is inoperative under wide-open throttle conditions. In modern cars with computerized engine controllers, all those sensors and the controller change both mixture and spark timing 50 to 100 times per second, and we don't even HAVE a distributor any more - it's all electronic.

Now, to the widely-misunderstood manifold-vs.-ported vacuum aberration. After 30-40 years of controlling vacuum advance with full manifold vacuum, along came emissions requirements, years before catalytic converter technology had been developed, and all manner of crude band-aid systems were developed to try and reduce hydrocarbons and oxides of nitrogen in the exhaust stream. One of these band-aids was "ported spark", which moved the vacuum pickup orifice in the carburetor venturi from below the throttle plate (where it was exposed to full manifold vacuum at idle) to above the throttle plate, where it saw no manifold vacuum at all at idle. This meant the vacuum advance was inoperative at idle (retarding spark timing from its optimum value), and these applications also had VERY low initial static timing (usually 4 degrees or less, and some actually were set at 2 degrees AFTER TDC). This was done in order to increase exhaust gas temperature (due to "lighting the fire late") to improve the effectiveness of the "afterburning" of hydrocarbons by the air injected into the exhaust manifolds by the A.I.R. system; as a result, these engines ran like crap, and an enormous amount of wasted heat energy was transferred through the exhaust port walls into the coolant, causing them to run hot at idle - cylinder pressure fell off, engine temperatures went up, combustion efficiency went down the drain, and fuel economy went down with it.

If you look at the centrifugal advance calibrations for these "ported spark, late-timed" engines, you'll see that instead of having 20 degrees of advance, they had up to 34 degrees of advance in the distributor, in order to get back to the 34-36 degrees "total timing" at high rpm wide-open throttle to get some of the performance back. The vacuum advance still worked at steady-state highway cruise (lean mixture = low emissions), but it was inoperative at idle, which caused all manner of problems - "ported vacuum" was strictly an early, pre-converter crude emissions strategy, and nothing more.

What about the Harry high-school non-vacuum advance polished billet "whizbang" distributors you see in the Summit and Jeg's catalogs? They're JUNK on a street-driven car, but some people keep buying them because they're "race car" parts, so they must be "good for my car" - they're NOT. "Race cars" run at wide-open throttle, rich mixture, full load, and high rpm all the time, so they don't need a system (vacuum advance) to deal with the full range of driving conditions encountered in street operation. Anyone driving a street-driven car without manifold-connected vacuum advance is sacrificing idle cooling, throttle response, engine efficiency, and fuel economy, probably because they don't understand what vacuum advance is, how it works, and what it's for - there are lots of long-time experienced "mechanics" who don't understand the principles and operation of vacuum advance either, so they're not alone.

Vacuum advance calibrations are different between stock engines and modified engines, especially if you have a lot of cam and have relatively low manifold vacuum at idle. Most stock vacuum advance cans aren’t fully-deployed until they see about 15” Hg. Manifold vacuum, so those cans don’t work very well on a modified engine; with less than 15” Hg. at a rough idle, the stock can will “dither” in and out in response to the rapidly-changing manifold vacuum, constantly varying the amount of vacuum advance, which creates an unstable idle. Modified engines with more cam that generate less than 15” Hg. of vacuum at idle need a vacuum advance can that’s fully-deployed at least 1”, preferably 2” of vacuum less than idle vacuum level so idle advance is solid and stable; the Echlin #VC-1810 advance can (about $10 at NAPA) provides the same amount of advance as the stock can (15 degrees), but is fully-deployed at only 8” of vacuum, so there is no variation in idle timing even with a stout cam.

For peak engine performance, driveability, idle cooling and efficiency in a street-driven car, you need vacuum advance, connected to full manifold vacuum. Absolutely. Positively. Don't ask Summit or Jeg's about it – they don’t understand it, they're on commission, and they want to sell "race car" parts.

Kev

From a GM Engineer in regards to HEI ignitions.....

As many of you are aware, timing and vacuum advance is one of my favorite subjects, as I was involved in the development of some of those systems in my GM days and I understand it. Many people don't, as there has been very little written about it anywhere that makes sense, and as a result, a lot of folks are under the misunderstanding that vacuum advance somehow compromises performance. Nothing could be further from the truth. I finally sat down the other day and wrote up a primer on the subject, with the objective of helping more folks to understand vacuum advance and how it works together with initial timing and centrifugal advance to optimize all-around operation and performance. I have this as a Word document if anyone wants it sent to them - I've cut-and-pasted it here; it's long, but hopefully it's also informative.

TIMING AND VACUUM ADVANCE 101

The most important concept to understand is that lean mixtures, such as at idle and steady highway cruise, take longer to burn than rich mixtures; idle in particular, as idle mixture is affected by exhaust gas dilution. This requires that lean mixtures have "the fire lit" earlier in the compression cycle (spark timing advanced), allowing more burn time so that peak cylinder pressure is reached just after TDC for peak efficiency and reduced exhaust gas temperature (wasted combustion energy). Rich mixtures, on the other hand, burn faster than lean mixtures, so they need to have "the fire lit" later in the compression cycle (spark timing retarded slightly) so maximum cylinder pressure is still achieved at the same point after TDC as with the lean mixture, for maximum efficiency.

The centrifugal advance system in a distributor advances spark timing purely as a function of engine rpm (irrespective of engine load or operating conditions), with the amount of advance and the rate at which it comes in determined by the weights and springs on top of the autocam mechanism. The amount of advance added by the distributor, combined with initial static timing, is "total timing" (i.e., the 34-36 degrees at high rpm that most SBC's like). Vacuum advance has absolutely nothing to do with total timing or performance, as when the throttle is opened, manifold vacuum drops essentially to zero, and the vacuum advance drops out entirely; it has no part in the "total timing" equation.

At idle, the engine needs additional spark advance in order to fire that lean, diluted mixture earlier in order to develop maximum cylinder pressure at the proper point, so the vacuum advance can (connected to manifold vacuum, not "ported" vacuum - more on that aberration later) is activated by the high manifold vacuum, and adds about 15 degrees of spark advance, on top of the initial static timing setting (i.e., if your static timing is at 10 degrees, at idle it's actually around 25 degrees with the vacuum advance connected). The same thing occurs at steady-state highway cruise; the mixture is lean, takes longer to burn, the load on the engine is low, the manifold vacuum is high, so the vacuum advance is again deployed, and if you had a timing light set up so you could see the balancer as you were going down the highway, you'd see about 50 degrees advance (10 degrees initial, 20-25 degrees from the centrifugal advance, and 15 degrees from the vacuum advance) at steady-state cruise (it only takes about 40 horsepower to cruise at 50mph).

When you accelerate, the mixture is instantly enriched (by the accelerator pump, power valve, etc.), burns faster, doesn't need the additional spark advance, and when the throttle plates open, manifold vacuum drops, and the vacuum advance can returns to zero, retarding the spark timing back to what is provided by the initial static timing plus the centrifugal advance provided by the distributor at that engine rpm; the vacuum advance doesn't come back into play until you back off the gas and manifold vacuum increases again as you return to steady-state cruise, when the mixture again becomes lean.

The key difference is that centrifugal advance (in the distributor autocam via weights and springs) is purely rpm-sensitive; nothing changes it except changes in rpm. Vacuum advance, on the other hand, responds to engine load and rapidly-changing operating conditions, providing the correct degree of spark advance at any point in time based on engine load, to deal with both lean and rich mixture conditions. By today's terms, this was a relatively crude mechanical system, but it did a good job of optimizing engine efficiency, throttle response, fuel economy, and idle cooling, with absolutely ZERO effect on wide-open throttle performance, as vacuum advance is inoperative under wide-open throttle conditions. In modern cars with computerized engine controllers, all those sensors and the controller change both mixture and spark timing 50 to 100 times per second, and we don't even HAVE a distributor any more - it's all electronic.

Now, to the widely-misunderstood manifold-vs.-ported vacuum aberration. After 30-40 years of controlling vacuum advance with full manifold vacuum, along came emissions requirements, years before catalytic converter technology had been developed, and all manner of crude band-aid systems were developed to try and reduce hydrocarbons and oxides of nitrogen in the exhaust stream. One of these band-aids was "ported spark", which moved the vacuum pickup orifice in the carburetor venturi from below the throttle plate (where it was exposed to full manifold vacuum at idle) to above the throttle plate, where it saw no manifold vacuum at all at idle. This meant the vacuum advance was inoperative at idle (retarding spark timing from its optimum value), and these applications also had VERY low initial static timing (usually 4 degrees or less, and some actually were set at 2 degrees AFTER TDC). This was done in order to increase exhaust gas temperature (due to "lighting the fire late") to improve the effectiveness of the "afterburning" of hydrocarbons by the air injected into the exhaust manifolds by the A.I.R. system; as a result, these engines ran like crap, and an enormous amount of wasted heat energy was transferred through the exhaust port walls into the coolant, causing them to run hot at idle - cylinder pressure fell off, engine temperatures went up, combustion efficiency went down the drain, and fuel economy went down with it.

If you look at the centrifugal advance calibrations for these "ported spark, late-timed" engines, you'll see that instead of having 20 degrees of advance, they had up to 34 degrees of advance in the distributor, in order to get back to the 34-36 degrees "total timing" at high rpm wide-open throttle to get some of the performance back. The vacuum advance still worked at steady-state highway cruise (lean mixture = low emissions), but it was inoperative at idle, which caused all manner of problems - "ported vacuum" was strictly an early, pre-converter crude emissions strategy, and nothing more.

What about the Harry high-school non-vacuum advance polished billet "whizbang" distributors you see in the Summit and Jeg's catalogs? They're JUNK on a street-driven car, but some people keep buying them because they're "race car" parts, so they must be "good for my car" - they're NOT. "Race cars" run at wide-open throttle, rich mixture, full load, and high rpm all the time, so they don't need a system (vacuum advance) to deal with the full range of driving conditions encountered in street operation. Anyone driving a street-driven car without manifold-connected vacuum advance is sacrificing idle cooling, throttle response, engine efficiency, and fuel economy, probably because they don't understand what vacuum advance is, how it works, and what it's for - there are lots of long-time experienced "mechanics" who don't understand the principles and operation of vacuum advance either, so they're not alone.

Vacuum advance calibrations are different between stock engines and modified engines, especially if you have a lot of cam and have relatively low manifold vacuum at idle. Most stock vacuum advance cans aren’t fully-deployed until they see about 15” Hg. Manifold vacuum, so those cans don’t work very well on a modified engine; with less than 15” Hg. at a rough idle, the stock can will “dither” in and out in response to the rapidly-changing manifold vacuum, constantly varying the amount of vacuum advance, which creates an unstable idle. Modified engines with more cam that generate less than 15” Hg. of vacuum at idle need a vacuum advance can that’s fully-deployed at least 1”, preferably 2” of vacuum less than idle vacuum level so idle advance is solid and stable; the Echlin #VC-1810 advance can (about $10 at NAPA) provides the same amount of advance as the stock can (15 degrees), but is fully-deployed at only 8” of vacuum, so there is no variation in idle timing even with a stout cam.

For peak engine performance, driveability, idle cooling and efficiency in a street-driven car, you need vacuum advance, connected to full manifold vacuum. Absolutely. Positively. Don't ask Summit or Jeg's about it – they don’t understand it, they're on commission, and they want to sell "race car" parts.

#45

I suppose the best thing is to try for yourself. There is lots of debate on port vs. manifold vac for the vac advance. The manifold vac would be easiest to try. Just drill/tap your manifold, add a nipple, and connect to the vacuum pots. If you want to replicate the stock setup, you'll need to either connect to a port vaccum (if your carb has one) or do something like we talked about before (manifold vac connected to a solenoid that switches from manifold vac to no vac at idle and decel).

For the remans, I have no experience with them. I'd probably just get a used SE dizzy if you want the 13b advance curve. It is rare for the dizzys to go bad.

For the remans, I have no experience with them. I'd probably just get a used SE dizzy if you want the 13b advance curve. It is rare for the dizzys to go bad.

#46

Waffles - hmmm good

iTrader: (1)

This one article elevates this running debate to an archive candidate, I think.

I'm gonna check it out with my Dellorto using manifold vacuum next time I get a chance. I bet its got a low vacuum on idle and the cans need to be changed. Excellent project I say.

I'm gonna check it out with my Dellorto using manifold vacuum next time I get a chance. I bet its got a low vacuum on idle and the cans need to be changed. Excellent project I say.

#47

Lives on the Forum

Feel free to call me a stuborn ***...

I have tried it both ways, and there is absolutely, positively, no comparison. I have only two vacuum lines on my motor, making it a very simple, clean setup. Testing both ways was no big deal. I started out with manifold vacuum, which I ran for years. But when this whole question originally came up, I simply tried it with ported vacuum. The results were so drastic that I never even considered putting it back to manifold vacuum.

So, I really don't care a whole lot who comes up with what that was written by whoever (although I do enjoy reading some of them). My own personal experience carries much more weight. And all I can figure is that if somebody still disagrees with me, then they simply haven't tried it both ways...

The changes that occurred in the car once I switched to ported advance:

1. No sign of any "stumble" coming off idle.

2. Increased torque when you are cruising, and need to speed up slightly. This is difficult to describe, but a smaller increase in the accelerator results in a larger increase in power. You don't need to push the gas pedal as far down as you did before, to get the same increase in power as before. Make any sense?

3. Increased gas mileage (roughly 2mpg).

4. Overall better feel of driveability and power.

For anybody who feels that they are up to testing this, all I ask is that you do it correctly. These are the steps to follow should you care to do so:

These are the steps to follow should you care to do so:

1. Remove vacuum line from advance mechanism and plug vacuum source.

2. Now that the vacuum advance won't be interfering with your timing at idle, set the timing according to spec at an idle speed of at least close to 800 (to avoid interference from centrifigul advance).

3. Correct idle speed and mixture once the timing is set (probably necessary, but might not be in all cases. I saw a significant change in both).

4. Once everything is running smoothly and correctly again, plug your vacuum advance line into the nipple furthest forward at the base of your carb.

5. Take it for a test drive.

6. Grin like an idiot.

7. Come back here and post results (whatever they may be).

Most of the articles that I have read, admitted that there will be different setups when considering the emissions/no emissions state. I do not doubt that under some circumstances, it may be beneficial to run it one way over another. But it all comes back to real world results, which (at least in my opinion) are the only ones that matter.

Back long ago, when I first became involved in this argument, I corresponded with a few people through posts and PMs to help them convert to ported vacuum. There was never once any negative feedback on the results, only thanks.

So, like I said, articles and documentation and such are nice, but still fail to trump my own personal experience. People once wrote that the world is flat too, but I never did believe that one!

Drivefast7; I don't know enough about your carb to be able to tell you if you have a viable option for ported vacuum or not. I wish that you were able to try it both ways, and post back with your findings and opinions. I hope that whatever you end up doing, you come out of it with a nice running setup. Best of luck to you!

I have tried it both ways, and there is absolutely, positively, no comparison. I have only two vacuum lines on my motor, making it a very simple, clean setup. Testing both ways was no big deal. I started out with manifold vacuum, which I ran for years. But when this whole question originally came up, I simply tried it with ported vacuum. The results were so drastic that I never even considered putting it back to manifold vacuum.

So, I really don't care a whole lot who comes up with what that was written by whoever (although I do enjoy reading some of them). My own personal experience carries much more weight. And all I can figure is that if somebody still disagrees with me, then they simply haven't tried it both ways...

The changes that occurred in the car once I switched to ported advance:

1. No sign of any "stumble" coming off idle.

2. Increased torque when you are cruising, and need to speed up slightly. This is difficult to describe, but a smaller increase in the accelerator results in a larger increase in power. You don't need to push the gas pedal as far down as you did before, to get the same increase in power as before. Make any sense?

3. Increased gas mileage (roughly 2mpg).

4. Overall better feel of driveability and power.

For anybody who feels that they are up to testing this, all I ask is that you do it correctly.

These are the steps to follow should you care to do so:

These are the steps to follow should you care to do so:1. Remove vacuum line from advance mechanism and plug vacuum source.

2. Now that the vacuum advance won't be interfering with your timing at idle, set the timing according to spec at an idle speed of at least close to 800 (to avoid interference from centrifigul advance).

3. Correct idle speed and mixture once the timing is set (probably necessary, but might not be in all cases. I saw a significant change in both).

4. Once everything is running smoothly and correctly again, plug your vacuum advance line into the nipple furthest forward at the base of your carb.

5. Take it for a test drive.

6. Grin like an idiot.

7. Come back here and post results (whatever they may be).

Most of the articles that I have read, admitted that there will be different setups when considering the emissions/no emissions state. I do not doubt that under some circumstances, it may be beneficial to run it one way over another. But it all comes back to real world results, which (at least in my opinion) are the only ones that matter.

Back long ago, when I first became involved in this argument, I corresponded with a few people through posts and PMs to help them convert to ported vacuum. There was never once any negative feedback on the results, only thanks.

So, like I said, articles and documentation and such are nice, but still fail to trump my own personal experience. People once wrote that the world is flat too, but I never did believe that one!

Drivefast7; I don't know enough about your carb to be able to tell you if you have a viable option for ported vacuum or not. I wish that you were able to try it both ways, and post back with your findings and opinions. I hope that whatever you end up doing, you come out of it with a nice running setup. Best of luck to you!

Last edited by Kentetsu; 11-14-07 at 04:53 PM.

#48

Waffles - hmmm good

iTrader: (1)

Ok, I have a stock port 12a in an 80 SA with a RB Dellorto DHLA and headers, tuned exhaust etc. I tried this out and here's my experience.

First I warmed the car up real good and hooked a vacuum guage up to the manifold vacuum to see what it was pulling. At idle it was doing about 13 in. hg. As I revved the engine, the vacuum dropped evenly down to zero as the revs went up. At about 2 or 3K there was no vacuum. I didn't look real closely at the tach when I was doing this as I just wanted to make sure the vacuum acted correctly.

Looking in the FSM they show some graphs of how timing advances as a function of the vacuum. At 400 mm. hg. (~15 in. hg) full vacuum advanced should be noticed. That would be 7.5 degrees. Since I was pulling 13 or so at idle my advance was probably around 5 degrees. This is a guess as I run the 2GDFIS and looking at the timing with my gun was problematic.

Anyway, on to the fun part. I plumbed up some vacuum hoses to drive the vacuum advance diaphrams on the distributor from manifold vacuum (came off the same source as the one for the brake booster that was already there). The idle immediately jumped from ~800 rpm to 1200 rpm, so I dialed back the idle to around 700 rpm. Then I took it out for a drive. I noticed no problems driving, in fact starting out the acceleration seemed smoother and had a a bit more authority. This was great as the Dell has always had a hesitation to it starting out and its virtually gone now Cruising I noticed if I was lugging it at around 2K it behaved better as well. I have to say this makes the whole driving experience much better. To think I've had the Dell on there for years and now I finally got it running pretty smooth.

Cruising I noticed if I was lugging it at around 2K it behaved better as well. I have to say this makes the whole driving experience much better. To think I've had the Dell on there for years and now I finally got it running pretty smooth.

So I think at least for large 2 barrel carbs this mod is a good thing and yes I got it to work with very little problem. Just connect the vacuum lines to a source of manifold vacuum. In this case thats all I have as the Dell has no "ported" vacuum connections on it.

First I warmed the car up real good and hooked a vacuum guage up to the manifold vacuum to see what it was pulling. At idle it was doing about 13 in. hg. As I revved the engine, the vacuum dropped evenly down to zero as the revs went up. At about 2 or 3K there was no vacuum. I didn't look real closely at the tach when I was doing this as I just wanted to make sure the vacuum acted correctly.

Looking in the FSM they show some graphs of how timing advances as a function of the vacuum. At 400 mm. hg. (~15 in. hg) full vacuum advanced should be noticed. That would be 7.5 degrees. Since I was pulling 13 or so at idle my advance was probably around 5 degrees. This is a guess as I run the 2GDFIS and looking at the timing with my gun was problematic.

Anyway, on to the fun part. I plumbed up some vacuum hoses to drive the vacuum advance diaphrams on the distributor from manifold vacuum (came off the same source as the one for the brake booster that was already there). The idle immediately jumped from ~800 rpm to 1200 rpm, so I dialed back the idle to around 700 rpm. Then I took it out for a drive. I noticed no problems driving, in fact starting out the acceleration seemed smoother and had a a bit more authority. This was great as the Dell has always had a hesitation to it starting out and its virtually gone now

Cruising I noticed if I was lugging it at around 2K it behaved better as well. I have to say this makes the whole driving experience much better. To think I've had the Dell on there for years and now I finally got it running pretty smooth.

Cruising I noticed if I was lugging it at around 2K it behaved better as well. I have to say this makes the whole driving experience much better. To think I've had the Dell on there for years and now I finally got it running pretty smooth. So I think at least for large 2 barrel carbs this mod is a good thing and yes I got it to work with very little problem. Just connect the vacuum lines to a source of manifold vacuum. In this case thats all I have as the Dell has no "ported" vacuum connections on it.

Thread

Thread Starter

Forum

Replies

Last Post