Cutting grooves in intake manifold?

#1

Thread Starter

Rotary Enthusiast

iTrader: (2)

Joined: Jul 2003

Posts: 1,088

Likes: 12

From: Wichita KS

Cutting grooves in intake manifold?

Anyone hear of doing this. I'm taking my intake off soon so I figure I might as well. Makes the air flow more turbulent helps stop fuel puddleing and betters atomization. Works great on piston engines and makes sense to me...

I'll give it a try.

http://somender-singh.com/content/view/101/37/

#2

I always thought you wanted the air to flow as smoothly as possible, isn't that why people would "port and polish" their intake. Seems like you would get inconsistent air flow and power. I dunno, never tried it, but doesn't seem like a good idea to me.

#3

Full Member

iTrader: (1)

Joined: May 2003

Posts: 198

Likes: 0

From: St. Simons, GA

On the exhaust side you are correct. You would want it polished to smooth the air flow. But in the intake side, you have fuel and air going in. A mirror finish would make the fuel cling to the sides of the intake some, forming droplets and falling out of suspension in the air path. The goal is a good intake is to deliver the fuel into the chamber in a mist, not droplets. The grooves, or some slight roughing up of the inner walls of the intake, intake port, and such will help tubulate the air which helps in keeping the fuel atomized. As I understand it. LOL

Cheers,

Travis

Cheers,

Travis

#5

All I've done to an intake manifold so far is to cut channels at the top below the carb spacer connecting primary to secondary runners. This is what Mazda started doing in the late '70s and continued through the '80s. Even the crappy FB manifolds with their flapper valve thing in one side still have a connecting hole beneath it. It increases vacuum signal to the carb because all four ports are pulling on the carb rather than just both intermediate ports.

I tried cutting channels on an earlier seperate-runner manifold, and it greatly improved low RPM running. I fired up a fresh rebuild with rather large street ports and it could idle all the way down to 600RPM within 5 minute of runtime on that manifold.

As for the grooves, I think I recall Sterling once mentioned he'd try to make a manifold out of aluiminum sheet some day, and the holes through each sheet wouldn't be the exact same shape or size or something. This would effectively produce a grooved runner. He said it would reduce the fuel's tendency to wet-out on the runner walls when the pedal is mashed and vacuum disappears... or something like that. It's been a while.

I tried cutting channels on an earlier seperate-runner manifold, and it greatly improved low RPM running. I fired up a fresh rebuild with rather large street ports and it could idle all the way down to 600RPM within 5 minute of runtime on that manifold.

As for the grooves, I think I recall Sterling once mentioned he'd try to make a manifold out of aluiminum sheet some day, and the holes through each sheet wouldn't be the exact same shape or size or something. This would effectively produce a grooved runner. He said it would reduce the fuel's tendency to wet-out on the runner walls when the pedal is mashed and vacuum disappears... or something like that. It's been a while.

Last edited by Jeff20B; 07-02-06 at 01:58 PM.

#6

It creates turbulent air right next to the wall. This will do two things, at low speeds it will squeeze the smooth flowing air into a smaller diameter 'tube' down the middle of the port which will keep the velocity up. At high air speeds it creates a 'bearing' effect and makes the air flow better by using the tumbling air as a buffer between the wall and fast moving air.

#7

Thread Starter

Rotary Enthusiast

iTrader: (2)

Joined: Jul 2003

Posts: 1,088

Likes: 12

From: Wichita KS

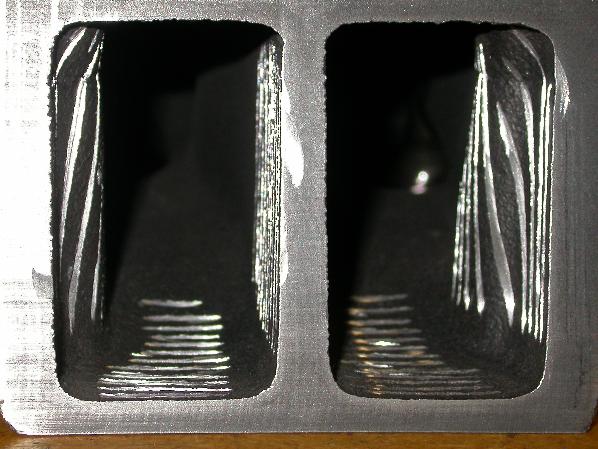

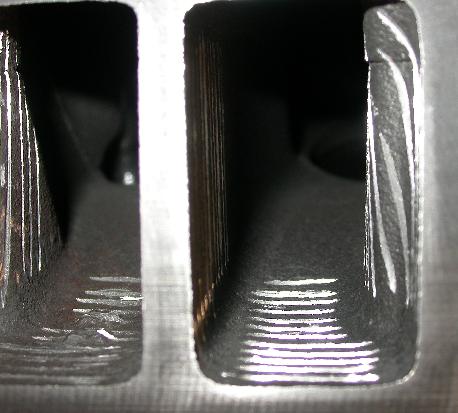

I ported my intake and removed the butterfly after fire valve. I went ahead and cut grooves in my intake like above.

I'll post up any MPG gains or losses over the next week or so.

I must say I'm impressed with the idle. I'll be happy to video tape it for the non-believers but with the car warmed up I can idle smooth as silk at 350rpm. Not that this is necessary for any reason but the car wouldn't do it before. It is definatly ALOT smoother. Where the engine would idle around 800rpm or so before it shook. Now if I were to video tape it and cut the sound you wouldn't even know it was running. Engine sits dead still.

https://www.rx7club.com/showthread.p...92#post6327992

I'll post up any MPG gains or losses over the next week or so.

I must say I'm impressed with the idle. I'll be happy to video tape it for the non-believers but with the car warmed up I can idle smooth as silk at 350rpm. Not that this is necessary for any reason but the car wouldn't do it before. It is definatly ALOT smoother. Where the engine would idle around 800rpm or so before it shook. Now if I were to video tape it and cut the sound you wouldn't even know it was running. Engine sits dead still.

https://www.rx7club.com/showthread.p...92#post6327992

Trending Topics

#13

Great job! I added a channeled spacer to my REPU's unchannled manifold and it produced similar results to a channeled manifold. I idled the truck up a hill which slowly brought the RPM down to 400. The whole truck was bumping in unison with the engine.  Satisfied, I slowly got on the throttle and drove the truck the rest of the way up the hill smoothly accelerating from 400 to about 1300 when I reached the top. A succesful test.

Satisfied, I slowly got on the throttle and drove the truck the rest of the way up the hill smoothly accelerating from 400 to about 1300 when I reached the top. A succesful test.

Those channels are where it's at!

Now I'm curious about cuts in the runners. I'm interested in anything that boosts ultra-low RPM performance as I'm currently researching rotary bajas.

Satisfied, I slowly got on the throttle and drove the truck the rest of the way up the hill smoothly accelerating from 400 to about 1300 when I reached the top. A succesful test.

Satisfied, I slowly got on the throttle and drove the truck the rest of the way up the hill smoothly accelerating from 400 to about 1300 when I reached the top. A succesful test.Those channels are where it's at!

Now I'm curious about cuts in the runners. I'm interested in anything that boosts ultra-low RPM performance as I'm currently researching rotary bajas.

#14

Thread Starter

Rotary Enthusiast

iTrader: (2)

Joined: Jul 2003

Posts: 1,088

Likes: 12

From: Wichita KS

Originally Posted by perfect_circle

have you noticed any increase in performance at all?

Unfortunatly I think I had to many variables to give a definate answer.

Seems the car woke up at extermly low rpm. From a dead stop the car would always die down a little to the point were I'd have to give it some gas as I let out the clutch to get it going. Now I can just let the clutch out, no gas, and the car just goes. (And this is with me setting the idle at 750 rpm I use to have it around 900).

I noticed what feels like a small gain up top too 6-7500 rpm were the car would die down before it seems to pull clean through to redline now. But i'd assume this is just because of the port job. And maybe a tiny bit larger secondary jet?

If U read up on my carb troubles post you'll see whehn I did the intake mods I rebuilt the carb as well. I hogged out the secondary jets way to much so my car was slower once finished. This weekend I put the jets back to #160's (or very close maybe 5% larger) and the car feels alot stronger now. But that is because I was driving it for about a week with the huge secondary jets. Also me porting the intake and removing the butterfly valve probably made some small gains as well.

I was really hoping to notice a mpg increase. I wasn't expecting to get any real power gains from the intake grooves. I'll post up any MPG losses or gains in teh next couple weeks.

Either way I'm happy with it. My friends always laugh when I tell them I have a 100hp car but are always impressed when they go for a ride! Still it's a pig compared to my other 7...

#15

Thread Starter

Rotary Enthusiast

iTrader: (2)

Joined: Jul 2003

Posts: 1,088

Likes: 12

From: Wichita KS

Originally Posted by Jeff20B

Great job! I added a channeled spacer to my REPU's unchannled manifold and it produced similar results to a channeled manifold. I idled the truck up a hill which slowly brought the RPM down to 400. The whole truck was bumping in unison with the engine.  Satisfied, I slowly got on the throttle and drove the truck the rest of the way up the hill smoothly accelerating from 400 to about 1300 when I reached the top. A succesful test.

Satisfied, I slowly got on the throttle and drove the truck the rest of the way up the hill smoothly accelerating from 400 to about 1300 when I reached the top. A succesful test.

Those channels are where it's at!

Now I'm curious about cuts in the runners. I'm interested in anything that boosts ultra-low RPM performance as I'm currently researching rotary bajas.

Satisfied, I slowly got on the throttle and drove the truck the rest of the way up the hill smoothly accelerating from 400 to about 1300 when I reached the top. A succesful test.

Satisfied, I slowly got on the throttle and drove the truck the rest of the way up the hill smoothly accelerating from 400 to about 1300 when I reached the top. A succesful test.Those channels are where it's at!

Now I'm curious about cuts in the runners. I'm interested in anything that boosts ultra-low RPM performance as I'm currently researching rotary bajas.

#17

It wont help the exhaust. It helps keep a boundary layer from forming and keeps the fuel from wetting out as much as was previously stated. If correctly shaped I believe it will also reduce intake reversion. I posted this idea over on mazspeed about a year ago.

#21

Originally Posted by jjlrx7

could i groove my racing beat holley intake and notice the difference?

Should the distance between lines be uniform or somewhat random ? Just minimal depth ? How far into the runner from the top ? 2 inches... 3 ? 4? more ?

#22

Thread Starter

Rotary Enthusiast

iTrader: (2)

Joined: Jul 2003

Posts: 1,088

Likes: 12

From: Wichita KS

No not on the exhaust side. Sorry that was a bad picture to use. I just meant on the rotor houseing. Intake side only.

As far as the rest of the questions read up on it here..

http://somender-singh.com/content/view/101/37/

I don't think spacing matters all that much. I'm sure if you wanted to take it to extreme levels you could design the grooves for maximum air turbulence mathmatically.

The basic idea is just to cause turbulence in the air flow. This maximizes atomization and reduces chances of fuel puddeling esp. on carb'd cars.

Cutting groves in the actual rotor houseing walls would be like the relief cuts in the heads shown in the sight above. But I'm not about to go carving up my engine!

This guy had some amazing results in his geo metro from these grooves.

http://www.jeremiahsviolins.com/grooves.htm

Good luck!

As far as the rest of the questions read up on it here..

http://somender-singh.com/content/view/101/37/

I don't think spacing matters all that much. I'm sure if you wanted to take it to extreme levels you could design the grooves for maximum air turbulence mathmatically.

The basic idea is just to cause turbulence in the air flow. This maximizes atomization and reduces chances of fuel puddeling esp. on carb'd cars.

Cutting groves in the actual rotor houseing walls would be like the relief cuts in the heads shown in the sight above. But I'm not about to go carving up my engine!

This guy had some amazing results in his geo metro from these grooves.

http://www.jeremiahsviolins.com/grooves.htm

Good luck!

#24

verify this and ill give it a go.

i have the two piece RB intake for a side draft dellorto. i can take this off, take a disc on a dremel and just cut "slashes" down the manifold. not a certain distance. on all sides. how deep? anything else?

i have the two piece RB intake for a side draft dellorto. i can take this off, take a disc on a dremel and just cut "slashes" down the manifold. not a certain distance. on all sides. how deep? anything else?

#25

Originally Posted by DAVID GRIMES

What is intake reversion exactly ?