chrome housings???

#1

chrome housings???

i want to know if this is possible . i know i can polish them . but why not just chrome them? heat issue maybe .. can i do this to stock 12a that i only drive on sunday to a car meet . let me know. problem a stupid question but dont kill me for asking(loo).

#3

Well choming is going to cost you a bit of cash, moreso then polishing.

Get some 220 grit 400 grit 800 grit 1000, and 1200 or 1500 although 2000 grit is ideal for the finishing step. Sand the housings down in steps starting with 220 and work your way up, when your finished sanding, get a tin of aluminum polish from Wal-mart (or any auto store) and polish several times to a shine.

Its a daunting task at first and the housings wont look good until you start polishing with the compound. It isnt hard, it is hard to screw up, and its time consuming BUT worth it!!

I refinished a set of stock aluminum wheels with this process and this will apply to rotor housings as well.

Its cheaper than chroming, and will be ALOT more durable.

Get some 220 grit 400 grit 800 grit 1000, and 1200 or 1500 although 2000 grit is ideal for the finishing step. Sand the housings down in steps starting with 220 and work your way up, when your finished sanding, get a tin of aluminum polish from Wal-mart (or any auto store) and polish several times to a shine.

Its a daunting task at first and the housings wont look good until you start polishing with the compound. It isnt hard, it is hard to screw up, and its time consuming BUT worth it!!

I refinished a set of stock aluminum wheels with this process and this will apply to rotor housings as well.

Its cheaper than chroming, and will be ALOT more durable.

#5

Another option wouild be to powdercoat them, but that gets tricky when heat is invovled and some powders are susceptible to chemicals, even fuel spills. As a test, you could try a brass wire brush in a drill and see what you think of that. It will shine the aluminum but won't polish it smooth or give it a mirror shine.

#6

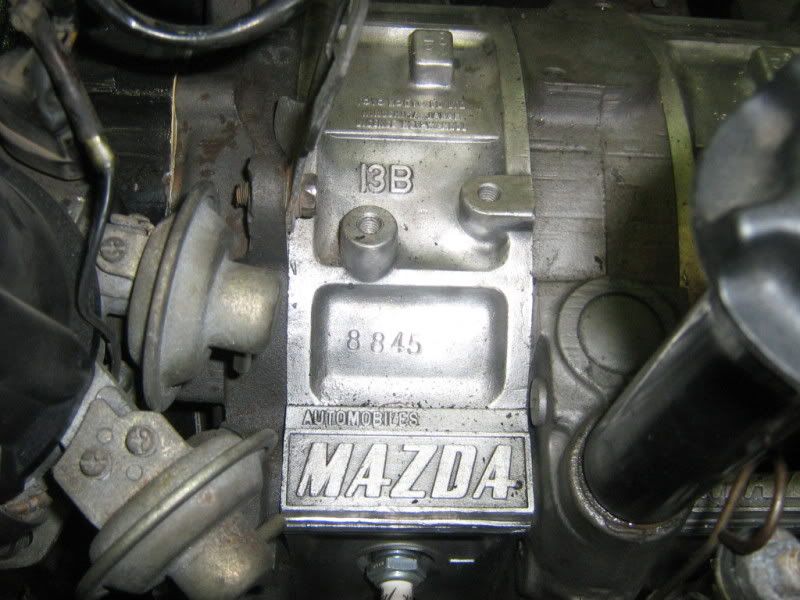

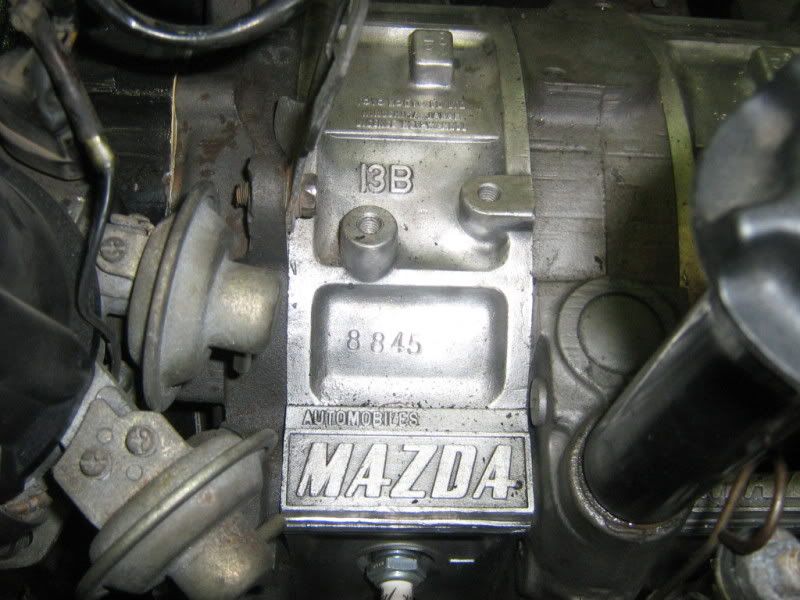

I used a brass wire wheel brush in a drill and this is how it turned out.

This is what they look like today. 1.5 years on the polish job, they have had water spilled on them and fuel. They don't look bad but if i have to rebuild then i will do it again.

This is what they look like today. 1.5 years on the polish job, they have had water spilled on them and fuel. They don't look bad but if i have to rebuild then i will do it again.

#7

I would have to agree, a brass wire wheel does wonders on these housings. I didn't go all out on polishing them, but all the aluminum parts were given a light wire wheel treatment and it really brought them to life.

https://www.rx7club.com/build-threads-293/rising-ashes-pics-warned-812400/page6/

https://www.rx7club.com/build-threads-293/rising-ashes-pics-warned-812400/page6/

Trending Topics

#8

DupliColor now has a clearcoat in thier VHT line of rattle can paint. Polished or wire wheeled it will keep the housing shineing for a long time. If one is asking themselves why brass and not a steel wire wheel, brass is softer, steel cuts deeper and makes the aluminum look grainier.

Blown7, thanks for posting pics of your old school 13B housings. Btw, how did you do the peripheral ports? Homemade or did you buy them that way?

Blown7, thanks for posting pics of your old school 13B housings. Btw, how did you do the peripheral ports? Homemade or did you buy them that way?

#11

+You must polish it after the wire brush treatment or else it will just go dull and lose that nice shine after a short period of time(faster than you think a kind of right before your eyes thing) trust me. Addind a clear coat as trochoid stated would just make all that hard work more enjoyable it would suck to see the housing look dull after all the hard work of getting them all shiny. I would just paint it all it is the easiset wasy imo. Thats what i did and my motor and bay look so damn nice compared to how it looked when i first got my se7en.

Last edited by CHiNO84gsl; 05-07-09 at 08:15 AM. Reason: bad spelling

#13

thanks for the replys . heat wound not be a big issue for me as i dont drive it much . i am willing to do the work to polish them but i am looking for a better look and one that would be easier to maintain. i do have a powder coat clear i could use . i have a housing that i powder coated red as a test and it looks gerat . and one have pictures of some chrome ones

#14

1st-Class Engine Janitor

iTrader: (15)

Joined: Jun 2008

Posts: 8,376

Likes: 28

From: Chino Hills, CA

For some reason, I didn't think you could chrome-plate aluminum directly... but I'm not a metallurgist, so I could well be wrong. I seem to remember that they have to plate it up with copper, then nickel, then chrome.

Wasn't there some safety issue that surrounded croming aluminum wheels? Something about crypto-galvanic corrosion problems? I think it led to them being outlawed in Germany.

I'd think it would be cheaper and easier to polish and then anodize housings. You can buy anodizing kits and DIY.

Most important thing though would be choosing a process that's not going to mess up the housing's side dimensions or the chamber lining.

Wasn't there some safety issue that surrounded croming aluminum wheels? Something about crypto-galvanic corrosion problems? I think it led to them being outlawed in Germany.

I'd think it would be cheaper and easier to polish and then anodize housings. You can buy anodizing kits and DIY.

Most important thing though would be choosing a process that's not going to mess up the housing's side dimensions or the chamber lining.

#15

. . . I seem to remember that they have to plate it up with copper, then nickel, then chrome.

Wasn't there some safety issue that surrounded croming aluminum wheels?

. . .

Most important thing though would be choosing a process that's not going to mess up the housing's side dimensions or the chamber lining.

Wasn't there some safety issue that surrounded croming aluminum wheels?

. . .

Most important thing though would be choosing a process that's not going to mess up the housing's side dimensions or the chamber lining.

Your final point is the one I'd me most concerned with. Things that I've seen plated usually get the treatment over the entire surface. You wouldn't want to get it on the mating surfaces, or the chamber lining, or the spark plug holes . . .

#16

Yes you can Chrome Plate Aluminium. Elwood is right, all the internal areas ect. would have to be sealed off to prevent exposure. The process involves basically dunking and submerging the parts into a series tanks containing the chemicals. There is industrial (wear resistance) chrome, and decorative chrome (what you want).

At only a few thousands thick, it thinner than paint which means that it first must be polished smooth if you want the mirror look. This is part of the reason it's more expensive. Like paint, it's all in the prep work. A properly chromed part will both look better and require less maintenance to maintain it appearance. Poor quality jobs can result in chipping or flaking but normally it is very durable for something like a rotor housing. The biggest disadvantage is it more noticable if you scratch it or it does flake.

A polished part will oxidize (normal reaction with air & moisture) over time and loose it's luster. When you clear coat it, that helps to protect it from the outside elements and slows that process down. By running an engine you are creating heat cycles each time you start and stop. Actual milage makes little difference, it the number of times (heat cycles) you subject it to. Each time the metal heats up from running, then cools down is a cycle, and guess what that also causes? Condensation or moisture. Only this time its from the inside.

So, if your following me you will understand that you will still get oxidation only slower.

When you chrome plate the part, it's a chemical process using nickel (among other elements). The Nickel gives it excellent corosion resistance properties (resistance to oxidation) from both the the inside and out. But remember, for the mirror look you still have to go through all the work of polishing before it's plated. If its a flawless finish and luster your after and you have the funds, there is no comparison between polished and chromed. It will also hold its luster longer/better with the mininium of maintenance. it will however also cost you the most. Simple math really, like speed=money.

Now annodizing, is also a plating process used on aluminium. It's not mirror like but translucent. You can get Gold,red, blue, black and clear. Maybe other colors not too sure but, it's really designed to be a corosion inhibitor.

At only a few thousands thick, it thinner than paint which means that it first must be polished smooth if you want the mirror look. This is part of the reason it's more expensive. Like paint, it's all in the prep work. A properly chromed part will both look better and require less maintenance to maintain it appearance. Poor quality jobs can result in chipping or flaking but normally it is very durable for something like a rotor housing. The biggest disadvantage is it more noticable if you scratch it or it does flake.

A polished part will oxidize (normal reaction with air & moisture) over time and loose it's luster. When you clear coat it, that helps to protect it from the outside elements and slows that process down. By running an engine you are creating heat cycles each time you start and stop. Actual milage makes little difference, it the number of times (heat cycles) you subject it to. Each time the metal heats up from running, then cools down is a cycle, and guess what that also causes? Condensation or moisture. Only this time its from the inside.

So, if your following me you will understand that you will still get oxidation only slower.

When you chrome plate the part, it's a chemical process using nickel (among other elements). The Nickel gives it excellent corosion resistance properties (resistance to oxidation) from both the the inside and out. But remember, for the mirror look you still have to go through all the work of polishing before it's plated. If its a flawless finish and luster your after and you have the funds, there is no comparison between polished and chromed. It will also hold its luster longer/better with the mininium of maintenance. it will however also cost you the most. Simple math really, like speed=money.

Now annodizing, is also a plating process used on aluminium. It's not mirror like but translucent. You can get Gold,red, blue, black and clear. Maybe other colors not too sure but, it's really designed to be a corosion inhibitor.

#17

#18

well i think what i will do is . strip down my spare motor and wire wheel the housings . i will do a little work to get them smooth then take them to my chrome shop and see what they say . i will let them know to block off all the holes and the internals . i cant wait to see the complete motor after the housings are chrome and the irons are powder coated .

#19

I am surprised that I don't see more of the aiuminium housings annodized, given the popularity of painting the cast iron ones. Maybe it's a cost thing. I would think wire brushing and clear annodizing might be a good compromise of looks vs cost.

I would talk to them before you do anything to them. Just take one over to see what they say. Decide after that, how to proceed. Could save you some time and effort. Wire brushing is basically cleaning them up, a step which might not have to be done if you go the full polish route. But on the other hand, if you brush them first, they could look so good to you then, you might decide not to go the full polish. Especially after getting the quote!

You should just have to show them you want them plated on the outside surfaces. If they don't know enough to go from there, I wouldn't give them the work anyway. You might want to try different types of brushes. You will get different looks depending on type (brass vs stainless for instance) and corseness/stiffness of the wire.

There is nothing saying you can't get it plated with out the polishing. You might be satisified with that. The polishing is required if your looking for the Mirror finish Chrome. Like what you see on bumbers and choppers and such. If your happy with a bright silver, not glass smooth-mirror like, then it doesn't have to be polished like that before hand. Think of it like a clear coat, it's not going to hide any flaws or textures that are there before hand.

I would talk to them before you do anything to them. Just take one over to see what they say. Decide after that, how to proceed. Could save you some time and effort. Wire brushing is basically cleaning them up, a step which might not have to be done if you go the full polish route. But on the other hand, if you brush them first, they could look so good to you then, you might decide not to go the full polish. Especially after getting the quote!

You should just have to show them you want them plated on the outside surfaces. If they don't know enough to go from there, I wouldn't give them the work anyway. You might want to try different types of brushes. You will get different looks depending on type (brass vs stainless for instance) and corseness/stiffness of the wire.

There is nothing saying you can't get it plated with out the polishing. You might be satisified with that. The polishing is required if your looking for the Mirror finish Chrome. Like what you see on bumbers and choppers and such. If your happy with a bright silver, not glass smooth-mirror like, then it doesn't have to be polished like that before hand. Think of it like a clear coat, it's not going to hide any flaws or textures that are there before hand.

#20

Well choming is going to cost you a bit of cash, moreso then polishing.

Get some 220 grit 400 grit 800 grit 1000, and 1200 or 1500 although 2000 grit is ideal for the finishing step. Sand the housings down in steps starting with 220 and work your way up, when your finished sanding, get a tin of aluminum polish from Wal-mart (or any auto store) and polish several times to a shine.

Its a daunting task at first and the housings wont look good until you start polishing with the compound. It isnt hard, it is hard to screw up, and its time consuming BUT worth it!!

I refinished a set of stock aluminum wheels with this process and this will apply to rotor housings as well.

Its cheaper than chroming, and will be ALOT more durable.

Get some 220 grit 400 grit 800 grit 1000, and 1200 or 1500 although 2000 grit is ideal for the finishing step. Sand the housings down in steps starting with 220 and work your way up, when your finished sanding, get a tin of aluminum polish from Wal-mart (or any auto store) and polish several times to a shine.

Its a daunting task at first and the housings wont look good until you start polishing with the compound. It isnt hard, it is hard to screw up, and its time consuming BUT worth it!!

I refinished a set of stock aluminum wheels with this process and this will apply to rotor housings as well.

Its cheaper than chroming, and will be ALOT more durable.