Cambering Solid Rear Axel

#1

Cambering Solid Rear Axel

hey guys. quick question for ya. i've heard a few people talking about it and have seen a few pictures of it done. i'm just looking for a bit more info on it. i dont even know what the proper term for such a process is. from what i've gathered they basically take your rear diff housing, cut it, camber it out a bit and re-weld it. apparently you can get about 3 degrees out of it and still have a fully functioning diff. does anybody know anything about this? any help would be greatly appreciated. thanks.

dave

dave

#2

Are you a fan of reducing your contact patch with the ground? The contact patch with the ground doesn't change with body roll on a solid axle like it does on independent suspension. The tires are almost always square with the ground unless you lift a rear tire or the tire is rolling over but there are much easier ways to fix both of the problems other then coming up with some off the wall angled axle tubes which certainly would cost way to much and add a bunch of unnecessary wear.

#3

I believe it actually involves running a bead of hot metal along the topside of the housing, then as it cools and contracts it creates the camber. Not sure, I may have it totally wrong. But yeah, it has been done.

I looked into this option a while back, and discussed it with Billy from Respeed. In the end, it came down to the trouble of obtaining the potential benefits Vs. the idea that my handling couldn't really be improved all that much. My car already handles great, which is why I haven't even bothered to install the tri-link/panhard bar setup that's been on a shelf in my garage for a couple of years.

Are you looking into this option in order to address a specific handling issue? There may be better ways to get to where you want to be.

.

I looked into this option a while back, and discussed it with Billy from Respeed. In the end, it came down to the trouble of obtaining the potential benefits Vs. the idea that my handling couldn't really be improved all that much. My car already handles great, which is why I haven't even bothered to install the tri-link/panhard bar setup that's been on a shelf in my garage for a couple of years.

Are you looking into this option in order to address a specific handling issue? There may be better ways to get to where you want to be.

.

#4

1st-Class Engine Janitor

iTrader: (15)

Joined: Jun 2008

Posts: 8,376

Likes: 28

From: Chino Hills, CA

Rear camber increase is compensation for a situation that doesn't occur with solid axles, as I understand it. That would move such a mod into the "pointless" category for me.

The fact that it would of necessity be causing misalignment of parts that are supposed to be carefully in line, pushes it the rest of the way into the "pointless and counterproductive" section.

The fact that it would of necessity be causing misalignment of parts that are supposed to be carefully in line, pushes it the rest of the way into the "pointless and counterproductive" section.

#5

There have been a few discussions about how to do this on the race car tech forum; do a search there.

I have been running cambered rear ends for years on my road racer, it is a definite performance improvement. Radial racing tires benefit more from camber than bias ply racing tires.

The MAXIMUM camber that a 1st gen RX-7 axle can withstand and have the axle bearings live is -3/4 degree per wheel. I have run as much as 1-1/4 degree, and my axle bearing life goes down to about 200 miles.

Also please note that the axle housing will bend slightly in the negative camber direction just from carrying the weight of the car. Running wider than stock racing wheels increases this axle housing deflection under load. Always make rear axle camber measurements under load; while the rear wheels are on the ground.

I have been running cambered rear ends for years on my road racer, it is a definite performance improvement. Radial racing tires benefit more from camber than bias ply racing tires.

The MAXIMUM camber that a 1st gen RX-7 axle can withstand and have the axle bearings live is -3/4 degree per wheel. I have run as much as 1-1/4 degree, and my axle bearing life goes down to about 200 miles.

Also please note that the axle housing will bend slightly in the negative camber direction just from carrying the weight of the car. Running wider than stock racing wheels increases this axle housing deflection under load. Always make rear axle camber measurements under load; while the rear wheels are on the ground.

#6

Rear camber increase is compensation for a situation that doesn't occur with solid axles, as I understand it. That would move such a mod into the "pointless" category for me.

The fact that it would of necessity be causing misalignment of parts that are supposed to be carefully in line, pushes it the rest of the way into the "pointless and counterproductive" section.

The fact that it would of necessity be causing misalignment of parts that are supposed to be carefully in line, pushes it the rest of the way into the "pointless and counterproductive" section.

#7

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,203

Likes: 2,826

From: https://www2.mazda.com/en/100th/

back in the pro7 days the pumpkin got chained down to a huge steel I beam and then you just put floor jacks under the "wheels"

we used to go about a degree, the pro7 only ran 185/75/13's so the axle deflection thing isn't as big a problem as it is with the IMSA 16x12 wheel/tire setup

we used to go about a degree, the pro7 only ran 185/75/13's so the axle deflection thing isn't as big a problem as it is with the IMSA 16x12 wheel/tire setup

Trending Topics

#8

mine was done, set it to 1.0* negative camber both sides. it did handle better afterwards, rear stuck better.

some pro7 guys set theirs to 0.7* as the max neg. camber allowed was 1.0*. That'll give some room to spare in case you hit berms or bend it with an off you won't be declared illegal.

the more you bend it, the quicker the axle bearings die. One ITA 1st gen did 3* and changed bearings a lot more often. Can't say I'd to that.

some pro7 guys set theirs to 0.7* as the max neg. camber allowed was 1.0*. That'll give some room to spare in case you hit berms or bend it with an off you won't be declared illegal.

the more you bend it, the quicker the axle bearings die. One ITA 1st gen did 3* and changed bearings a lot more often. Can't say I'd to that.

#9

This would certainly be in the "last tenth of a second" category. Really only seems necessary when under highly scrutinized rules (spec) and you have already done everything else that is legal.

As far as handling, this would not be the first thing I tried, I would leave it to the last.

-billy

As far as handling, this would not be the first thing I tried, I would leave it to the last.

-billy

#10

Go ahead and lie down on the couch, just tell us all about it....

What are you currently running for suspension?

Do you have a LSD?

What are your plans for the car?

Is this question part of an attempt to address a specific handling issue?

What are you currently running for suspension?

Do you have a LSD?

What are your plans for the car?

Is this question part of an attempt to address a specific handling issue?

#11

1 degree was the most the bearings and splines would handle with reliablility. Radials have what is called camber thrust and it is very useful to get that extra grip they offer. You can heat up the top of the axle tubes near the pumpkin and quench them or the old accidentally drop it if rules are a big issue. Be careful though, you can change toe while you're looking for camber.

I actually had stock housings that had .5 degree on one side and .3 on the other so its good to check them anyway.

I actually had stock housings that had .5 degree on one side and .3 on the other so its good to check them anyway.

#12

thanks for all the input. the car is currently under the knife getting the FC front subframe and steering rack as well as FC front coilovers. the rear im undecided between using billy's coilover kit or doing a custom rig back there. now before you guys get into it i dont need advice or options on the coilovers at the moment. as for cambering the rear diff...i do not plan to track this car more than a few times a year. i'm merely looking into it for the sheer sake that a cambered rear end looks ****** badass on a low car. that is all. so does anyone know if this has a certain name? thanks.

#14

-billy

#15

Personally, I would hold off on doing this. Your best bet is to take care of all of your other suspension stuff and get all that dialed in. Once you take care of all this stuff, you might very well find that the cambered rear end is not needed or may not be worth the short bearing life to get the kind of camber you are looking for. I agree with Billy and say to hold this to your last upgrade.

#17

A lot of camber in the front and stock in the back can still look badass. Look at this car for example, I think it looks like it's ready to take on anything. And it's probably still very functional, and will not wear out parts like crazy.

#18

Yep, camber on the front looks pretty tough. Teenage girls go crazy for it, and I have to chase them off with a big stick all the time. lol.

Rear would look good too, but not at the cost of replacing bearings every 200 miles (that's not a very easy job).

Maybe spend your money on an air dam, or a spoiler, or an underbody lighting kit...

Rear would look good too, but not at the cost of replacing bearings every 200 miles (that's not a very easy job).

Maybe spend your money on an air dam, or a spoiler, or an underbody lighting kit...

#19

The Shadetree Project

iTrader: (40)

Joined: Jul 2002

Posts: 7,301

Likes: 3

From: District of Columbia

I've also heard if you place the weld just right you can get .25" toe in and .7* of camber to keep the rear end much more under control. I've heard from others if you do it right it makes a huge difference on race tires.

#20

If you can weld you can do a FC independent rear. theres a guy on here I've met at a few meets goes by Gambone I think. Has a bad *** RX-4 with a 13BT It may have been twin turbo? I don't remember. He has a FC rear end. If it can be done in an RX-4 it can be done in an FB. Good luck. I like the way cambered cars look also. But I'm just going to stick to the front. I don't think the benifit would outway the cost and time. but if your going for looks.

#21

Or, maybe I'll just do it in my garage, might be more fun that way. Need to consider how to measure everything though, hmmmm

I have a friend that can weld a bit. Or I've got an engine hoist I might be able to use to bend it.

Dammit Hyper, now I'm gonna have to start researching!!!

But maybe by spring I'll have camber, toe, and tri/pan. Then come race tires with income tax return. Then hit the divisional circuit? God, I'd be embarassed to lose if my car had all that ****. lol

#22

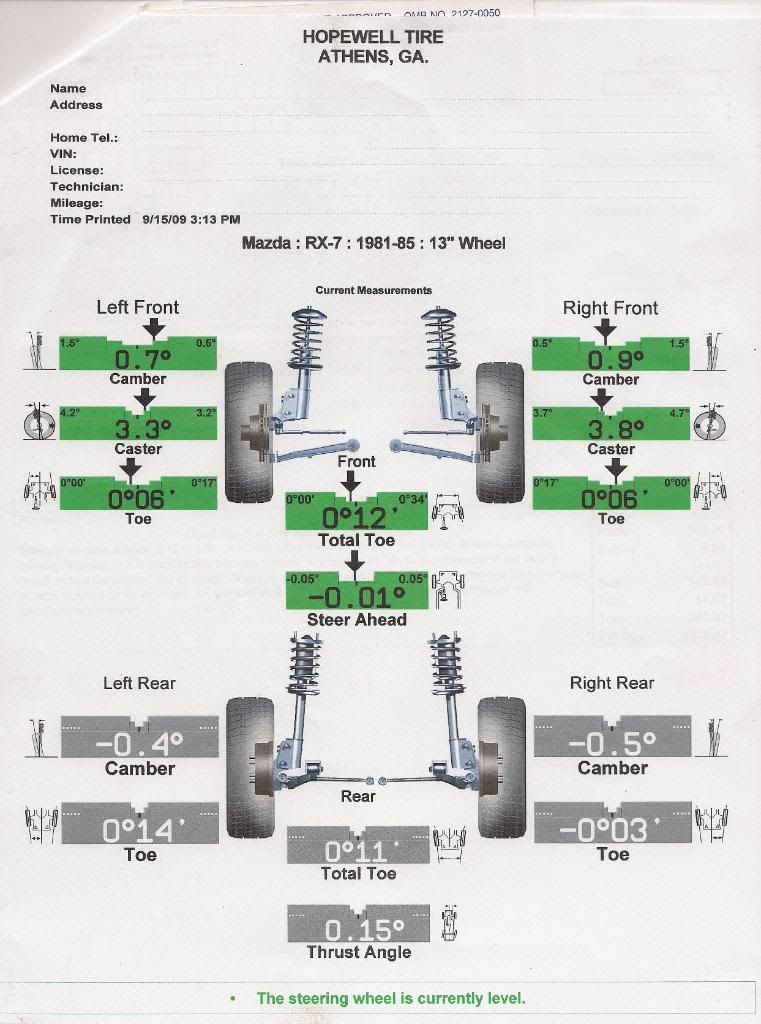

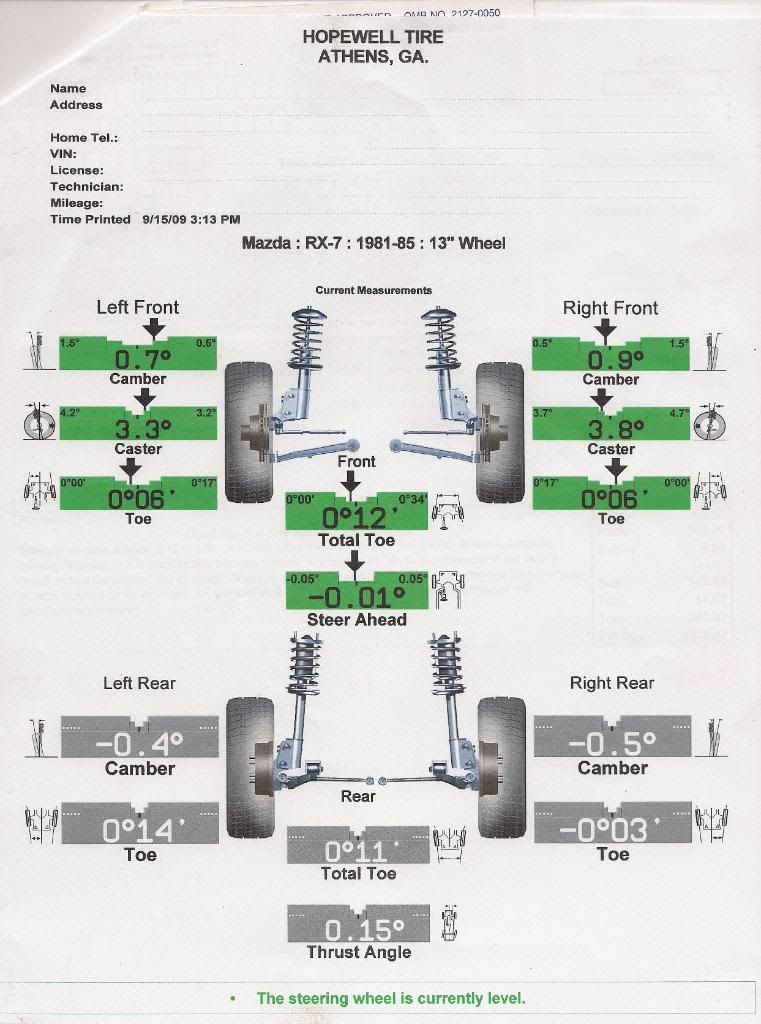

During the recent alignment for my 85 GSL I discovered it has NEGATIVE camber on the rear, which is not normally adjustable. Do you suppose the Mazda engineers did that so that you would have LESS control of the car?

#24

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,203

Likes: 2,826

From: https://www2.mazda.com/en/100th/

Now that's a good point. I have a spare 3rd member, that goes along with my tri-link/panhard (which is not installed). Maybe I'll look around for a race shop and see what they'd charge to add camber/toe, and how they would go about doing it.

Or, maybe I'll just do it in my garage, might be more fun that way. Need to consider how to measure everything though, hmmmm

I have a friend that can weld a bit. Or I've got an engine hoist I might be able to use to bend it.

Dammit Hyper, now I'm gonna have to start researching!!!

But maybe by spring I'll have camber, toe, and tri/pan. Then come race tires with income tax return. Then hit the divisional circuit? God, I'd be embarassed to lose if my car had all that ****. lol

Or, maybe I'll just do it in my garage, might be more fun that way. Need to consider how to measure everything though, hmmmm

I have a friend that can weld a bit. Or I've got an engine hoist I might be able to use to bend it.

Dammit Hyper, now I'm gonna have to start researching!!!

But maybe by spring I'll have camber, toe, and tri/pan. Then come race tires with income tax return. Then hit the divisional circuit? God, I'd be embarassed to lose if my car had all that ****. lol

#25

Thanks for helping me figure this out Kent, the little diagrams on my alignment readout are confusing me. So what we see in this picture is negative camber?

Having the wheels splay out like that would seem to make more sense than having them splay the other way. And if that's negative camber and that's good, why do the stock settings call for positive camber in front? It seems like this would make the front end kind of pigeon toed. Why is it one way in front and the other way in back?

Having the wheels splay out like that would seem to make more sense than having them splay the other way. And if that's negative camber and that's good, why do the stock settings call for positive camber in front? It seems like this would make the front end kind of pigeon toed. Why is it one way in front and the other way in back?