Alternator Relocation Brackets

#1

Alternator Relocation Brackets

Just wanted to gauge interest in fabricated Alternator Relocation Brackets. These mild steel brackets would relocate the alternator to the lower, driver-side of the engine, where the A/C and PS pumps are typically mounted. Why? It would permit running a Meziere electric water pump adaptor; moves weight lower (lower CG); cleans up the top of the engine (alt sticks up like a sore thumb if you have an IDA intake, or similar). It should also reduce water pump slipping if the Air Pump is eliminated. It should work on everything from a Rotary Truck to an FC TII (FDs have a different front cover upper stud location), except perhaps the 83-85 12A with stock air/water oil cooler (hard line may interfere).

I've made several rough prototypes already, checking for fitment. I have a final prototype getting laser cut right now. When that gets back, I will have the bends done and weld on the mounting and adjustment components (lathe items). No idea of cost yet, but if there is enough demand it will help keep the unit cost reasonable. Still, it requires laser cutting, bending, turning and welding, so this is not a simple item. Expect anything from $50-85 each...hopefully, at the lower end of the range. I'm talking complete, bolt-on, powdercoated, including fasteners and a new V-belt.

When the final prototype is finished, I will take some pictures and post them. Right now, share your thoughts but please stay positive (I don't need to hear about how you could rip-off the design at half the cost or that it needs to be made of Titanium or that it's worthless to you because you have AC and/or Power Steering). I'm just proposing to make some slick little Alt Relocation Brackets and sell them in quantity to reduce the unit cost. Anyone interested?

BTW, if anyone wants to do a Meziere electric water pump, I can hook you up.

--

Blake Qualley

Pineapple Racing

I've made several rough prototypes already, checking for fitment. I have a final prototype getting laser cut right now. When that gets back, I will have the bends done and weld on the mounting and adjustment components (lathe items). No idea of cost yet, but if there is enough demand it will help keep the unit cost reasonable. Still, it requires laser cutting, bending, turning and welding, so this is not a simple item. Expect anything from $50-85 each...hopefully, at the lower end of the range. I'm talking complete, bolt-on, powdercoated, including fasteners and a new V-belt.

When the final prototype is finished, I will take some pictures and post them. Right now, share your thoughts but please stay positive (I don't need to hear about how you could rip-off the design at half the cost or that it needs to be made of Titanium or that it's worthless to you because you have AC and/or Power Steering). I'm just proposing to make some slick little Alt Relocation Brackets and sell them in quantity to reduce the unit cost. Anyone interested?

BTW, if anyone wants to do a Meziere electric water pump, I can hook you up.

--

Blake Qualley

Pineapple Racing

Trending Topics

#8

im interested in it.

but i have a few questions, not trying to bag on you or anything but just curious

does it require a different belt than factory?if so have you figured out the stock number on it? i get enough confused looks from the guy behind the parts counter as it is, imagine when i start asking for an oddball belt.

is it possible to keep the factory ac?this used to not be that important to me but lately it has.

but i have a few questions, not trying to bag on you or anything but just curious

does it require a different belt than factory?if so have you figured out the stock number on it? i get enough confused looks from the guy behind the parts counter as it is, imagine when i start asking for an oddball belt.

is it possible to keep the factory ac?this used to not be that important to me but lately it has.

#9

Originally Posted by Hades12

I have always liked the look of this one.

ooohh that looks bitchin. yeah what about serpentine set-ups?

a little off topic but will later serpentine pullies and belts fit on a first gen?

#12

Originally Posted by DAVID GRIMES

Count me in. That is too cool.

If people are really interested in ordering the Meziere electric water pump kits, I can probably put something together. The more the merrier, as it will greatly affect pricing. They don't really sell a kit, but I can spec out all the parts and get some pricing info for you. Expect it to be in the $500 range, including the rotary WP adaptor. Another option is the Davies Craig EWP setup, out of Australia. It is less expensive (~$250) and proven very reliable in racing, plus you can opt for a slick controller (~$150), which varies flow based on temperature. The only "gotcha" is the lack of rotary adaptor. In that case, we could either order the adaptors through Meziere (~$90) or, as I am inclined to do, make our own. We have an FC cast aluminum oil pan mold getting finished off, so after that, I can have them do a casting for the WP adaptors.

#16

Rotary Enthusiast

iTrader: (14)

Joined: May 2004

Posts: 1,366

Likes: 10

From: Drifting a Roundabout near you!

Blake, between ebay and the forum I would go with 50 and keep your cost as low as possible. I was going to do this mod but if you are offering one I will take one. Thanks for doing this sort of thing, there's not enough mods out on the market for the FB's.

#18

Originally Posted by Slammed_GSL

Blake, between ebay and the forum I would go with 50 and keep your cost as low as possible.

] With this sort of part 25 is enough to get the ball rolling. More would not lower the unit cost enough to justify tying up the capital. If the demand is there, I can knock out 25, 50, 100 more, as necessary. Until then, I'd rather spend the capital developing new products (e.g. water pump adapter).

] With this sort of part 25 is enough to get the ball rolling. More would not lower the unit cost enough to justify tying up the capital. If the demand is there, I can knock out 25, 50, 100 more, as necessary. Until then, I'd rather spend the capital developing new products (e.g. water pump adapter).--

Blake Qualley

Pineapple Racing

#20

As a matter of fact, I've been working on the final prototype most of the afternoon. Got the laser-cut material back Friday, dropped it off for bending Monday, got it back yesterday, then turned the top and bottom pieces on the lathe and welded them on today. I also test-fitted the bracket on my rotary truck, a turbo 12A and a 2nd gen NA. Clearance is good, but I might make one or two minor changes before going into production. It's amazing how many little details there are to account for between the vehicles. The paint on the prototype is drying as I type. In a couple hours, I'll take some pictures and post them here.

The next big decision is what to use for the tensioner. I can have a simple, flat one lasered, which would look like the stock one. That's pretty cheap and easy. However, the other option is to make a turnbuckle assembly with 5/16 left- and right-hand threaded rod ends. I already bought some hex rod and 20 rod ends (10 left, 10 right), but need to get a left-hand 5/16th tap. I would expect the rod end turnbuckle assembly to add $15 or so to the final price. Worth it?

The next big decision is what to use for the tensioner. I can have a simple, flat one lasered, which would look like the stock one. That's pretty cheap and easy. However, the other option is to make a turnbuckle assembly with 5/16 left- and right-hand threaded rod ends. I already bought some hex rod and 20 rod ends (10 left, 10 right), but need to get a left-hand 5/16th tap. I would expect the rod end turnbuckle assembly to add $15 or so to the final price. Worth it?

#23

Right near Malloy

iTrader: (28)

Joined: Dec 1999

Posts: 7,847

Likes: 513

From: Behind a workbench, repairing FC Electronics.

Originally Posted by Blake

The next big decision is what to use for the tensioner. I can have a simple, flat one lasered, which would look like the stock one. That's pretty cheap and easy. However, the other option is to make a turnbuckle assembly with 5/16 left- and right-hand threaded rod ends. I already bought some hex rod and 20 rod ends (10 left, 10 right), but need to get a left-hand 5/16th tap. I would expect the rod end turnbuckle assembly to add $15 or so to the final price. Worth it?

#25

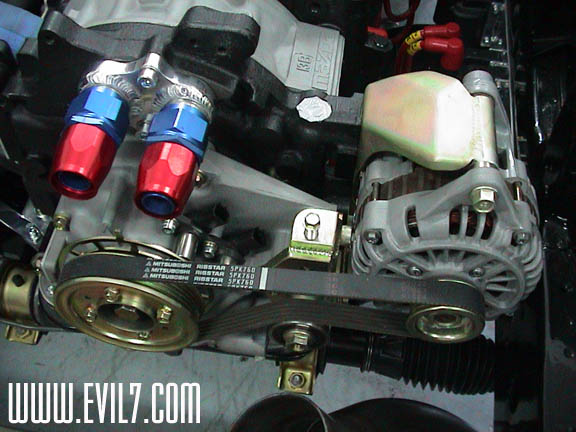

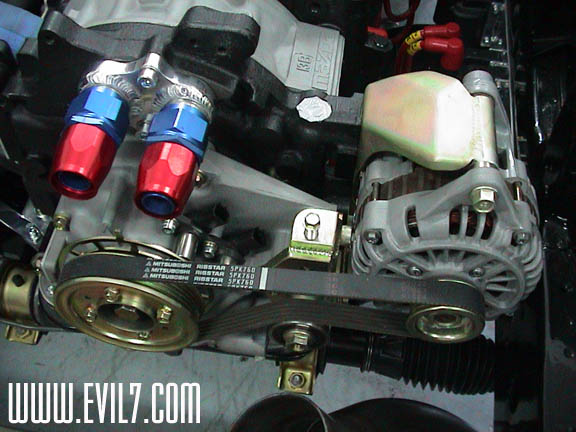

Here are a couple quick shots of the bracket. When I get a chance, I will take some more with it mounted on a vehicle. The tensioner in the picture is the flat one, but we may end up going with the rod end turnbuckle one...it would look much better and makes adjustment easier.

--

Blake Qualley

--

Blake Qualley

pm me when u have it done and ready to ship out

pm me when u have it done and ready to ship out