6 port 12A

#1

Thread Starter

Lapping = Fapping

iTrader: (13)

Joined: Aug 2001

Posts: 15,725

Likes: 83

From: Near Seattle

6 port 12A

I think it would be great to use an '83-'85 rotating assembly in the 6 port 12A with GSL-SE or RE-SI (rotary engine super injection: J-spec only) side plates since stock 6 port 12A plates have the tiniest ports I have ever seen... at least from the outside. I have yet to crack one open to see how they measure up to GSL-SE or RE-SI.

Something rotartygod said about total port area and how it has to add up to a certain amount in order to have good performance, whether 6 port or 4 port, and why it's not good to port hugely like what too many people do, really stuck with me. He passed on very strong reasons why the RX-8's 6 port setup works as well as it does, the manifold design etc. I don't remember which thread it was in but anyway I think the reason why the 6 port 12A had such tiny ports is because a regular old Nikki was expected to flow within reason from low RPM when only the primary intermediate ports were open, or maybe all four low RPM ports were open at low RPM (not sure until I study the manifold) and then obviously at high load and/or RPM the aux ports would open just like any 6 port EFI engine and you'd have flow through all 6 ports. Again all this air and fuel sucking through a pretty much stock Nikki (oh I think the secondary air bleeds were 120 instead of 140 like what all us 1st gen guys are used to, for more fuel up to a slightly higher CFM, and the secondary vacuum dealy had an extended lower housing and looks like the top came from a Hitachi, or whatever) and it's expected to perform to a certain level.

What I'd like to do is see whether I can get away with RE-SI end plates since their aux ports have less port timing (they close sooner) than GSL-SE. As for the intermediate ports, the RE-SI is quite small (it's hard to poke a thumb in it where as a GSL-SE/NO sized port is easy because it's bigger) but I suspect the 6 port 12A is far smaller. At least the runners are probably smaller (all in the name of building torque from a 12A, heh, but hurting high RPM total power potential in the process, even being a 6 port and all that).

Let me break it down to you. From limited observations of a 6 port 12A manifold that I've seen online and a little side view of the port runners-only at Atkins, I believe the port timing is going to be disturbingly small. The next size up is RE-SI which has the same runner size and aux sleeves as GSL-SE, but the port timing is smaller on primary and aux (not sure about the so called 3rd and 4th ports in the end plates). The next step up is obviously GSL-SE and I think I can lump S4 NA 6 ports in as well because I believe their intake ports are the same, however their exhaust ports are slightly larger with T2 port timing but also diffuser sleeves adding a bit of a restriction while reducing noise a bit. Whatever.

It's my goal to rebuild the 6 port using RE-SI end plates, a GSL-SE intermediate plate and lightly ported rotor housings (because as we know US-spec 12A rotor housings are pretty small) and close them a few degrees later like 12A turbo housings.

It all depends on whether the increased port timing will still work and not outflow a Nikki.

Oh and another thing, I'm not really interested in any aftermarket carbs for this because driveability and low end torque are more important on this project than raw mid to high RPM power. For that, I'd do a ported 4 port 12A and be done with it. Rather, this project is for educational purposes and will make an awesome daily driver for somebody. I doubt I'll even need a Sterling carb because the intermediate ports will probably be no larger than GSL-SE/NO and therefore the stock Nikki venturi size of 20mm is all that's required. Plus I'm affraid that swapping over to a Y plate, with its tall runners and larger '76-'85 12A ports would increase total port area to a level beyond what a stock Nikki could handle at high RPM and hurt low RPM velocity and driveability. I'll need to study the manifold to see which carb barrels flow into which ports, but I suspect primary barrels go to the intermediate plate only, and there are channels up under the carb spacer allowing sharing of vacuum signal like any FB/SA intake manifold. Then the aux port actuators are controlled by exhaust backpressure fed into the ACV port from a tube inside the exhaust manifold connecting to a hole in a rotor housing just like any NA FC manifold I've seen.

Think it will work? Where is rotarygod?

Something rotartygod said about total port area and how it has to add up to a certain amount in order to have good performance, whether 6 port or 4 port, and why it's not good to port hugely like what too many people do, really stuck with me. He passed on very strong reasons why the RX-8's 6 port setup works as well as it does, the manifold design etc. I don't remember which thread it was in but anyway I think the reason why the 6 port 12A had such tiny ports is because a regular old Nikki was expected to flow within reason from low RPM when only the primary intermediate ports were open, or maybe all four low RPM ports were open at low RPM (not sure until I study the manifold) and then obviously at high load and/or RPM the aux ports would open just like any 6 port EFI engine and you'd have flow through all 6 ports. Again all this air and fuel sucking through a pretty much stock Nikki (oh I think the secondary air bleeds were 120 instead of 140 like what all us 1st gen guys are used to, for more fuel up to a slightly higher CFM, and the secondary vacuum dealy had an extended lower housing and looks like the top came from a Hitachi, or whatever) and it's expected to perform to a certain level.

What I'd like to do is see whether I can get away with RE-SI end plates since their aux ports have less port timing (they close sooner) than GSL-SE. As for the intermediate ports, the RE-SI is quite small (it's hard to poke a thumb in it where as a GSL-SE/NO sized port is easy because it's bigger) but I suspect the 6 port 12A is far smaller. At least the runners are probably smaller (all in the name of building torque from a 12A, heh, but hurting high RPM total power potential in the process, even being a 6 port and all that).

Let me break it down to you. From limited observations of a 6 port 12A manifold that I've seen online and a little side view of the port runners-only at Atkins, I believe the port timing is going to be disturbingly small. The next size up is RE-SI which has the same runner size and aux sleeves as GSL-SE, but the port timing is smaller on primary and aux (not sure about the so called 3rd and 4th ports in the end plates). The next step up is obviously GSL-SE and I think I can lump S4 NA 6 ports in as well because I believe their intake ports are the same, however their exhaust ports are slightly larger with T2 port timing but also diffuser sleeves adding a bit of a restriction while reducing noise a bit. Whatever.

It's my goal to rebuild the 6 port using RE-SI end plates, a GSL-SE intermediate plate and lightly ported rotor housings (because as we know US-spec 12A rotor housings are pretty small) and close them a few degrees later like 12A turbo housings.

It all depends on whether the increased port timing will still work and not outflow a Nikki.

Oh and another thing, I'm not really interested in any aftermarket carbs for this because driveability and low end torque are more important on this project than raw mid to high RPM power. For that, I'd do a ported 4 port 12A and be done with it. Rather, this project is for educational purposes and will make an awesome daily driver for somebody. I doubt I'll even need a Sterling carb because the intermediate ports will probably be no larger than GSL-SE/NO and therefore the stock Nikki venturi size of 20mm is all that's required. Plus I'm affraid that swapping over to a Y plate, with its tall runners and larger '76-'85 12A ports would increase total port area to a level beyond what a stock Nikki could handle at high RPM and hurt low RPM velocity and driveability. I'll need to study the manifold to see which carb barrels flow into which ports, but I suspect primary barrels go to the intermediate plate only, and there are channels up under the carb spacer allowing sharing of vacuum signal like any FB/SA intake manifold. Then the aux port actuators are controlled by exhaust backpressure fed into the ACV port from a tube inside the exhaust manifold connecting to a hole in a rotor housing just like any NA FC manifold I've seen.

Think it will work? Where is rotarygod?

#2

Thread Starter

Lapping = Fapping

iTrader: (13)

Joined: Aug 2001

Posts: 15,725

Likes: 83

From: Near Seattle

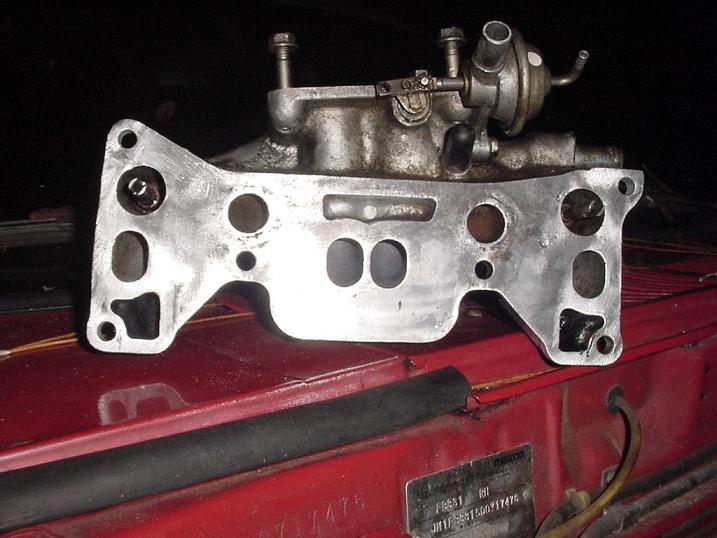

And now for some pictures.

6 port 12A intake manifold I found on the forum. The runners are so small! I hope the positions are compatible with 13B 6 port end plates.

Here is the engine.

EGR port.

Awesome cast iron header. Note the motor mount studs like a GSL-SE.

6 port manifold with a Nikki. Not sure how it flows yet, which runners etc.

'80 type dizzy. Short oil filter pedestal. Motor mount studs.

6 port 12A intake manifold I found on the forum. The runners are so small! I hope the positions are compatible with 13B 6 port end plates.

Here is the engine.

EGR port.

Awesome cast iron header. Note the motor mount studs like a GSL-SE.

6 port manifold with a Nikki. Not sure how it flows yet, which runners etc.

'80 type dizzy. Short oil filter pedestal. Motor mount studs.

#3

I dont know that much about all this stuff but if it seems that you may end up outflowing a stock Nikki, the Sterling would be a great choice. Actually, I'm thinking a Sterling would be a great choice even if it doesnt really "need it". I doubt it would hurt low end much if at all but would most definitely help the mid and upper ranges. Seems like a win-win with a Sterling. Of course, Im kind of biased as i have one and love the **** out of it.

Very cool project, keep us up to date on whats going on with it.

Very cool project, keep us up to date on whats going on with it.

#4

I have a question. Why the h*ll is this is the non tech section. This has tech written all over it.

Looks like a fun project. I like the way you get to experiment on rotaries and usually on someone elses nickel Jeff. Keep it up and post all the results.

Looks like a fun project. I like the way you get to experiment on rotaries and usually on someone elses nickel Jeff. Keep it up and post all the results.

#5

Yea this does have tech written all over it... Very intersting post like most of yours are Jeff, I always seem to learn something from you posts lol. I'll be watching this project, where did you find the 6 port 12a? I've been looking for one for a while...

#6

i agree. this is tech if i've ever seen tech, but i guess technically, not Gen I tech.

perhaps, General Rotary? at any rate, glad i saw it. soon as i can secure a 12A core, i'll be building a 6-port for kicks. not sure what to put it in yet ... i was thinking an old 626 coupe, but finding has been impossible thus far. who knows?

i must say i repect your project to most projects as you seem to be willing to always show restraint for the sake of torque, which in actuality is what matters out here on the street. i promised myself a long time ago that i'd NEVER build another stockport engine unless that's what a customer wants, so i can safely say you're a better man than me in that repsect. will be watching your progress.

perhaps, General Rotary? at any rate, glad i saw it. soon as i can secure a 12A core, i'll be building a 6-port for kicks. not sure what to put it in yet ... i was thinking an old 626 coupe, but finding has been impossible thus far. who knows?

i must say i repect your project to most projects as you seem to be willing to always show restraint for the sake of torque, which in actuality is what matters out here on the street. i promised myself a long time ago that i'd NEVER build another stockport engine unless that's what a customer wants, so i can safely say you're a better man than me in that repsect. will be watching your progress.

Trending Topics

#8

Thread Starter

Lapping = Fapping

iTrader: (13)

Joined: Aug 2001

Posts: 15,725

Likes: 83

From: Near Seattle

When it's not related to keeping a 1st gen running, I tend to keep it out of the tech section. Oh well, I tried.

The 6 ports are rare. This one is J-spec. According to Robert at RotaryShack, these engines have good torque, but the high end is weak. That's a good enough reason for me to want to bring the high end up to more reasonable standards while not killing off the low end, which would be a travisty.

But yes I agree with rotarygod that most people port way too big and then wonder why they don't make enough power. I've already been there done that.

The baja engine was my first attempt at porting for torque. I carefully selected the best parts I had to make a good torquing engine without having to resort to a 6 port 13B and all the EFI crap that goes along with it. A baja doesn't need that kind of complication, or at least mine didn't. A simple carb and a long runner manifold with stock port timing and a short & sweet exhaust were my design goals. Everything is in place and it won't start because the motor is too tight. I built it with all new seals and there is too much drag/friction on the high torque VW starter! I need to break it in somewhere else! Doh! That was the original plan last year after I built the engine; I installed it in my Cosmo but the project kind of stalled out because I was busy doing other stuff. Then my brother became interested in the Cosmo so I had to swap in another engine and finished it, and put the baja's engine directly into the baja, still waiting to be broken in. That's what I get for rushing things. But at least I got to hear it crank and pop a little bit out of the exhaust. I'm not going to bother tow-starting it because it still wouldn't be broken in fully for another thousand miles. It has to be reliable and fire up easily, even on cold mornings without a choke, which is possible on a well broken in engine. If I had another available I'd throw it in there just to work the bugs out of the rest of the car but I digress. The baja engine will go into the GLC which has a fast starter and a working choke cable.

I wonder what I could put the 6 port into once I get it going?

The 6 ports are rare. This one is J-spec. According to Robert at RotaryShack, these engines have good torque, but the high end is weak. That's a good enough reason for me to want to bring the high end up to more reasonable standards while not killing off the low end, which would be a travisty.

But yes I agree with rotarygod that most people port way too big and then wonder why they don't make enough power. I've already been there done that.

The baja engine was my first attempt at porting for torque. I carefully selected the best parts I had to make a good torquing engine without having to resort to a 6 port 13B and all the EFI crap that goes along with it. A baja doesn't need that kind of complication, or at least mine didn't. A simple carb and a long runner manifold with stock port timing and a short & sweet exhaust were my design goals. Everything is in place and it won't start because the motor is too tight. I built it with all new seals and there is too much drag/friction on the high torque VW starter! I need to break it in somewhere else! Doh! That was the original plan last year after I built the engine; I installed it in my Cosmo but the project kind of stalled out because I was busy doing other stuff. Then my brother became interested in the Cosmo so I had to swap in another engine and finished it, and put the baja's engine directly into the baja, still waiting to be broken in. That's what I get for rushing things. But at least I got to hear it crank and pop a little bit out of the exhaust. I'm not going to bother tow-starting it because it still wouldn't be broken in fully for another thousand miles. It has to be reliable and fire up easily, even on cold mornings without a choke, which is possible on a well broken in engine. If I had another available I'd throw it in there just to work the bugs out of the rest of the car but I digress. The baja engine will go into the GLC which has a fast starter and a working choke cable.

I wonder what I could put the 6 port into once I get it going?

#10

Thread Starter

Lapping = Fapping

iTrader: (13)

Joined: Aug 2001

Posts: 15,725

Likes: 83

From: Near Seattle

Maybe, but it already has a supercharged 13B in it. It would be interesting though. Hmm... maybe I will.

I have to swap in a 7" SC into the S though, first, so I've got to do that before considering a 12A.

I have to swap in a 7" SC into the S though, first, so I've got to do that before considering a 12A.

#14

Thread Starter

Lapping = Fapping

iTrader: (13)

Joined: Aug 2001

Posts: 15,725

Likes: 83

From: Near Seattle

The 6 port rotor housings have these weird holes in them. Obviously to pipe the 'backpressure' up into the intake manifold and ultimately into the aux port actuators to open under load.

Then I realized those holes looked familer so I got on the forum and searched for the old thread about making an '84 automatic go faster. We had used a set of 12A turbo rotor housings in the engine and while I was in the mddle of swapping exhaust systems, I snapped a couple of pics.

Well blow me sideways! They're identical!

That engine recently went into my bro's '84 manual car with power steering. It wouldn't take much to pull it and use the rotor housings and rotating assembly in the 6 port. I'd probably swap my brother over to a 4 port 13B as well for his trouble.

Then I realized those holes looked familer so I got on the forum and searched for the old thread about making an '84 automatic go faster. We had used a set of 12A turbo rotor housings in the engine and while I was in the mddle of swapping exhaust systems, I snapped a couple of pics.

Well blow me sideways! They're identical!

That engine recently went into my bro's '84 manual car with power steering. It wouldn't take much to pull it and use the rotor housings and rotating assembly in the 6 port. I'd probably swap my brother over to a 4 port 13B as well for his trouble.

#17

Thread Starter

Lapping = Fapping

iTrader: (13)

Joined: Aug 2001

Posts: 15,725

Likes: 83

From: Near Seattle

I helped the process advance further today by swapping out a 5" SC for a 7" on the engine I'm giving my bro. It was a succesful test with noticebly more power so I'm sure he'll be happy. Now I just gotta get something else running around here so I can pull the 13B out of my car and drop it in his. Gotta pull his 12A first though to do the 6 port build.

I'll test run the 6 port in my car since it's just temporary. I've got another '6 port' in mind for it later, with even more torque as the goal. EFI, too.

And and by the way I found an old loose 6 port FC S4 engine that I can use in the baja until its tight engine is broken in enough to start quickly and easily. That's just some closure for something I mentioned earlier in this thread about the baja. It's a 6 port too so I felt I should mention it.

I'll test run the 6 port in my car since it's just temporary. I've got another '6 port' in mind for it later, with even more torque as the goal. EFI, too.

And and by the way I found an old loose 6 port FC S4 engine that I can use in the baja until its tight engine is broken in enough to start quickly and easily. That's just some closure for something I mentioned earlier in this thread about the baja. It's a 6 port too so I felt I should mention it.

#18

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,203

Likes: 2,826

From: https://www2.mazda.com/en/100th/

the book rotary engine lays out mazda's theory about the 6 ports, and has charts and graphs to illustrate their findings.

so basically as an OEM they need the engine to do certain things, some of which conflict

they want more power; all across the range, better fuel economy, lower emissions.

in a side port engine the port timing is dictated by the seal paths, and this gives a certain amount of port area.

in a 4 port engine to make power all 4 ports have to be big. in a low rpm situation, the primary ports close late, and lack velocity, due to the size. at high rpm they close a little early.

in the 6 port configuration, the primary ports are made smaller, this aids several things. velocity is up, because the port is smaller. port timing is better for low rpm operation, so its better for economy and emissions.

the secondary port is similar to the 4 port one, its sized for mid range power.

then the aux ports open, these have later port timing than the 4 port engines, closing timing is close to the PP engine.

the combination of the 6 ports gives you slightly more area than the 4 port, while lowering emissions and making more power all thru the rpm range.

it works great on the street.

on the exhaust port side its kind of the same deal, the later you open them, the better the efficiency of the engine, and the earlier you close them the less overlap you have. but you still need enough area.

overlap is good, because you get a lot of port area, and the more the better, but its bad because the more overlap you have the more the engine is gong to be sensitive to backpressure.

so basically as an OEM they need the engine to do certain things, some of which conflict

they want more power; all across the range, better fuel economy, lower emissions.

in a side port engine the port timing is dictated by the seal paths, and this gives a certain amount of port area.

in a 4 port engine to make power all 4 ports have to be big. in a low rpm situation, the primary ports close late, and lack velocity, due to the size. at high rpm they close a little early.

in the 6 port configuration, the primary ports are made smaller, this aids several things. velocity is up, because the port is smaller. port timing is better for low rpm operation, so its better for economy and emissions.

the secondary port is similar to the 4 port one, its sized for mid range power.

then the aux ports open, these have later port timing than the 4 port engines, closing timing is close to the PP engine.

the combination of the 6 ports gives you slightly more area than the 4 port, while lowering emissions and making more power all thru the rpm range.

it works great on the street.

on the exhaust port side its kind of the same deal, the later you open them, the better the efficiency of the engine, and the earlier you close them the less overlap you have. but you still need enough area.

overlap is good, because you get a lot of port area, and the more the better, but its bad because the more overlap you have the more the engine is gong to be sensitive to backpressure.

#19

Thread Starter

Lapping = Fapping

iTrader: (13)

Joined: Aug 2001

Posts: 15,725

Likes: 83

From: Near Seattle

My but aren't you helpful, fella!

I'm hoping to strike up a good compromise between torque and HP with this one. The known knowns at this point are:

A) according to Robert at RotaryShack, the stock 6 port 12A has great low end torque but pretty much no high end. It's not worth the hype surrounding it (in stock form anyway).

B) the ports are apparently painfully small, which of course allows for the good low RPM torque as mentioned above, as well as the lackluster high end.

C) in the pictures comparing 6 port 12A exhaust ports to 12A turbo ports, they both open early but the 6 port closes earlier than the 12AT. The 12A T closes later like an FC but not sure of actual port timing until I tear my bro's engine apart.

D) the GSL-SE and FC 6 ports are capable of decent all around street performance from low, to mid, to high. It seems Mazda didn't have to compromise as much as they did with the 6 port 12A.

So assuming all of this is true and accurate, I wonder whether I could get away with increased port timing until I've maxed out the flow of the Nikki at high RPM without going over. Emissions are not a concern.

Mike, you know how US-spec 12A exhaust ports have restrictive timing? The 6 port 12A appears to have the same timing. Do you think the engine will benefit from using the 12A turbo rotor housings with their later closing ports? It should only increase overlap just a little.

I'd also like to swap to a GSL-SE intermediate plate. It should still be small enough to keep velocity up even at really low RPM while at the same time provide a nice flow improvement over the painfully small stock ports.

I'd like your thoughts on this. All I know is I want to avoid a 4 port intermediate plate.

I'm hoping to strike up a good compromise between torque and HP with this one. The known knowns at this point are:

A) according to Robert at RotaryShack, the stock 6 port 12A has great low end torque but pretty much no high end. It's not worth the hype surrounding it (in stock form anyway).

B) the ports are apparently painfully small, which of course allows for the good low RPM torque as mentioned above, as well as the lackluster high end.

C) in the pictures comparing 6 port 12A exhaust ports to 12A turbo ports, they both open early but the 6 port closes earlier than the 12AT. The 12A T closes later like an FC but not sure of actual port timing until I tear my bro's engine apart.

D) the GSL-SE and FC 6 ports are capable of decent all around street performance from low, to mid, to high. It seems Mazda didn't have to compromise as much as they did with the 6 port 12A.

So assuming all of this is true and accurate, I wonder whether I could get away with increased port timing until I've maxed out the flow of the Nikki at high RPM without going over. Emissions are not a concern.

Mike, you know how US-spec 12A exhaust ports have restrictive timing? The 6 port 12A appears to have the same timing. Do you think the engine will benefit from using the 12A turbo rotor housings with their later closing ports? It should only increase overlap just a little.

I'd also like to swap to a GSL-SE intermediate plate. It should still be small enough to keep velocity up even at really low RPM while at the same time provide a nice flow improvement over the painfully small stock ports.

I'd like your thoughts on this. All I know is I want to avoid a 4 port intermediate plate.

Last edited by Jeff20B; 11-21-08 at 01:35 AM.

#20

my pics

top-

s4 NA FC plates ( 1986 onwards ) one is previously taken to near s4T primary plate specs

( the air pump passage to top of plate is the limit )

bottom-

identified by the lack of water grooves

- and by the mounting bosses for engine mounts suit install to 81 -87 929

left OEM 12a six port ( jap 12at is very similar, has injector boss )

right OEM 13b RESI ( jap spec, 1984 929 )

as you can see, 12a 6 port, and 12at have particularly small primary ports

the earlier 4 port primary plates are all much better starting points but lack the mounting boss

( so beware if you need that )

PS

the 12aT and 12a 6 port motors have a similar evolution of housing

( both have the usually have H casting on top and boss ready for oil injector, though only 12at is tapped an drilled )

- i say usually, this one has an earlier housing at front , maybe a fix up

- usually most have the H top casting

though the 6 port engine was avail prior, and alongside the 12aT engine , so may have evolved with it

check out the funky shroud on the front rotor sparks !!

#21

Wouldn't it be a problem to use the -SE plates? I am not too sure on the -SE's, but the 2nd gen NA plates have a later closing that provides a slight increase in manifold pressure as the ports close later in the compression stroke. This creates boost (very little, almost 2lbs) inside the manifold. The 12a ports being smaller than the -SE could be because of the carburetor and lack of intake manifold routing to take advantage of it, being with no VDI.

Just my .02, though may be wrong.

Just my .02, though may be wrong.

#22

Thread Starter

Lapping = Fapping

iTrader: (13)

Joined: Aug 2001

Posts: 15,725

Likes: 83

From: Near Seattle

Thanks for posting the pictures! It looks like the one on the lower right is an NO plate. I could actually use of of those instead of a GSL-SE because the port timing is the same and they both have an EGR port. Not that I'd use it but the lack of coolant flow there shouldn't be a problem as long as the 12AT housings are ok with it.

Yep there is no VDI on the 6 port 12A so I suppose small aux ports are the only way to go.

Yep there is no VDI on the 6 port 12A so I suppose small aux ports are the only way to go.

#23

Thanks for posting the pictures! It looks like the one on the lower right is an NO plate. I could actually use of of those instead of a GSL-SE because the port timing is the same and they both have an EGR port. Not that I'd use it but the lack of coolant flow there shouldn't be a problem as long as the 12AT housings are ok with it.

Yep there is no VDI on the 6 port 12A so I suppose small aux ports are the only way to go.

Yep there is no VDI on the 6 port 12A so I suppose small aux ports are the only way to go.

#24

Are the holes below the exhasut port supposed to be covered by the exhaust manifold? Ya this sounds like a really dumb question but i just pulled the stock manifold (well, I think its the stock exhaust) and they are completely covered.