12A MOP MOD Illustrated

#1

12A MOP MOD Illustrated

I have been interested in feeding my engine 2 cycle oil through the OMP/MOP/oil metering pump. I was interested in one of these: http://rotaryaviation.com/oil_inject...p_adaptors.htm

But after browsing around the forum for a bit I decided to mod my own OMP.

I chose to use a set screw instead of using a block-off plate, because it seemed like an easy enough way to get the job done.

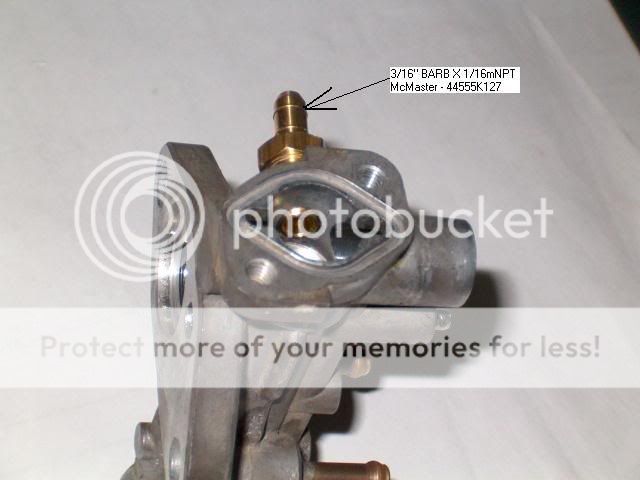

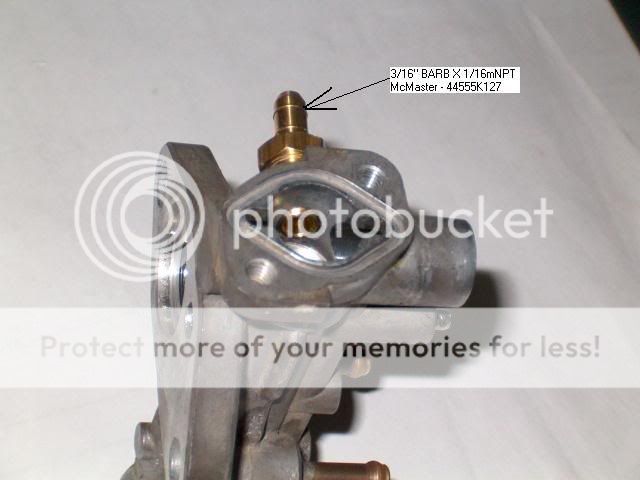

I installed the aux inlet nipple vertically centered on the main bore 0.325" in from the end with the actuation lever. After inspecting the passages it looked like the easies spot to tap the supply in.

I used LOCTITE 7649 primer and 648 retaining compound to hold the threaded hardware in place.

After these mods and a thurough cleaning a rebuild was in order. Viton O'rings were chosen because of superior resistance to synthetic oils.

O'ring sizes used were:

1 x 7/32" x 13/32" (-107) - Actuation Lever Seal

1 x 3/8" x 1/2" (-12) - Drive Bushing/Retainer Seal

2 x 11/16" x 13/16" (-17) - End Plate Seals

I need to find a suitable tank for the oil and then I will test.

But after browsing around the forum for a bit I decided to mod my own OMP.

I chose to use a set screw instead of using a block-off plate, because it seemed like an easy enough way to get the job done.

I installed the aux inlet nipple vertically centered on the main bore 0.325" in from the end with the actuation lever. After inspecting the passages it looked like the easies spot to tap the supply in.

I used LOCTITE 7649 primer and 648 retaining compound to hold the threaded hardware in place.

After these mods and a thurough cleaning a rebuild was in order. Viton O'rings were chosen because of superior resistance to synthetic oils.

O'ring sizes used were:

1 x 7/32" x 13/32" (-107) - Actuation Lever Seal

1 x 3/8" x 1/2" (-12) - Drive Bushing/Retainer Seal

2 x 11/16" x 13/16" (-17) - End Plate Seals

I need to find a suitable tank for the oil and then I will test.

#2

I really like it. But, there wouldn't be much need to run synthetic oil through that, because that's going to the combustions, where all the crap from the synthetic oil would end up. But, you could now run it in your engine, because it's not longer being put into the combustion chamber, correct?

#3

Originally Posted by boostedHULK

I really like it. But, there wouldn't be much need to run synthetic oil through that, because that's going to the combustions, where all the crap from the synthetic oil would end up. But, you could now run it in your engine, because it's not longer being put into the combustion chamber, correct?

My plan is to use some sort of 2-cycle oil. Not sure which brand to run yet. Just that it needs to be TWC 3.

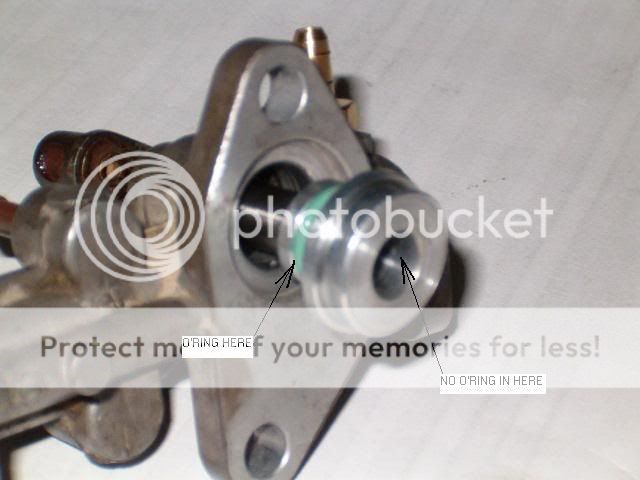

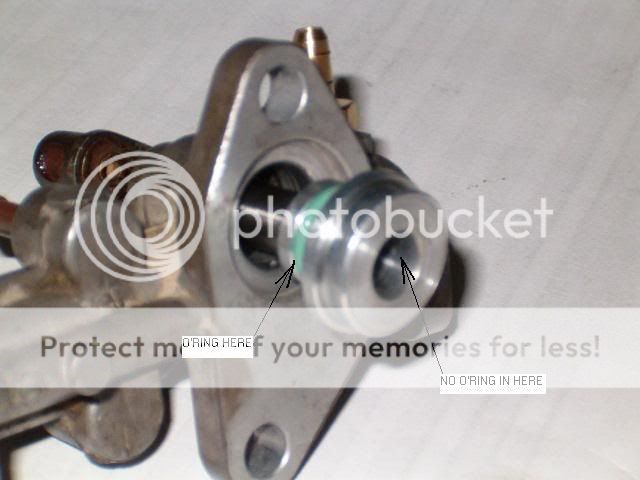

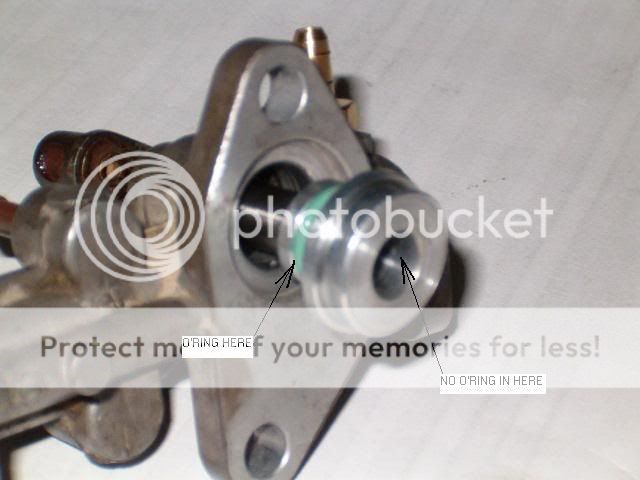

I see a possible problem now though. Look at this:

Would the 2 cycle oil bleed into the main oil supply without a mod to install another o'ring at the shaft? If so, how will this effect the engine oil? Will it move the other way? Will it move at all?

#4

Has anyone ever played arount with the spring rate in the OMP? The spring seems a little weak. A stiffer spring might give more "top end" oil flow. What is the drive ratio? Engine RPM to Pump RPM?

#6

Have you seen this thread, it should help.

https://www.rx7club.com/showthread.p...hlight=MOP+MOD

And what do you plan on doing for the tank?

https://www.rx7club.com/showthread.p...hlight=MOP+MOD

And what do you plan on doing for the tank?

Trending Topics

#8

Originally Posted by IanS

I use an oil catch can from ebay for my tank. I have the RA adapter.

https://www.rx7club.com/showthread.p...hlight=omp+mod

With the 12A OMP the gasket could be relieved instead of the front cover. Just not sure if blocking the omp effects how much pressure is left at the connection between OMP and the front cover. I am leaning towards "not significantly".

#10

Originally Posted by 13BT_RX3

I see a possible problem now though. Look at this:

Would the 2 cycle oil bleed into the main oil supply without a mod to install another o'ring at the shaft? If so, how will this effect the engine oil? Will it move the other way? Will it move at all?

Would the 2 cycle oil bleed into the main oil supply without a mod to install another o'ring at the shaft? If so, how will this effect the engine oil? Will it move the other way? Will it move at all?

Last edited by 13BT_RX3; 11-16-06 at 10:36 AM.

#11

Looks like a nice job dude. I did this a couple years ago ( i think i was the first diy-er), and i have a couple small bits of info to add as far as the whole system goes.

I had the best luck with the tank mounted so that the bottom was about 6" above the pump. that gave me good flow without too much pressure to cause leaks.

You cannot use a plastic tank, the 2-stroke oil will degrade the plastic. I welded one together from thin aluminum treadplate.

It is a very good idea to use a level sensor in the tank. I used a stock oil pan level sensor and an LED inside the car.

2-cycle oil will cause rubber hose to swell and leak, so use either viton hose or -4AN braided stainless that has a teflon or ptfe liner.

here is a link to my old thread if anyone wants some more info:

https://www.rx7club.com/rotary-car-performance-77/diy-2-stroke-mop-write-up-pics-372329/

pat

I had the best luck with the tank mounted so that the bottom was about 6" above the pump. that gave me good flow without too much pressure to cause leaks.

You cannot use a plastic tank, the 2-stroke oil will degrade the plastic. I welded one together from thin aluminum treadplate.

It is a very good idea to use a level sensor in the tank. I used a stock oil pan level sensor and an LED inside the car.

2-cycle oil will cause rubber hose to swell and leak, so use either viton hose or -4AN braided stainless that has a teflon or ptfe liner.

here is a link to my old thread if anyone wants some more info:

https://www.rx7club.com/rotary-car-performance-77/diy-2-stroke-mop-write-up-pics-372329/

pat

#12

Originally Posted by Hyper4mance2k

Why tcw3 over any other? I found recently that my car runs better on 2t. What is the difference?

(trains and huge ships and **** use 2-stroke diesel engines, but i dont think they require spare lubrication because they run off very unrefined fuel; many if not most use straight crude oil)

#13

Originally Posted by patman

Looks like a nice job dude. I did this a couple years ago ( i think i was the first diy-er), and i have a couple small bits of info to add as far as the whole system goes.

I had the best luck with the tank mounted so that the bottom was about 6" above the pump. that gave me good flow without too much pressure to cause leaks.

You cannot use a plastic tank, the 2-stroke oil will degrade the plastic. I welded one together from thin aluminum treadplate.

It is a very good idea to use a level sensor in the tank. I used a stock oil pan level sensor and an LED inside the car.

2-cycle oil will cause rubber hose to swell and leak, so use either viton hose or -4AN braided stainless that has a teflon or ptfe liner.

here is a link to my old thread if anyone wants some more info:

https://www.rx7club.com/showthread.php?t=372329

pat

I had the best luck with the tank mounted so that the bottom was about 6" above the pump. that gave me good flow without too much pressure to cause leaks.

You cannot use a plastic tank, the 2-stroke oil will degrade the plastic. I welded one together from thin aluminum treadplate.

It is a very good idea to use a level sensor in the tank. I used a stock oil pan level sensor and an LED inside the car.

2-cycle oil will cause rubber hose to swell and leak, so use either viton hose or -4AN braided stainless that has a teflon or ptfe liner.

here is a link to my old thread if anyone wants some more info:

https://www.rx7club.com/showthread.php?t=372329

pat

#14

Rotoholic Moderookie

iTrader: (4)

Joined: May 2002

Posts: 5,962

Likes: 33

From: Ottawa, Soviet Canuckistan

Awesome info.

I've archived a copy of this. Seems like an awesome alternative to getting the adapter. I just may do this come springtime.

What do you think the best way of fixing the actuator in "FULL OPEN" position would be? It would be nice to get full-on 2-stroke all the time and not have the damn rod in the way each time you go to remove the carb. It would also give people running aftermarket carbs a good way to get around the lack of a spot to mount the actuator arm to their linkages.

Jon

I've archived a copy of this. Seems like an awesome alternative to getting the adapter. I just may do this come springtime.

What do you think the best way of fixing the actuator in "FULL OPEN" position would be? It would be nice to get full-on 2-stroke all the time and not have the damn rod in the way each time you go to remove the carb. It would also give people running aftermarket carbs a good way to get around the lack of a spot to mount the actuator arm to their linkages.

Jon

#15

i used the rod.

imho, the metering capability of the Metering oil pump is the main advantage over premixing. at low rpm and light loads, you dont need as much oil. the pump is the only way to vary this. if you wire it open, you kinda ruin the whole point.

that said, if you really want to do it, i would assume a zip tie would suffice.

imho, the metering capability of the Metering oil pump is the main advantage over premixing. at low rpm and light loads, you dont need as much oil. the pump is the only way to vary this. if you wire it open, you kinda ruin the whole point.

that said, if you really want to do it, i would assume a zip tie would suffice.

#17

Originally Posted by 13BT_RX3

Does the RA part have cross porting of the stock oil feed to the port around the drive area. I have not seen any pics of the backside. I see some people mod their front covers to relieve oil pressure once the OMP feed is blocked off? Like this pic taken from:

https://www.rx7club.com/showthread.p...hlight=omp+mod

With the 12A OMP the gasket could be relieved instead of the front cover. Just not sure if blocking the omp effects how much pressure is left at the connection between OMP and the front cover. I am leaning towards "not significantly".

https://www.rx7club.com/showthread.p...hlight=omp+mod

With the 12A OMP the gasket could be relieved instead of the front cover. Just not sure if blocking the omp effects how much pressure is left at the connection between OMP and the front cover. I am leaning towards "not significantly".

https://www.rx7club.com/showthread.p...light=bore+omp

The oil that feeds the OMP is connected to the internal hole with the roll pin. The OMP supply pressure will bleed off here with no modifications.

#18

Here are some measurments from my 12A OMP:

Plunger bore = 0.134"

Stroke min = 0.015" (Actuator full down)

Stroke max = 0.075" (Actuator full up)

Pumping drum exit orifice diameter = 0.055" (2 orifii, 1 for each nozzle)

22 Input Revolutions per Pump Cycle(2 strokes, 1 for each nozzle)

Spring Dims:

7 coils including two 1/2 coils on each end

Wire Diameter = 0.028"

O.D. = .065"

Uncompressed height = 0.625"

Compressed height = 0.22

Plunger bore = 0.134"

Stroke min = 0.015" (Actuator full down)

Stroke max = 0.075" (Actuator full up)

Pumping drum exit orifice diameter = 0.055" (2 orifii, 1 for each nozzle)

22 Input Revolutions per Pump Cycle(2 strokes, 1 for each nozzle)

Spring Dims:

7 coils including two 1/2 coils on each end

Wire Diameter = 0.028"

O.D. = .065"

Uncompressed height = 0.625"

Compressed height = 0.22

Thread

Thread Starter

Forum

Replies

Last Post

Jeff20B

1st Generation Specific (1979-1985)

73

09-16-18 07:16 PM